Automobile expansion tank pressure relief cover reliability test method and system

A technology of an expansion tank and a test system, which is used in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problems of not being able to observe whether the pressure relief cover is qualified or not, and the test results are not intuitive. Intuitive process and high test accuracy

Inactive Publication Date: 2015-03-25

SHANDONG HUA TONG AUTOMOBILE MOLDS PLASTICS TECH

View PDF6 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] When using the above principle to carry out the reliability test of the pressure relief cover of the automobile expansion tank, the common proble

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

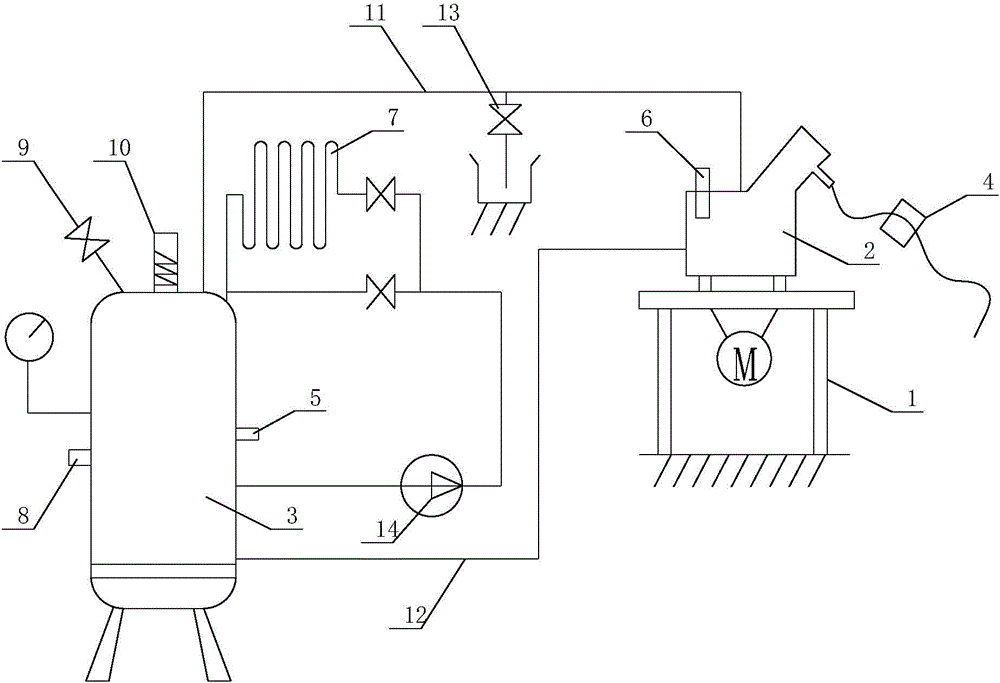

The invention relates to the technical field of service life tests of automobile expansion tank pressure relief covers, in particular to an automobile expansion tank pressure relief cover reliability test method and system. The system structurally comprises an expansion tank installed on a vibration test table fixing support with a vibration device. The expansion tank is provided with a pressure relief cover and connected with a heating device through a pipeline. An air flow sensor is arranged on the pressure relief cover. A temperature sensor connected with a temperature measurement instrument is arranged in the heating device. A pressure sensor connected with a pressure measurement instrument is arranged in the expansion tank. The vibration device, the air flow sensor, the temperature measurement instrument and the pressure measurement instrument are electrically connected with a programmable logic controller. According to the automobile expansion tank pressure relief cover reliability test method and system, the pressure value, the temperature value and time are measured and compared with the standard range of a test tank for judgment, so that whether the pressure relief cover is qualified or not is accurately and visually observed.

Description

technical field [0001] The invention relates to the technical field of service life testing of a pressure relief cover of an automobile expansion water tank, in particular to a reliability test method and system for a pressure relief cover of an automobile expansion water tank. Background technique [0002] Under the existing technology, the country has corresponding national standards for the service life of the pressure relief cover of the automobile expansion tank. In order to verify the reliability of the product, a simulation system will be used to test the reliability of the pressure relief cover of the automobile expansion tank The test principle is as follows: [0003] Under certain conditions, with a closed circulation system (including heating equipment and expansion tank) with a certain volume of coolant, when the heating temperature of the system rises, the pressure in the system rises, and when the opening pressure of the pressure relief cap is reached, the pres...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M17/007

Inventor 葛衍鹍王勇杨红旗

Owner SHANDONG HUA TONG AUTOMOBILE MOLDS PLASTICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com