Preparation method of red fluorescent powder

A technology of red fluorescent powder and fluorescent powder, which is applied in the field of fluorescent powder, can solve the problems of high price of white LED, low LED luminous flux, low color rendering index, etc., and achieve the effect of large contact surface area, simple synthesis conditions and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

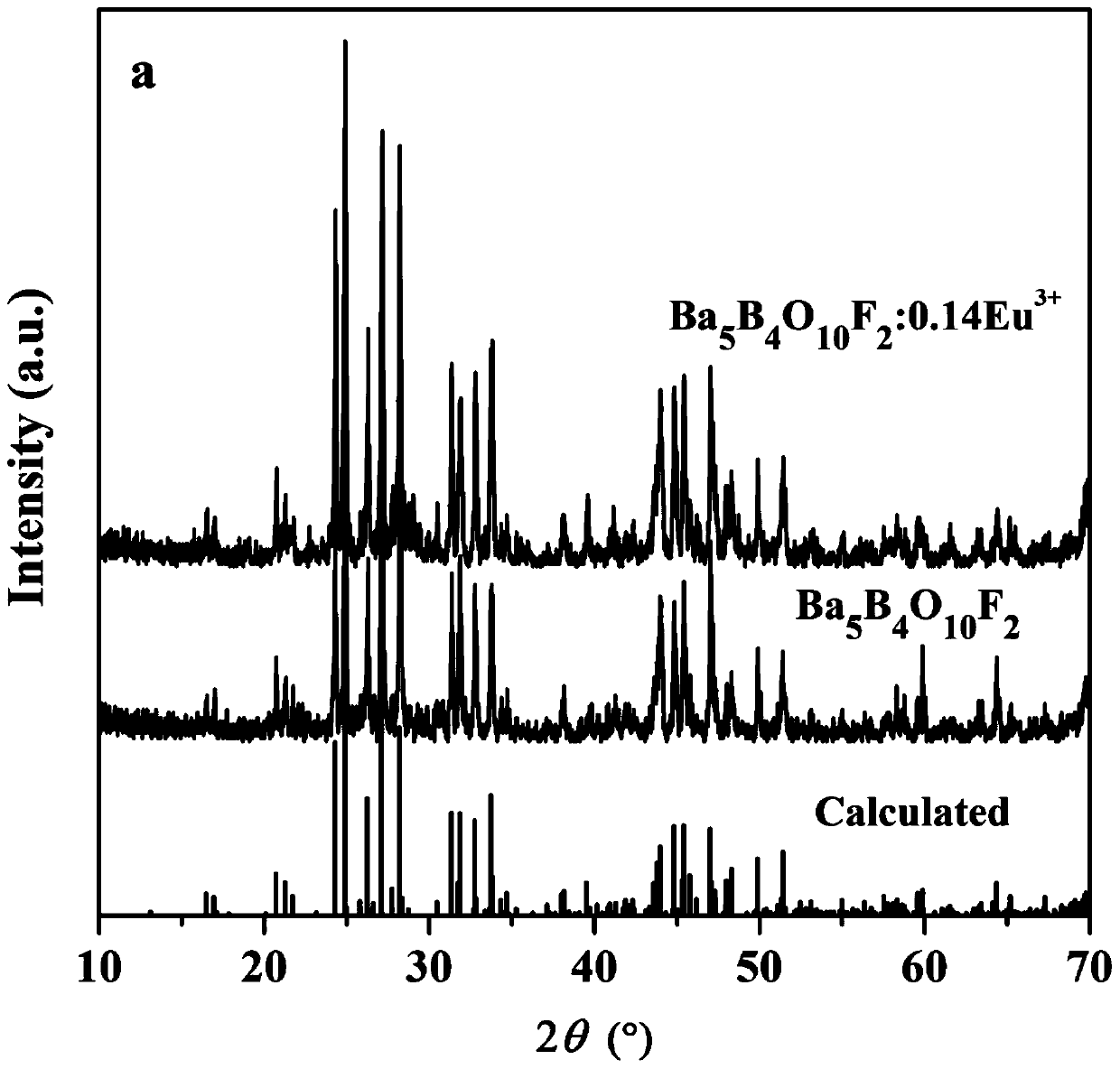

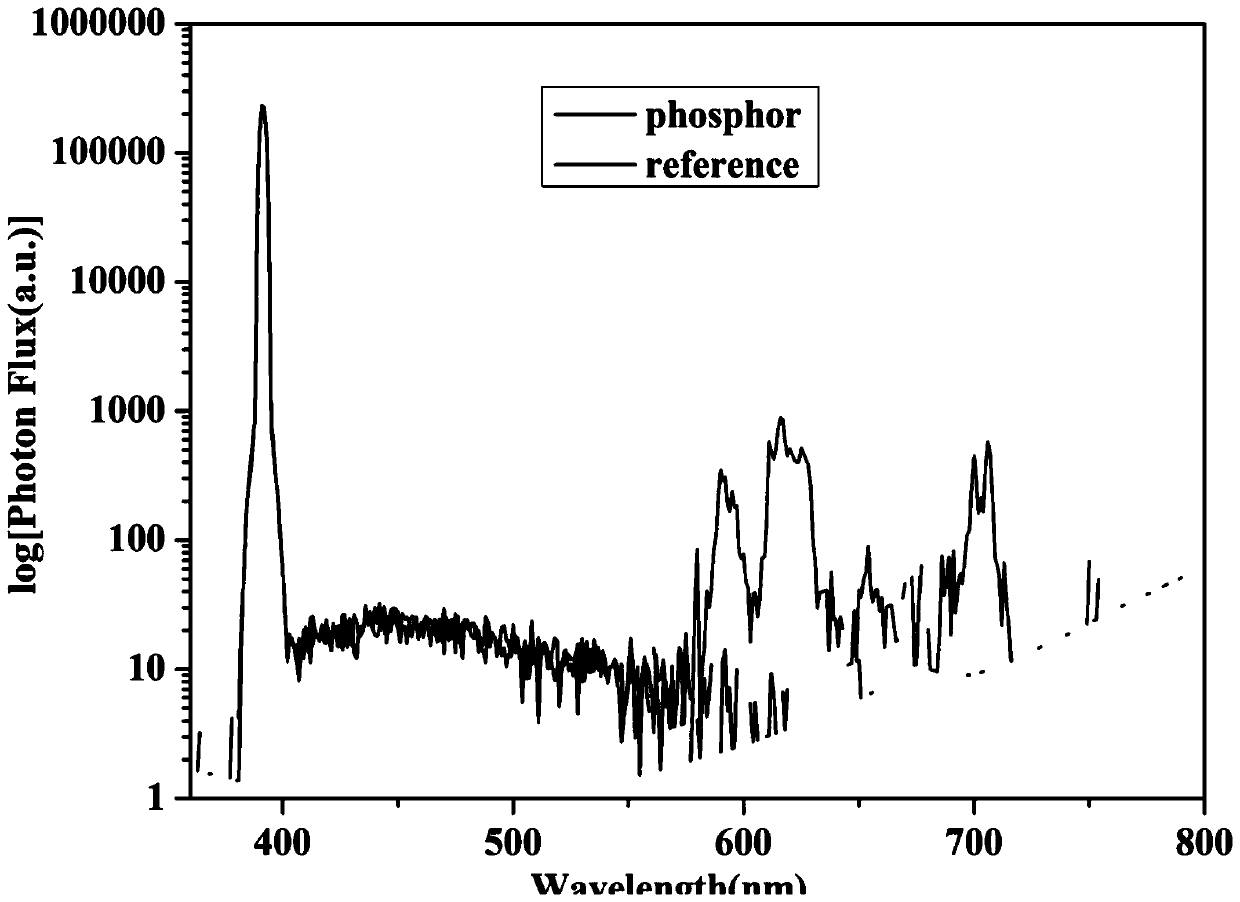

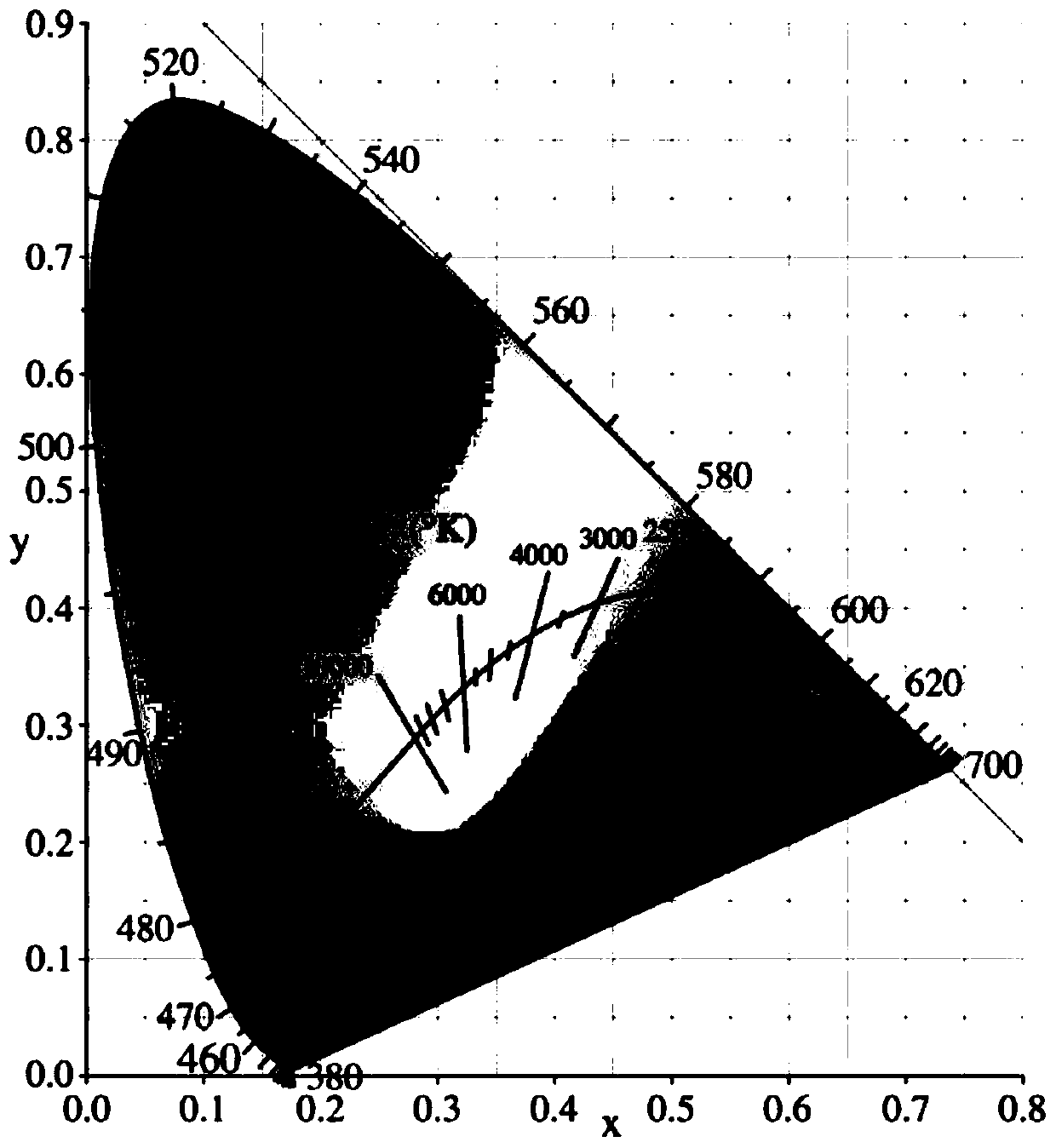

Image

Examples

Embodiment 1

[0037] A kind of preparation method of red fluorescent powder provided by the invention comprises the following steps:

[0038] First, use an analytical balance (FA22048) to accurately weigh BaCO according to the stoichiometric ratio. 3 、BaF 2 、H 3 BO 3 and Eu 2 o 3 , wherein the purity of rare earth oxides is 99.99%, and the rest are analytically pure;

[0039] (4-0.14)BaCO 3 +BaF 2 +4H 3 BO 3 +0.14 / 2Eu 2 o 3 →Ba 5-x B 4 o 10 f 2 :0.14Eu 3+

[0040] Then put the above-mentioned samples weighed in an agate mortar, mix and grind them, place them in a crucible after grinding for 30 minutes, put them into a high-temperature box-type resistance furnace (SRJX-4-13) and heat them for 2 hours at 400°C for initial calcination. Boric acid decomposes slowly to form B 2 o 3 , to obtain sintered block A.

[0041] It should be noted that boric acid decomposition provides a boron source for subsequent products, and boric acid decomposition is used to generate B 2 o 3 P...

Embodiment 2

[0049] First, use an analytical balance (FA22048) to accurately weigh BaCO according to the stoichiometric ratio. 3 、BaF 2 、H 3 BO 3 and Eu 2 o 3 , wherein the purity of rare earth oxides is 99.99%, and the rest are analytically pure;

[0050] (4-0.11)BaCO 3 +BaF 2 +4H 3 BO 3 +0.11 / 2Eu 2 o 3 →Ba 5-x B 4 o 10 f 2 :0.11Eu 3+

[0051] Then put the above-mentioned sample weighed in an agate mortar, mix and grind, put it in a crucible after grinding for 40min, put it into a high-temperature box-type resistance furnace (SRJX-4-13) and heat it at 450°C for 3h for initial calcination. Boric acid decomposes slowly to form B 2 o 3 , to obtain sintered block A.

[0052] Then, the sintered block A obtained by the above operation is taken out and ground, and the temperature is raised to 650°C at a rate of 20°C / min and kept at this temperature for 7 hours to make the BaCO 3 Slowly decompose to form BaO to obtain sintered block B. It should be noted that the decomposition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com