Method for extracting proanthocyanidin from peanut coats

A technology of peanut clothing and anthocyanin, applied in chemical/physical/physicochemical processes of applied energy, anti-toxins, cardiovascular system diseases, etc., can solve the problems of high maintenance costs, long extraction time, pollution of the environment, etc., and achieve warming Uniform speed, short extraction time, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

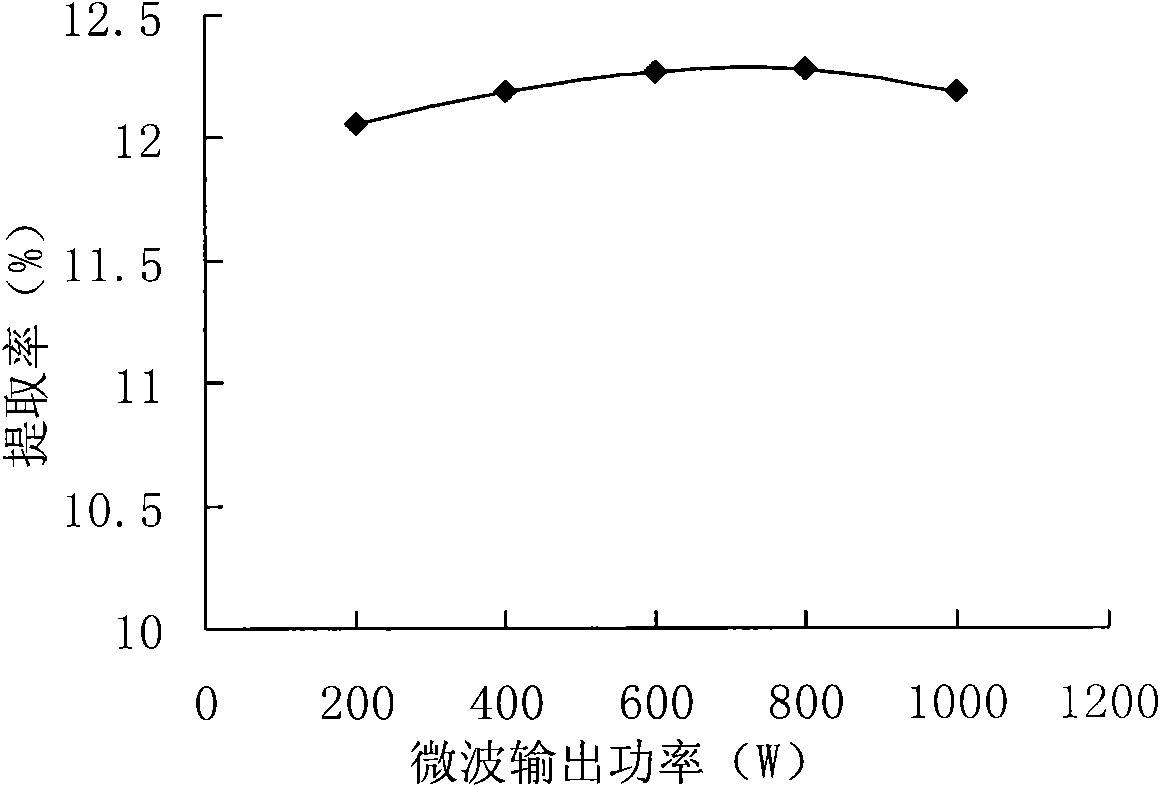

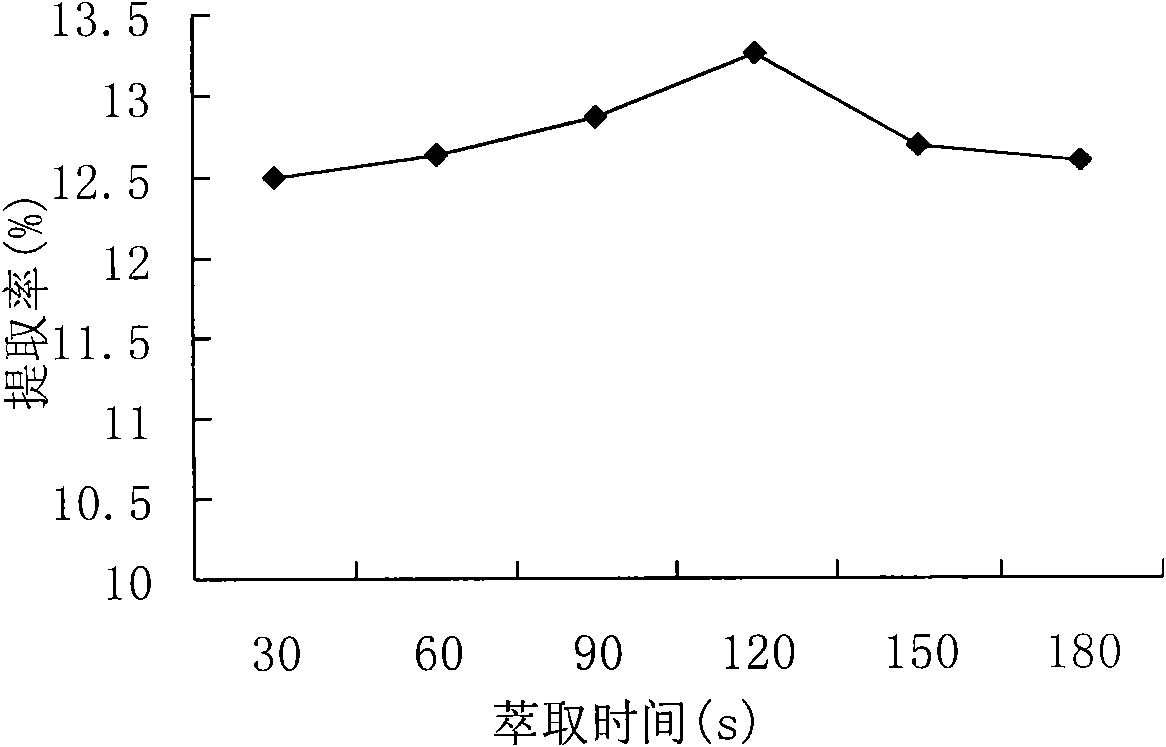

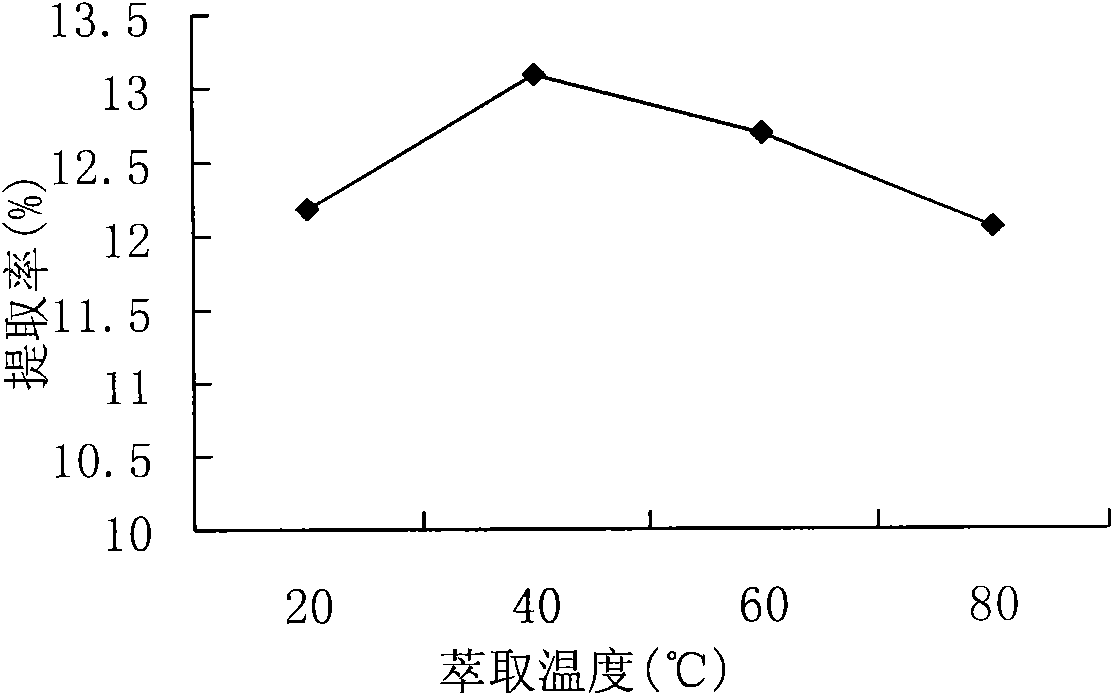

[0027] Crush the peanut shells in a grinder, pass through a 40-mesh sieve, add petroleum ether at a ratio of 1:20 (m / v), degrease at 30°C for 5 hours, filter with suction, and remove the residual petroleum ether in the filter residue in a fume hood to obtain degreased Peanut coats, stored in a desiccator for later use. Add the obtained defatted peanut shells to distilled water, the ratio of solid to liquid is 1:10, the microwave power is 200W, the extraction temperature is 20°C, and the extraction time is 30s to extract the proanthocyanidin; then the liquid-material mixture is conventionally vacuum filtered to obtain the extract , the extract is concentrated by vacuum rotary evaporation, ethanol is recovered, and the concentrate is freeze-dried to obtain the obtained product.

Embodiment 2

[0029] Crush the peanut shells in a grinder, pass through a 40-mesh sieve, add petroleum ether at a ratio of 1:20 (m / v), degrease at 30°C for 5 hours, filter with suction, and remove the residual petroleum ether in the filter residue in a fume hood to obtain degreased Peanut coats, stored in a desiccator for later use. Add 20% ethanol to the obtained defatted peanut shells, the ratio of solid to liquid is 1:15, the microwave power is 400W, the extraction temperature is 40°C, and the extraction time is 60s to extract proanthocyanidin; then the liquid-material mixture is conventionally vacuum-filtered to obtain The extract is concentrated by vacuum rotary evaporation, ethanol is recovered, and the concentrate is freeze-dried to obtain the product.

Embodiment 3

[0031] Crush the peanut shells in a grinder, pass through a 40-mesh sieve, add petroleum ether at a ratio of 1:20 (m / v), degrease at 30°C for 5 hours, filter with suction, and remove the residual petroleum ether in the filter residue in a fume hood to obtain degreased Peanut coats, stored in a desiccator for later use. Add 40% ethanol to the obtained defatted peanut shells, the ratio of solid to liquid is 1:20, the microwave power is 600W, the extraction temperature is 40°C, and the extraction time is 120s to extract proanthocyanidin; then the liquid-material mixture is conventionally vacuum filtered to obtain The extract is concentrated by vacuum rotary evaporation, ethanol is recovered, and the concentrate is freeze-dried to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com