Inert gas shielding immersion type heating difunctional low-pressure casting furnace

An inert gas, low pressure casting technology, applied in the field of low pressure casting, can solve problems such as affecting production continuity, increasing power consumption, increasing hydrogen and oxygen content, etc., achieving excellent thermal shock resistance, avoiding the introduction of impurities, excellent electrical insulating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

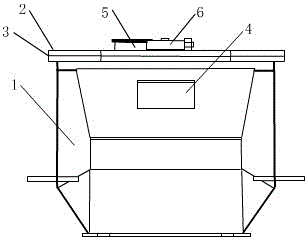

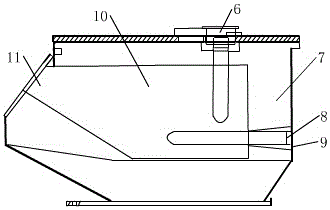

[0020] As shown in the figure, a furnace cover 2 is installed on the upper part of the furnace shell 1 through a cover seal 3, and the furnace door 4 is located at the upper right side of the furnace shell. The heater 6 is also inserted into the aluminum melting pool from the upper part of the furnace cover, and the aluminum melting pool lining 7 is arranged between the outer side of the aluminum melting pool and the furnace shell;

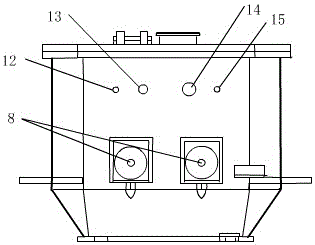

[0021] Two immersion heaters 8 are installed in the aluminum melting pool in the furnace shell through YF cement seal 9, and a PID temperature control component 16 is installed between the two immersion heaters;

[0022] The upper edge of the rear part of the furnace shell is provided with an air inlet 12, an air outlet 15, a pressure sensor interface 13, and a thermocouple interface 14;

[0023] Furnace door replenishment 11 is provided on the front side of the furnace door;

[0024] The inner lining of the molten aluminum pool is composed of hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com