Polymer reactor with novel structure

A polymerization reactor and a new structure technology, applied in the direction of chemical/physical/physicochemical fixed reactors, etc., can solve the problems of different reaction time of each particle of the material, large power consumption, uneven heat removal, etc., to achieve uniform quality improvement stability, cooling or heating rate uniformity, and product quality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

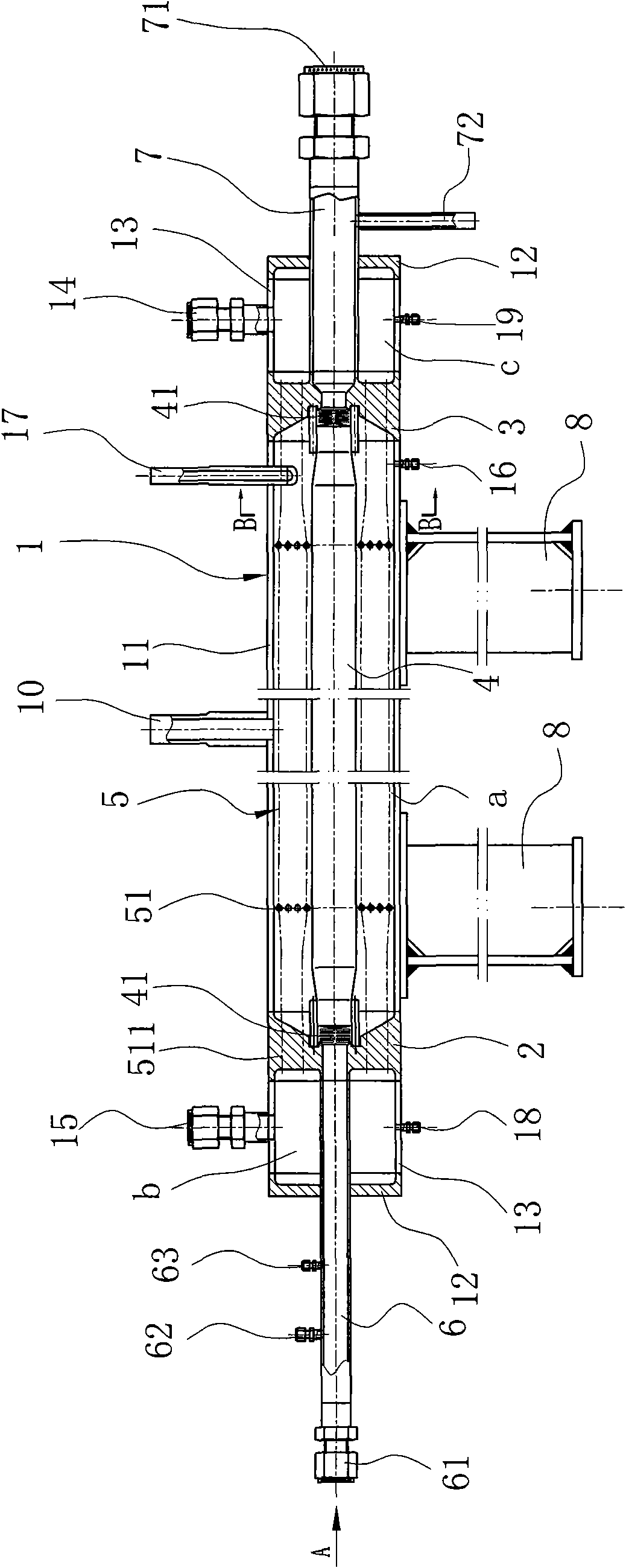

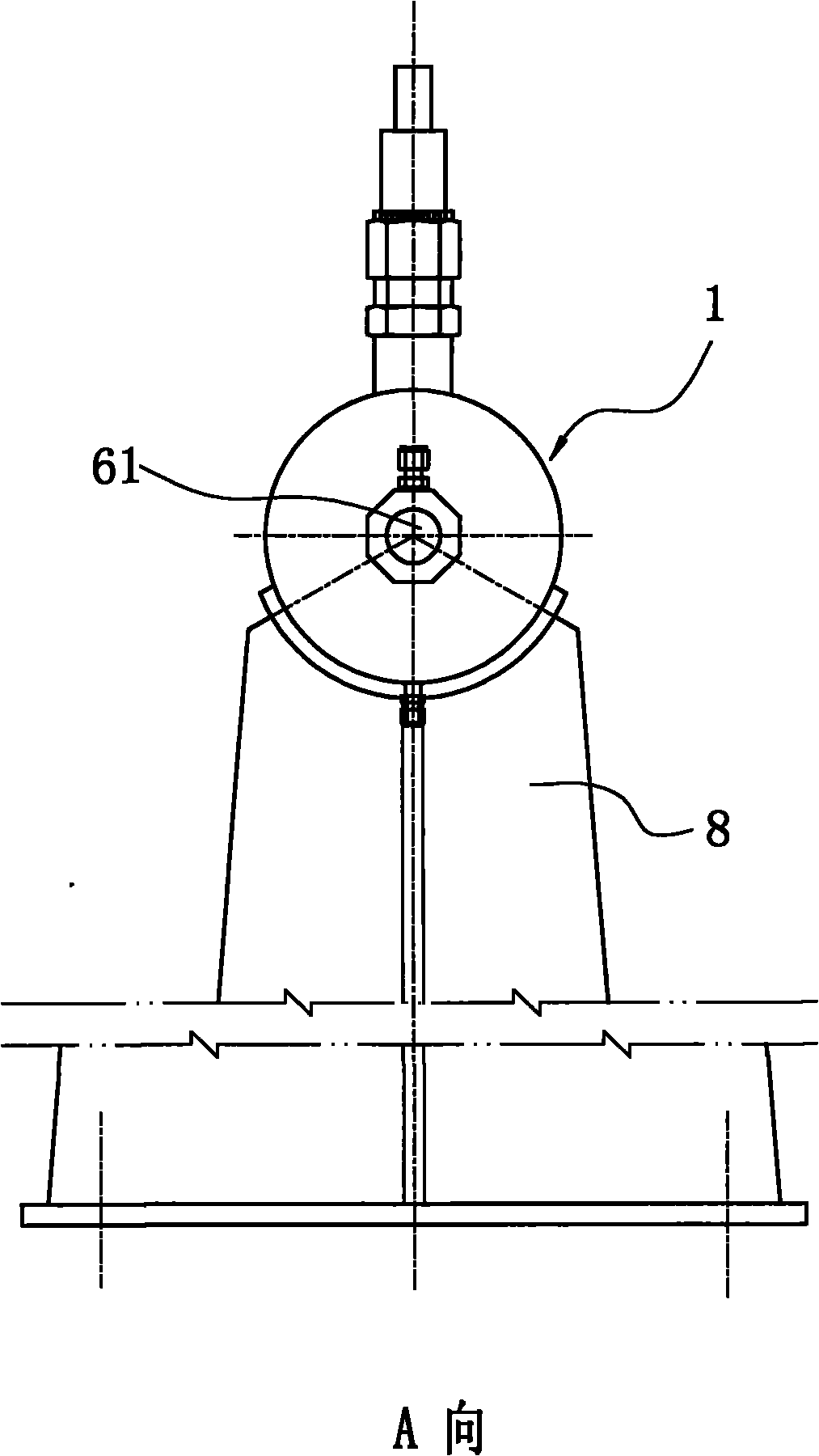

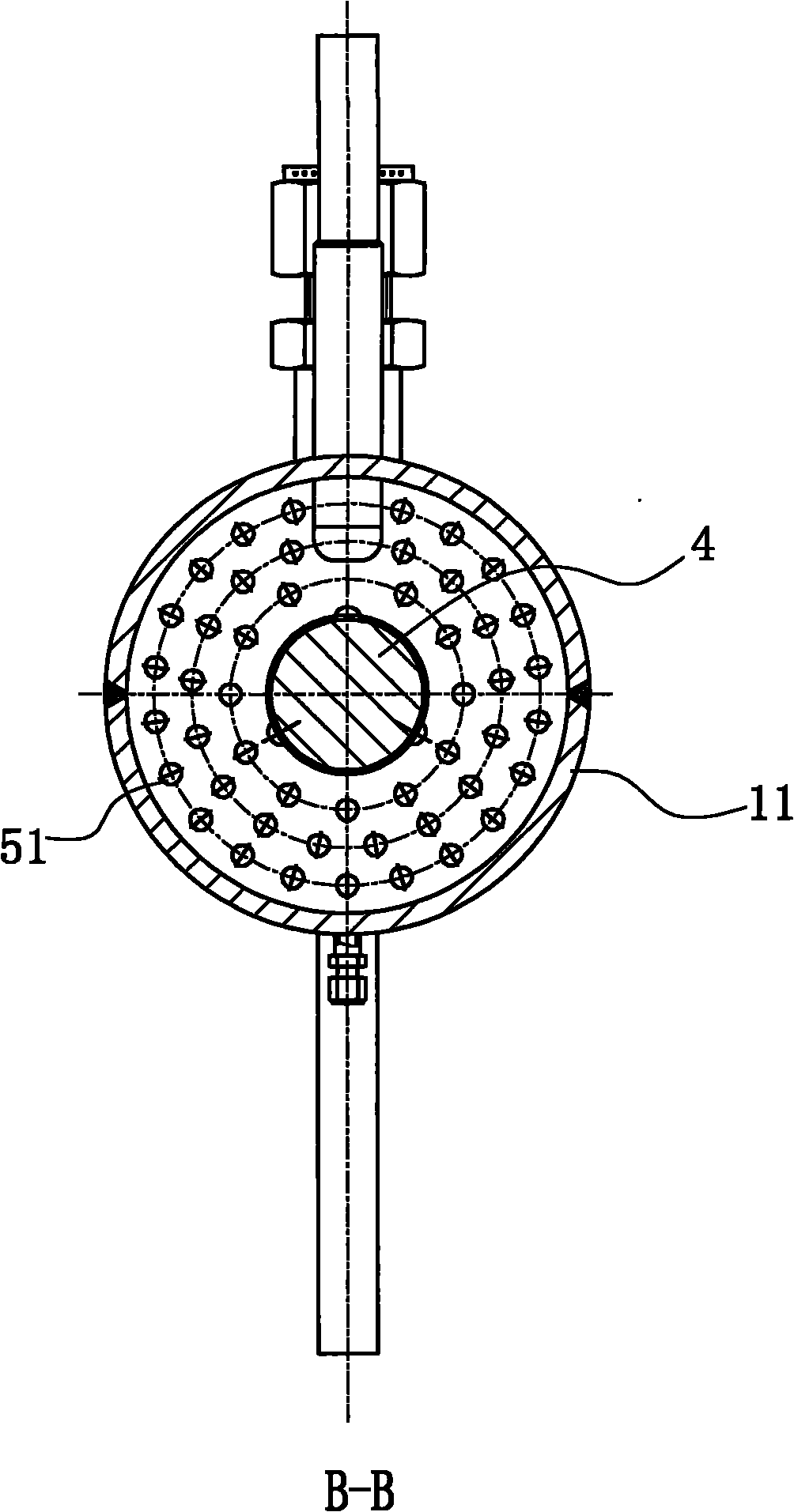

[0020] like Figure 1 to Figure 3 As shown, the polymerization reactor includes a cylinder 1 with a heat exchange medium outlet 15 at one end and a heat exchange medium inlet 14 at the other end, and a first tube sheet 2, a second tube sheet 3, and a core installed in the cylinder. 4 and a plurality of spiral tubes 5, wherein the cylinder body 1 includes a tubular shell 11, which is placed horizontally on the two saddles 8, and the left and right ends of the tubular shell 11 are respectively fixed with the first tube sheet 2 and the second tube sheet 3, so that a closed middle chamber a is formed between the tubular shell 11 and the first tube sheet 2 and the second tube sheet 3. The outer sides of the first tube sheet 2 and the second tube sheet 3 are respectively connected with a short cylinder body 13 and a flat cover head 12. A right cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com