Forging and rolling technology and hot rolling and forging apparatus for making large pulley

A rolling technology and rolling equipment technology, applied in the field of hot rolling and forging equipment, forging rolling of large pulleys, can solve the problems of mechanical properties such as strength and toughness decline, discontinuous metal fiber structure, deformation during processing and use, etc. , to achieve uniform heating and cooling rates, good streamline organization of metal fibers, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

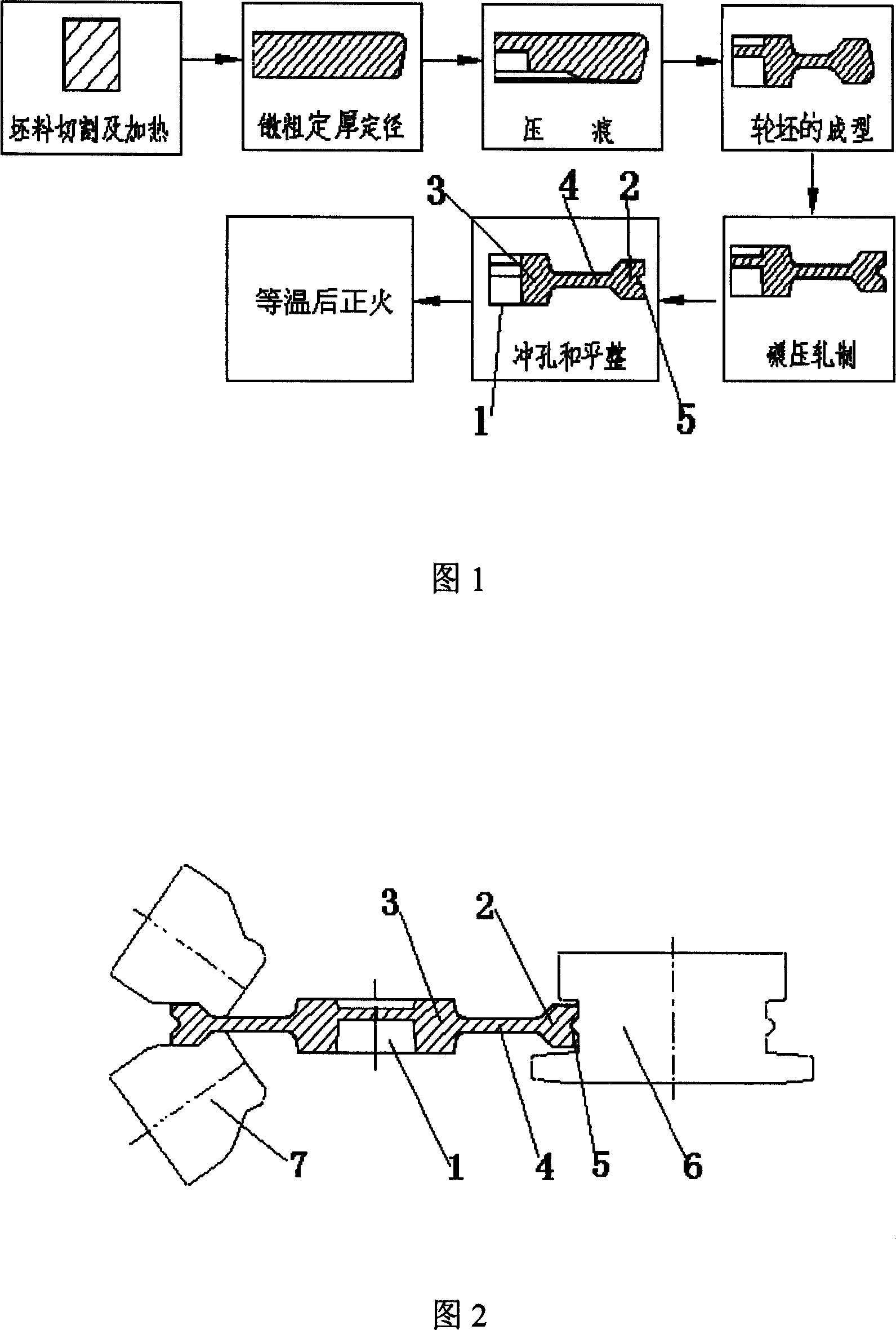

[0029] What the present invention provides is a kind of forging rolling technology of large-scale pulley, and Fig. 1 is the processing technological flow diagram that this forging rolling technology adopts; The present invention also provides the hot rolling forging equipment that adopts this forging rolling technology Technical solution, Fig. 2 is a structural schematic diagram of the hot rolling rolling equipment.

[0030] This large pulley 1 includes a rim 2, a hub 3, and a spoke 4. The outer circumference of the rim 2 is provided with an annular wheel groove 5. The pulley 1 is obtained by thermal processing before cutting.

[0031] In order to achieve the purpose of improving the mechanical performance of the large pulley and reducing the manufacturing cost, the technical solution adopted by the present invention is: during the processing of the process, the steel ingot blank or continuous casting blank of the pulley 1 is subjected to hot forging, upsetting, and setting. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com