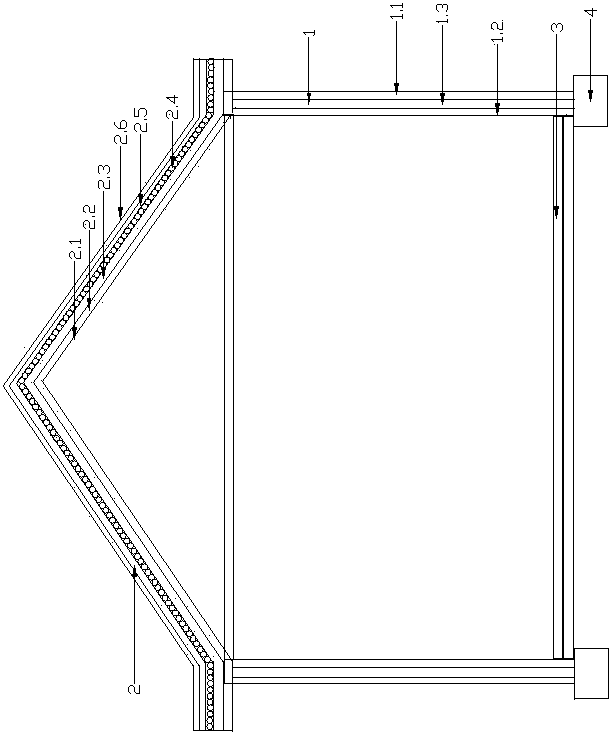

Waterproof wooden house based on assembly-type tenon-mortise connection process and manufacturing method thereof

A prefabricated, tenon-and-mortise technology, used in wood treatment, manufacturing tools, wood heat treatment, etc., can solve problems such as affecting the air permeability of wooden houses, and achieve the effect of reducing cracking and deformation, reducing internal moisture, and ensuring anti-corrosion durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The production method comprises the steps of:

[0024] (1) Treatment of the boards required for the wooden house: First, sort and stack according to the wall boards and roof boards. When stacking, each adjacent two pieces of wood are separated by a spacer to facilitate ventilation. Both types of boards are ventilated and dry. until the moisture content is lower than 60%; then use a forklift to send different types of wood boards into their respective drying kilns. In the drying kiln, steam is sprayed from top to bottom in the drying kiln to control the steam of the wood boards on the wall The drying temperature in the drying kiln is raised from 60°C to 110°C at a constant speed of 8°C / min. Raise the temperature from 70°C to 120°C, heat-preserve and bake for 35 days after heating; then, send the dried wall planks and roof planks to their respective carbonization kilns for carbonization treatment, and control the temperature in the carbonization kiln of the wall planks to...

Embodiment 2

[0029] The production method comprises the steps of:

[0030] (1) Treatment of the boards required for the wooden house: First, sort and stack according to the wall boards and roof boards. When stacking, each adjacent two pieces of wood are separated by a spacer to facilitate ventilation. Both types of boards are ventilated and dry. until the moisture content is lower than 60%; then use a forklift to send different types of wood boards into their respective drying kilns. In the drying kiln, steam is sprayed from top to bottom in the drying kiln to control the steam of the wood boards on the wall The drying temperature in the drying kiln is raised from 60°C to 110°C at a constant speed of 5°C / min. Raise the temperature from 70°C to 120°C, keep warm and bake for 25 days after heating; then, send the dried wall planks and roof planks to their respective carbonization kilns for carbonization treatment, and control the temperature in the carbonization kiln of the wall planks to 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com