Oil industry wellhead repairing device

A technology of the petroleum industry and key sleeves, which is applied in the field of coiled tubing cut recovery and repair devices, can solve the problems of uncertain formation energy, high formation energy of oil and gas wells, and operation poisoning, so as to increase the liquid output or gas output and avoid self-destructive Effect of spraying or spilling, avoiding large spills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

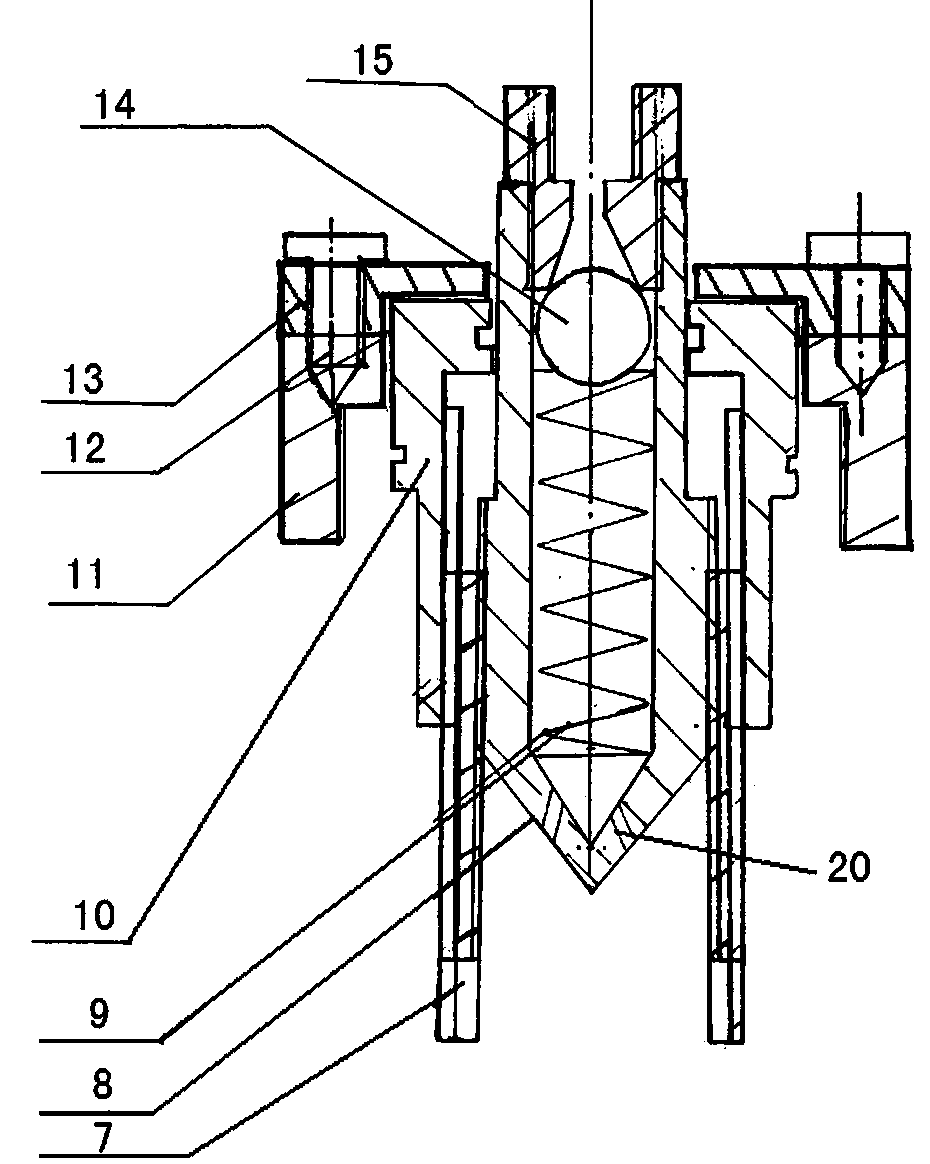

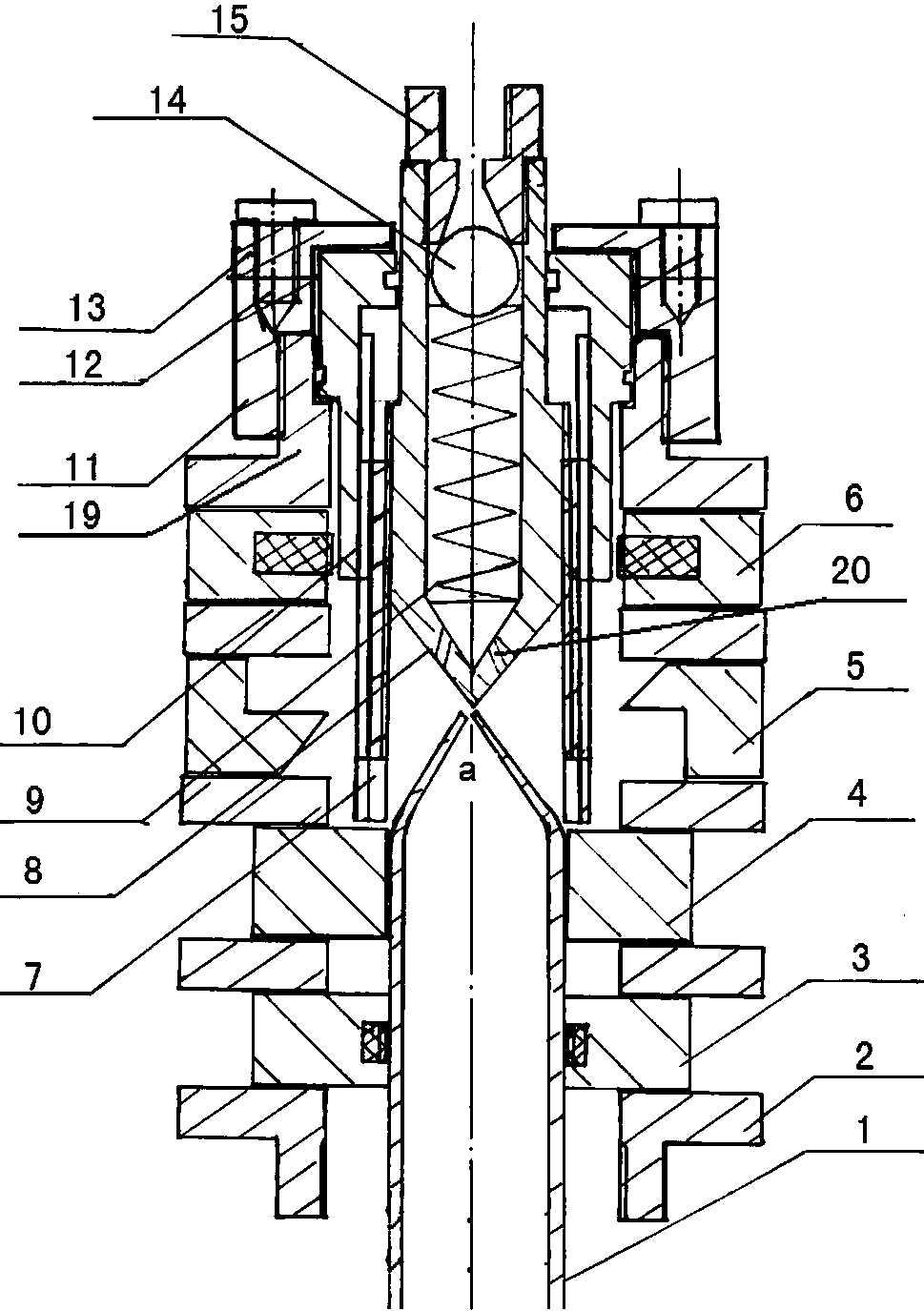

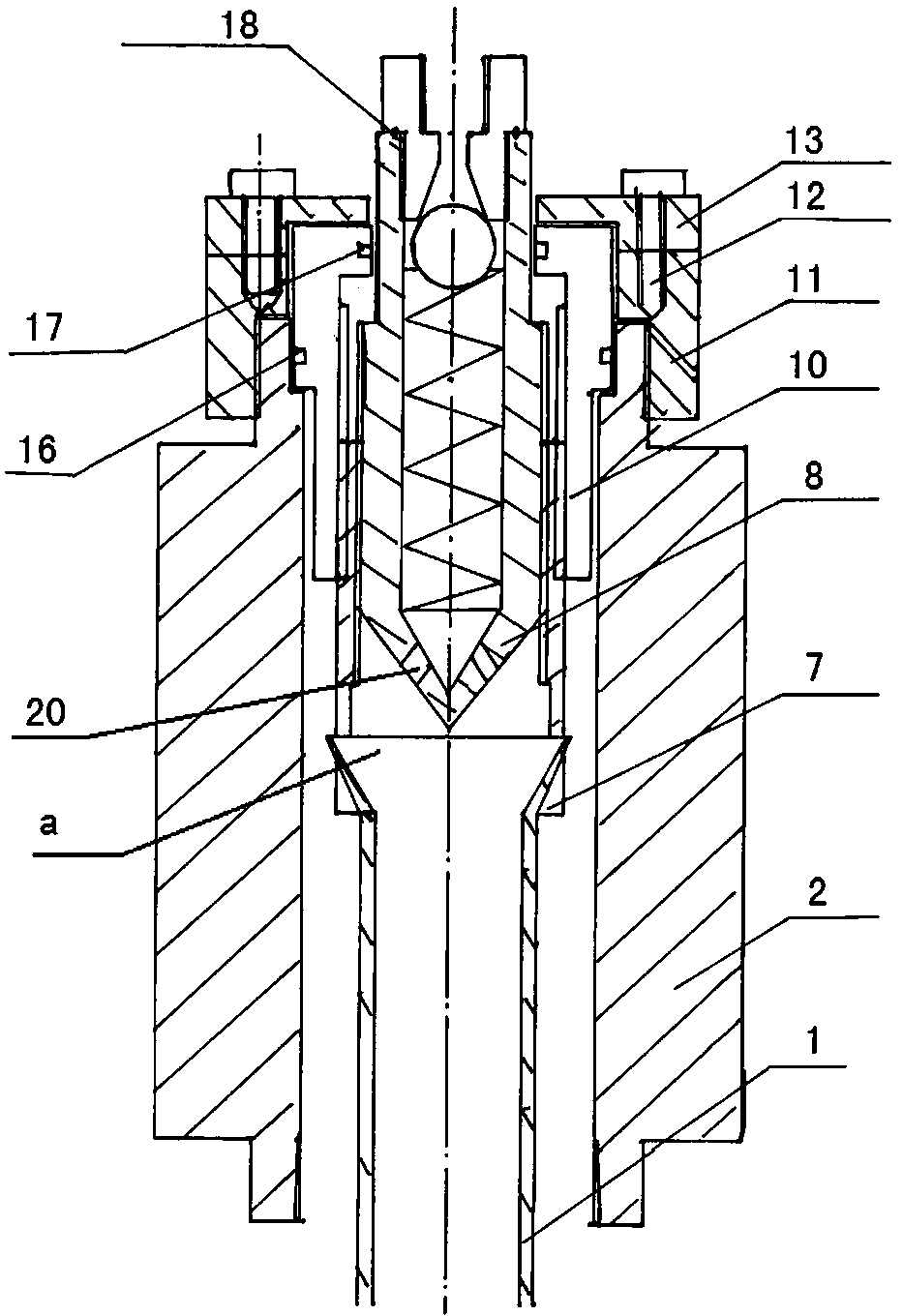

[0029] Example 1, see attached Figure 1-3 , The coiled tubing incision restoration repair device mentioned in the present invention, its technical solution is: including repair mouth jacket (7), repair mouth inner mold (8), support spring (9), key sleeve (10), transition sleeve (11) Connecting bolts (12), upper pressure cap (13), check valve sealing steel ball (14), check valve inlet balloon seat (15), among which, the four-gate packer includes four-gate guard The sprayer body (2), half-sealed ram (3), suspension ram (4), shear ram (5), fully-sealed ram (6), coiled tubing (1) is provided in the oil well, and the end A straight cut a for shearing the gate (5). The transitional connecting sleeve (11) is connected with the upper joint (19) of the four-ram blowout preventer through internal threads, and the upper part of the transitional connecting sleeve (11) is connected with the upper pressure cap (13) through the connecting bolt (12), and the upper pressure The key sleeve (1...

Embodiment 2

[0043] In Embodiment 2, the difference between the present invention and Embodiment 1 is that the bottom of the repair port cover (7) can be provided with an L-shaped groove, and the two extruded ends of the in-line incision can still be grasped and then lifted up. At the same time, the conical structure is used to expand and squeeze the incision.

Embodiment 3

[0044] Embodiment 3, the difference between the present invention and embodiment 1 is: the repair port outer shell (7) and the repair port inner mold (8) of the present invention can be provided with a bearing, so that the rotation is easier and the operation is more labor-saving .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com