Heating body and curing object matched with heating body, electronic cigarette atomizer and electronic cigarette

A heating element and electronic cigarette technology, applied in the field of electronic cigarettes, can solve the problems of affecting the smell and taste, unstable temperature control, and too fast atomization, so as to prevent metal oxidation and pollute the filling, and ensure the smell and taste , long-lasting effect of atomization speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

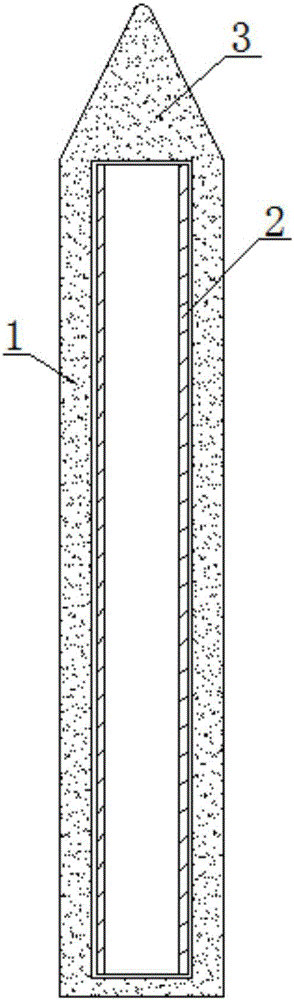

[0036] From figure 1 It can be seen that the cone 3 and the glass sleeve 1 of the present invention are an integral structure formed by one blow molding of quartz glass material, and a piece of metal 2 is embedded in the glass sleeve 1 .

Embodiment 2

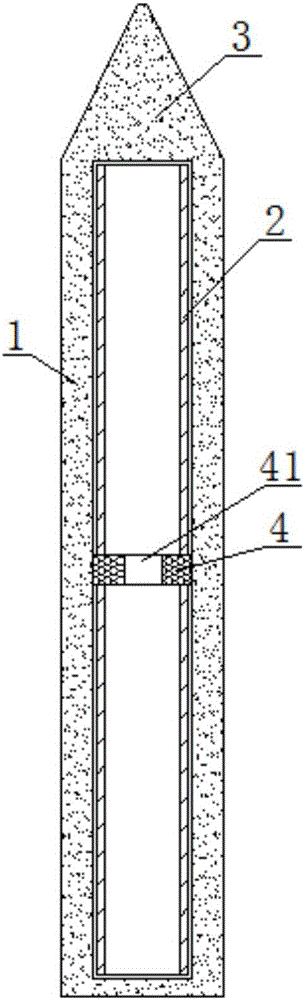

[0038] From figure 2 It can be seen that the cone 3 and the glass sleeve 1 of the present invention are blow-molded by quartz glass material at one time, and two sections of metal 2 are embedded in the glass sleeve 1, and an isolation layer 4 is arranged between the two metals 2. The center of the layer 4 is provided with a pressure discharge hole 41 .

Embodiment 3

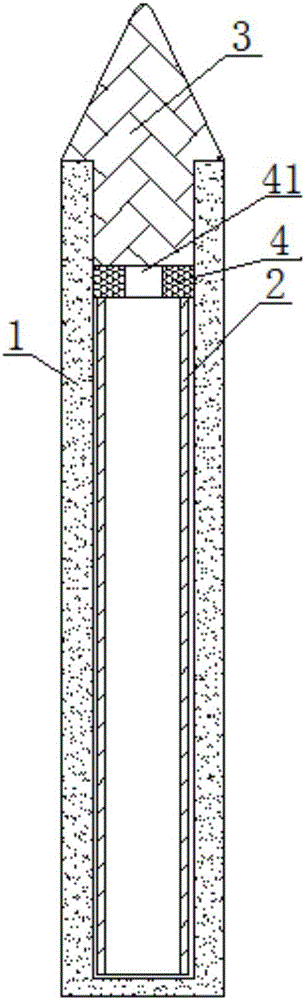

[0040] From image 3 It can be seen that the cone 3 of the present invention is made of an austenitic material or a high-temperature resistant material that does not generate magnetic induction, and the bottom of the cone 3 is inserted into the glass sleeve 2 and sealed. A section of metal 2 is embedded, an isolation layer 4 is provided between the metal 2 and the bottom of the cone 3 , and a pressure discharge hole 41 is provided in the center of the isolation layer 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com