Method and device for recovering volatile organic compound through adsorption-electric heat desorption

A technology for desorption of organic compounds, applied in chemical instruments and methods, separation methods, purification of combustible gases, etc., can solve problems that restrict the sustainable development of the national economy, hidden dangers of production enterprises, and long desorption time of water vapor , to achieve the effect of rapid and thorough desorption, fast desorption speed and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

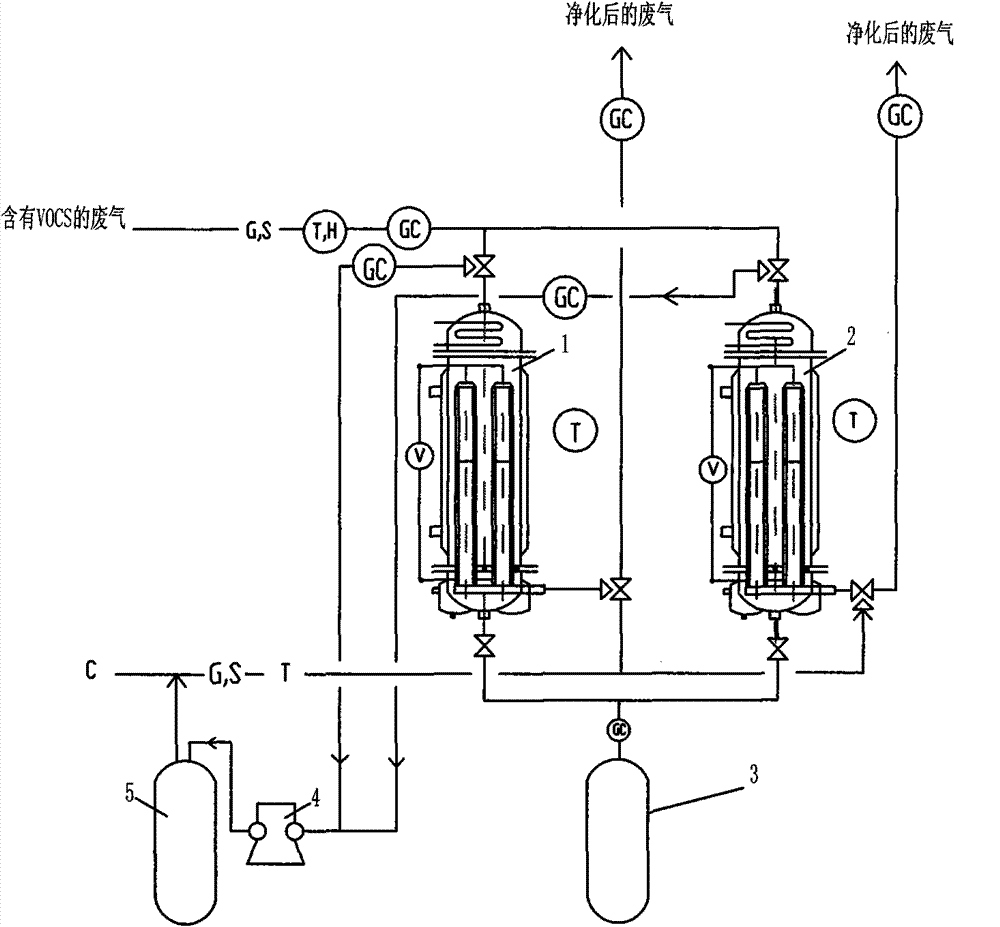

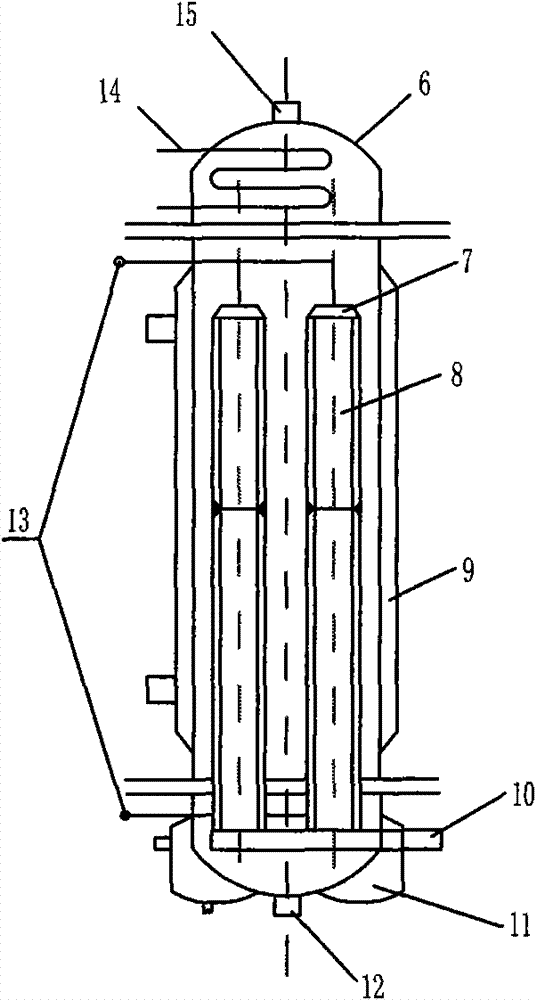

[0018] Example 1 The waste gas discharged from the printing plastic film product workshop is usually a mixed gas containing ethyl acetate, acetone, toluene and methyl ethyl ketone (MEK). GB16297-1996 has regulations on their emission concentration, such as butanone (MEK) is 120mg / m 3 . The normal-temperature dry mixed gas transported from the above-mentioned workshop, MEK (marked assessment component of this embodiment) is 800-1000 ppmv, relative humidity is 4-8%, and flow rate is 20-24 liters / minute. The device of the present invention and its connection such as figure 1 As shown, two adsorption electrothermal desorption devices (1, 2) are included. The adsorption electrothermal desorption device includes a housing 6, and two hollow cylinders 8 are arranged inside the housing, and a sealing plug is arranged on the top of the hollow cylinder. 7. A coil heat exchanger 14 is provided at the upper end of the shell, and jacketed heat exchangers (9, 11) are provided at the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com