Preparation method of fine metal powder coarsening

A fine powder and coarsening technology, which is applied in the field of metal fine powder coarsening, can solve the problems of increasing consumables and costs, reducing material density, and reducing mechanical strength, so as to reduce die loss, improve fluidity, Mutual friction force weakening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

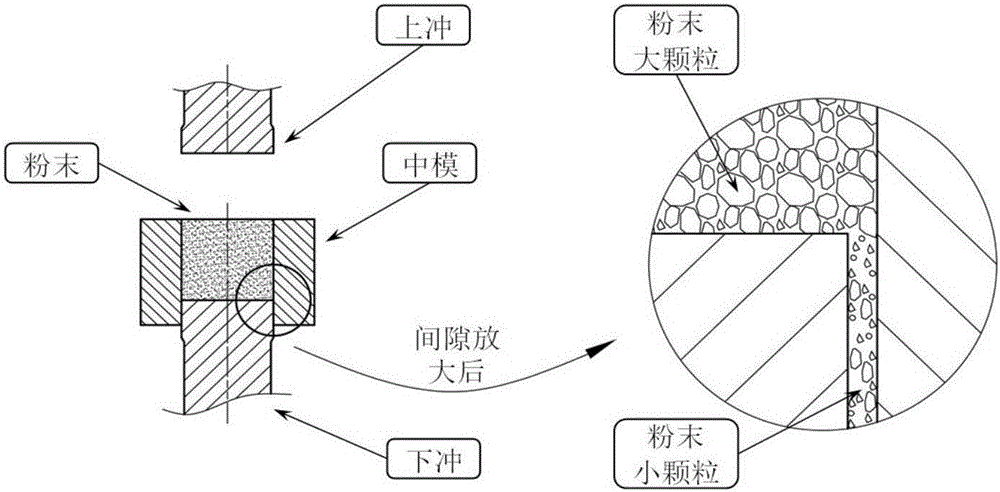

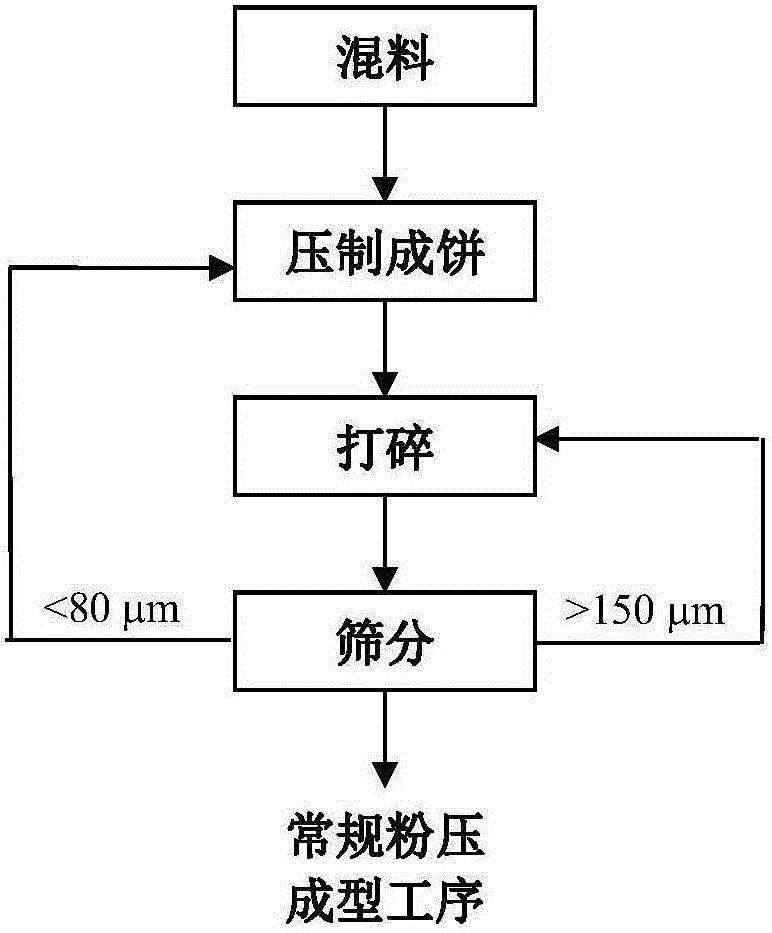

[0019] The process of coarsening the aluminum powder in this embodiment includes four processes of mixing materials, pressing into cakes, crushing and sieving, and the specific process steps are:

[0020] (1) Mixing: 67.5-68.3wt.% high-purity gas atomization (GasAtomization) aluminum powder, 20wt.% silicon carbide (SiC), 7.4wt.% Al50-Cu50 (that is, containing 50wt.% Copper aluminum alloy) alloy powder, 3.6wt.% Al50-Mg50 (that is, aluminum alloy containing 50wt.% magnesium) alloy powder and 0.7-1.5wt.% lubricant are uniformly mixed together to obtain loose fine powder;

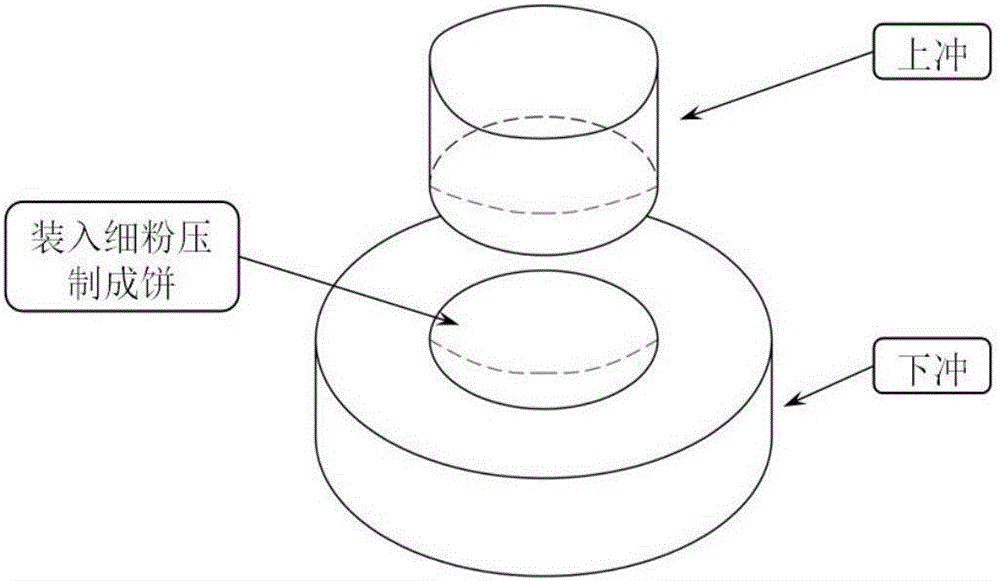

[0021] (2) pressing into cake: adopt press and mold to compress the loose fine powder that step (1) makes to obtain powder cake;

[0022] (3) crushing: the powder cake obtained by pressing step (2) is first ground into large particles, and then finely ground and crushed to obtain crushed powder;

[0023] (4) Sieving: Use a sieving machine to sieve the powder particles crushed in step (3) into three groups acco...

Embodiment 2

[0026] In this embodiment, the coarsening process of water atomization (WaterAtomization) ferroalloy powder includes four processes of mixing materials, pressing into cakes, crushing and sieving, and the specific process steps are:

[0027] (1) Mixing: 92.2-96.9wt.% atomized iron alloy powder (containing 0.45-1.80wt.% molybdenum and 0.0-1.8% nickel), 1.0-3.0wt.% copper powder, 1.0-3.0 wt.% nickel powder, 0.5-0.8wt.% graphite powder and 0.6-1.0wt.% lubricant are uniformly mixed together to obtain loose fine powder;

[0028] (2) pressing into cake: adopt press and mold to compress the loose fine powder that step (1) makes to obtain powder cake;

[0029] (3) crushing: the powder cake obtained by pressing step (2) is first ground into large particles, and then finely ground and crushed to obtain crushed powder;

[0030](4) Sieving: use a sieving machine to sieve the powder after step (3) into three groups according to the particle size, the diameter is less than 80 μm, the diamet...

Embodiment 3

[0033] In this embodiment, the coarsening process of water atomized copper powder includes four processes of mixing materials, pressing into cakes, crushing and sieving. The specific process steps are:

[0034] (1) Mixing: uniformly mix not less than 69% of high-purity water atomized copper powder, 30wt.% of tungsten powder particles and no more than 1.0wt.% of lubricant to obtain a loose fine powder;

[0035] (2) pressing into cake: adopt press and mold to compress the loose fine powder that step (1) makes to obtain powder cake;

[0036] (3) crushing: the powder cake obtained by pressing step (2) is first ground into large particles, and then finely ground and crushed to obtain crushed powder;

[0037] (4) Sieving: use a sieving machine to sieve the powder after step (3) into three groups according to the particle size, the diameter is less than 80 μm, the diameter is 80 μm ~ 150 μm, and the diameter is greater than 150 μm. Among them, the particle diameter is 80 μm ~ 150 μm....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com