Nitrogen protection microwave vacuum drying device and drying method for optical plastic raw materials

A technology of microwave vacuum drying and nitrogen protection. It is applied in the direction of drying gas arrangement, heating device, and drying solid materials. It can solve the problems of destroying the characteristics of optical materials, reducing drying temperature, and prolonging drying time, so as to avoid moisture reabsorption, Lower drying temperature and faster heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be described in detail below in conjunction with the drawings and examples. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

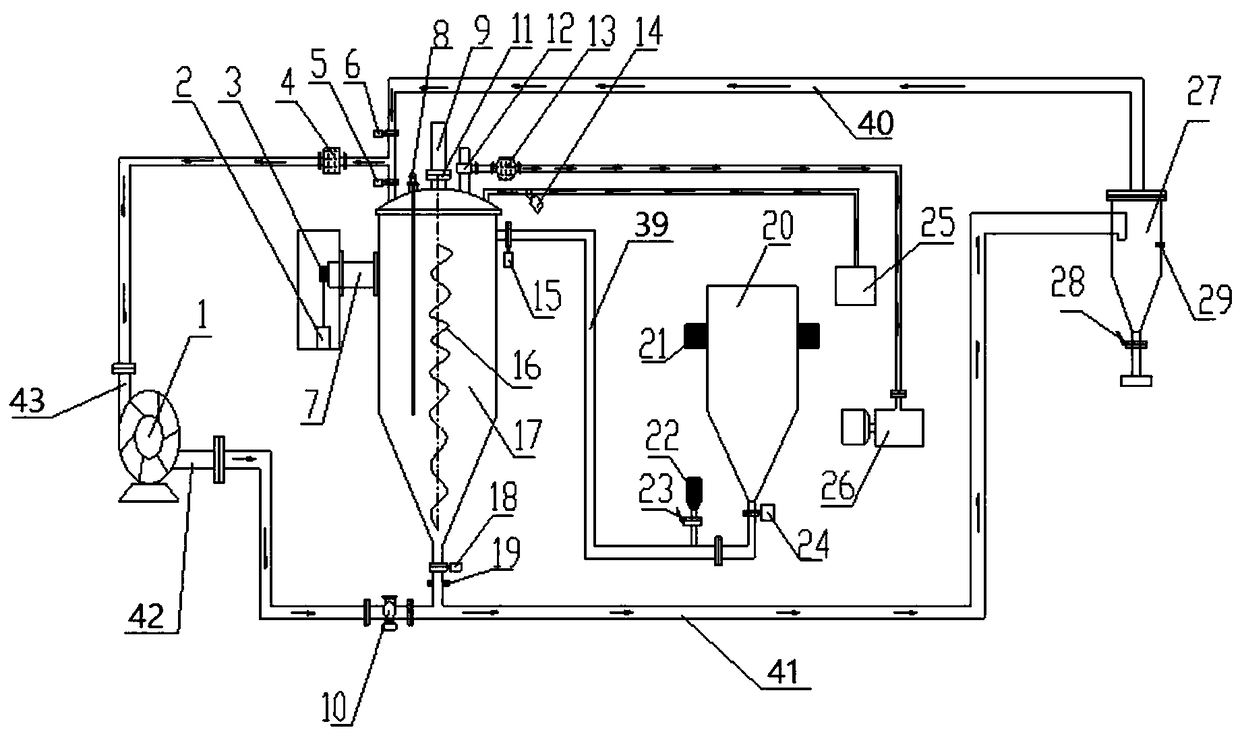

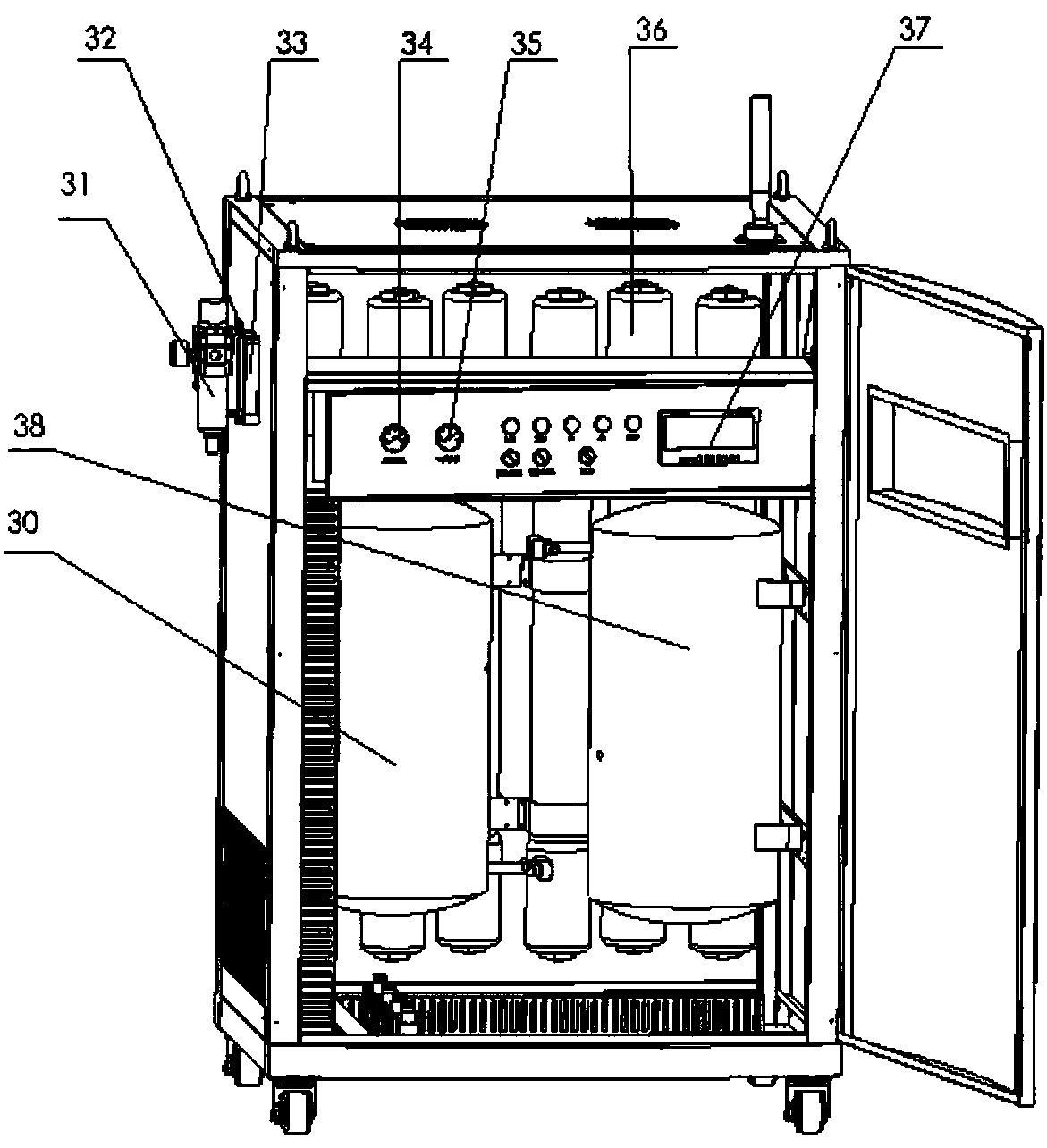

[0028] Such as figure 1 , 2 As shown, a nitrogen-protected microwave vacuum drying device for optical plastic raw materials includes a drying tank 17, a storage bin 20, and a heater. The drying device is also provided with a conveying fan 1, a terminal hopper 27, and multiple sets of valve devices; The air inlet 43 of the conveying fan 1, the drying tank 17, and the terminal hopper 27 are connected through an air duct 40; a feeding pipeline 39 is connected between the storage bin 20 and the drying tank 17; Connect the terminal hopper 27; the air outlet 42 of the delivery fan 1 is connected to the discharge pipeline 41 through the pipeline of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com