Spray pipe structure for underwater welding and underwater welding equipment

An underwater welding and nozzle technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve problems such as turbidity, achieve the effects of reducing smoke, reducing high-temperature gasification, and improving welding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

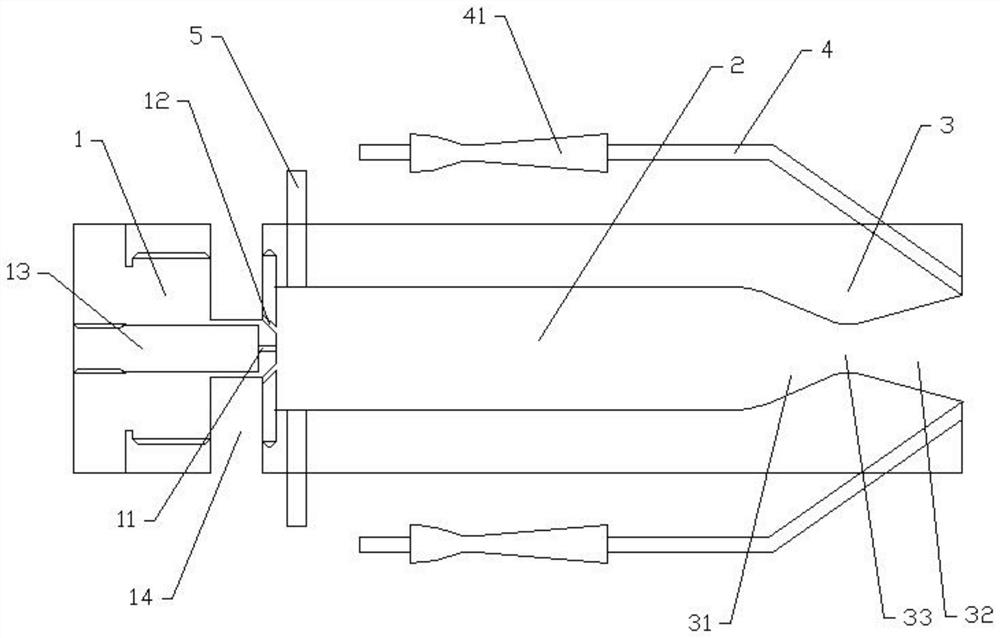

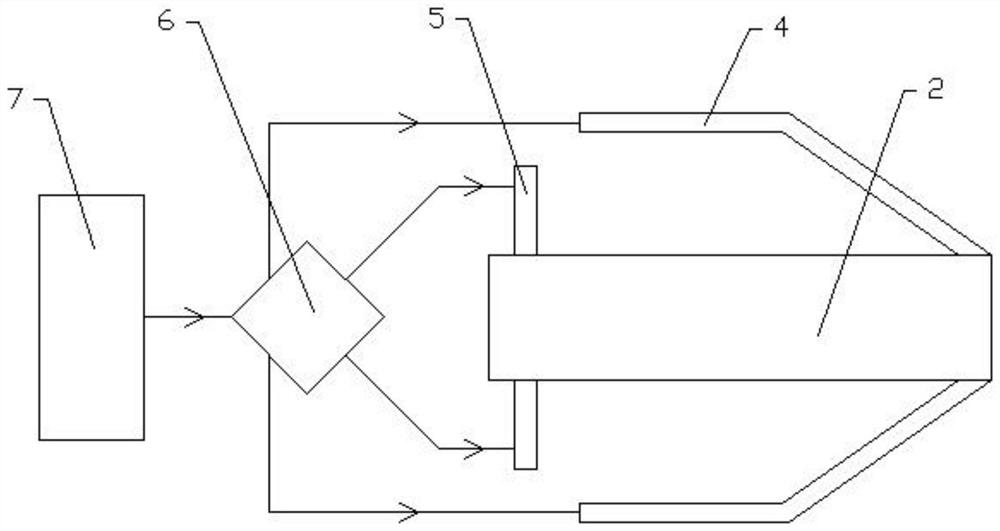

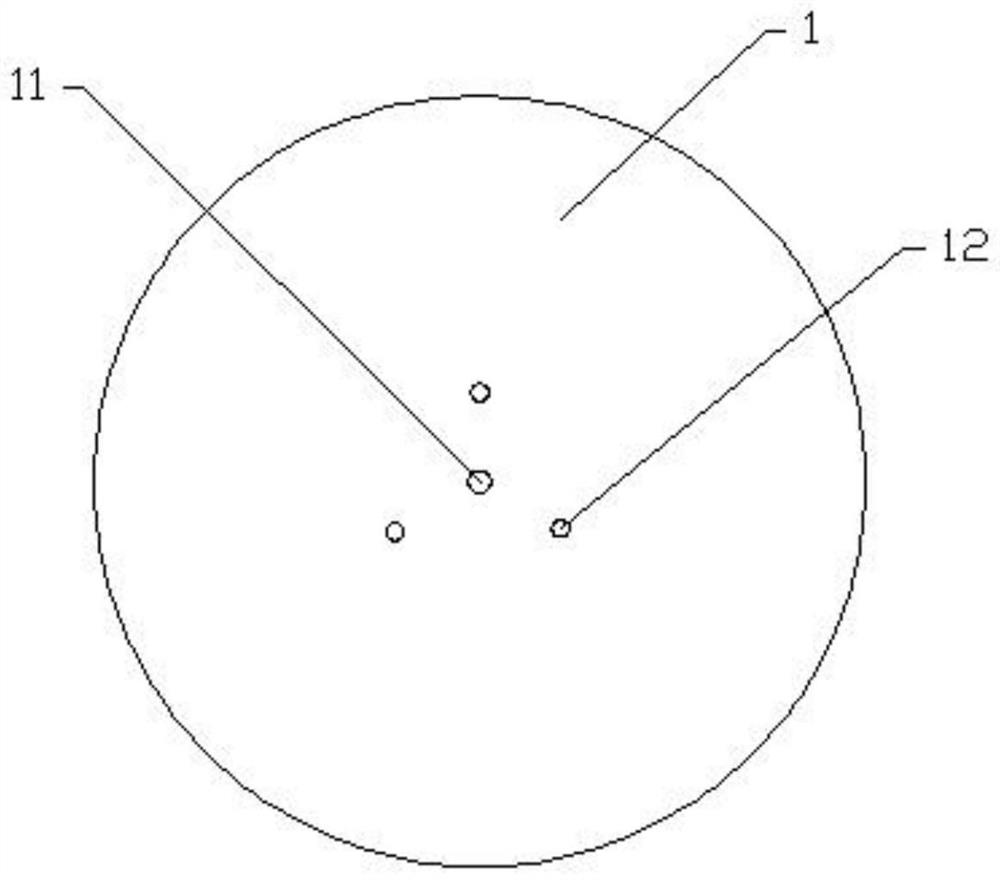

[0035] like figure 1 As shown, the embodiment of the present invention proposes a nozzle structure device for underwater welding, including a nozzle, which includes an injector 1, a combustion chamber 2 and a nozzle 3 connected in sequence, wherein the injector 1 A number of injection ports are respectively provided on the upper part of the injection port. One end of the inlet of the injection port is connected with a fuel passage. There is a sealed connection between them, so that one end of the outlet of the injection port communicates with the combustion chamber 2. It should be noted that the end face connecting the injector 1 and the combustion chamber 2 is a plane, and the outlet of the injection port is located on this end face. The nozzle 3 includes a converging section 31 and a diverging section 32 arranged sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com