Cooling equipment for use in machining of GH4169 turbine disk forgings

A technology of GH4169, cooling equipment, applied in the direction of heat treatment equipment, manufacturing tools, furnaces, etc., can solve the problems of unstable product quality and low cooling rate, to improve heat exchange speed and heat diffusion speed, occupy a small area, reduce The effect of turning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

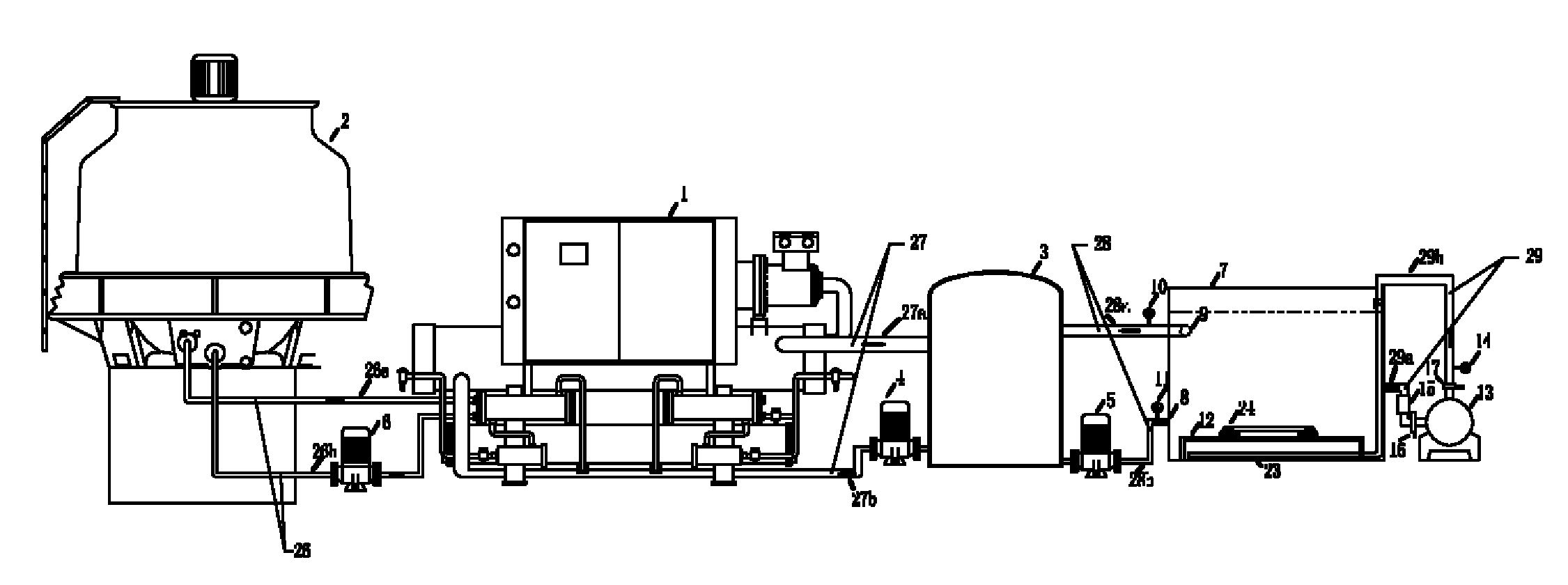

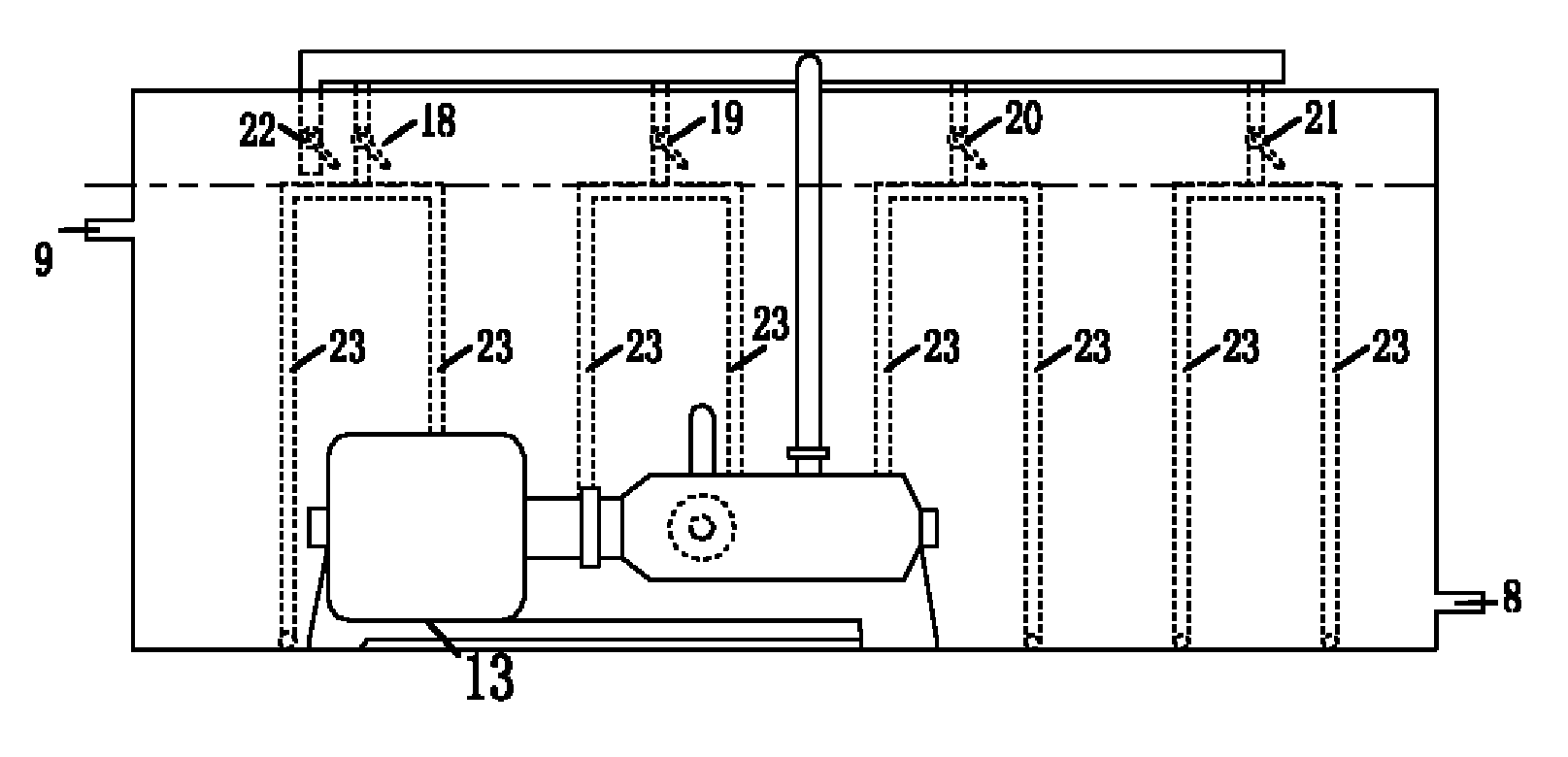

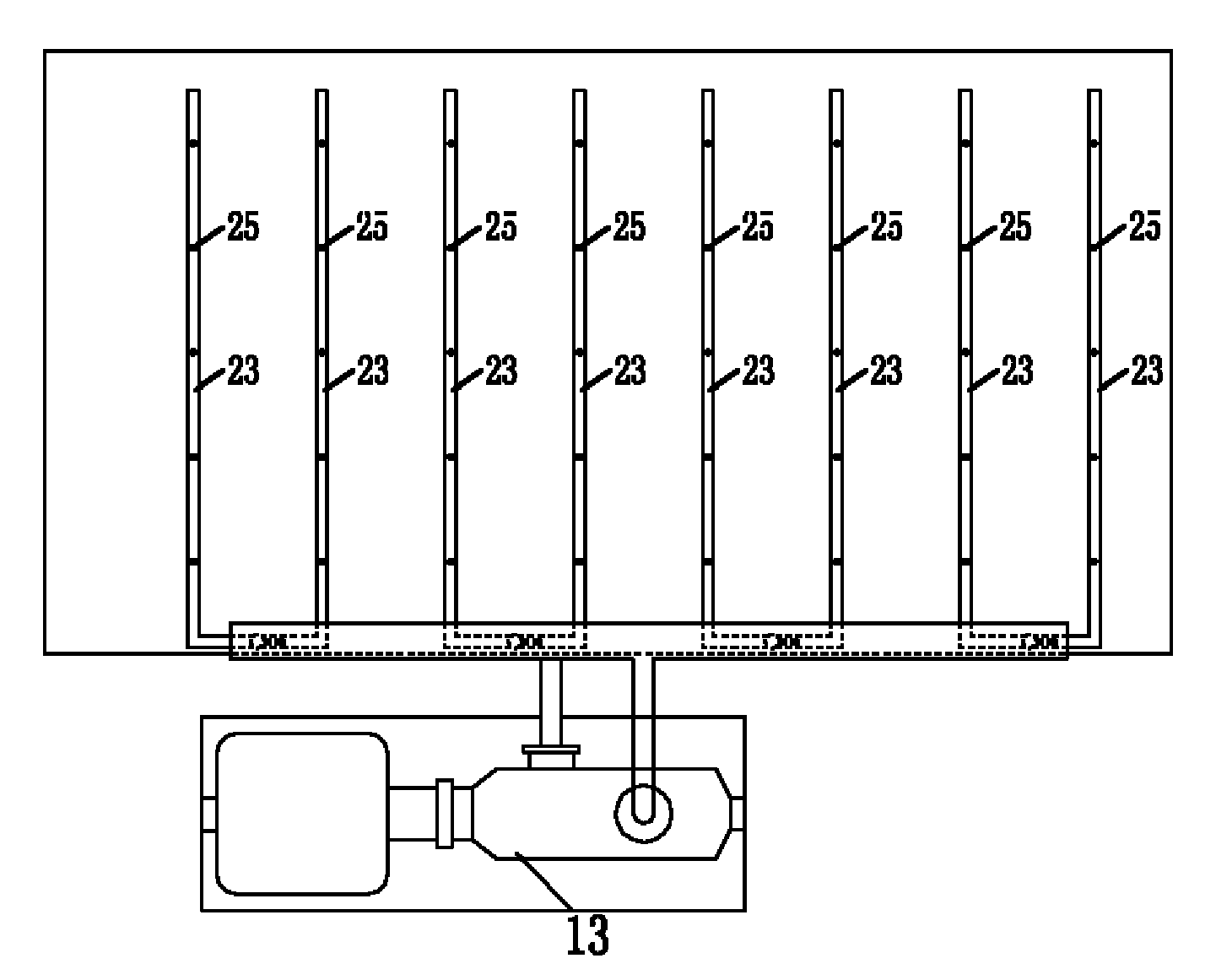

[0010] See figure 1 , figure 2 and image 3 , the present invention includes a cooling water tank 7, the bottom of the cooling water tank 7 is equipped with a rack 12, and it also includes a cooling unit, the cooling unit and the cooling water tank 7 are connected through an external circulation pipeline 28, and the cooling water tank 7 is also connected with an internal water circulation system. The cooling unit includes a refrigeration compressor 1, a cooling water tower 2, and an insulated water tank 3. The two ends of the refrigeration compressor 1 are respectively connected to the cooling water tower 2 and the insulated water tank 3 through the cooling circulation pipeline 26 and the internal circulation pipeline 27; the insulated water tank 3 passes through The outer circulation pipeline 28 is connected to the cooling water tank 7; the outlet pipes 26b, 27b, and 28b of the cooling circulation pipeline 26, the inner circulation pipeline 27, and the outer circulation pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com