Heating device used for pipe orifice preheating

A heating device and pipeline technology, which is applied in the field of welding and pipe nozzle preheating, can solve the problems of construction environment influence, uneven temperature, large heat loss, etc., and achieve safe and reliable use, improve weld quality, and fast heating speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

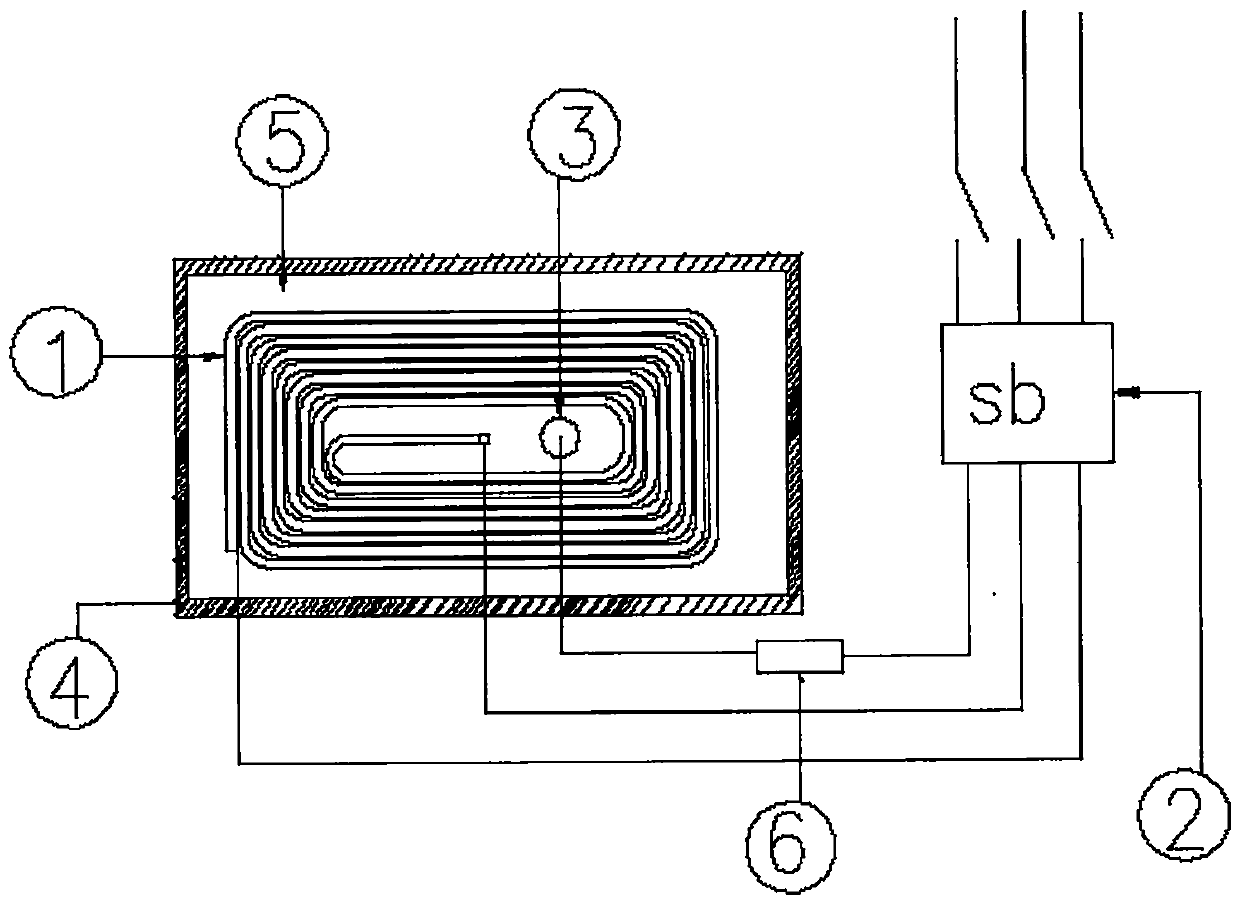

[0009] A heating device for preheating the nozzle of a pipeline, including installing the induction coil 1 on the heat insulation material 4, potting it in a flexible shell 5, wrapping it along the circumference of the pipeline, and connecting the sb variable frequency power supply 2 and the temperature sensor 3 After being installed in the middle of the induction coil, it is connected with the temperature control device 6 and then connected with the sb variable frequency power supply. The principle of the present invention is to output the intermediate frequency electricity to the induction coil 1 through the sb variable frequency power supply 2, and the intermediate frequency electricity forms an eddy current on the surface of the pipe body 4 through the induction coil 1 to realize heating. The temperature control device 6 controls the output of the sb variable frequency power supply according to the set temperature required for nozzle preheating and the real-time temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com