Transparent graphene ink and preparation method thereof, heating glass using transparent graphene ink and preparation method of heating glass

A technology of heating glass and graphene, which is applied in the direction of ink, applications, household appliances, etc., can solve the problems of poor comprehensive performance of products, increase the cost of conductive film, and low transparency of glass, and achieve stable electric heating performance, low price, and light transmittance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention also proposes a kind of preparation method of transparent graphene ink, and it comprises the following steps:

[0048] 1) Mix deionized water, graphene dispersion and conductive polymer aqueous solution, and ultrasonically disperse;

[0049] 2) Add an adhesion promoter and a surfactant during the ultrasonic dispersion process to disperse evenly to obtain a transparent graphene ink.

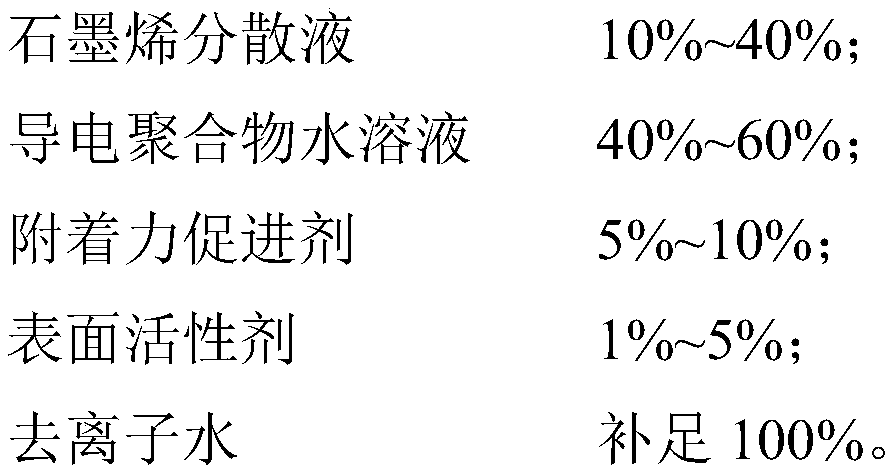

[0050] Mix deionized water, 10-40wt% graphene dispersion, 40-60wt% PEDOT:PSS solution by mass ratio, add 5-10wt% adhesion promoter and 1-5wt% Surfactant, evenly dispersed to obtain transparent graphene ink.

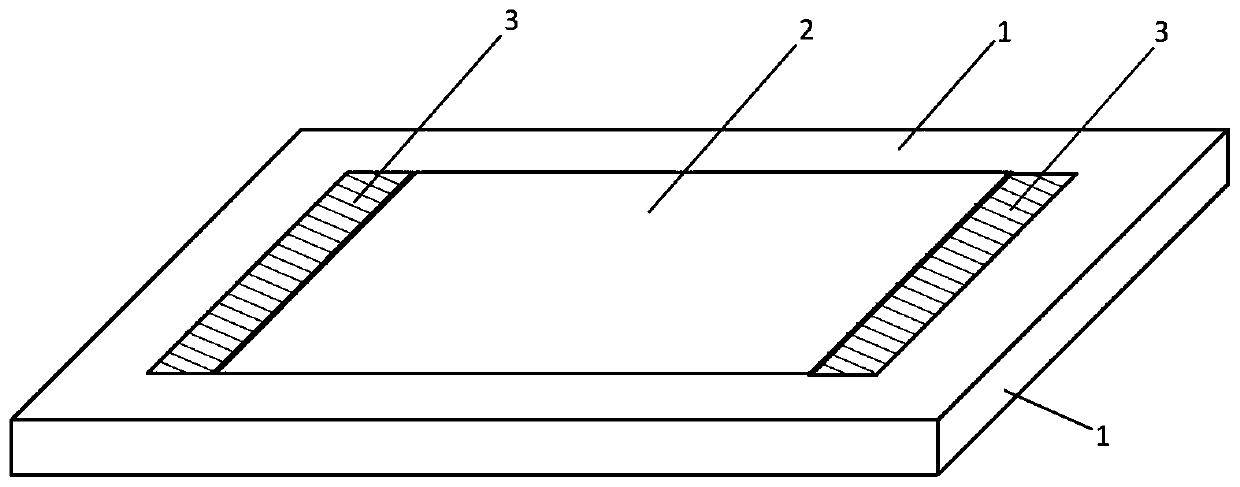

[0051] The present invention also proposes a heating glass, which includes:

[0052] Glass substrate 1;

[0053] Graphene ink layer 2, it is arranged on the side surface of glass substrate 1;

[0054] The electrodes 3 are arranged on both sides of the graphene ink layer 2 and connected to the graphene ink layer 2.

[0055] The graphene ink layer 2 is a transp...

Embodiment 1~6 and comparative example 1~2

[0075] 1) Preparation of graphene dispersion:

[0076] Purchasing commercially available graphene, adding a dispersant, a wetting agent and water, and stirring evenly to obtain a graphene dispersion; wherein, the mass percentage of graphene in the graphene dispersion is 3%;

[0077] 2) Preparation of transparent graphene ink:

[0078] Prepare deionized water, graphene dispersion, PEDOT:PSS aqueous solution (commercially available, the mass percentage of PEDOT and PSS in the PEDOT:PSS aqueous solution is 1.3-1.7%) according to the formula in Table 1, mix, and ultrasonically disperse ; Add adhesion promoter and tensio-active agent of amount shown in table 1 in the process of ultrasonic dispersion treatment, disperse evenly, get transparent graphene ink;

[0079] 3) Prepare heating glass according to the following method:

[0080] Using the coating process in Table 2, apply the transparent graphene ink on a glass substrate with a specification of 15cm×15cm×1cm, and dry it at 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com