Patents

Literature

38results about How to "Increase heat exchange speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermophone device

ActiveCN102307325AIncreased sound pressure outputHigh light transmittanceTransducer detailsUltrasonic imagingEngineering

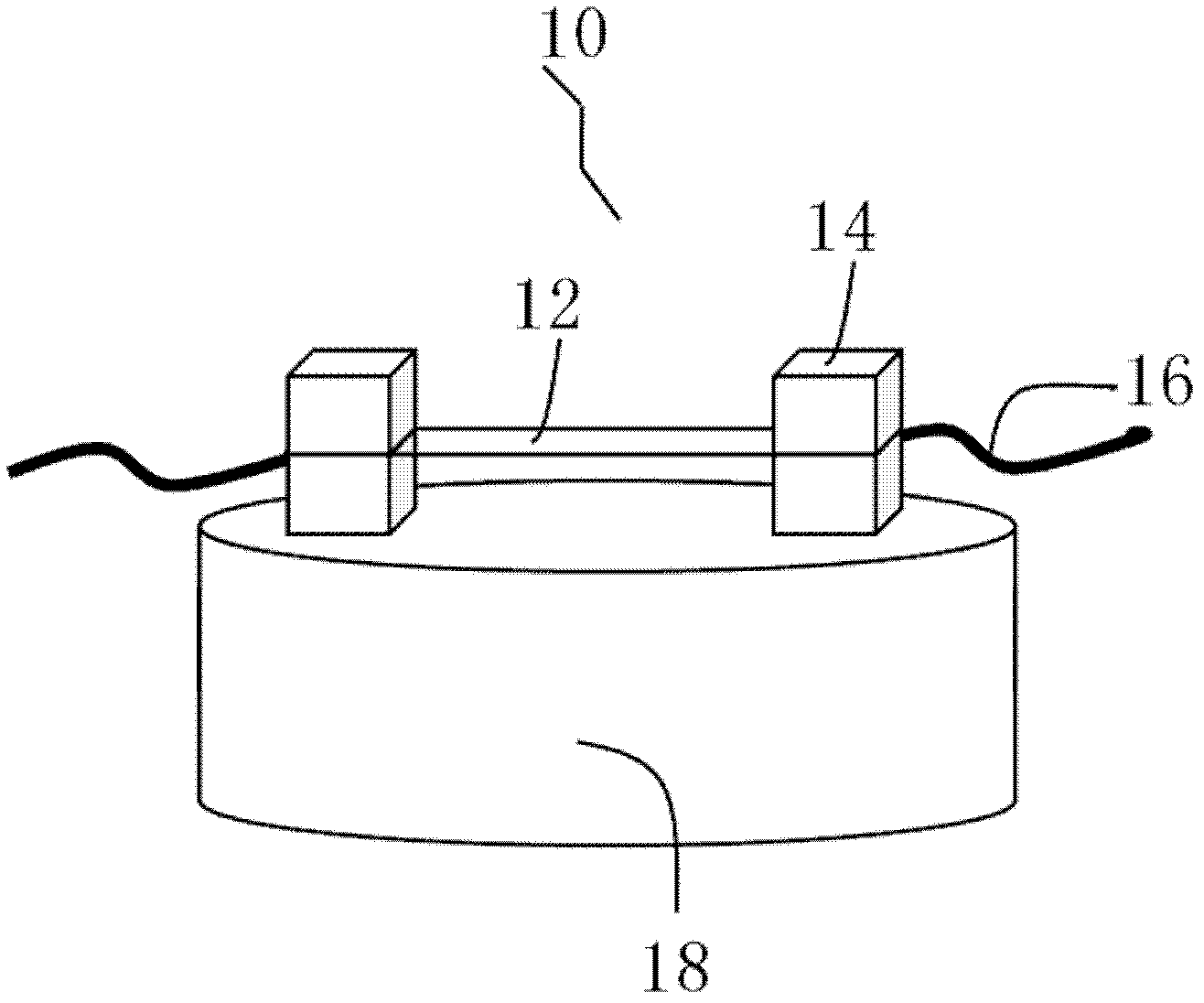

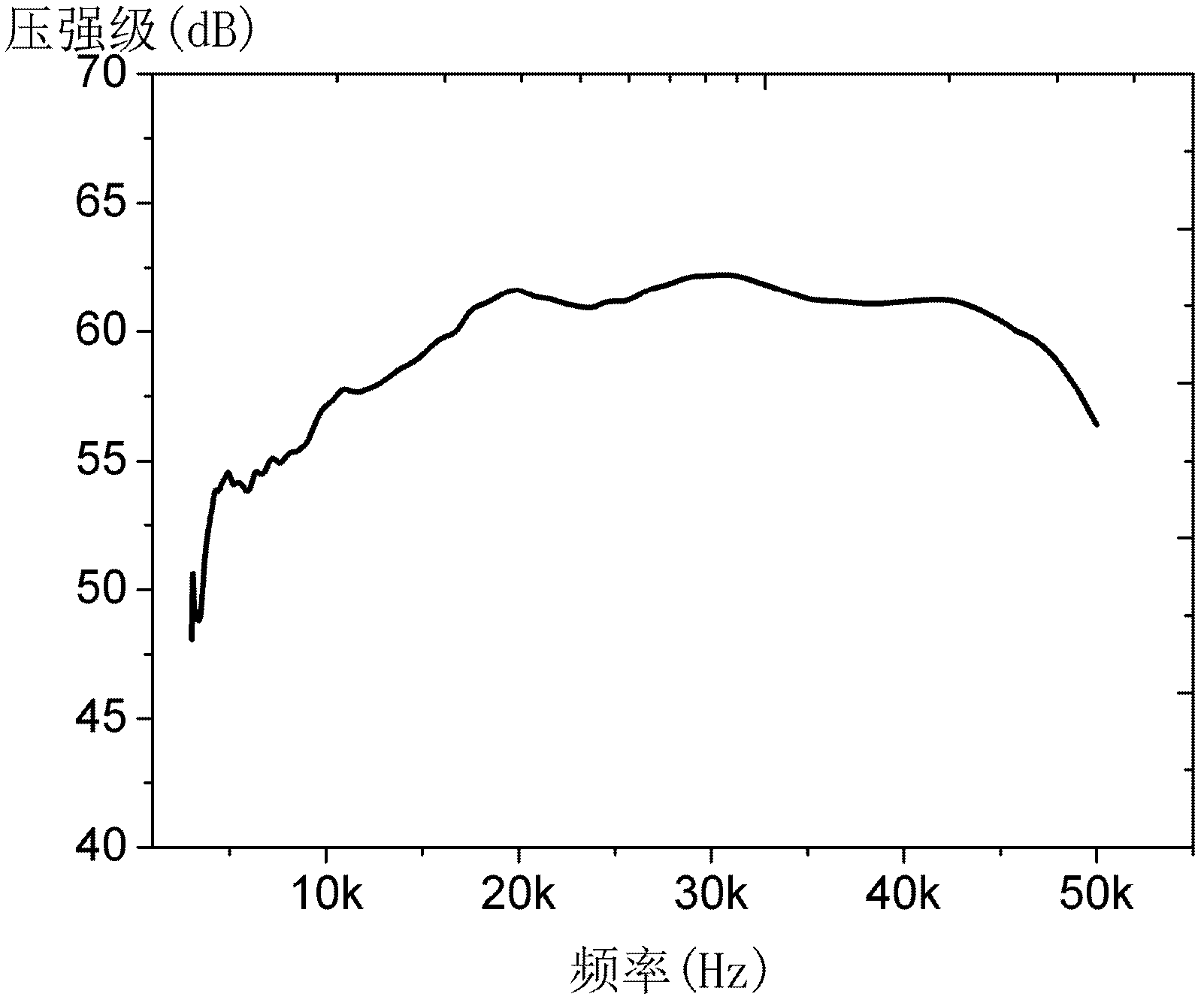

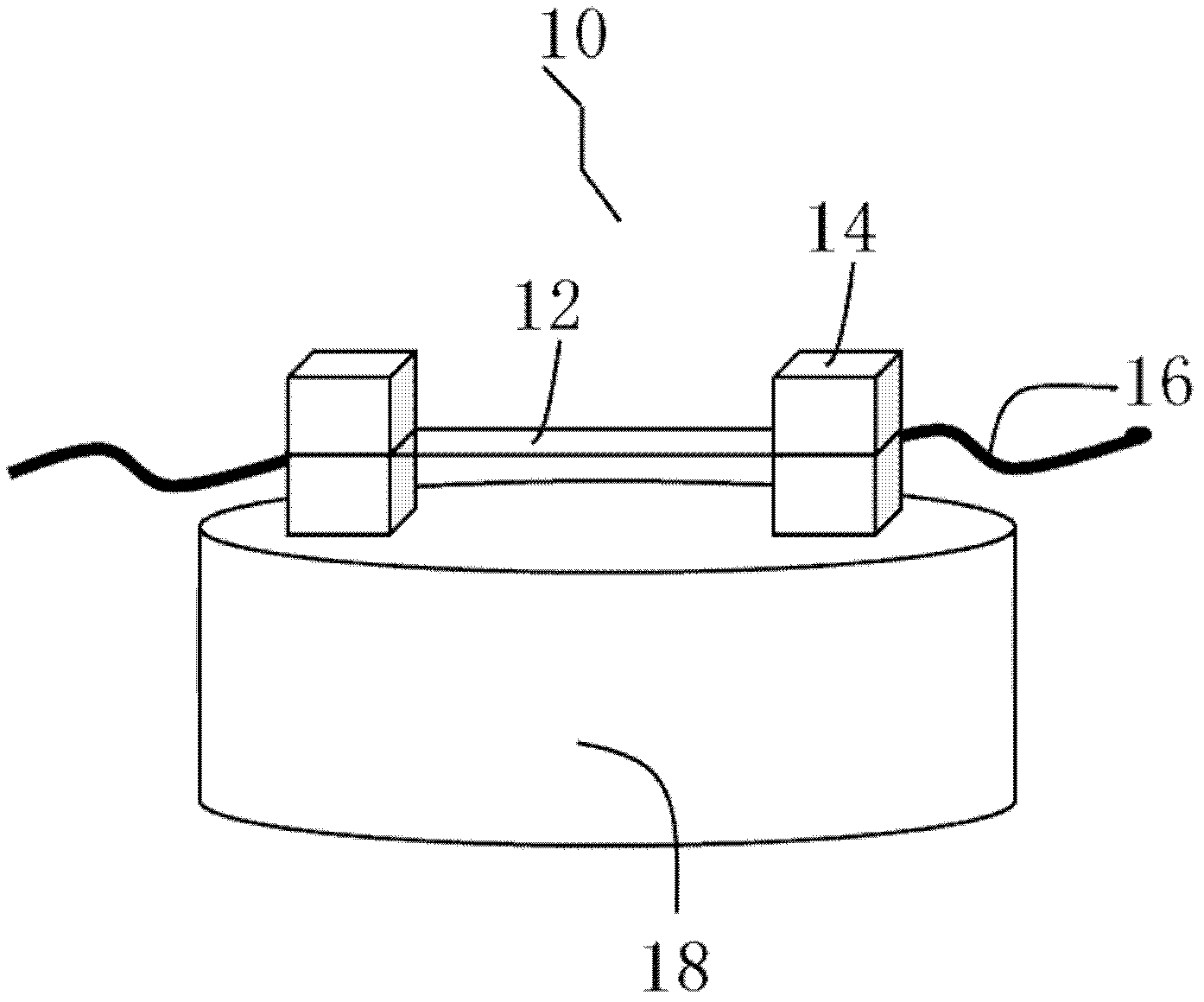

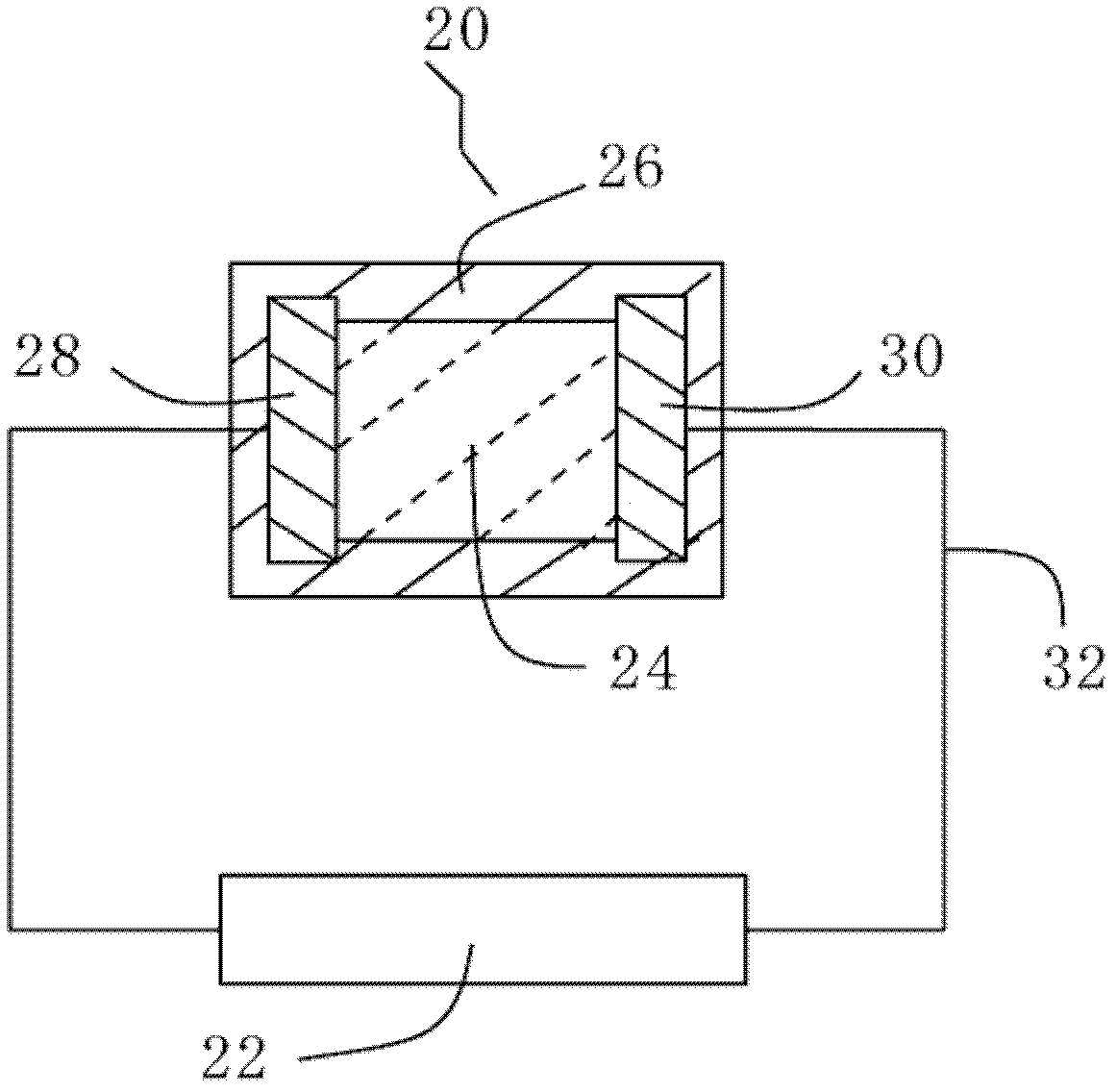

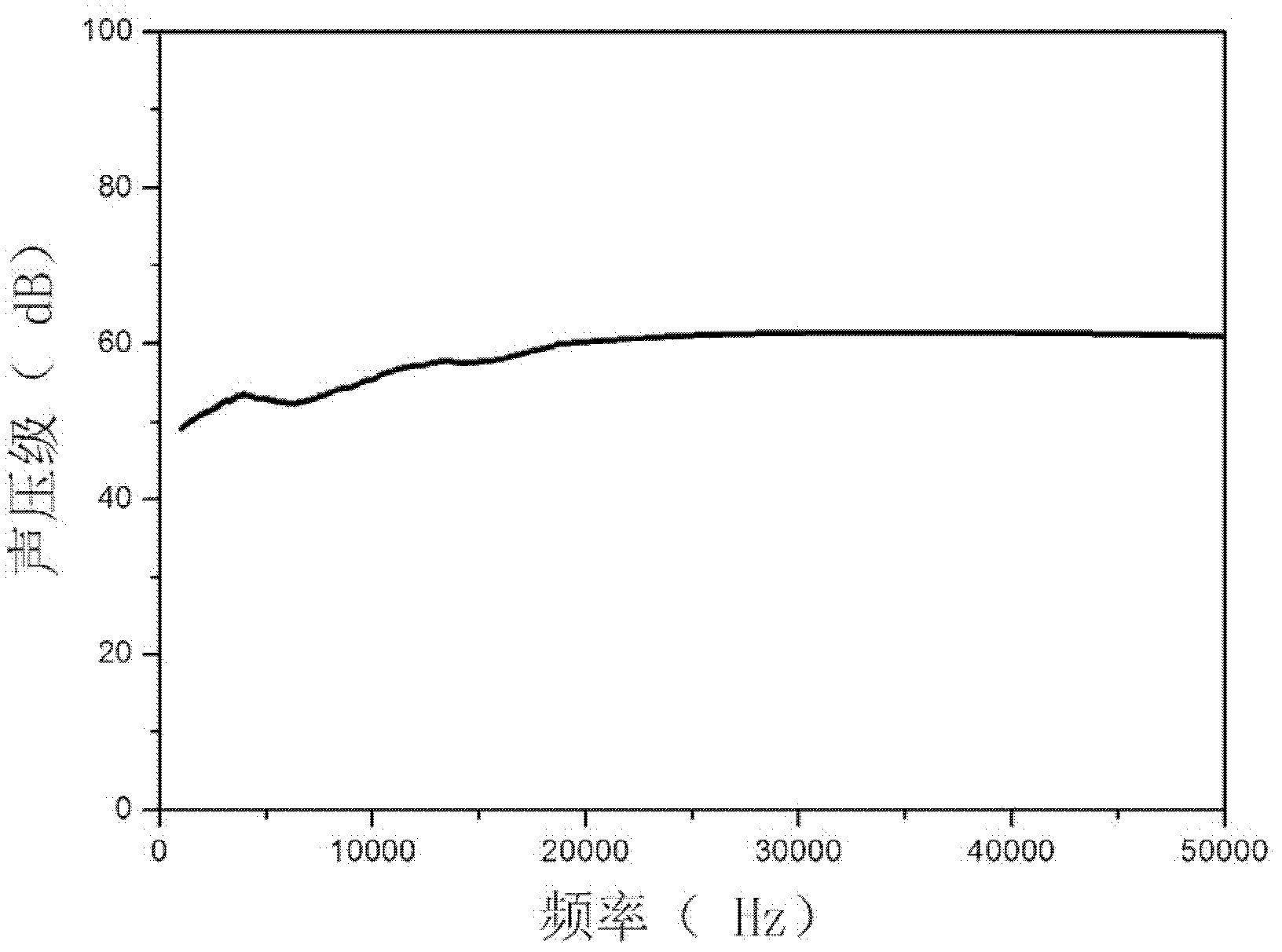

The invention relates to a thermophone device, which belongs to the technical field of sound-producing devices. The thermophone device comprises a sound-producing element and a signal input device connected with the sound-producing element. The thermophone device is characterized in that the sound-producing element comprises at least one grapheme film structure; and the signal input device is used for inputting a signal to the grapheme film structure, so that the grapheme film structure can be used for changing the density of an ambient medium and sending out sound wave. The thermophone device has no mechanical vibration and can be used for generating high sound pressure output within a frequency range of 10 to 0.1 million of Hz. The invention has the advantages of high reliability, flexibility, transparency, low cost and high performance and can be widely applied to electronic fields of mobile phones, MP3 (Moving Picture Experts Group Audio Layer-3), MP4 (Mobile Pentium 4), televisions, computers, ultrasonic imaging, ranging systems and the like.

Owner:TSINGHUA UNIV

Flexible and transparent thermotropic sounding apparatus

InactiveCN102572667AHigh light transmittanceHigh mechanical strengthTransducer detailsChange densityEngineering

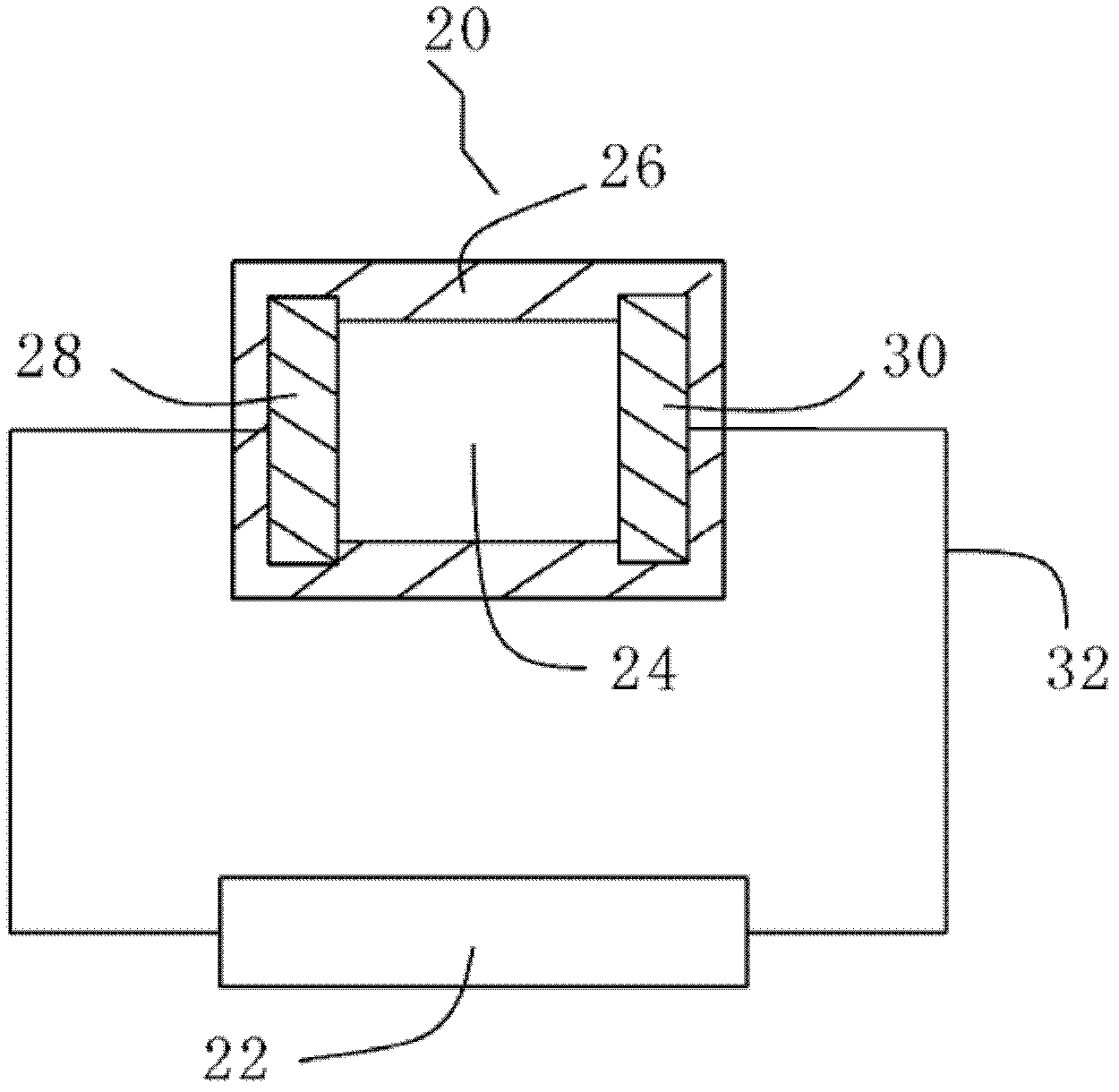

The invention, which belongs to the sounding apparatus technology field, relates to a flexible and transparent thermotropic sounding apparatus. The apparatus comprises a sound element and a signal input device connected with the sound element. The sound element includes a flexible and transparent substrate; and at least one conductive film structure and a pair of electrodes or multi-pair electrodes are arranged on the substrate, wherein one ends of the pair of electrodes or the multi-pair electrodes are connected at two sides of the conductive film structure. And an input terminal of the signal input device is connected with the other ends of the electrodes. Therefore, the conductive film structure changes density of surrounding mediums to emit sound waves. According to the invention, there is no mechanical oscillation on the sound element itself and the sound element is transparent and can be bent and stretched. The thermotropic sounding apparatus can generate high sound pressure output within a frequency range of from 101 kHz to 100 MHz as well as has advantages of high reliability, flexibility, transparency, low cost, and high performance; besides, the apparatus can be integrated with a display screen and simultaneously enables sounding and display functions to be realized. Therefore, the provided apparatus can be widely applied to electronic fields like a mobile phone, a MP3, a MP4, a television, a computer, ultrasonic imaging, and a range finding system and the like.

Owner:TSINGHUA UNIV

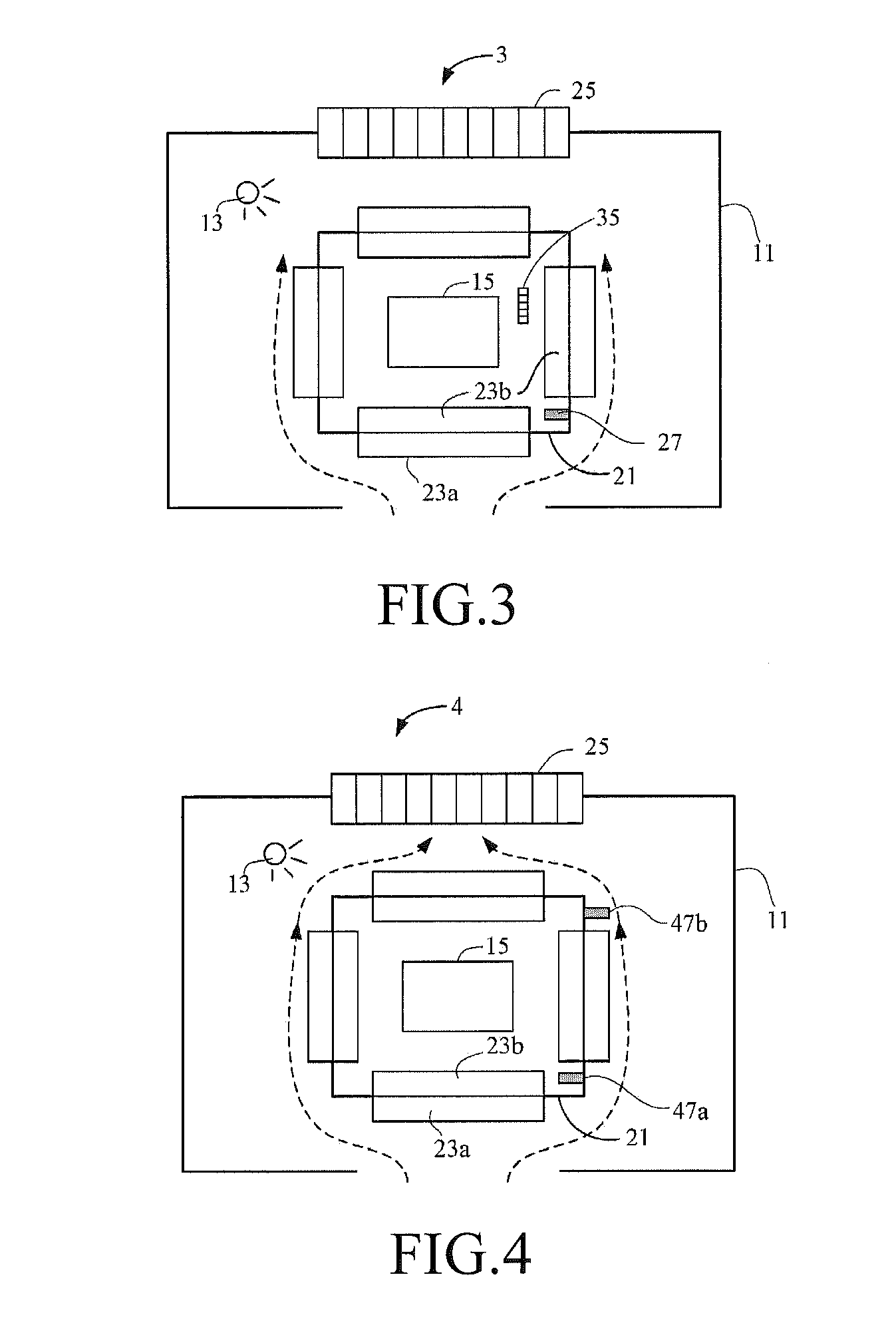

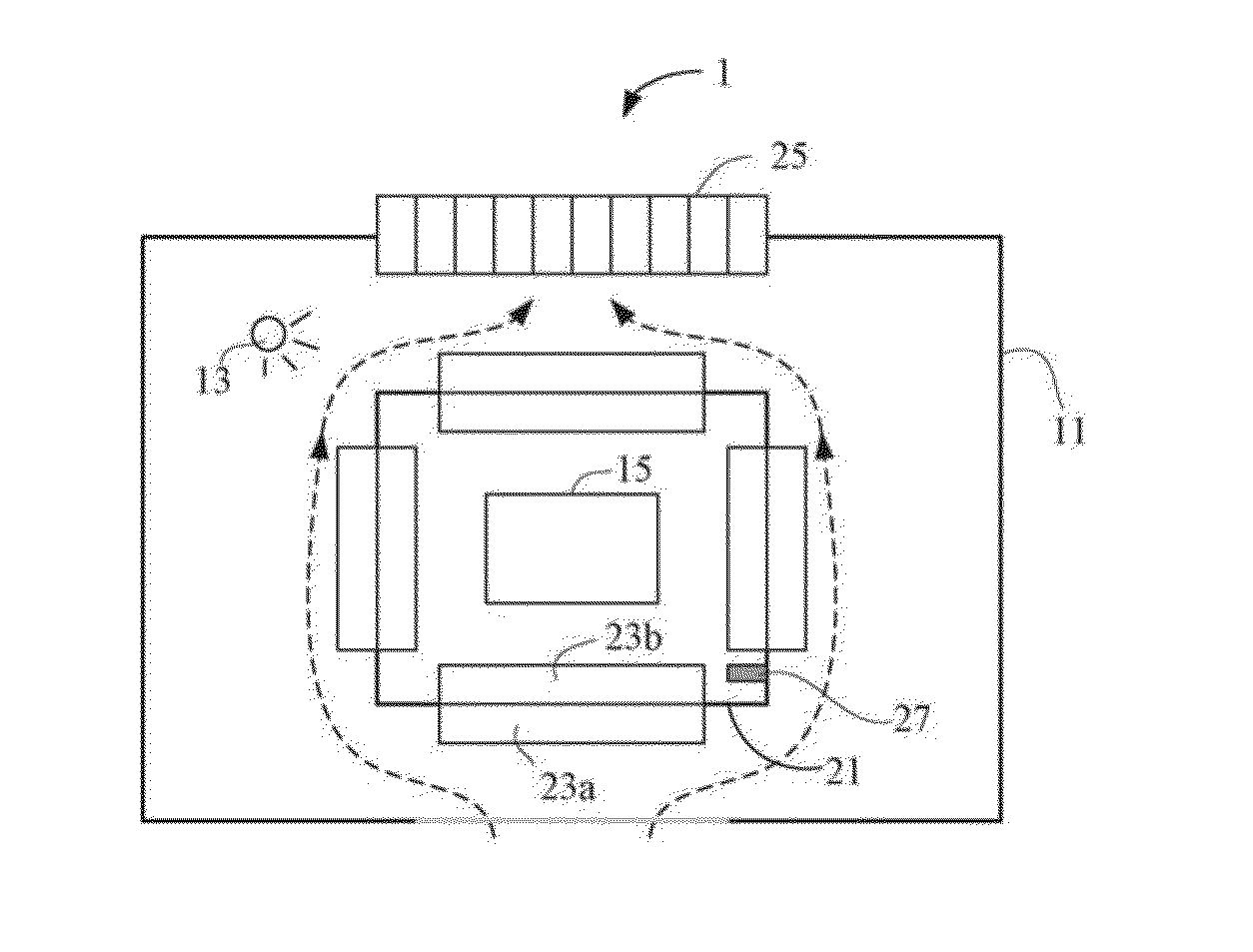

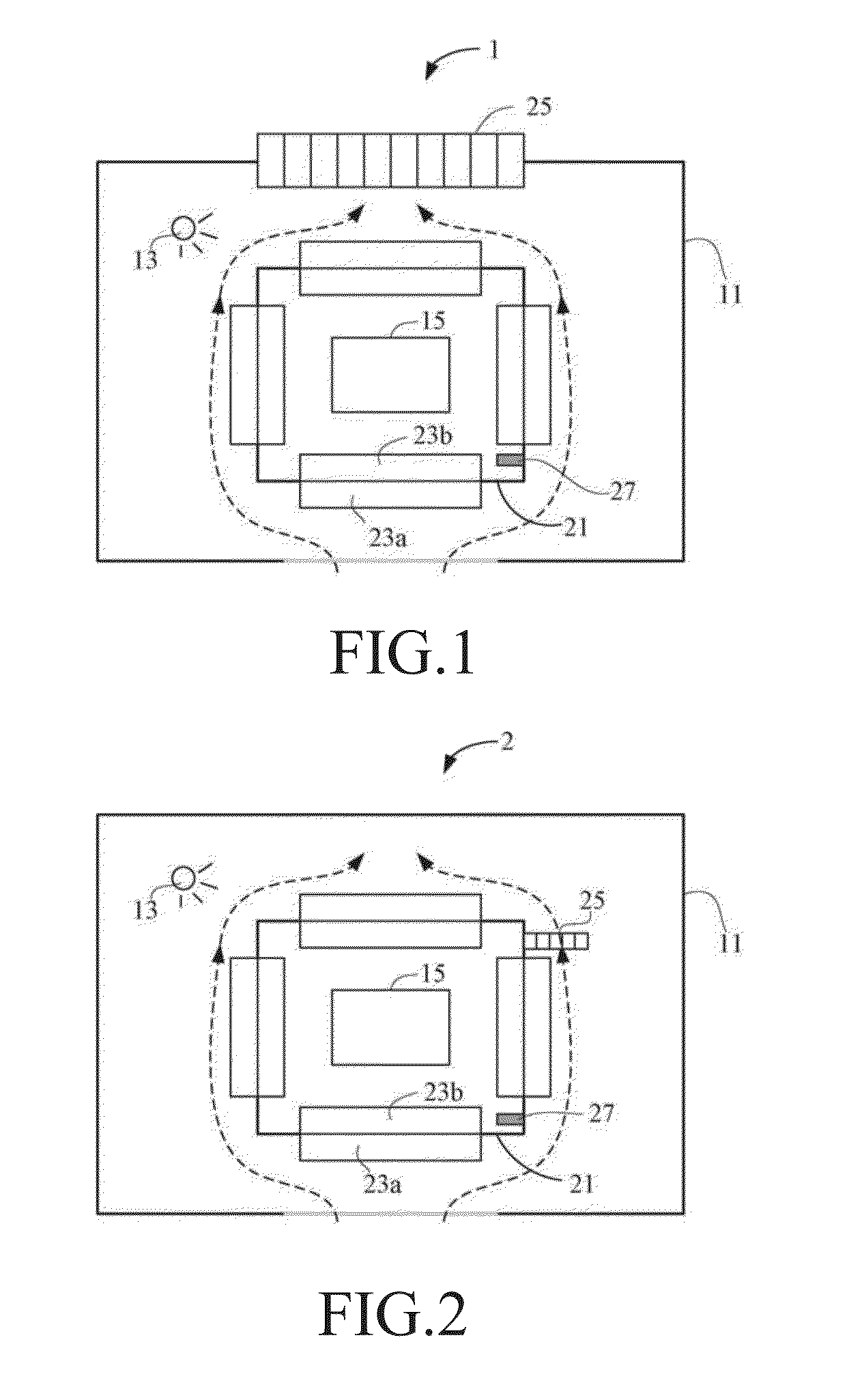

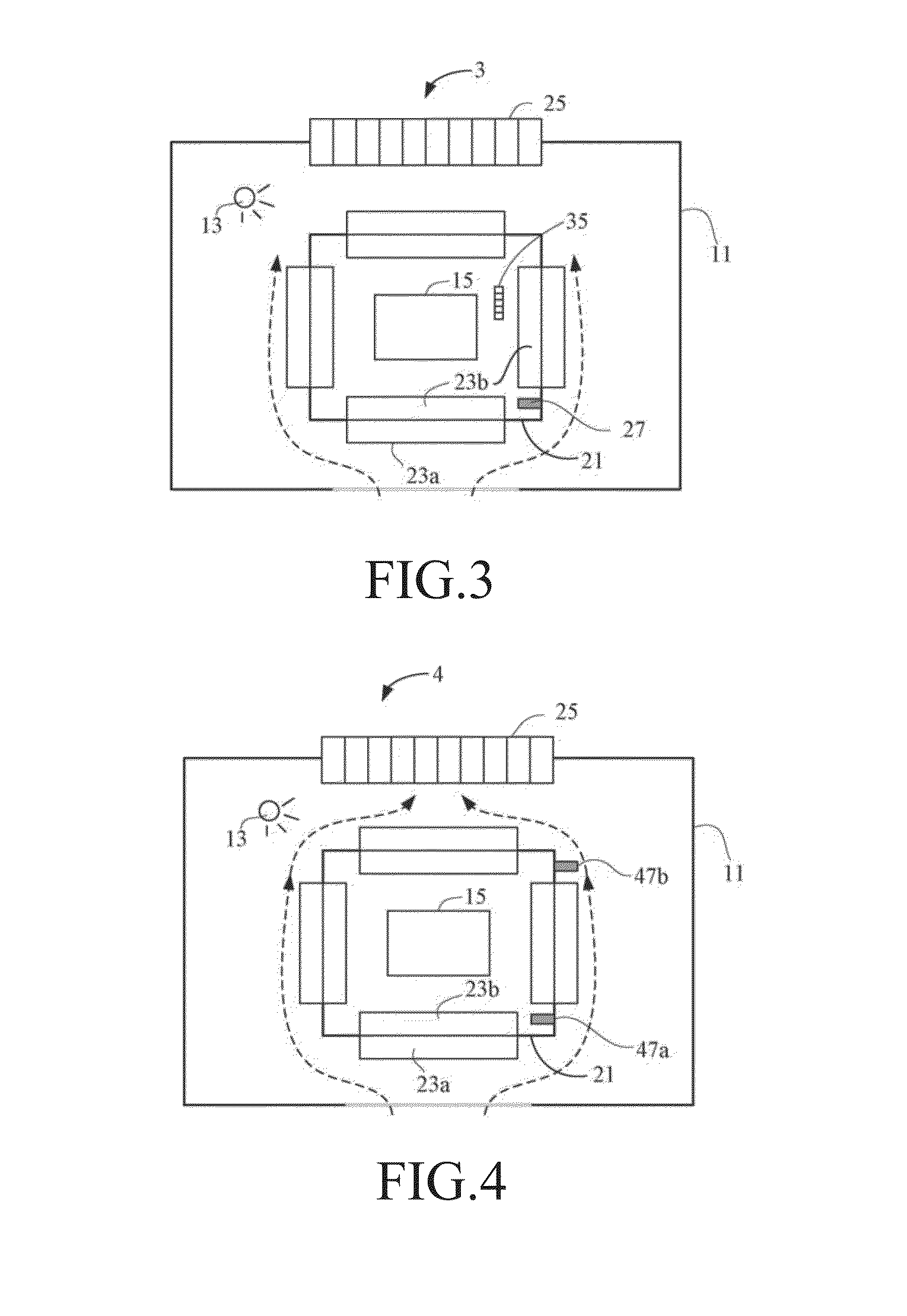

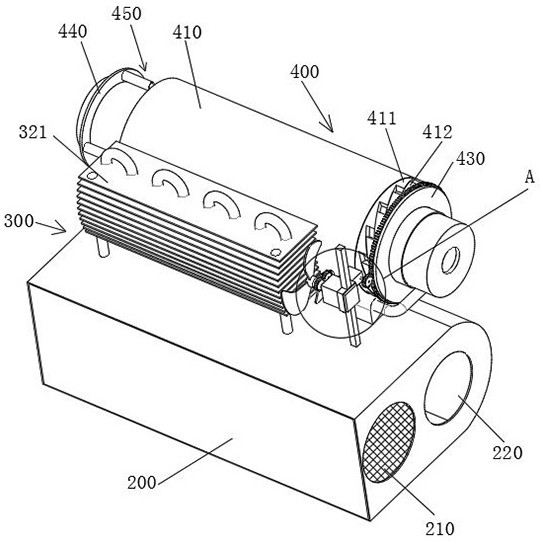

Heat dissipation assembly and projection apparatus with the same

ActiveUS20120182530A1Effective preventionImprove luminanceProjectorsColor television detailsLight sourceLight beam

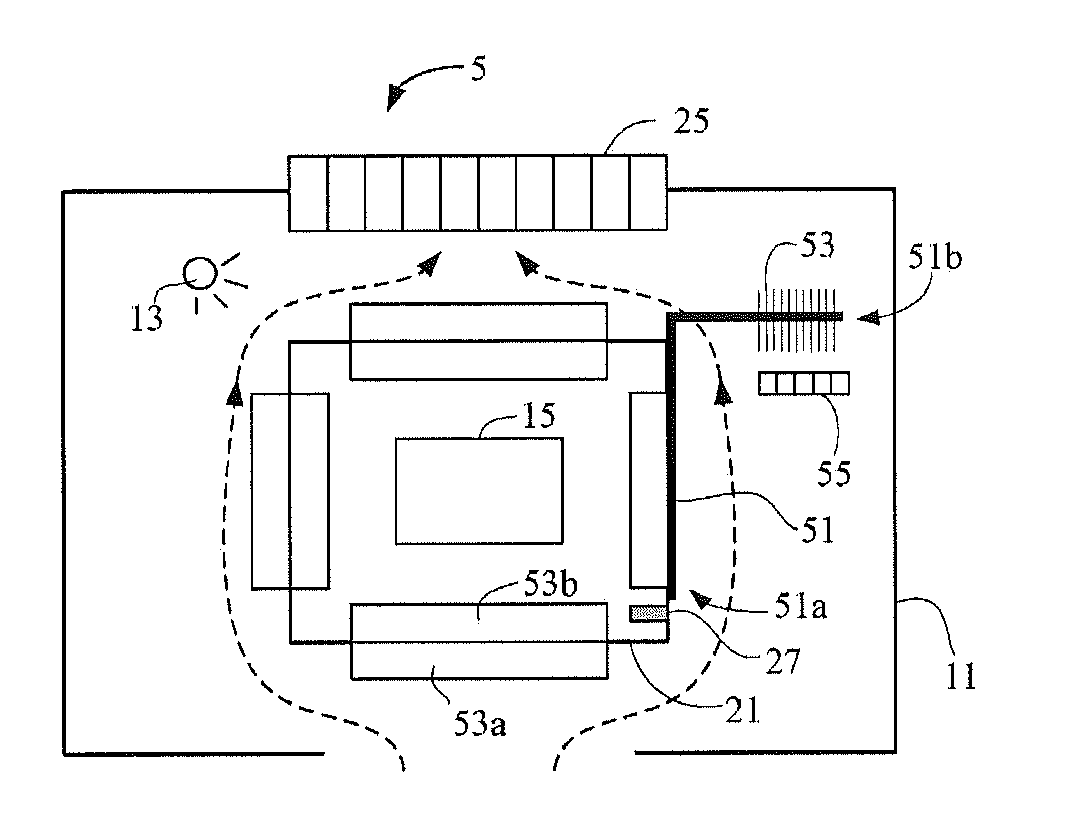

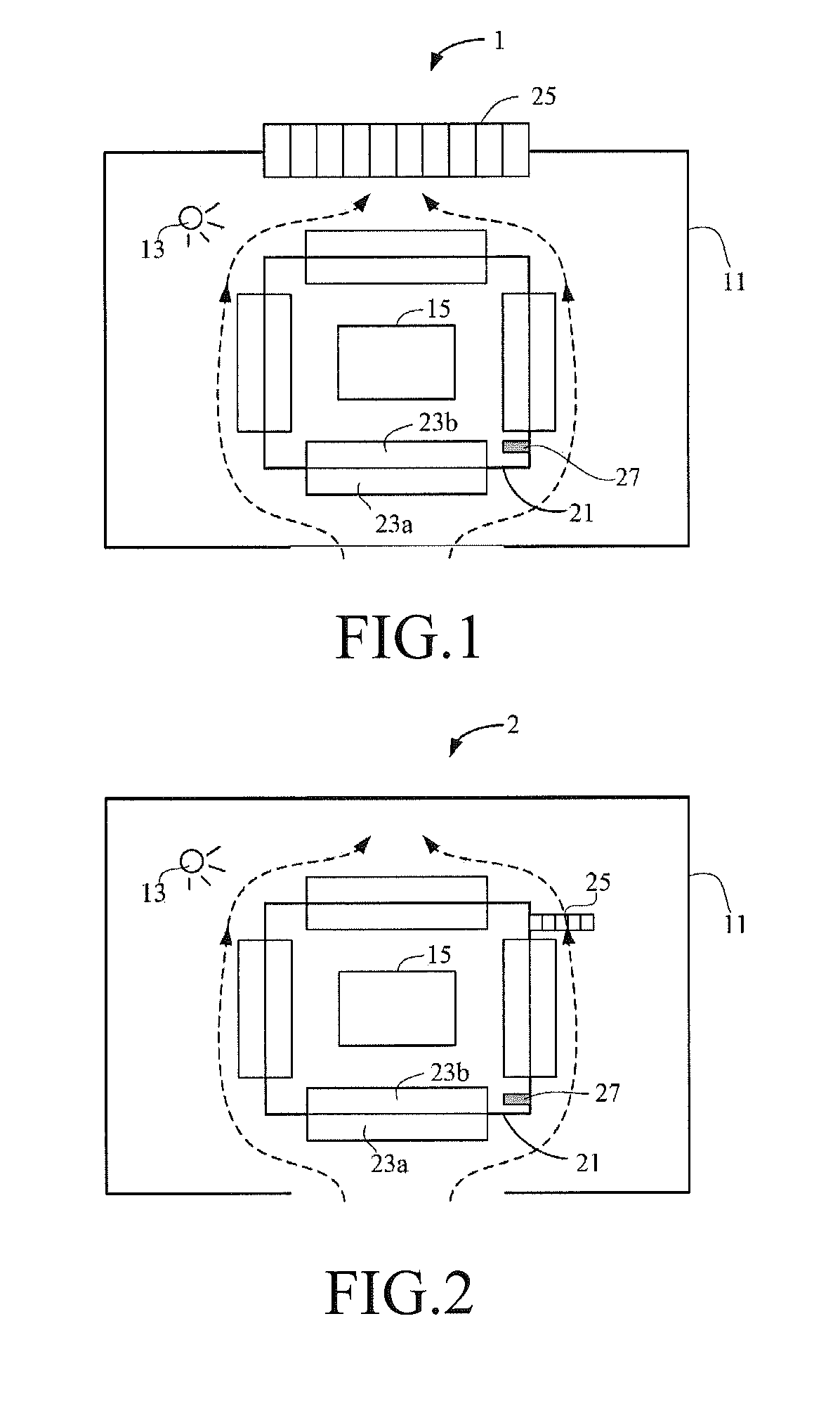

A heat dissipation assembly for a projection apparatus is provided. The projection apparatus includes a light source, optical elements and a heat dissipation assembly. The heat dissipation assembly includes a case, a heat dissipation element, a fan and a temperature controlling unit. The optical elements transmit a light beam generated by the light source, and thereby generate heat. The heat dissipation assembly is adapted for heat dissipation correspondingly. In the heat dissipation assembly, the case protects the optical elements from being polluted by the dust during heat dissipation. The temperature controlling unit senses the surrounding temperature to control the fan for cooling the heat dissipation element, and the durability of the optical elements are thereby enhanced.

Owner:DELTA ELECTRONICS INC

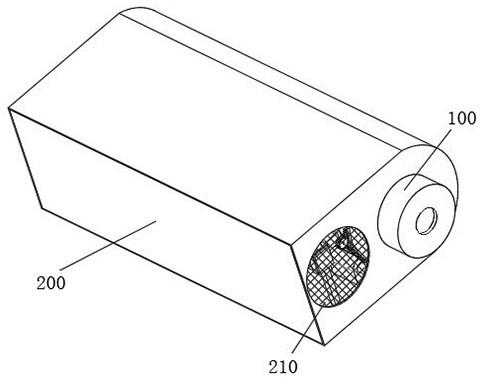

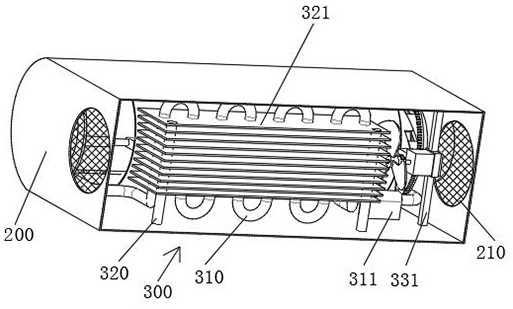

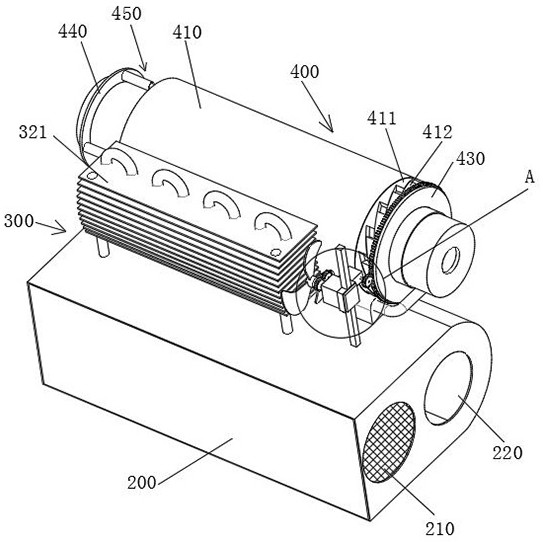

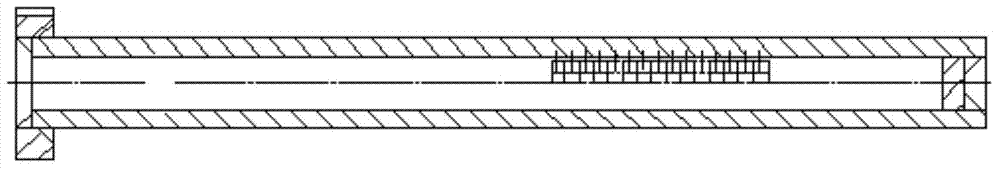

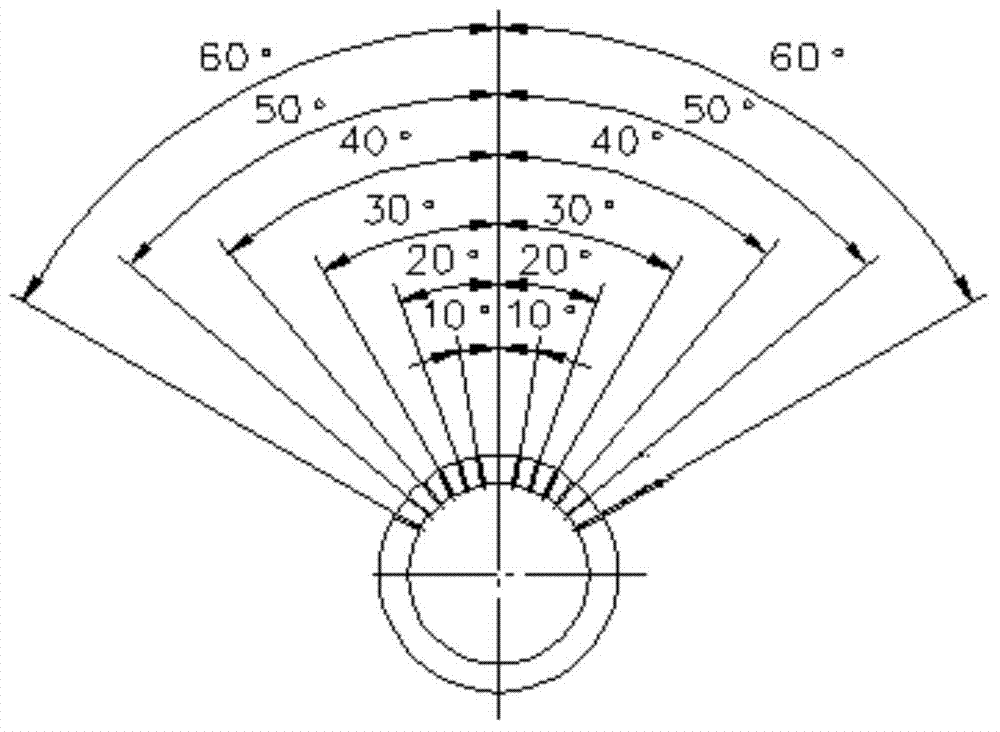

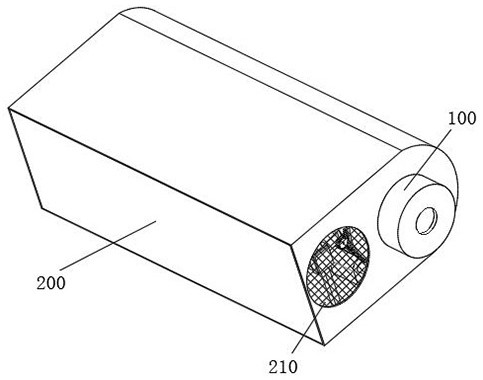

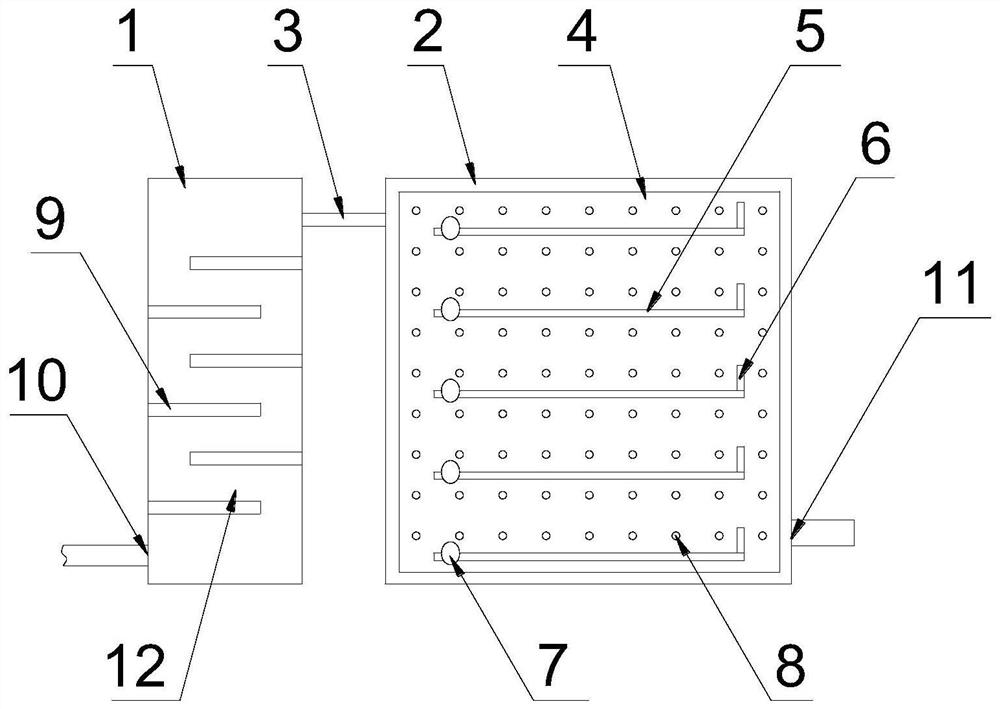

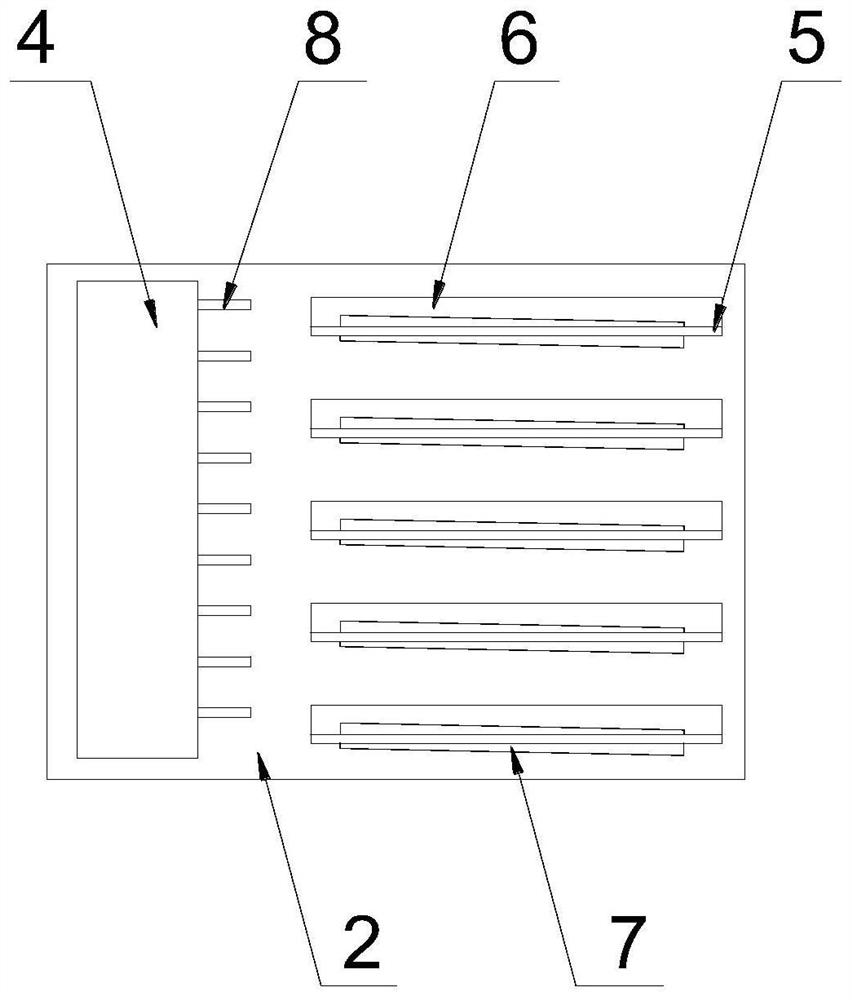

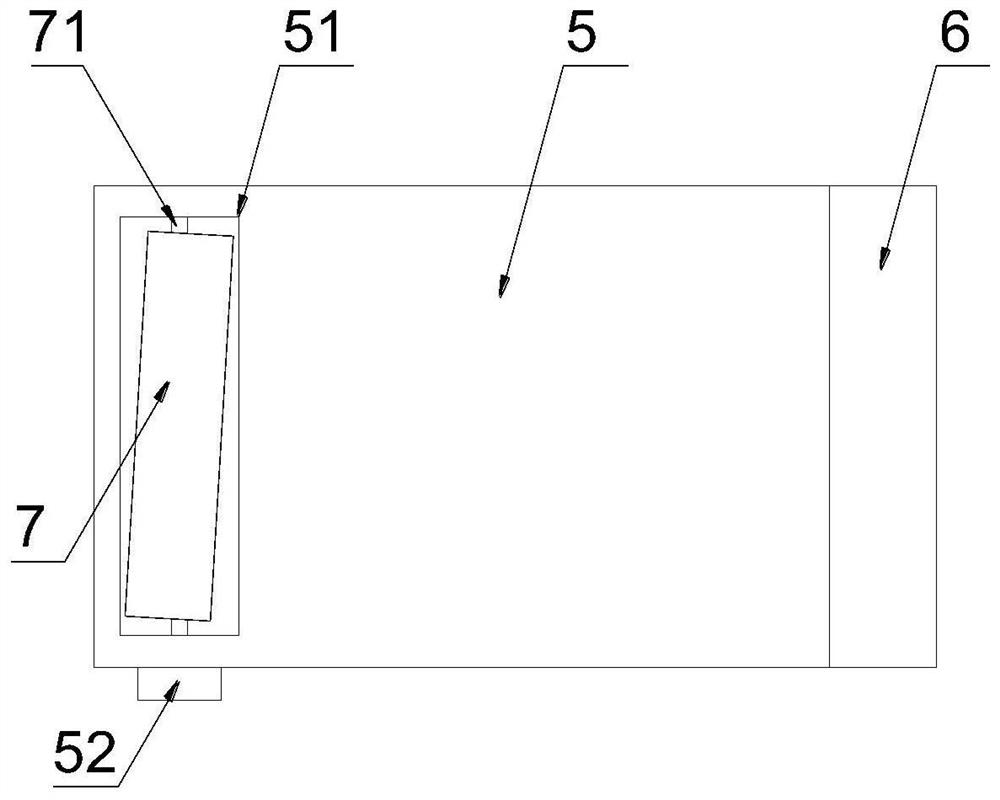

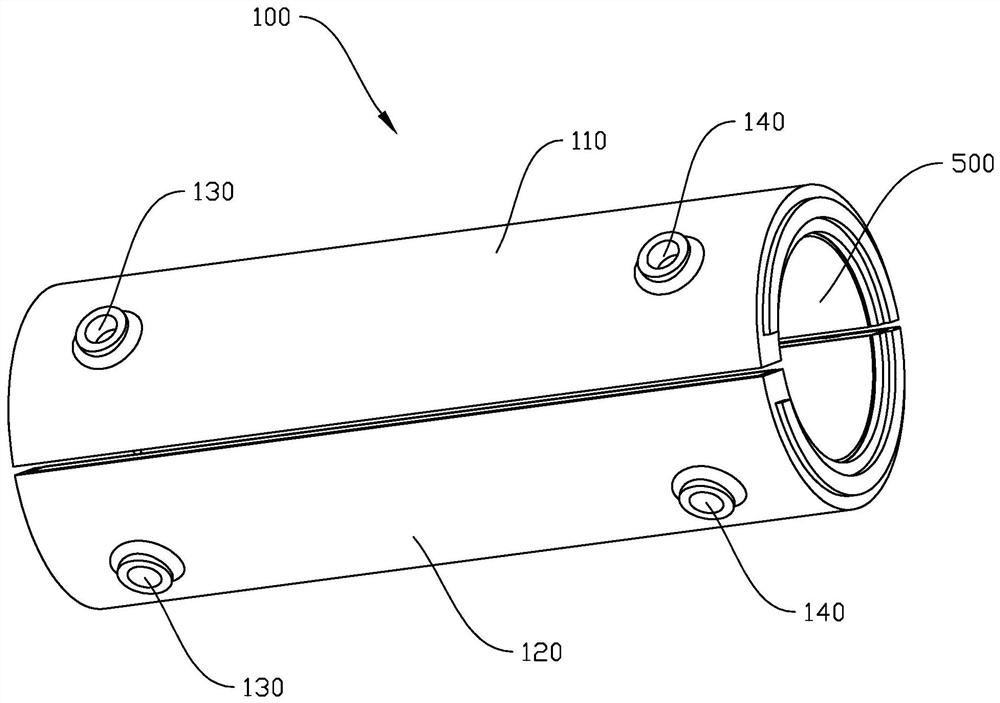

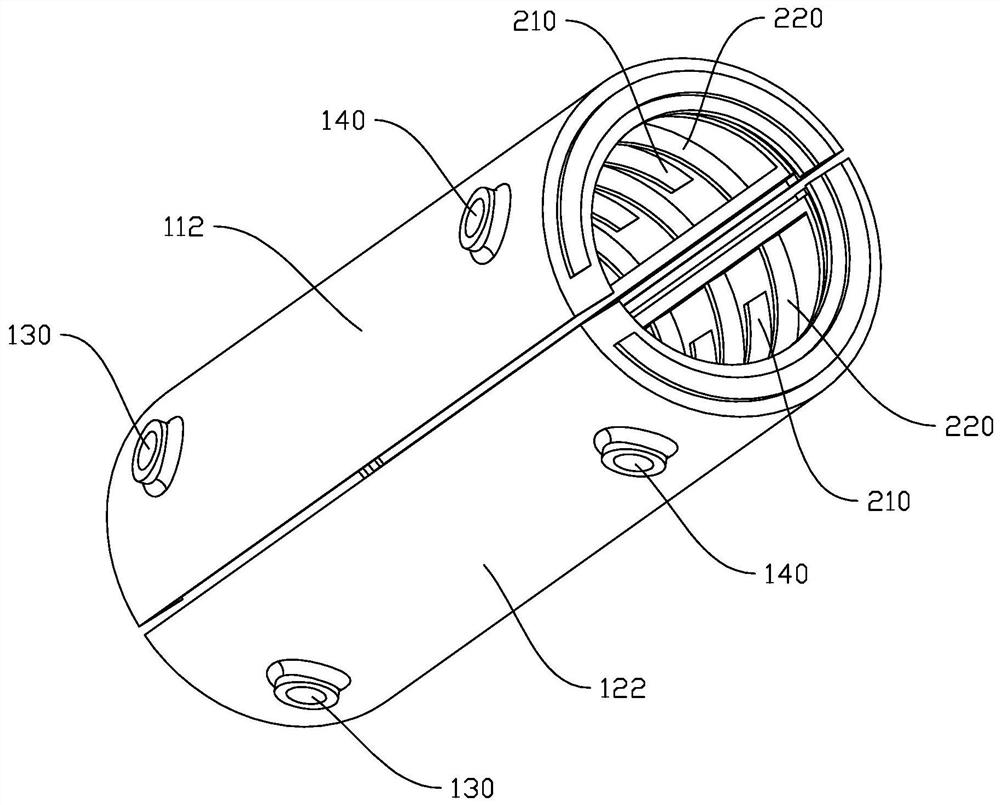

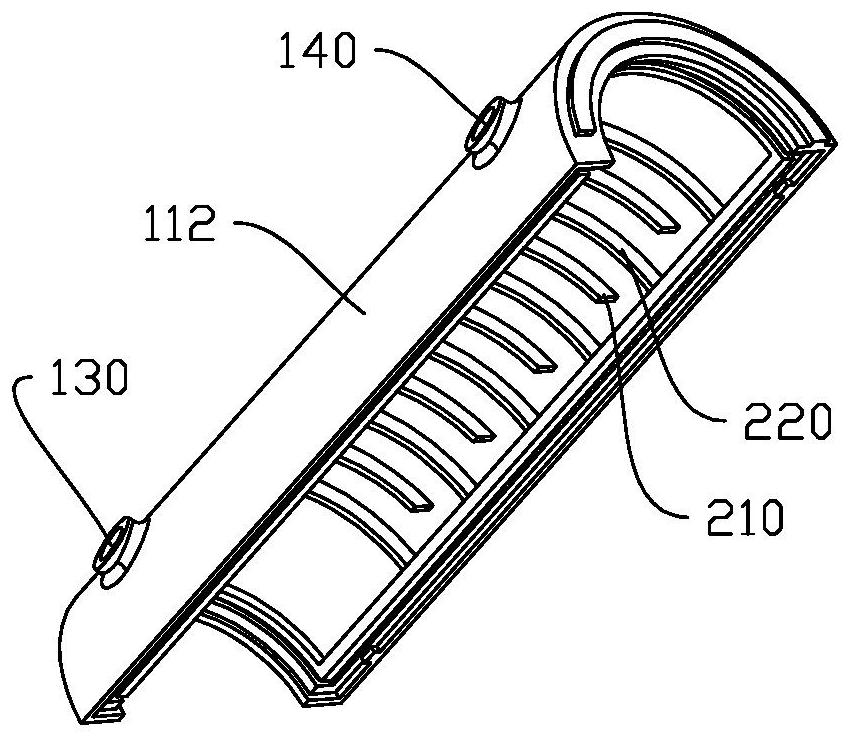

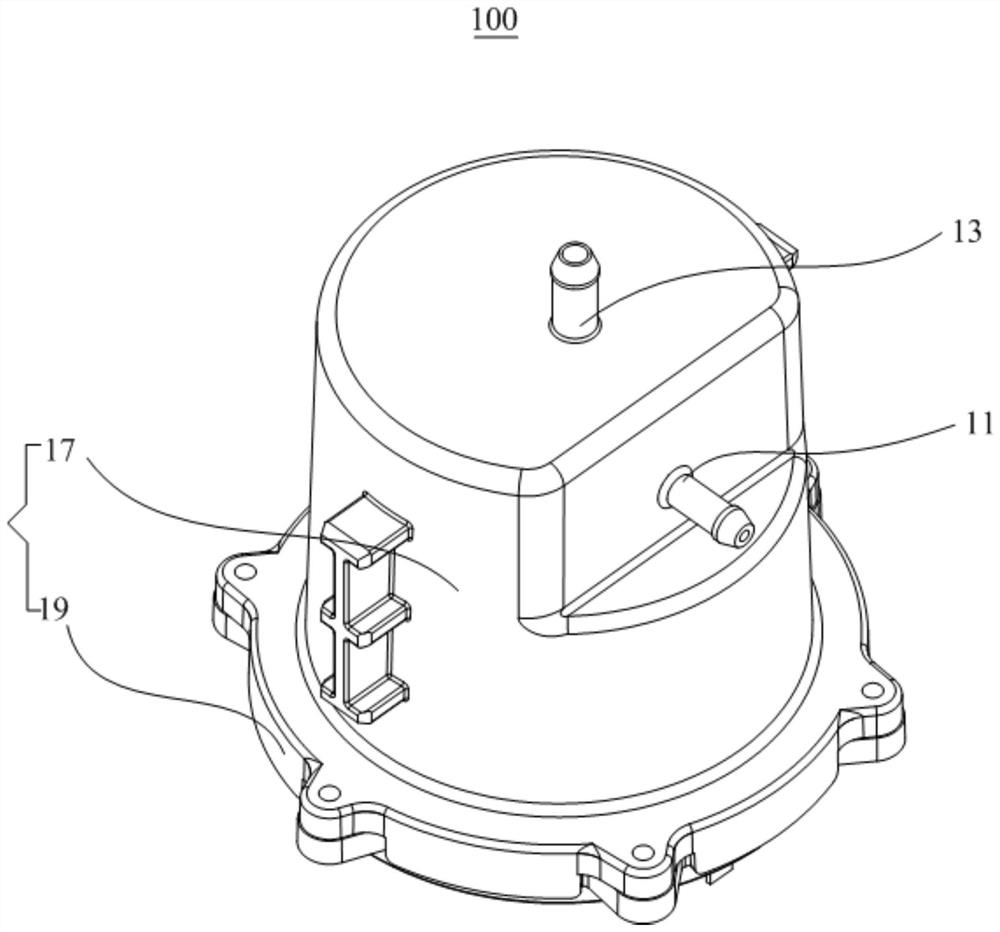

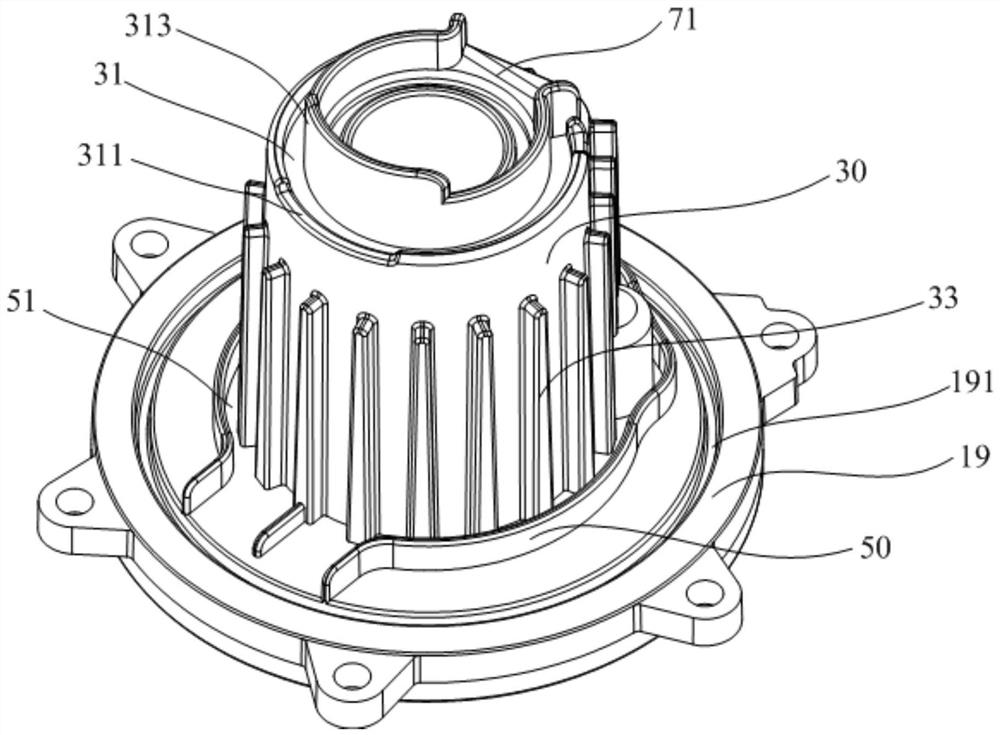

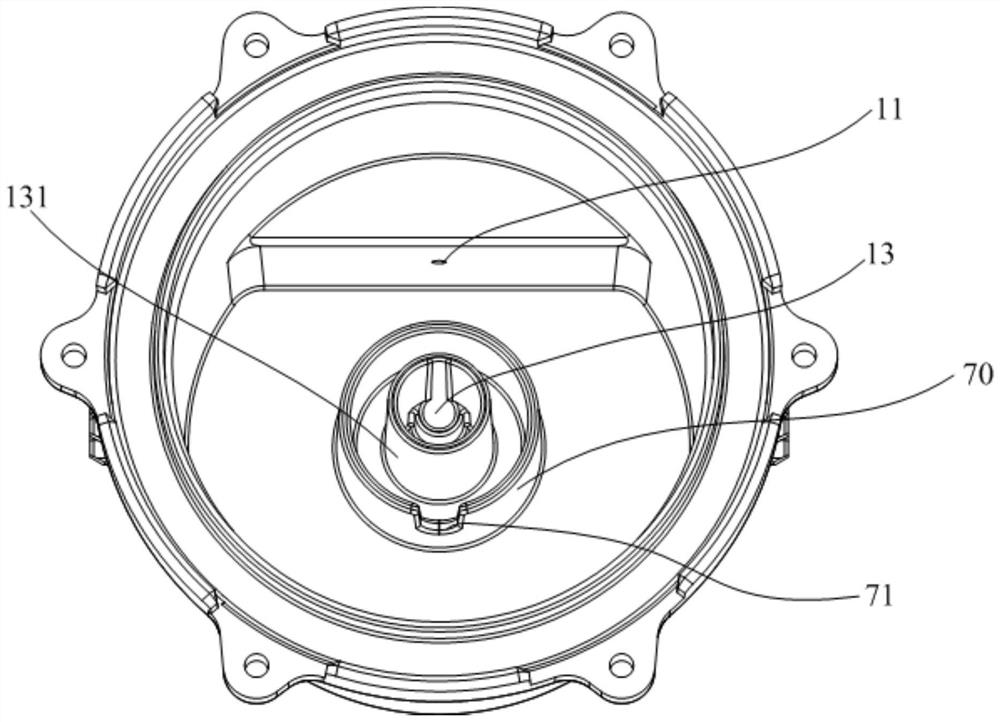

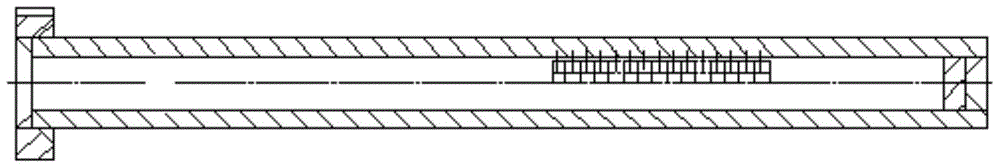

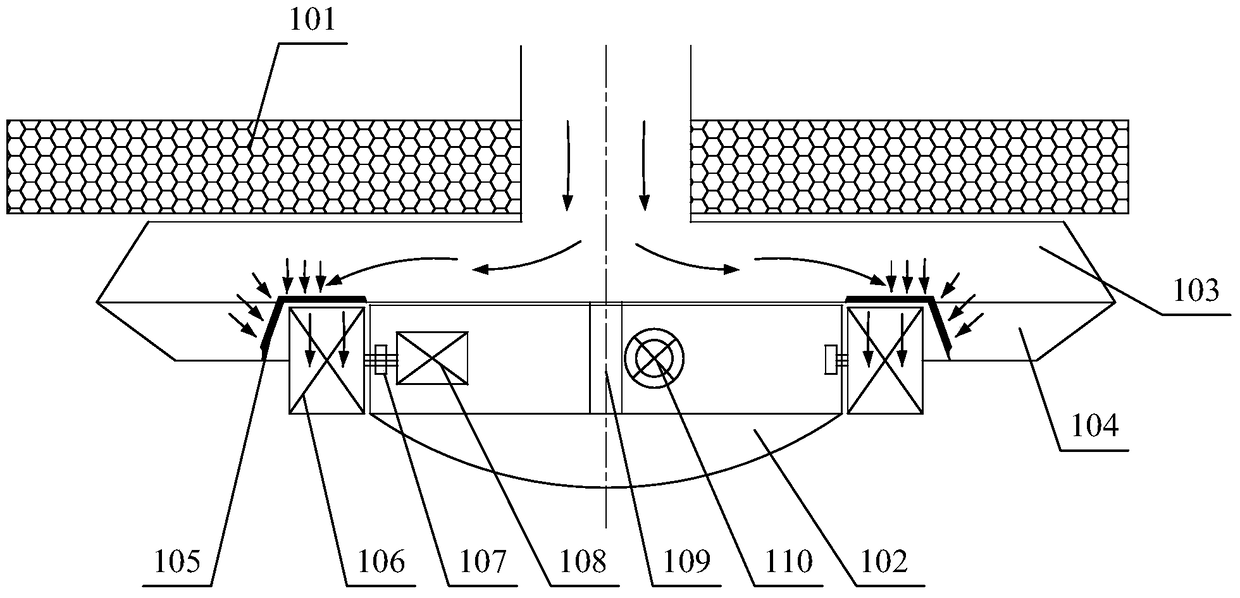

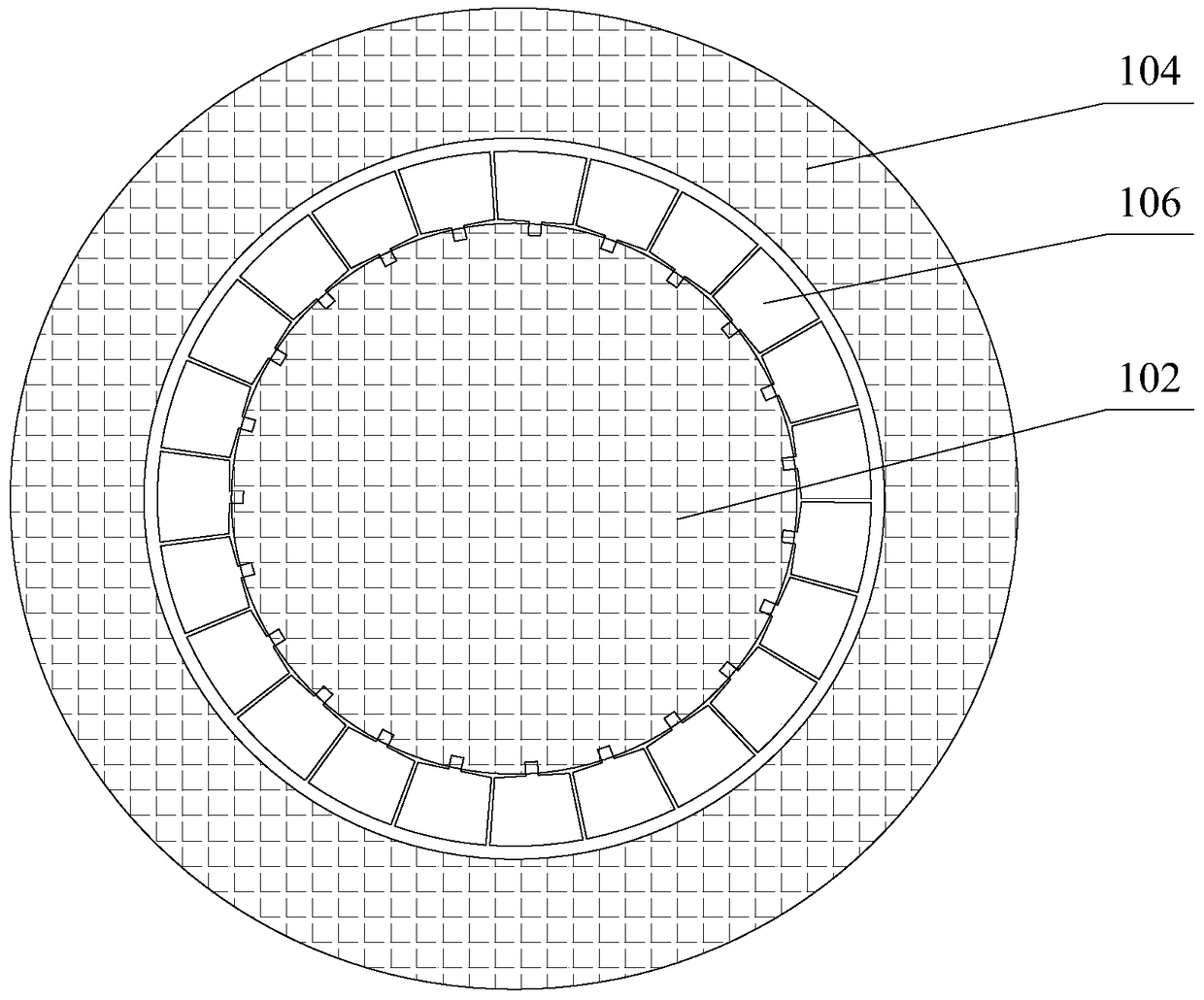

Laser with rapid heat dissipation function

ActiveCN112397976AIncrease heat exchange speedRapid cooling and heat dissipationLaser cooling arrangementsCold airThermodynamics

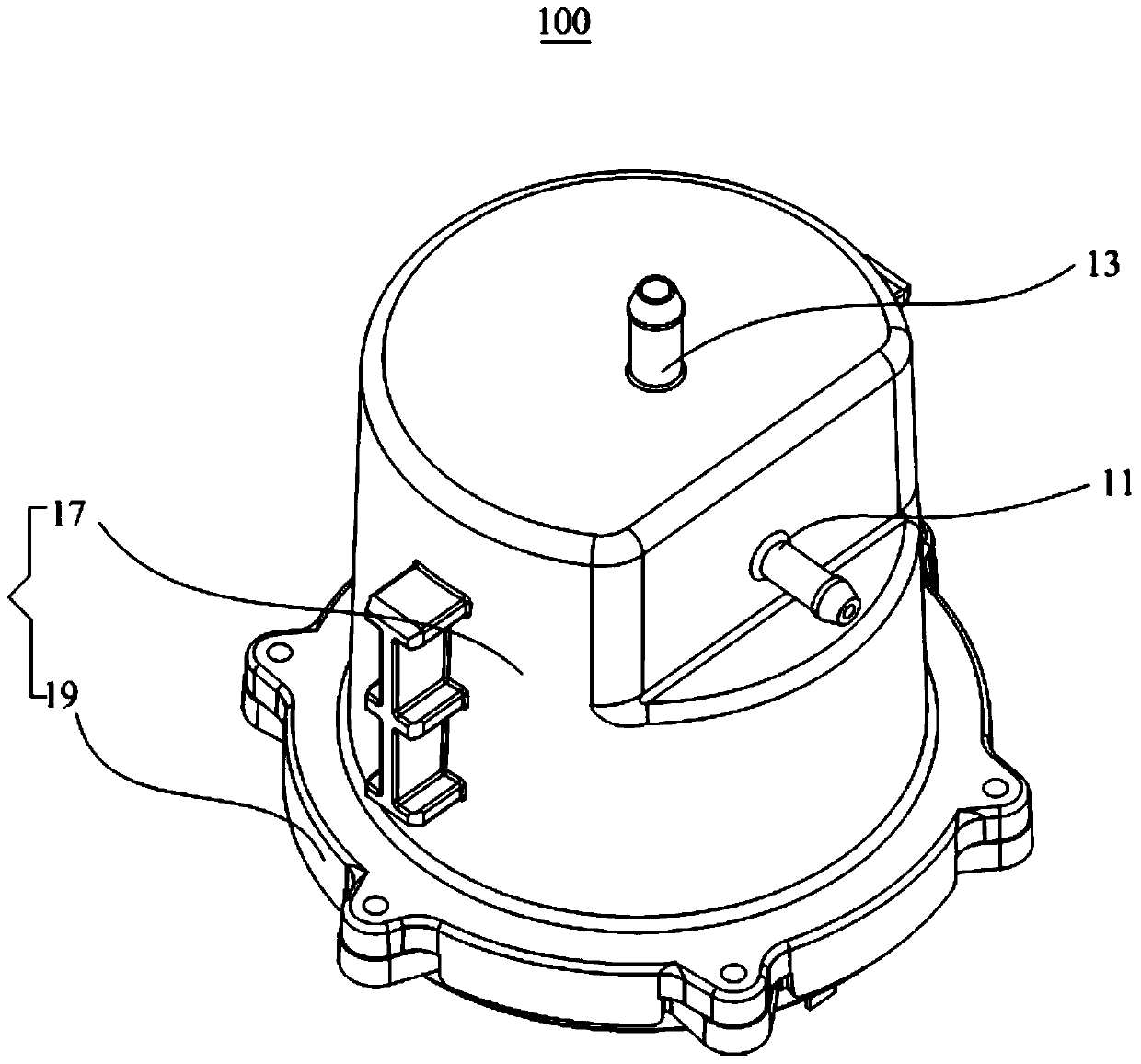

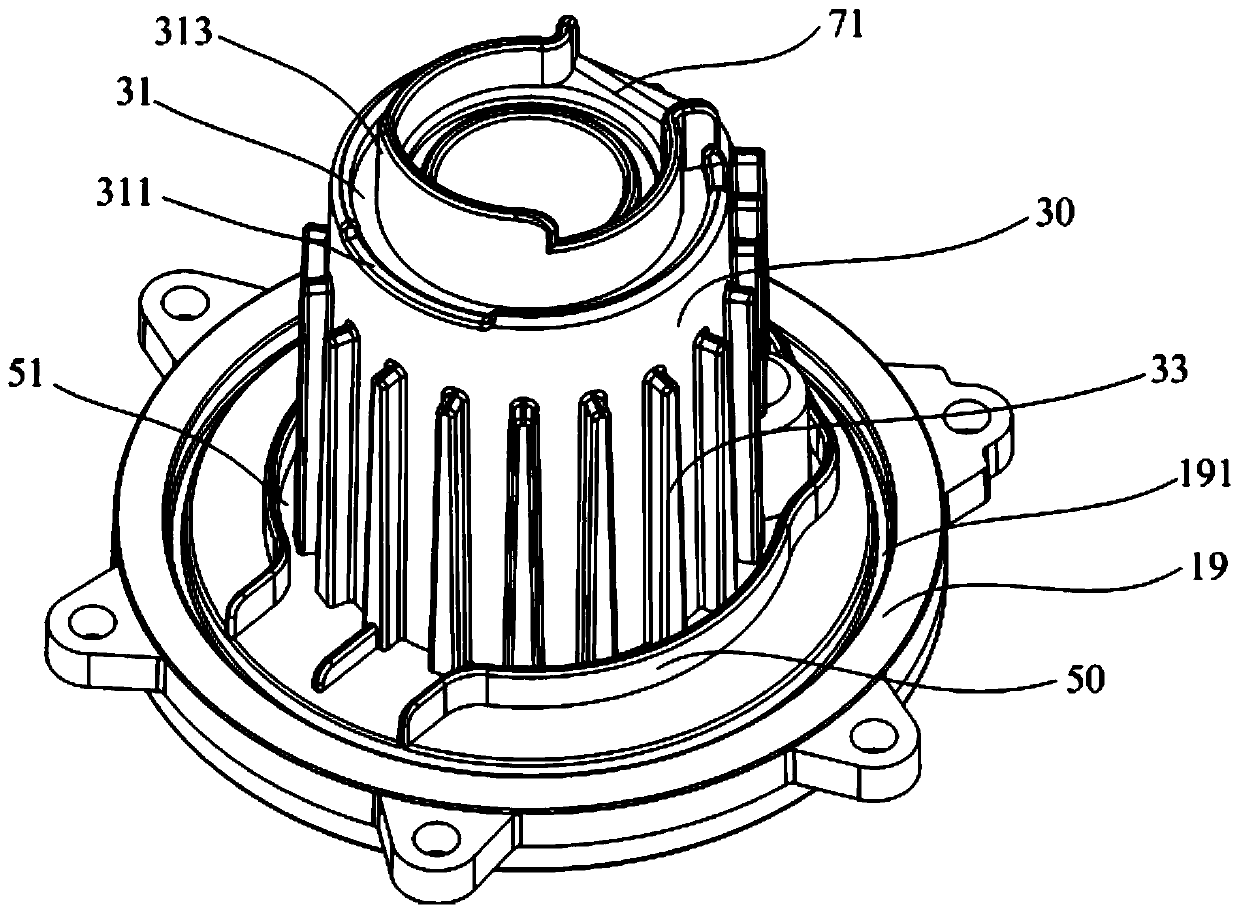

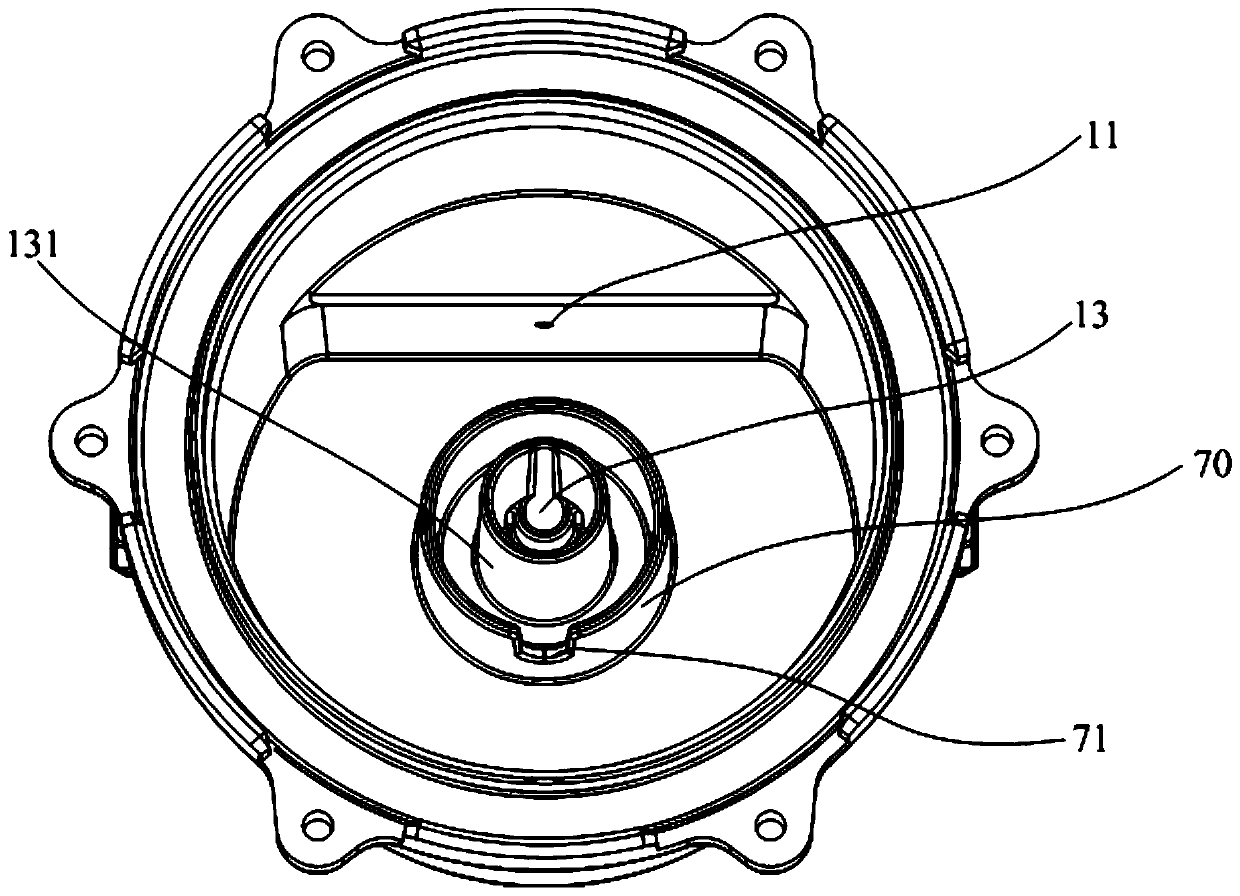

The invention relates to the technical field of rapid heat dissipation lasers, in particular to a laser with a rapid heat dissipation function. The laser comprises a shell, a heat dissipation mechanism is fixedly connected to the interior of the shell, the heat dissipation mechanism comprises a heat conduction cylinder, and one end of the heat conduction cylinder is fixedly connected with the inner side wall of one end of the shell, and the inner side wall of the heat conduction cylinder is fixedly sleeved with a laser generator. According to the laser with the rapid heat dissipation function,through the arrangement of an annular cavity, cooling liquid makes direct contact with the outer side wall of the heat conduction cylinder, the heat exchange speed between the cooling liquid and theheat conduction cylinder is increased, and the laser generator can achieve rapid cooling and heat dissipation, the high-lower temperature stratification phenomenon can be broken through the arrangement of a flow guide plate, so that the temperature in the annular cavity is uniform and stable, the use stability of the laser generator is improved, a straight air duct is formed in the shell through two vent holes in the shell, hot air is conveniently and quickly exhausted, cold air is conveniently sucked in, and rapid heat dissipation of the laser generator is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

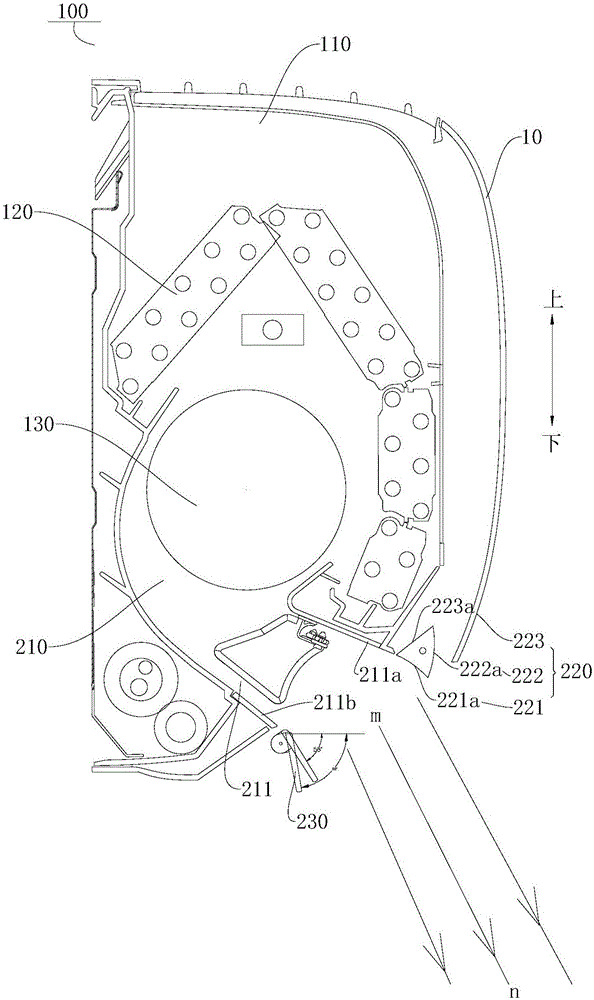

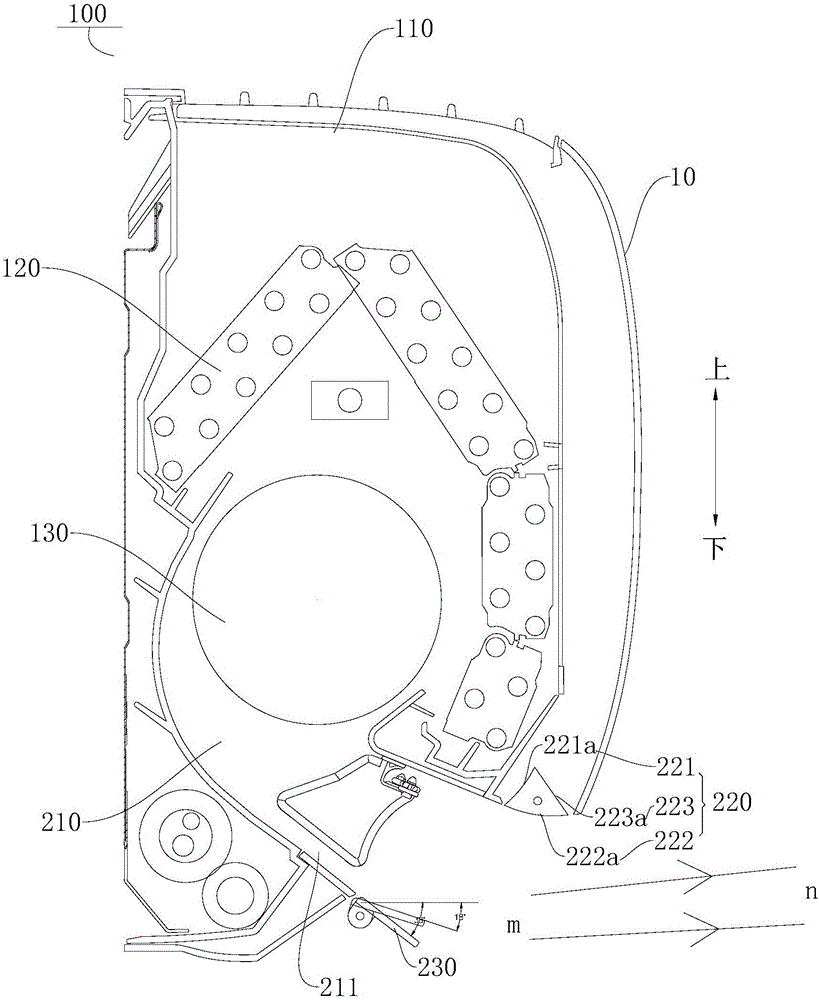

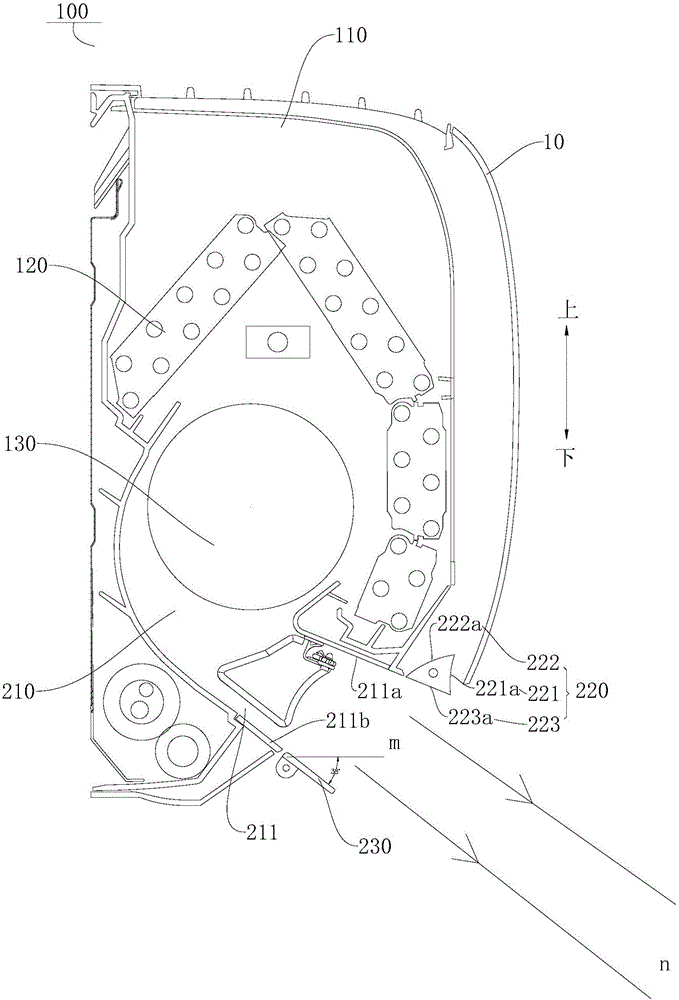

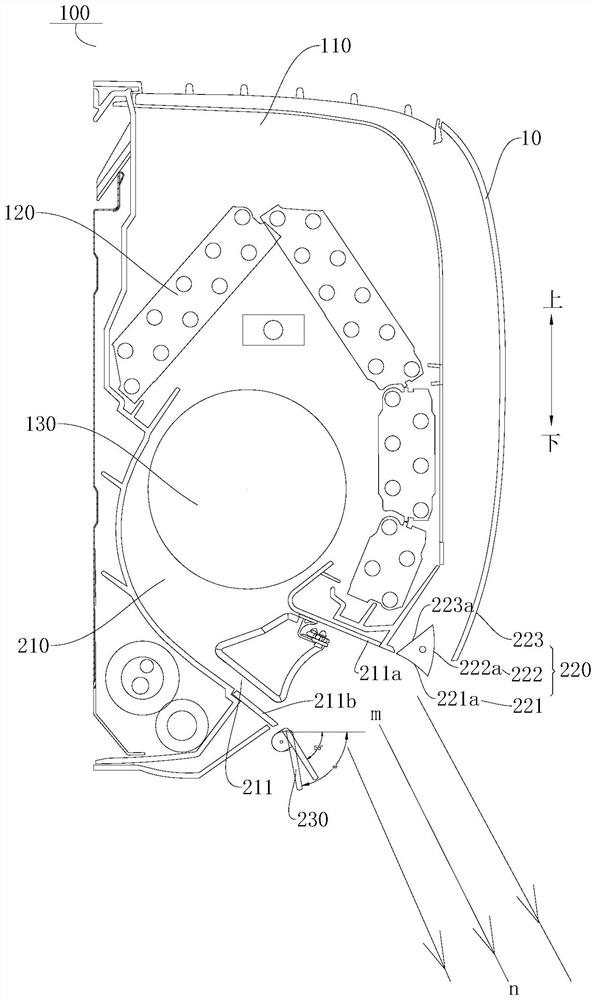

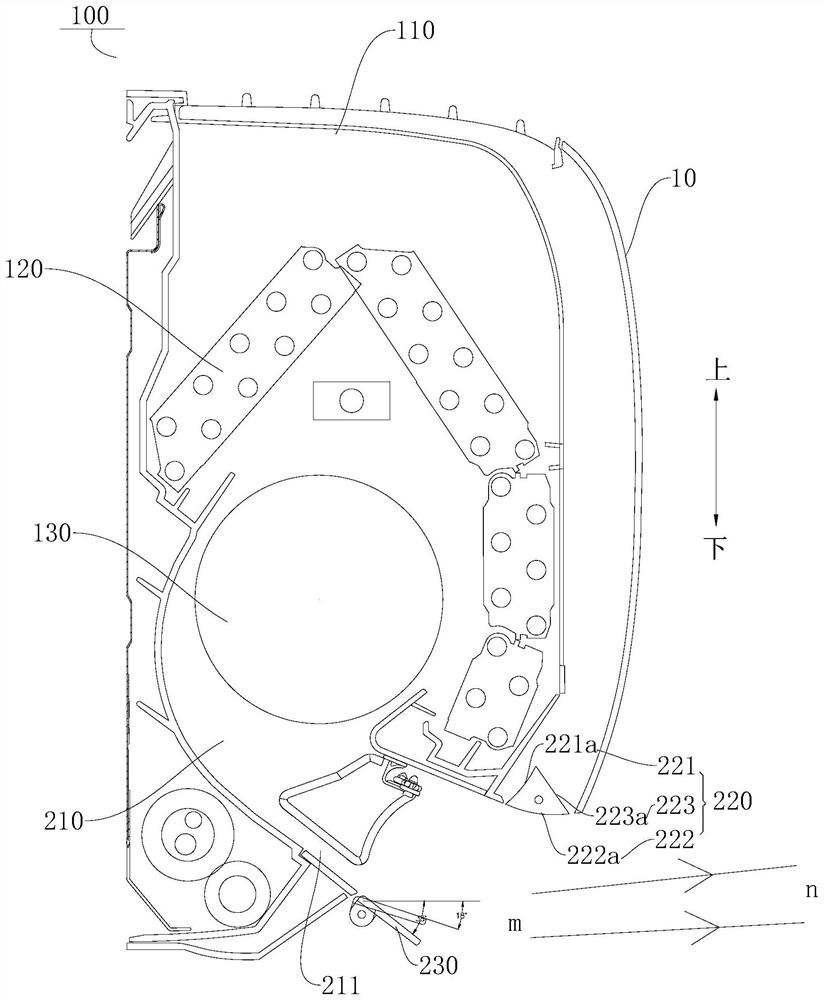

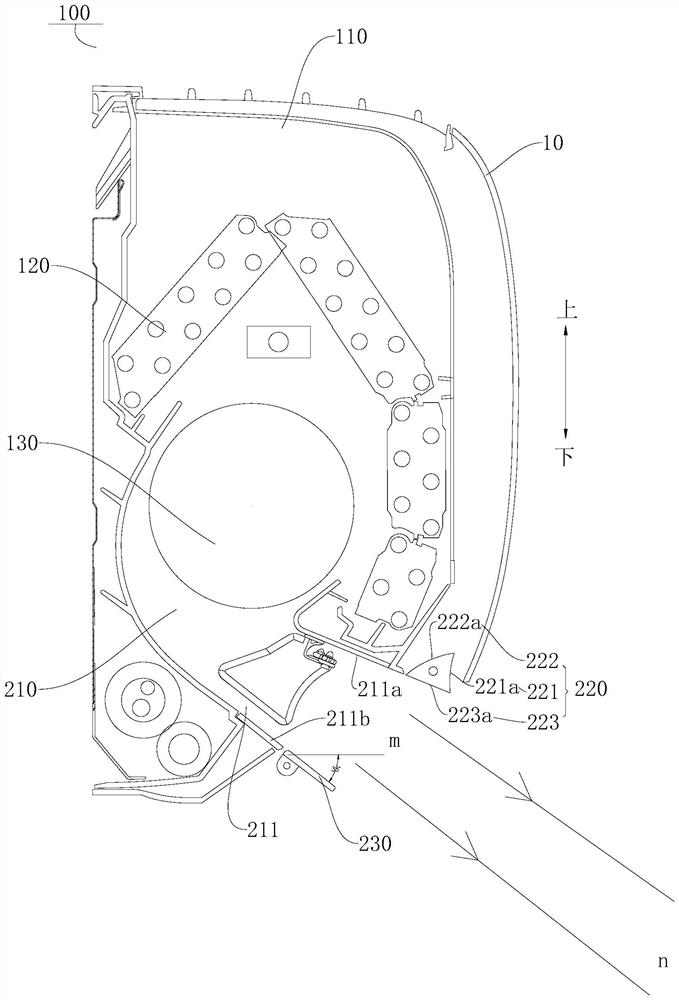

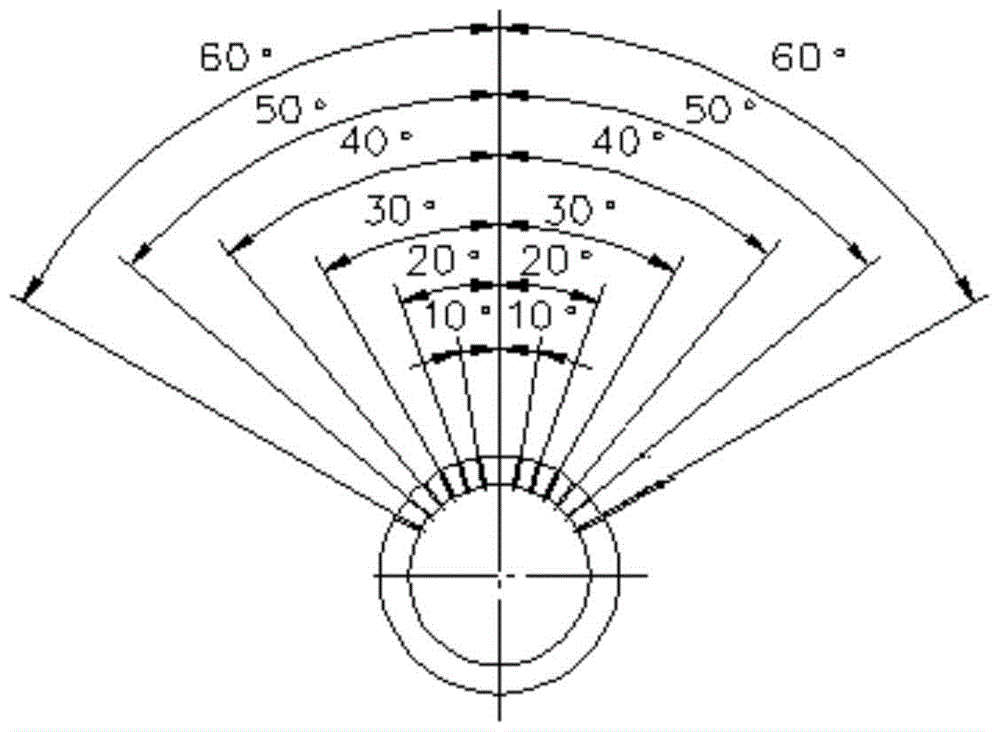

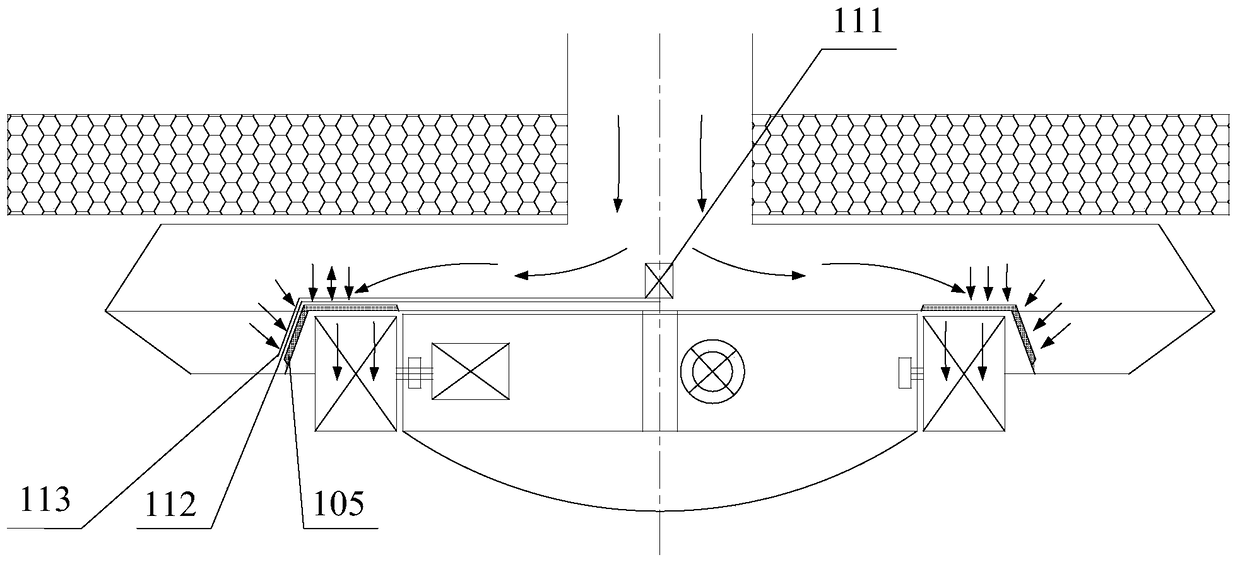

Air guide component of air conditioner and air conditioner

ActiveCN106123268AImprove comfortSpeed up the flowLighting and heating apparatusHeating and ventilation casings/coversEngineeringTriangular prism

The invention discloses an air guide component of an air conditioner and the air conditioner. The air conditioner comprises a shell; the air guide component is arranged in the shell and comprises an air duct and a main air guide component. The air duct is provided with an air outlet, the air outlet is provided with an upper side air outlet edge and a lower side air outlet side which are opposite to each other, the main guide component is arranged on the upper side air outlet edge in a pivoted mode, the main guide component is formed into a triangular prism shape, the side wall faces of the main guide component are a first air guide face, a second air guide face and a third air guide face respectively, and the main guide component has a first position state, a second position state and a third position state. According to the air guide component of the air conditioner in the embodiment of the invention, through the arrangement of the main air guide component, when the air conditioner is in different working states, the main air guide component can be adjusted to the corresponding position state to correspondingly adjust the air flow direction of the air outlet, therefore the flow speed of the indoor air and the heat exchange speed can be improved, and the air supply comfort of the air conditioner is enhanced.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

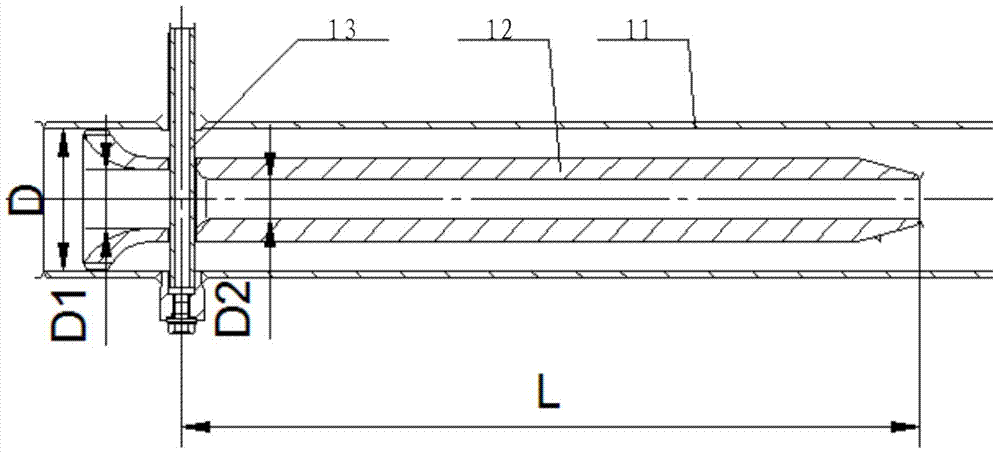

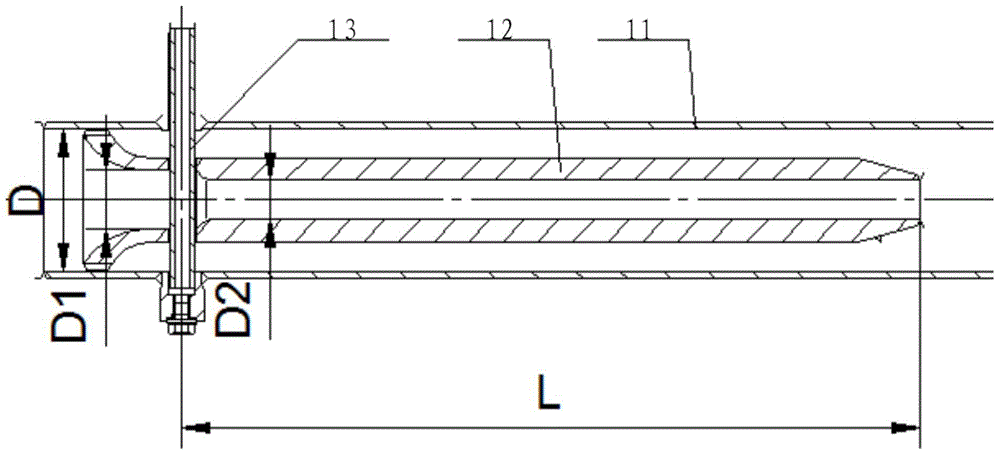

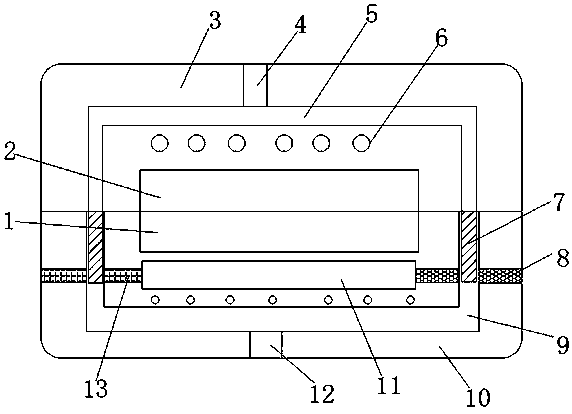

Steam temperature-reducing system

ActiveCN104501132AShorten the lengthGuaranteed qualitySuperheating controlEngineeringSteam temperature

The invention discloses a steam temperature-reducing system. The steam temperature-reducing system comprises a steam outer tube, a venturi tube and a nozzle, wherein the venturi tube is connected to the inner wall of the steam outer tube in an inserted manner and comprises a front end and a throat portion; the front end of the venturi tube faces the left side of the steam outer tube; the inner diameter (D) of the left side of the front end of the venturi tube is smaller than the inner diameter (D1) of the right side of the front end of the venturi tube; the inner diameter of the steam outer tube is equal to the inner diameter of the left side of the front end of the venturi tube; the right side of the front end of the venturi tube is connected with the throat portion of the venturi tube; the inner diameter (D2) of the throat portion of the venturi tube is smaller than the inner diameter (D1) of the right side of the front end of the venturi tube; the nozzle penetrates in the steam outer tube and the front end of the venturi tube and is hermetically connected with the steam outer tube and the front end of the venturi tube; and a plurality of small holes are formed in a portion, which is positioned in the front end of the venturi tube, of the nozzle. Because steam entering the steam temperature-reducing system is accelerated twice, the steam and temperature-reducing water are mixed uniformly, the efficiency of heat transfer between the steam and the temperature-reducing water is high, and the length of the steam temperature-reducing system is reduced.

Owner:HANGZHOU WORLDWISE VALVE

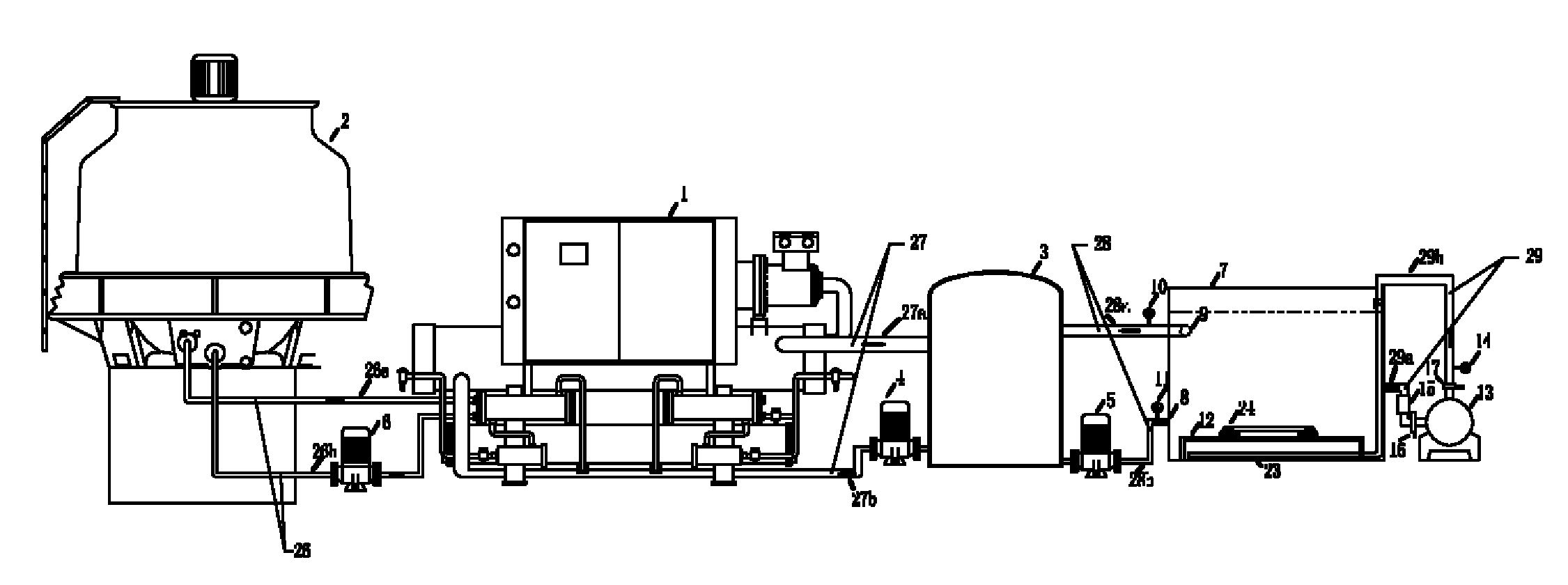

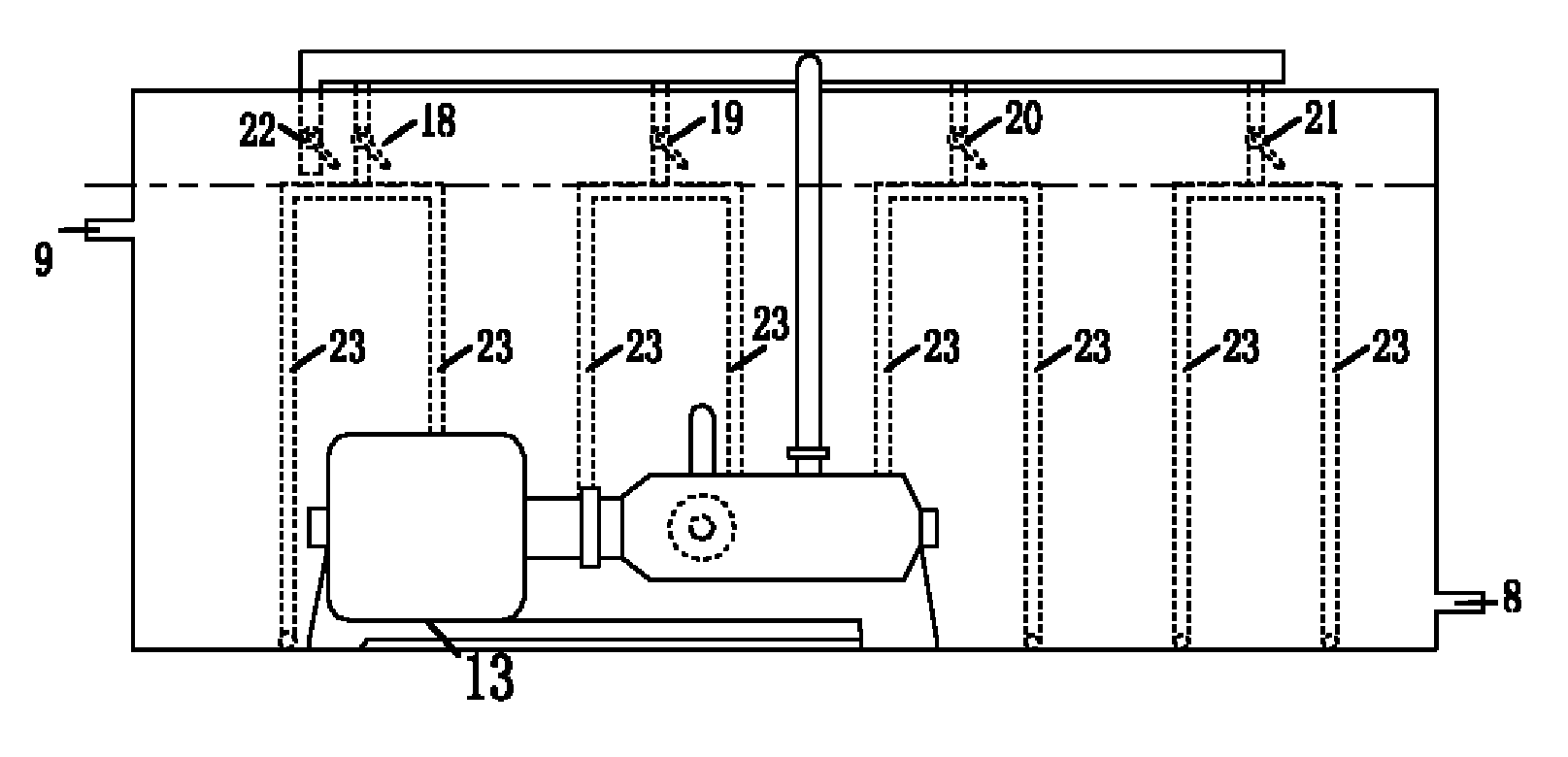

Cooling equipment for use in machining of GH4169 turbine disk forgings

ActiveCN102424909ASmall footprintIncrease cooling rateFurnace typesHeat treatment furnacesAlloyWater circulation

The invention provides cooling equipment for use in machining of GH4169 turbine disk forgings, which can solve the problems of low cooling rate, instable product quality and the like in the conventional GH4169 ally forging cooling process. The cooling equipment comprises a cooling water tank, wherein the bottom of the cooling water tank is provided with a rack. The cooling equipment is characterized by also comprising a cooling machine, wherein the cooling machine is connected with the cooling water tank through an external circulating pipe; and the cooling water tank is also connected and provided with an internal circulation system.

Owner:WUXI TURBINE BLADE

Water circulation floor heating electromagnetic heater and descaling device

InactiveCN107842905ASimple structureReduce volumeHeating fuelLighting and heating apparatusWarm waterWater circulation

The invention relates to home decoration floor heating equipment, in particular to a water circulation floor heating electromagnetic heater and a descaling device. Including: water tank, heating body, electromagnetic coil, water inlet pipe, water outlet pipe, water pump, descaling mechanism, and scale collection box; this device effectively avoids scale on the heating body through a simple mechanism without affecting the heating efficiency The accumulation and formation of the heating body wall solves the problem of scaling removal.

Owner:ZHENGZHOU BEIYATE ELECTRONICS TECH CO LTD

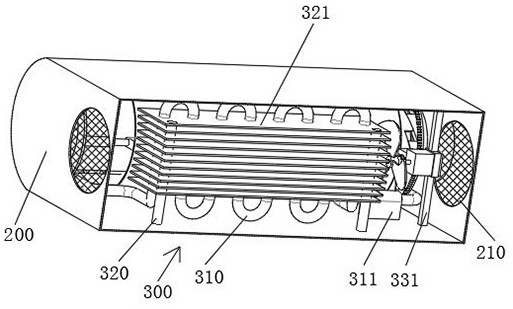

Heat dissipation assembly and projection apparatus with the same

InactiveUS20160026075A1Effective preventionImprove luminanceProjectorsColor television detailsTemperature controlLight beam

A heat dissipation assembly for a projection apparatus is provided. The projection apparatus includes a light source, optical elements and a heat dissipation assembly. The heat dissipation assembly includes a case, a heat dissipation element, a fan and a temperature controlling unit. The optical elements transmit a light beam generated by the light source, and thereby generate heat. The heat dissipation assembly is adapted for heat dissipation correspondingly. In the heat dissipation assembly, the case protects the optical elements from being polluted by the dust during heat dissipation. The temperature controlling unit senses the surrounding temperature to control the fan for cooling the heat dissipation element, and the durability of the optical elements are thereby enhanced.

Owner:DELTA ELECTRONICS INC

A laser with fast cooling function

ActiveCN112397976BIncrease heat exchange speedRapid cooling and heat dissipationLaser cooling arrangementsCold airThermodynamics

The present invention relates to the technical field of rapid heat dissipation lasers, in particular to a laser with rapid heat dissipation function, comprising a casing, a heat dissipation mechanism is fixedly connected to the inside of the casing, and the heat dissipation mechanism includes a heat conduction tube, one end of the heat conduction cylinder is connected to the shell One end of the inner wall is fixedly connected, and the inner wall of the heat conduction cylinder is fixedly sleeved with a laser generator. In the present invention, a laser device with rapid heat dissipation function, through the setting of the annular cavity, the cooling liquid is directly in contact with the outer wall of the heat-conducting cylinder, and the heat exchange speed between the cooling liquid and the heat-conducting cylinder is increased, so that the laser generator can quickly Cooling and heat dissipation, through the setting of the deflector, break the high and low temperature stratification phenomenon of the coolant, make the temperature in the annular cavity uniform and stable, thereby increasing the stability of the laser generator during use, through the setting of two ventilation holes on the shell, A straight air passage is formed in the casing, which facilitates the rapid discharge of hot air and the intake of cold air, and realizes rapid heat dissipation of the laser generator.

Owner:SOUTHWEST PETROLEUM UNIV

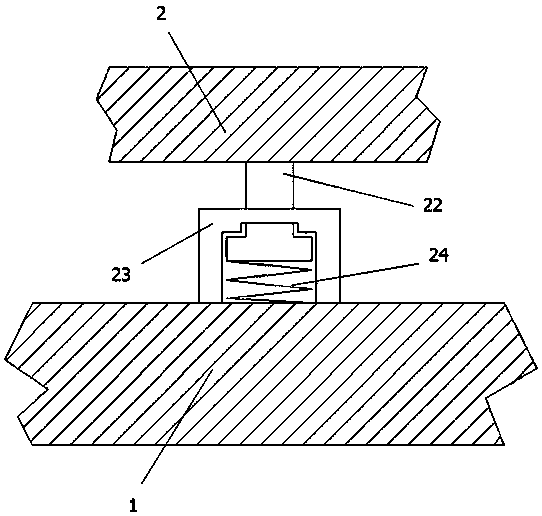

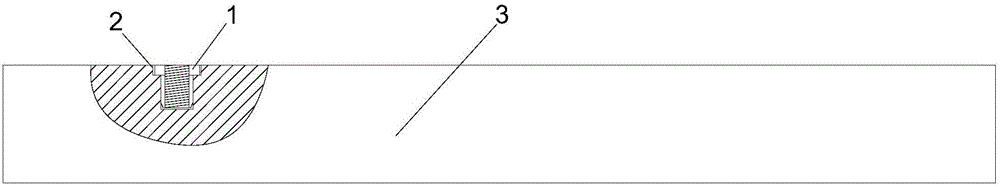

Rivet pressing nut used for installing heat sink

The invention discloses a rivet pressing nut used for installing a heat sink. The rivet pressing nut comprises a nut body and a plate provided with a riveting hole. The nut body sequentially comprises a threaded layer, a body layer and a riveting layer from inside to outside. A plurality of lattice teeth are evenly arranged on the outer circumference of the riveting layer. The threaded layer is detachably connected with a bolt. The body layer is thicker than the riveting layer. The heights of the lattice teeth become larger gradually in the direction from the first end of the nut body to the second end of the nut body. The thicknesses of the lattice teeth become larger gradually in the direction from the first end of the nut body to the second end of the nut body. The outer diameter of the first end of the nut body is smaller than the diameter of the riveting hole. The outer diameter of the second end of the nut body is larger than the diameter of the riveting hole. The first end of the nut body is inserted into the riveting hole from the first side of the plate. The second end of the nut body is aligned with the second end of the plate. According to the rivet pressing nut used for installing the heat sink, a thread inside the nut body can be prevented from being damaged.

Owner:安徽汇展热交换系统股份有限公司

Vapor generator and ironing equipment

ActiveCN110553239ATake advantage ofReduce moisture contentSteam generation heating methodsHand ironWater storage tankEngineering

The invention discloses a vapor generator and ironing equipment. The vapor generator comprises a shell and a heating piece, wherein a heating cavity is formed in the shell; the shell is provided witha liquid inlet and an air outlet; the heating piece is arranged in the heating cavity; and at least part of liquid entering from the liquid inlet flows to the bottom of the heating piece after being heated by the wall surface of the heating piece. The vapor generator can reduce or prevent remaining of water in a water storage tank, and meanwhile, improves the ironing effect.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

Heat sink, fin and heater

PendingCN111811032AIncrease gas outputIncrease air volumeHeating fuelLighting and heating apparatusAir volumeEngineering

The invention discloses a heat sink, a fin and a heater. The heat sink comprises a main body used for heat exchange, wherein one side of the main body is provided with a first folding part, the firstfolding part forms an angle with the main body, and a first notch is provided on the first folding part. In the heat sink described above, the first folding part can cooperate with the main body to form a channel for heating the air since the first folding part and the main body are arranged at an angle, the air will rise after the heat exchange with the heat sink to form a chimney effect in the channel to accelerate heat exchange and convection of air, while the structure of the first folding part allows air to enter and exit the channel from the outer side of the heat sink to be able to increase the air intake or air output of the channel, and the air volume and the speed of heat exchange can be increased under the action of the chimney effect, so that the indoor temperature can be quickly raised.

Owner:GREE ELECTRIC APPLIANCES INC

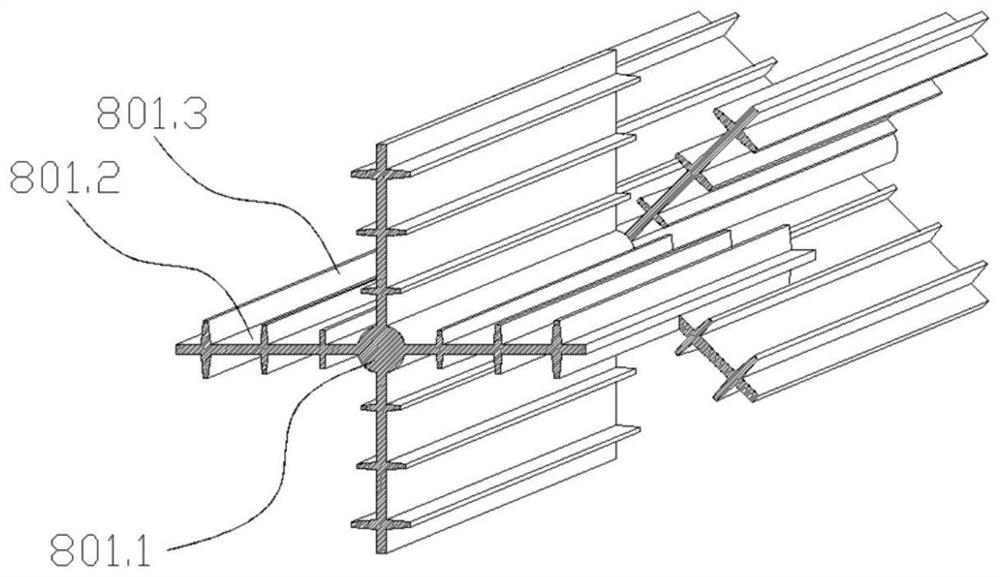

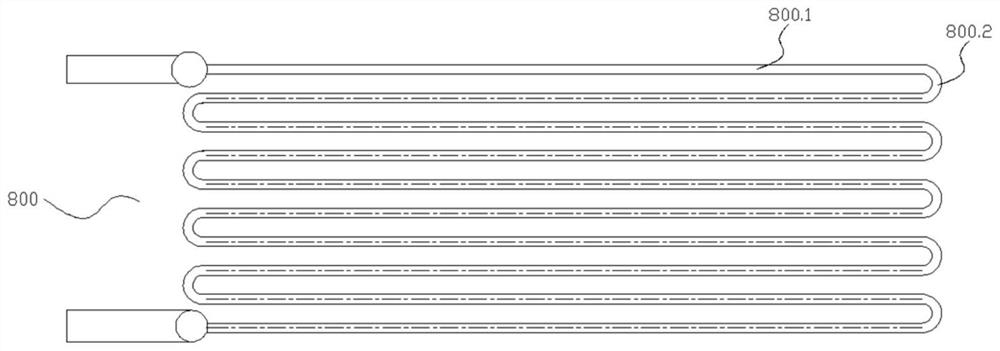

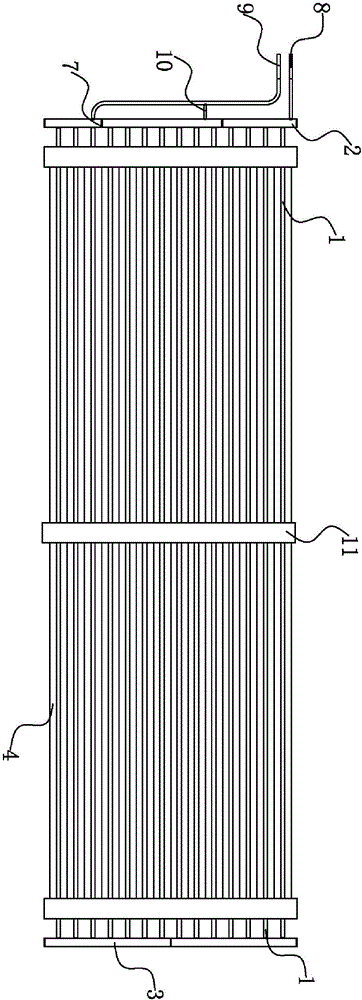

Production method of heat exchange coil pipe with heat conduction profile with auxiliary fins

The invention relates to a production method of a heat exchange coil pipe with a heat conduction profile with an auxiliary fin, which is characterized by comprising the following specific steps: step 1, firstly, extruding and molding a full-length profile which is matched with a fin group in section shape by adopting a die, and additionally, producing a full-length sleeve which is consistent with a heat exchange coil pipe main body in caliber; secondly, the full-length sectional material is twisted into a heat conduction sectional material with auxiliary fins, and the heat conduction sectional material is internally installed in the full-length sleeve to form a straight pipe section; and thirdly, the straight pipe sections and the bent pipe sections are connected to form the heat exchange coil pipe of the heat conduction sectional material with the auxiliary fins. According to the production method of the heat exchange coil pipe with the heat conduction sectional material with the auxiliary fins, fluid in a product can conduct heat to the heat exchange coil pipe body through the heat conduction sectional material arranged in the pipe with the excellent heat conduction performance, and therefore the heat exchange amount and the heat exchange speed are greatly increased.

Owner:江苏金荣森制冷科技有限公司

Molding device

PendingCN114290011AIncrease the heat exchange areaAdequate heat conductionMechanical engineeringMucous membrane

The forming device is characterized by comprising a rolling wheel set, the rolling wheel set comprises a rolling male die set and a rolling female die set which are arranged up and down, and protrusions matched with special-shaped structures in size are arranged on rolling male dies at intervals in the circumferential direction; and recesses matched with the special-shaped structures in size are formed in the rolling concave die in the circumferential direction at intervals. The special-shaped structures are arranged on the main fins of the heat conduction profile produced by the forming device, the special-shaped structures not only increase the heat exchange area of fluid in a pipe, but also can continuously break a liquid mucous membrane which prevents heat from being conducted to the inner pipe wall, and the heat exchange effect of the heat conduction profile is improved.

Owner:江苏金荣森制冷科技有限公司

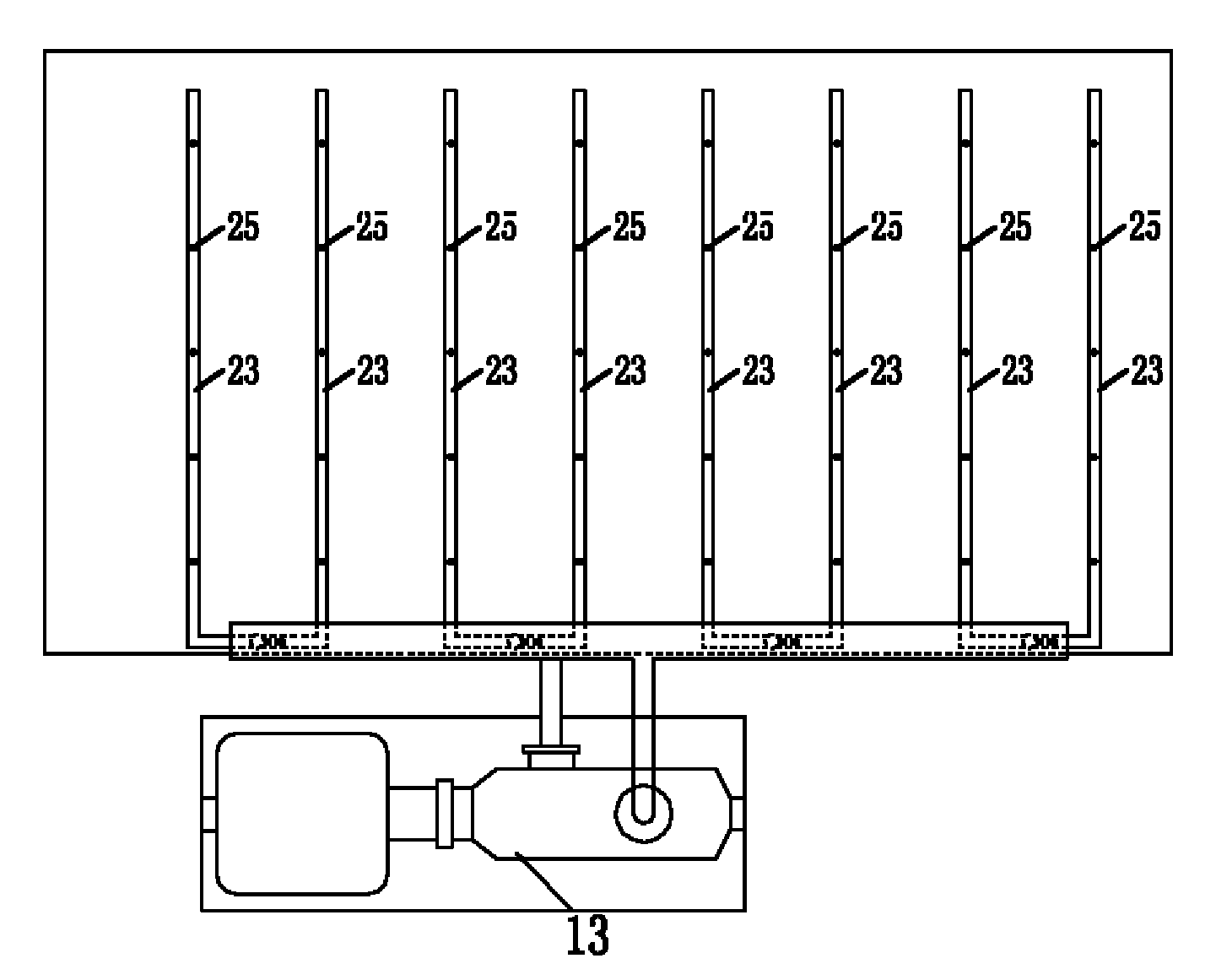

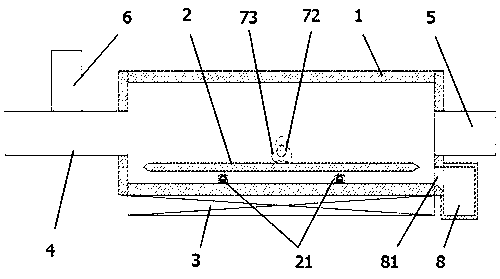

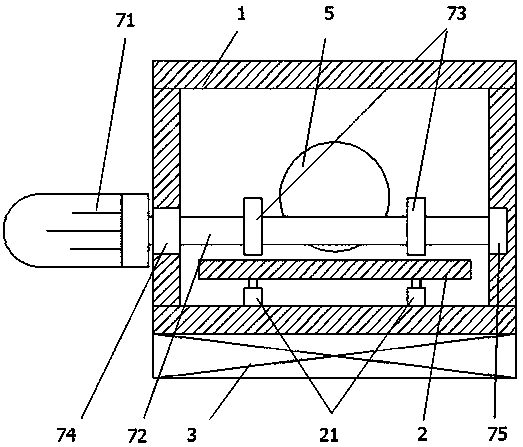

An automatic wood drying equipment

InactiveCN109405455BRealize automatic shakingImprove drying qualityDrying gas arrangementsDrying machines with local agitationVertical planeMechanical engineering

Owner:阜南县东方柳编工艺品有限公司

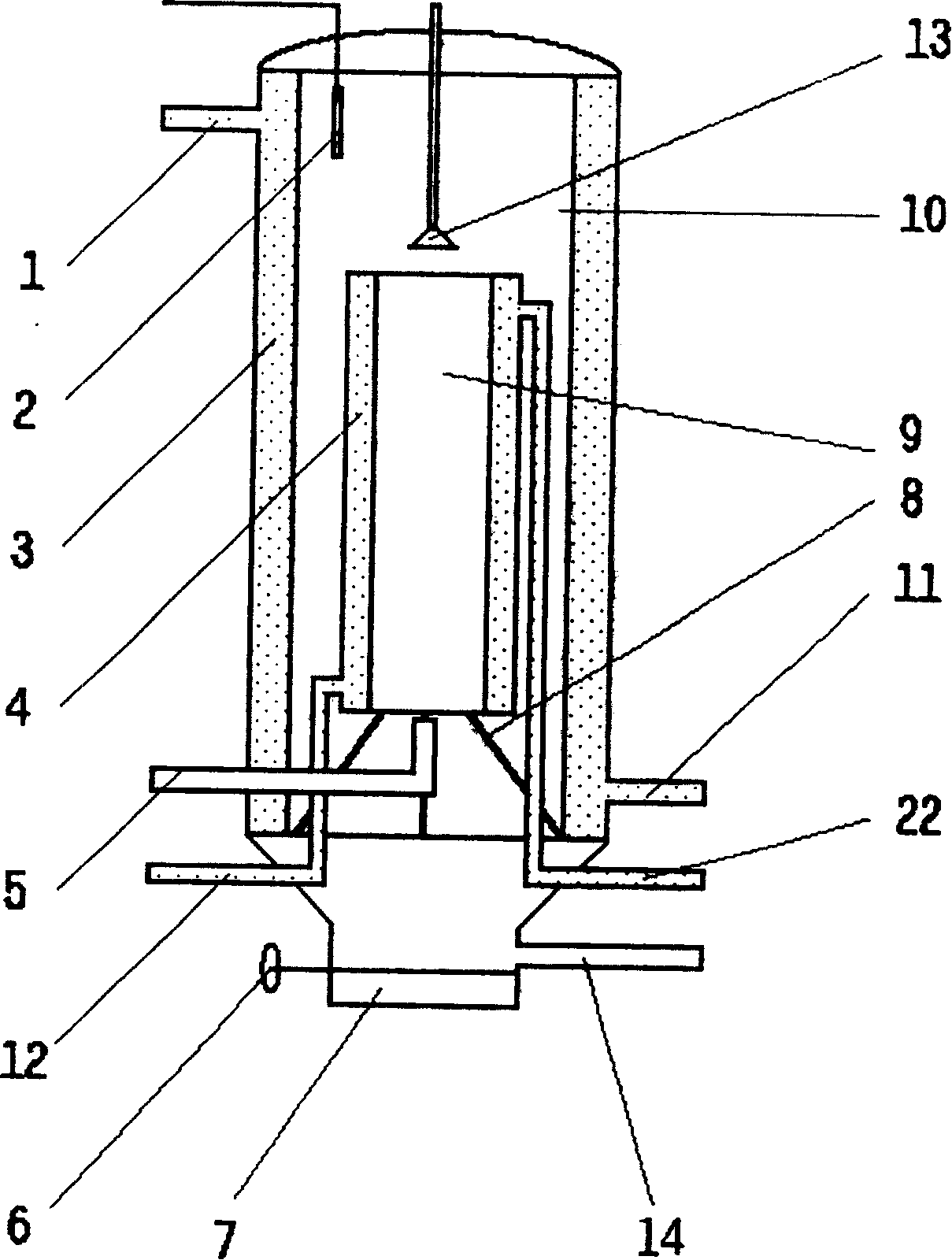

Reactor for synthesizing phosphorus pentachloride

InactiveCN100393613CIncreased chance of collisionIncrease contact areaPhosphorus halides/oxyhalidesChemical/physical/physico-chemical nozzle-type rreactorsEngineeringPhosphorus trichloride

The invention discloses a synthetic reactor of phosphorus pentachloride, which is composed of inner and outer cylinders with spraying hole of phsophorus trichloride on the top and chlorine inlet and outlet on the bottom, wherein the rack is supported in the middle of inner cylinder, which possesses cool water sandwich and inlet-to-outlet hole to increase collision frequency and contacting area of reactants.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

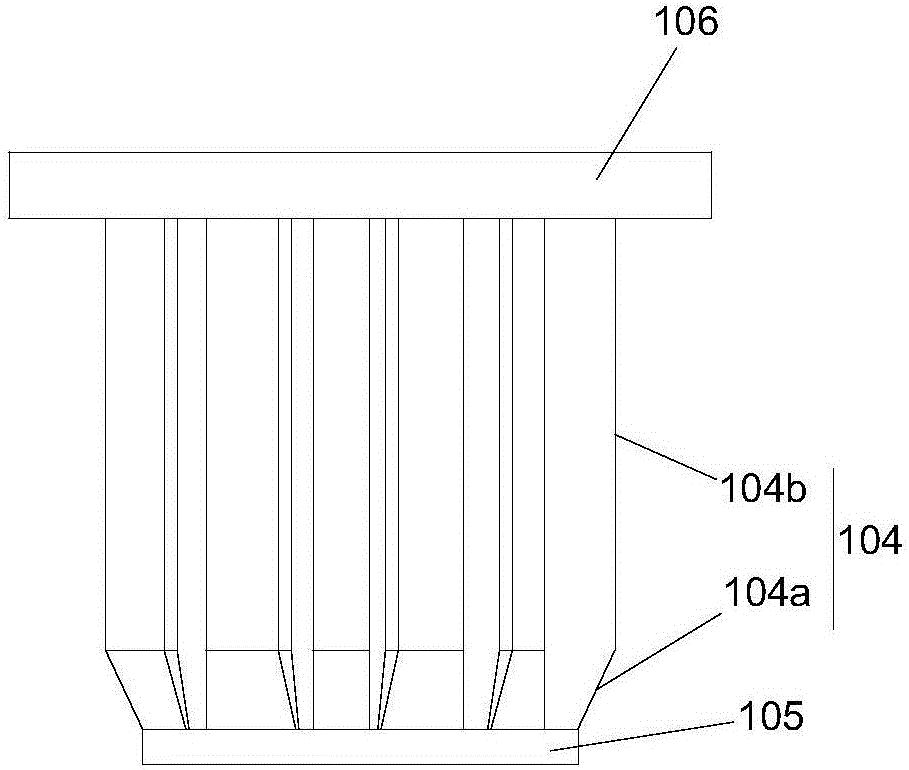

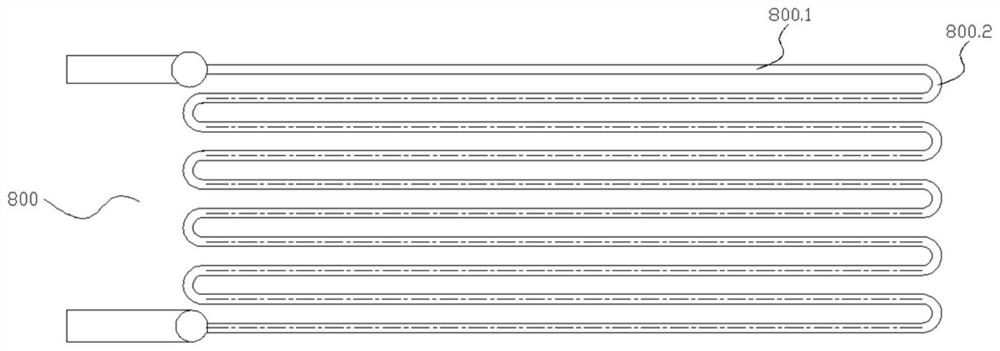

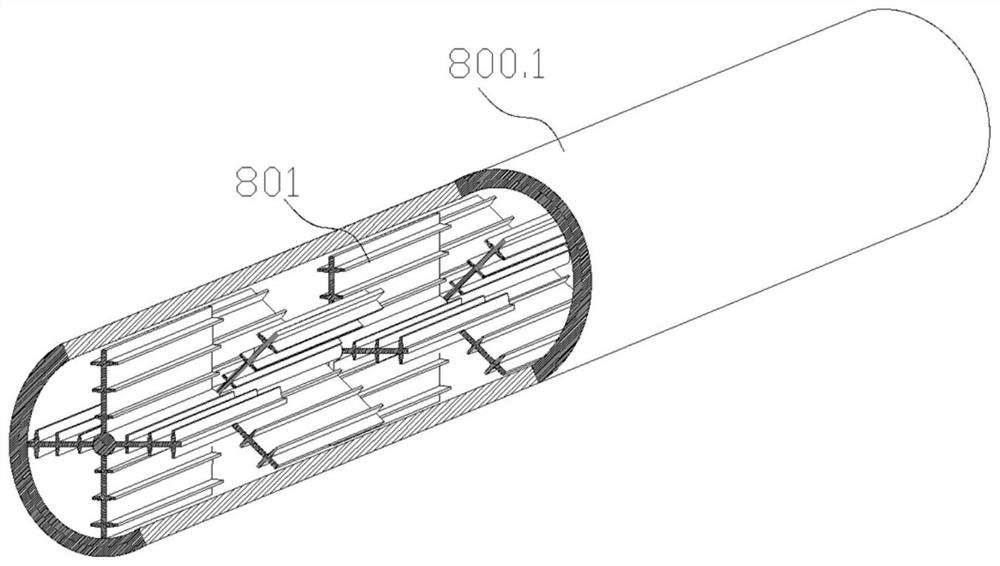

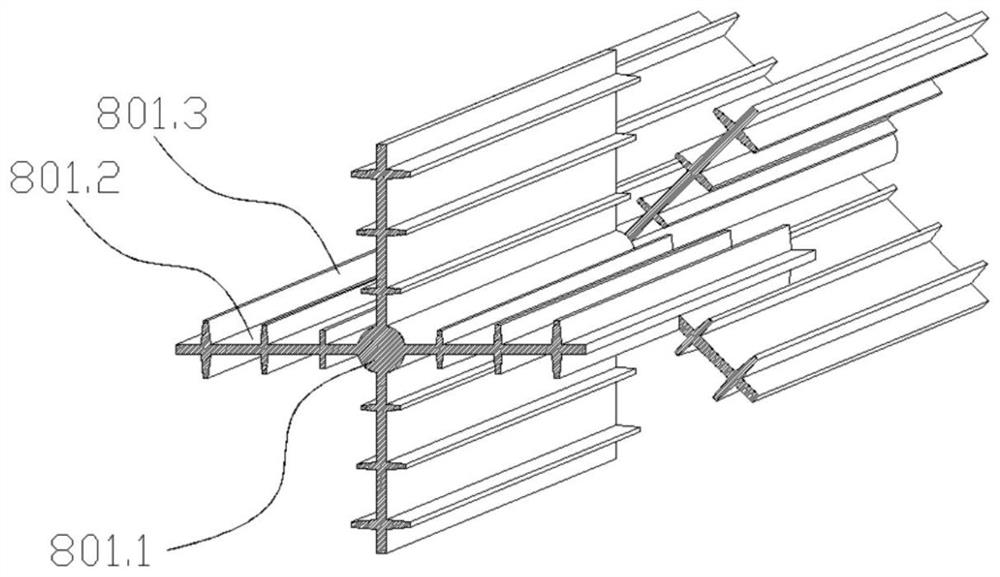

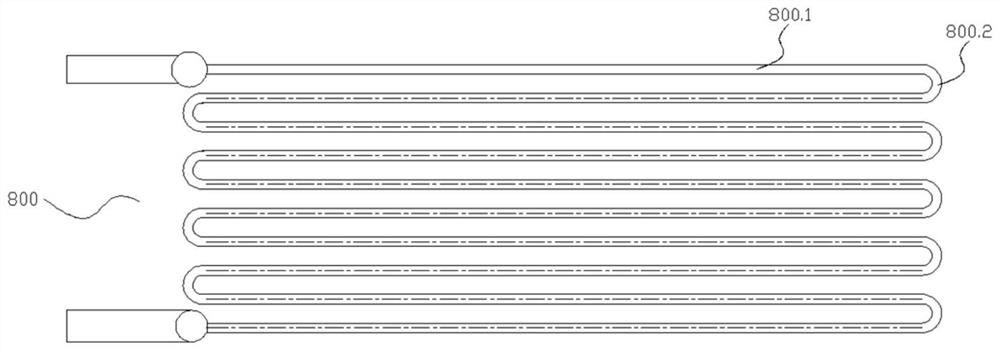

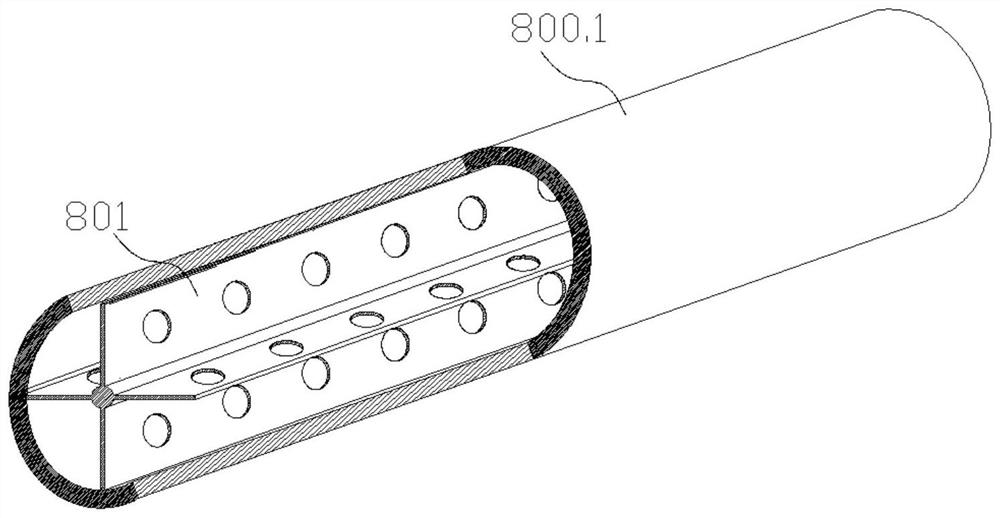

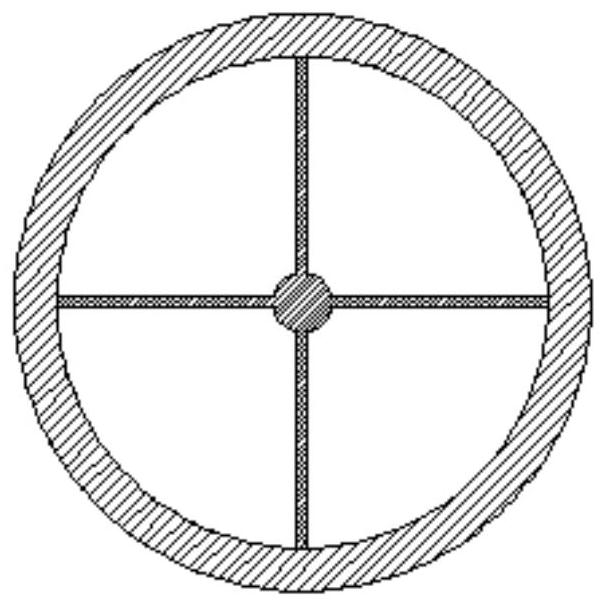

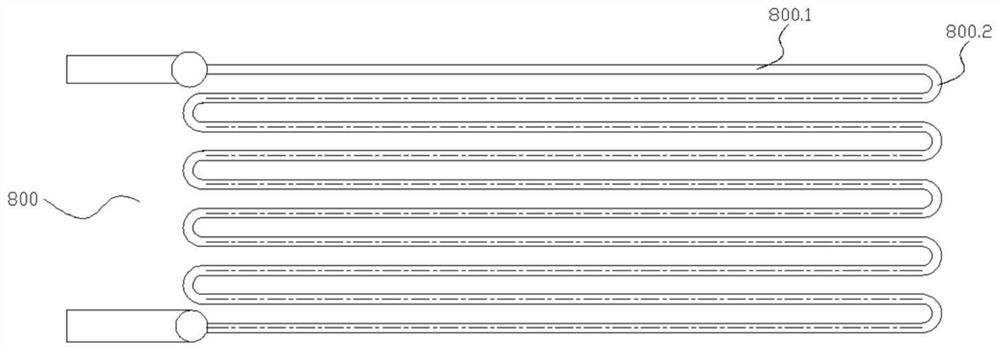

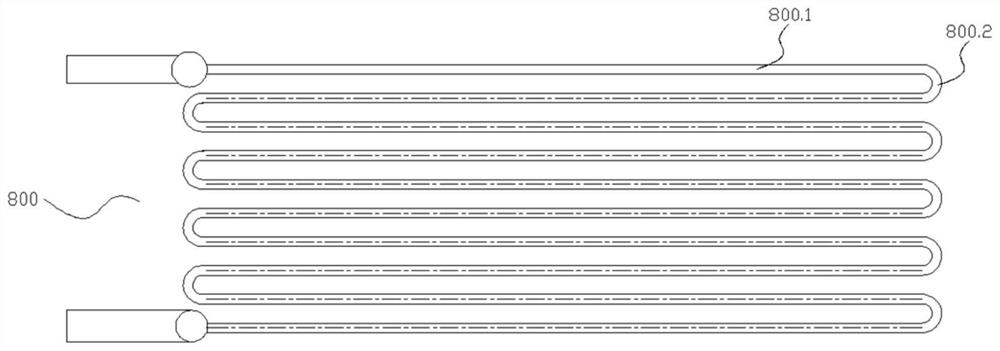

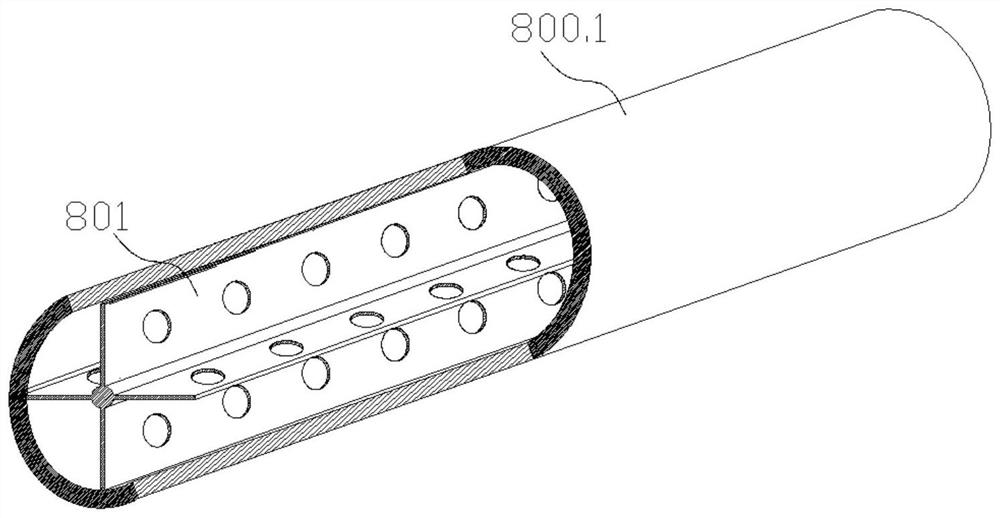

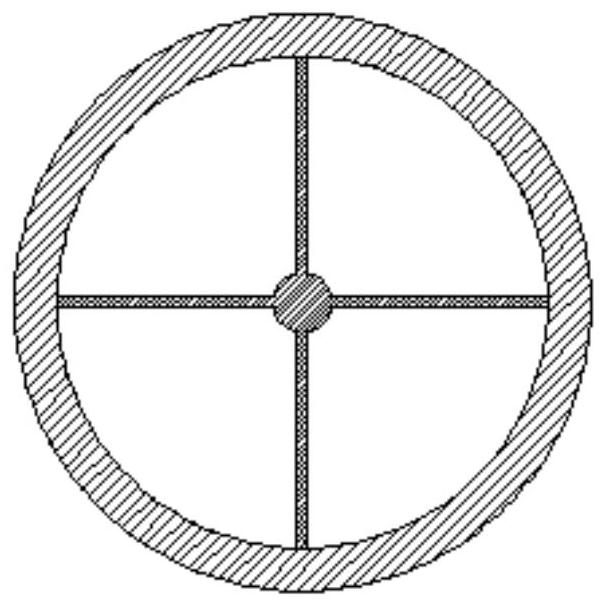

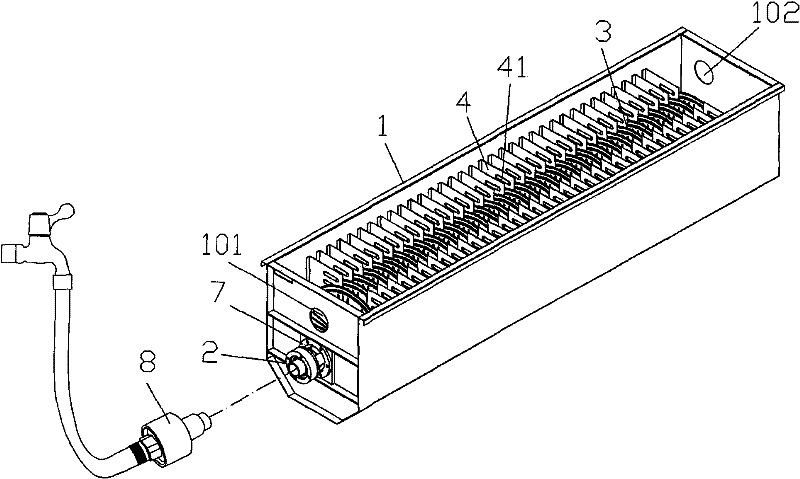

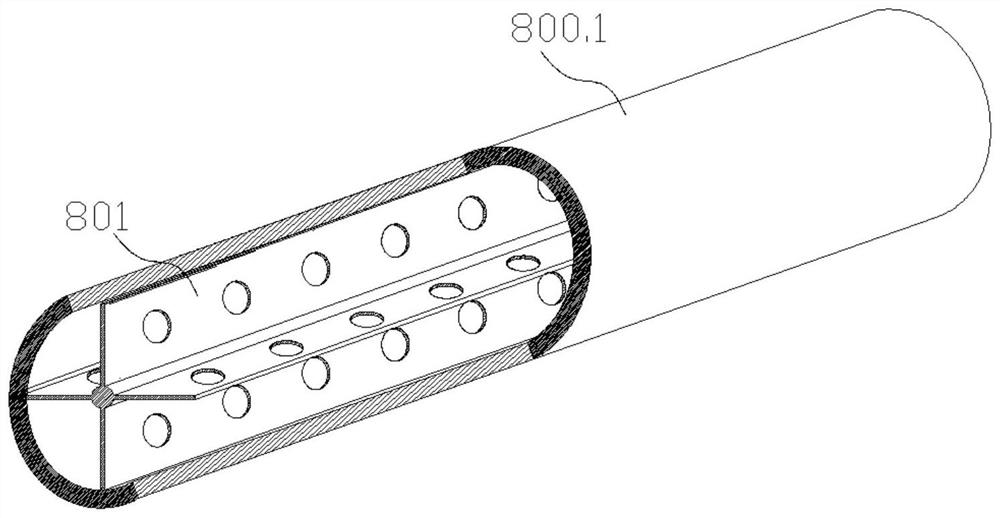

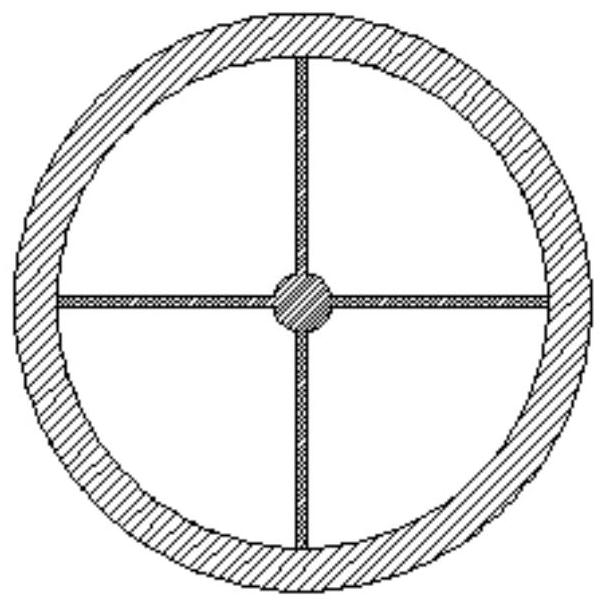

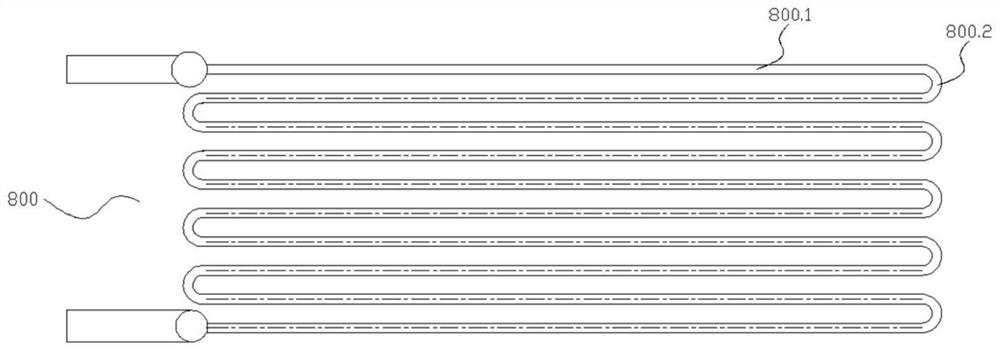

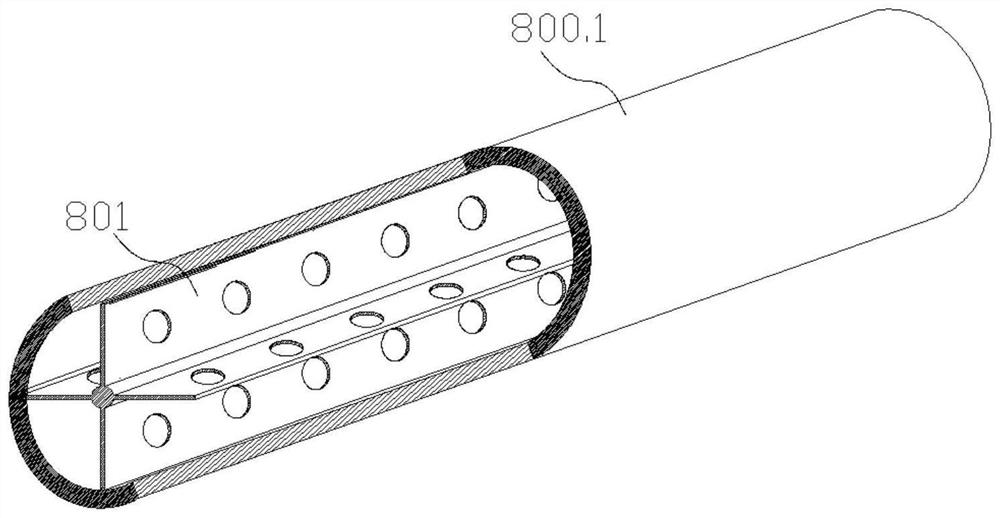

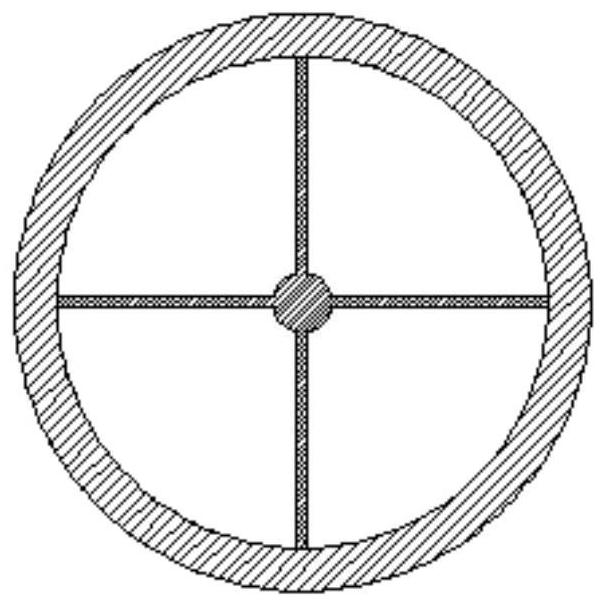

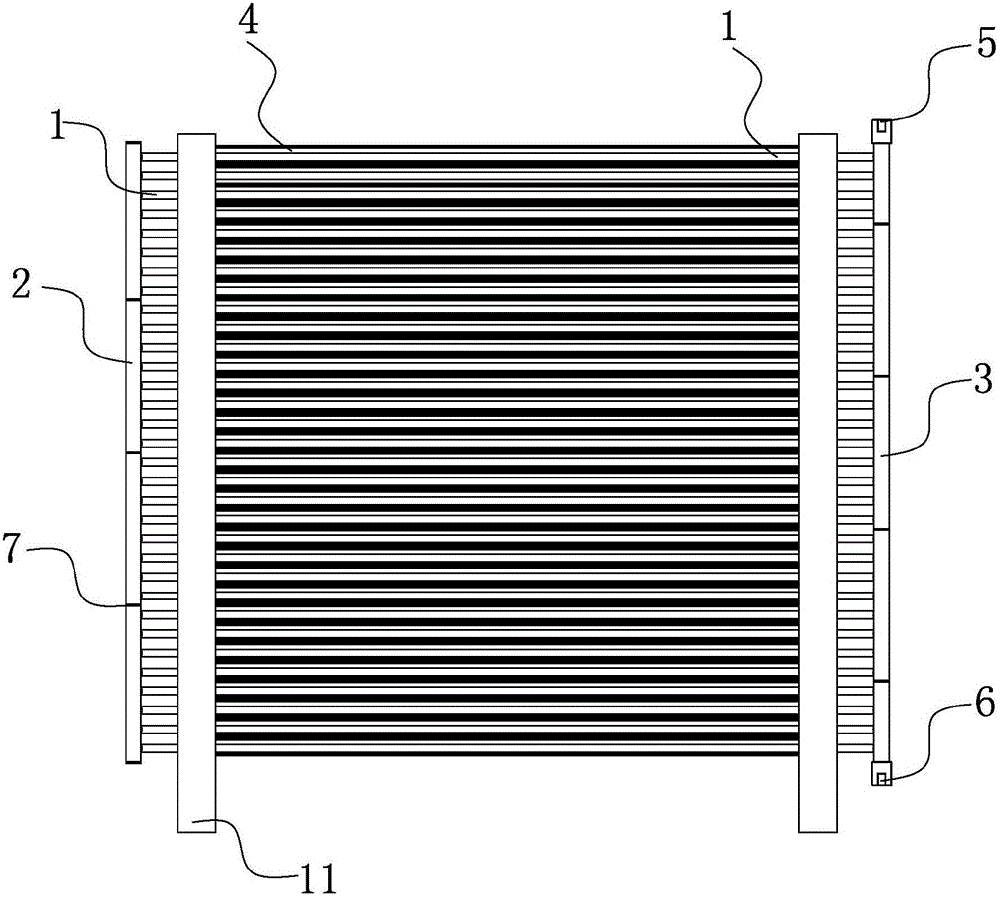

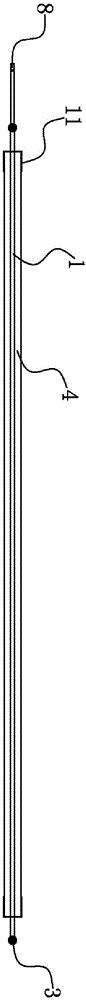

Heat exchange coil pipe with heat conduction section bar with auxiliary fins

PendingCN114353577AIncrease the heat exchange areaAdequate heat conductionTubular elementsStraight tubeMechanics

The heat exchange coil pipe comprises a heat exchange coil pipe main body, the heat exchange coil pipe main body comprises a straight pipe section and a bent pipe section, the straight pipe section of the heat exchange coil pipe main body is internally provided with the heat conduction profile with the auxiliary fins, and the bent pipe section of the heat exchange coil pipe main body is internally provided with the heat conduction profile with the auxiliary fins. The heat conduction profile with the auxiliary fins comprises a circular core rod arranged in the direction of the heat exchange coil body, main fins are arranged outside the core rod, and the auxiliary fins are arranged outside the main fins. Fluid in the heat exchange coil pipe with the heat conduction sectional material with the auxiliary fins can conduct heat to the heat exchange coil pipe body through the heat conduction sectional material arranged in the pipe with the good heat conduction performance, and therefore the heat exchange capacity and the heat exchange speed are greatly increased.

Owner:江苏金荣森制冷科技有限公司

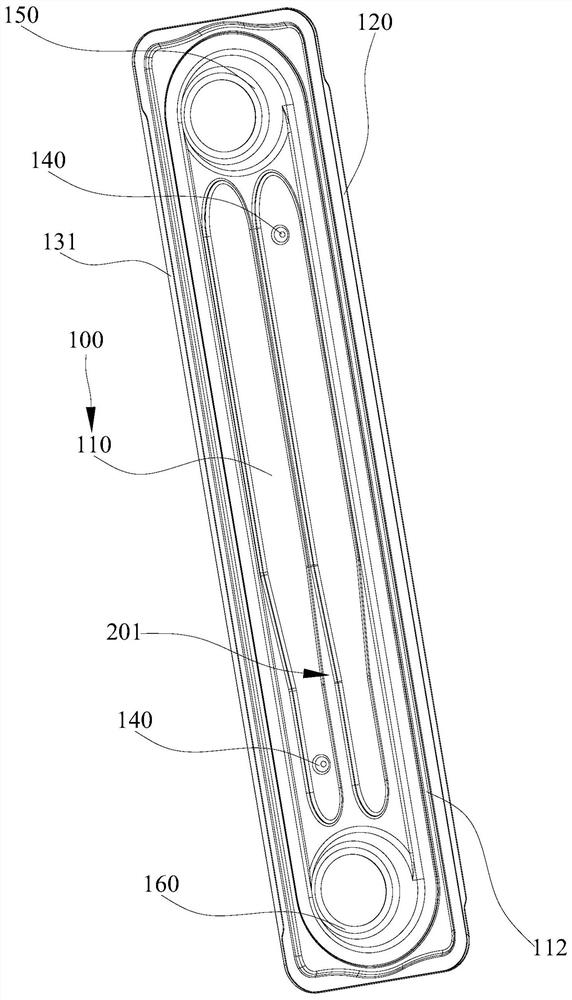

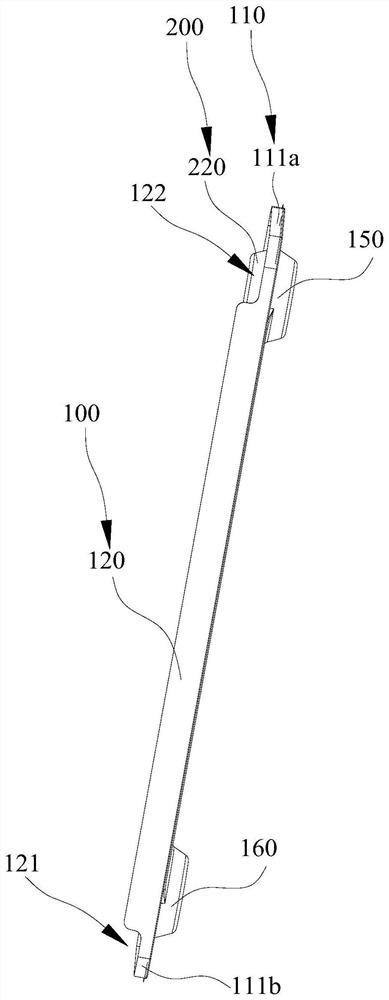

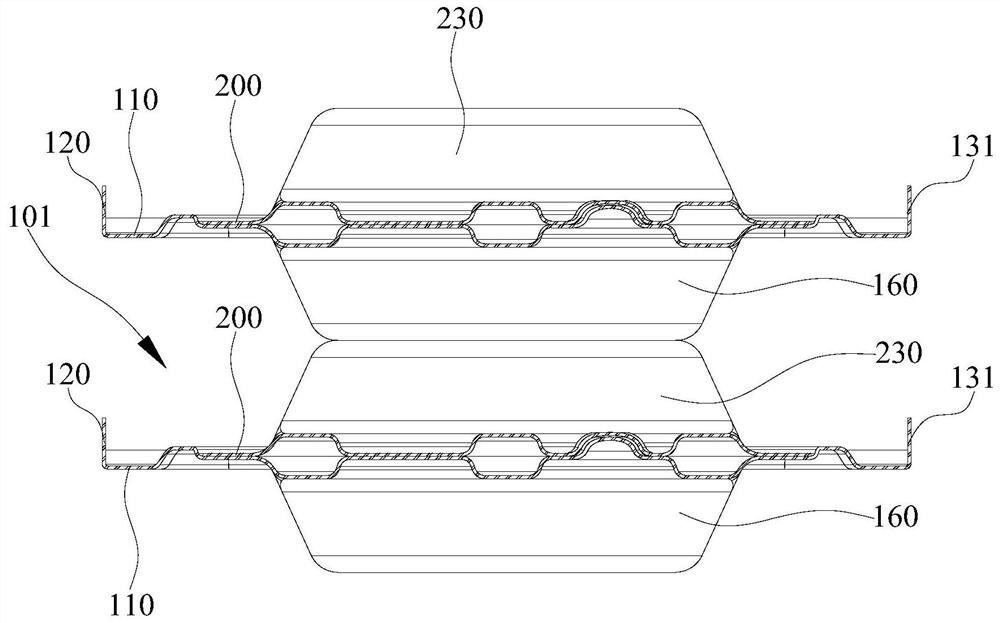

Quick-cooling device and refrigerator

ActiveCN113310260AGuaranteed to be fullImprove heat exchange efficiencyLighting and heating apparatusDomestic refrigeratorsThermodynamicsIcebox

The invention discloses a quick-cooling device and a refrigerator with the quick-cooling device. The quick-cooling device comprises a cooling assembly and a cavity provided with a liquid inlet and a liquid outlet used for accommodating cold storage liquid, a flow channel for the cold storage liquid to flow is arranged in the cavity, one end of the flow channel communicates with the liquid inlet of the cavity, and the other end of the flow channel communicates with the liquid outlet; and a cooling cavity used for accommodating beverages is formed in the cooling assembly, the liquid inlet is formed in the lower end of the cooling cavity, and the liquid outlet is formed in the higher end of the cooling cavity. The cavity is filled with the cold storage liquid from low to high, and the cavity surrounds the cooling cavity for accommodating the beverages, so that the heat exchange efficiency of the cold storage liquid and the beverage is improved; and the cold storage liquid flows in the continuously bent flow channel, the flowing state is kept, deposition is avoided, the heat exchange efficiency and speed can be improved, the beverages can be rapidly cooled, and consumed time is shortened.

Owner:HEFEI HUALING CO LTD +2

Air guide assembly of air conditioner and air conditioner

ActiveCN106123268BImprove comfortSpeed up the flowLighting and heating apparatusHeating and ventilation casings/coversEngineeringMechanical engineering

The invention discloses an air guide assembly of an air conditioner and the air conditioner. The air conditioner includes a casing, and the air guide assembly is arranged in the casing, and the air guide assembly includes: an air duct and a main air flow assembly. The air duct has an air outlet, and the air outlet has opposite upper side air outlet sides and lower side air outlet sides. The wall surfaces are respectively the first wind guiding surface, the second wind guiding surface and the third wind guiding surface, and the leading wind guiding element has a first position state, a second position state and a third position state. According to the air guide assembly of the air conditioner according to the embodiment of the present invention, by setting the main air part, when the air conditioner is in different working states, the main air part can be adjusted to the corresponding position and the airflow direction at the air outlet can be adjusted accordingly. Therefore, the flow velocity and the heat exchange velocity of the indoor air can be increased, and the air supply comfort of the air conditioner can be enhanced.

Owner:WUHAN REFRIGERATION EQUIP OF MIDEA GROUP +1

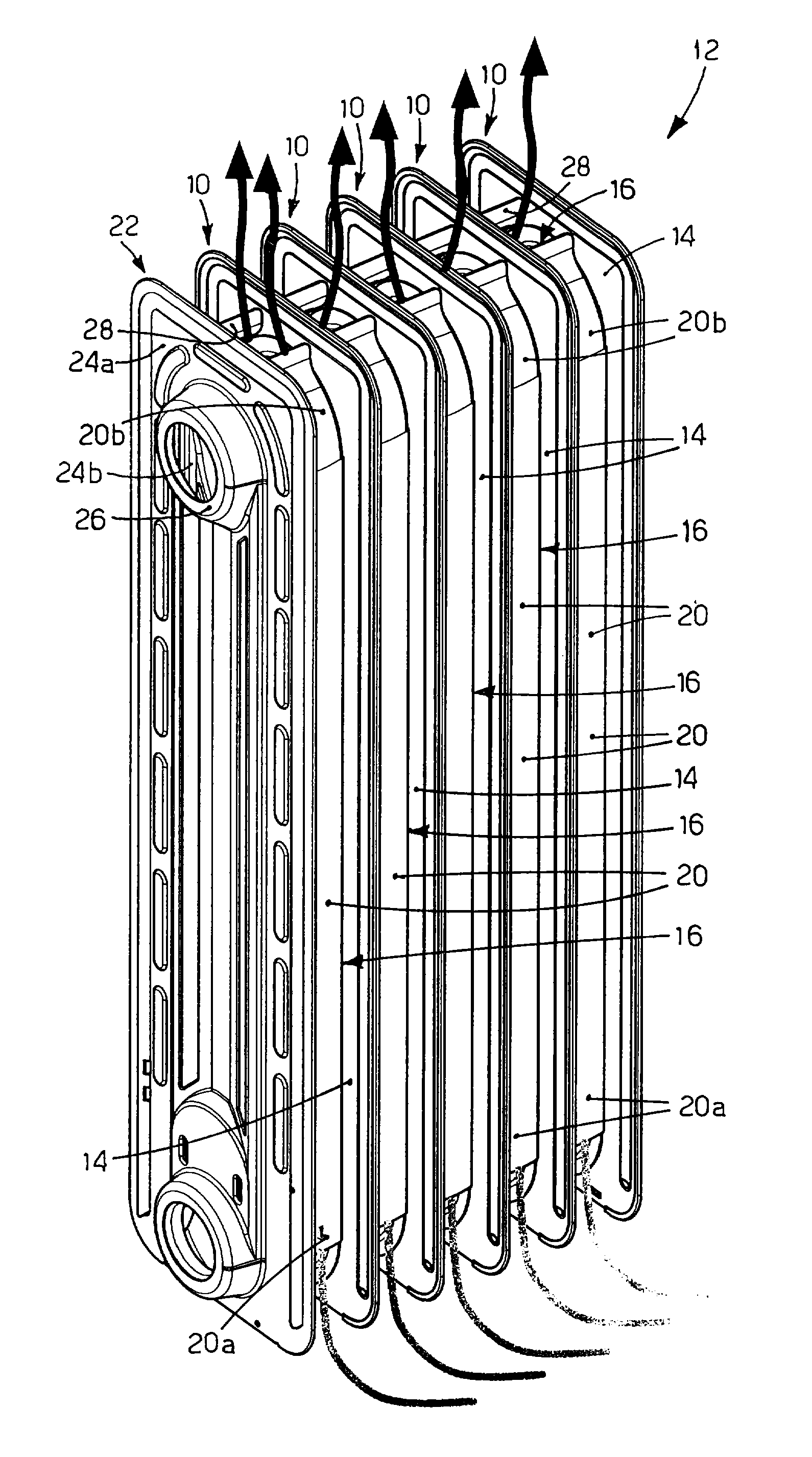

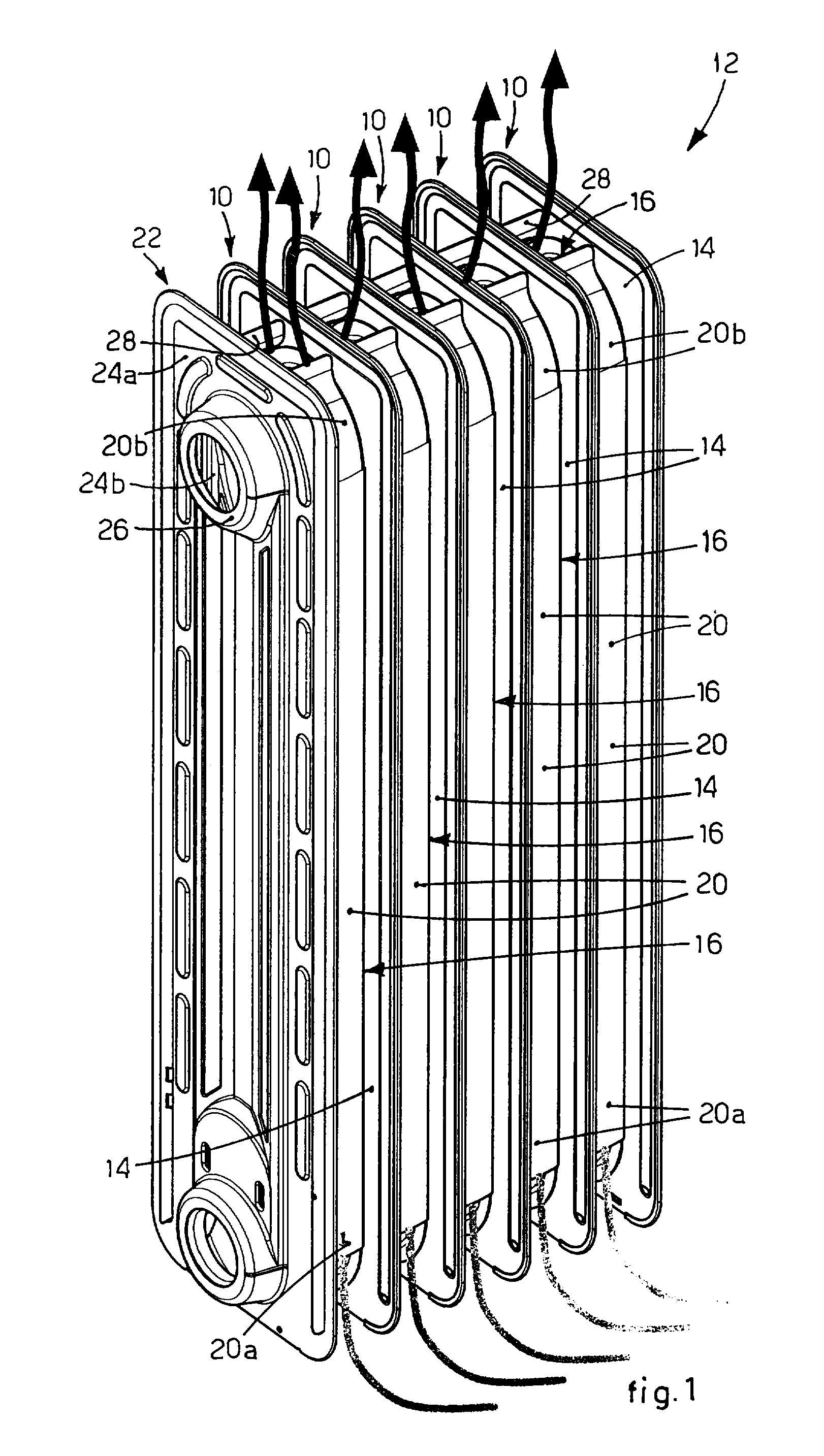

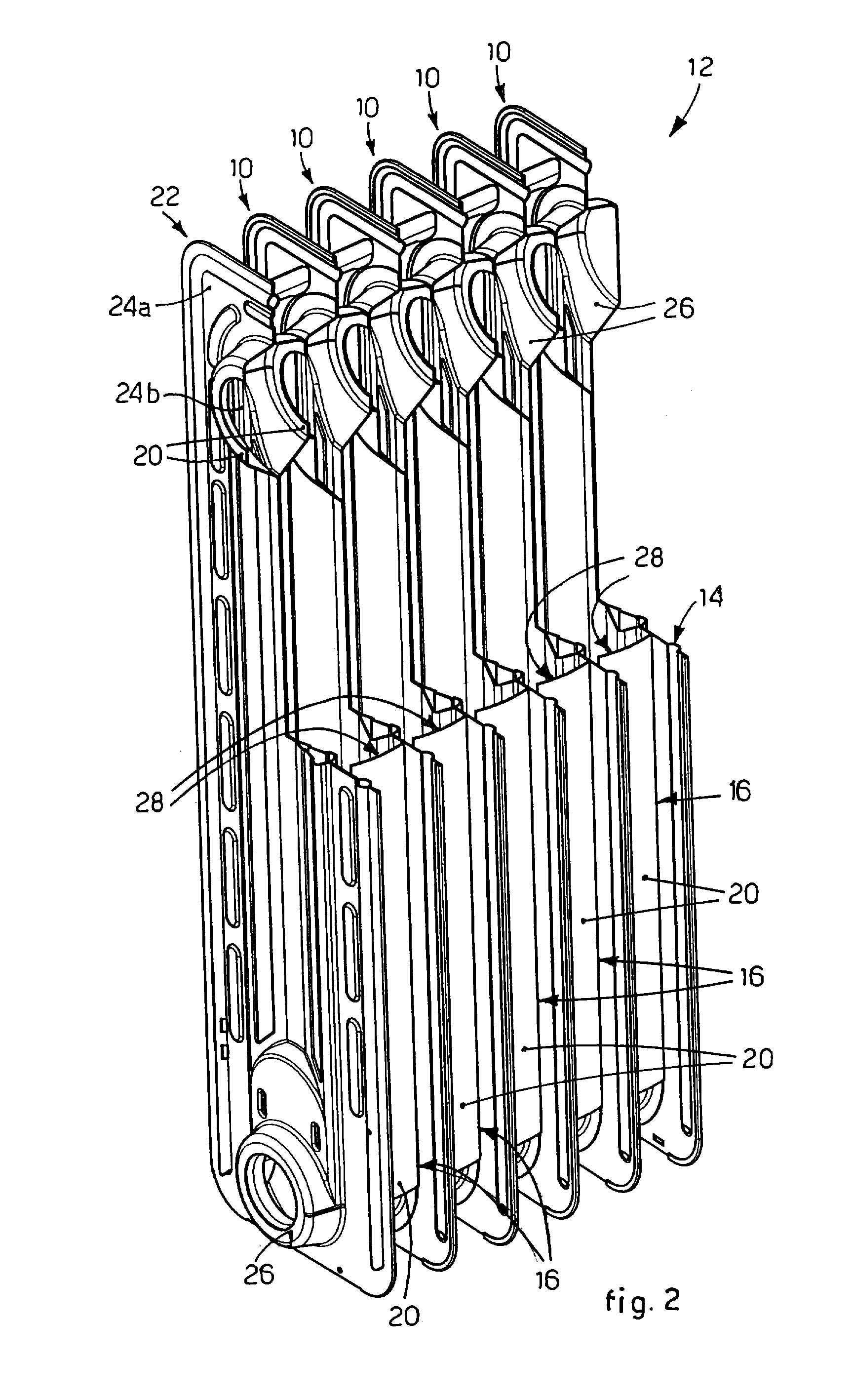

Radiant module for a heating device for rooms, and method to produce said radiant module

InactiveUS20100314459A1Increase heat exchange speedShorten the timeMetal-working apparatusAir heatersComputer moduleMethods of production

Owner:DE LONGHI SPA

Steam generators and ironing equipment

ActiveCN110553239BReduce moisture contentTake advantage ofSteam generation heating methodsHand ironWater storageThermodynamics

The invention discloses a steam generator and ironing equipment. Wherein, the steam generator comprises: a casing, a heating cavity is formed in the casing, the casing is further provided with a liquid inlet and an air outlet; and a heating element, the heating element is arranged in the heating cavity, the At least part of the liquid entered by the liquid inlet flows to the bottom of the heating element after being heated by the wall surface of the heating element. The technical solution of the present invention can reduce or avoid remaining water in the water storage tank, and at the same time improve the ironing effect.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG +1

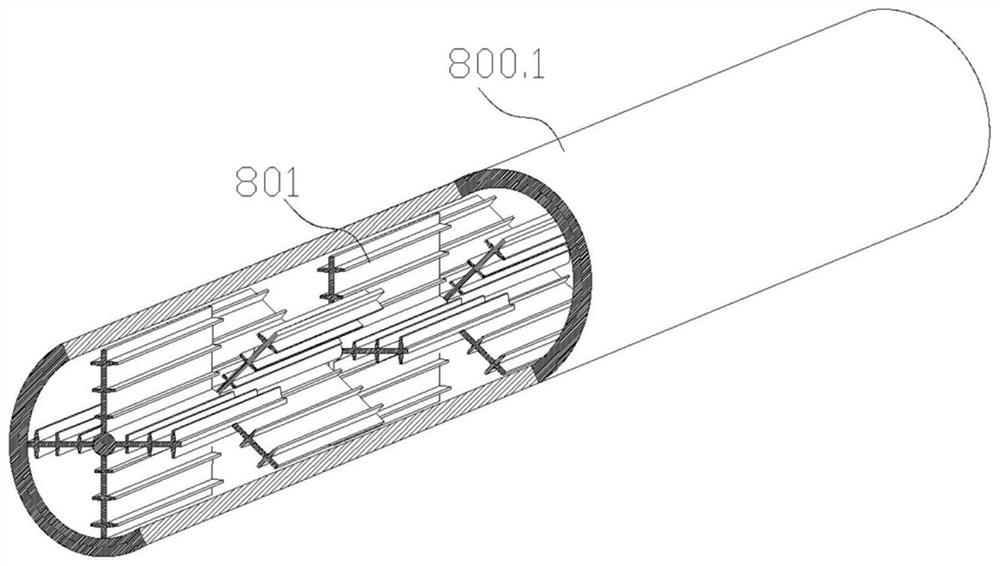

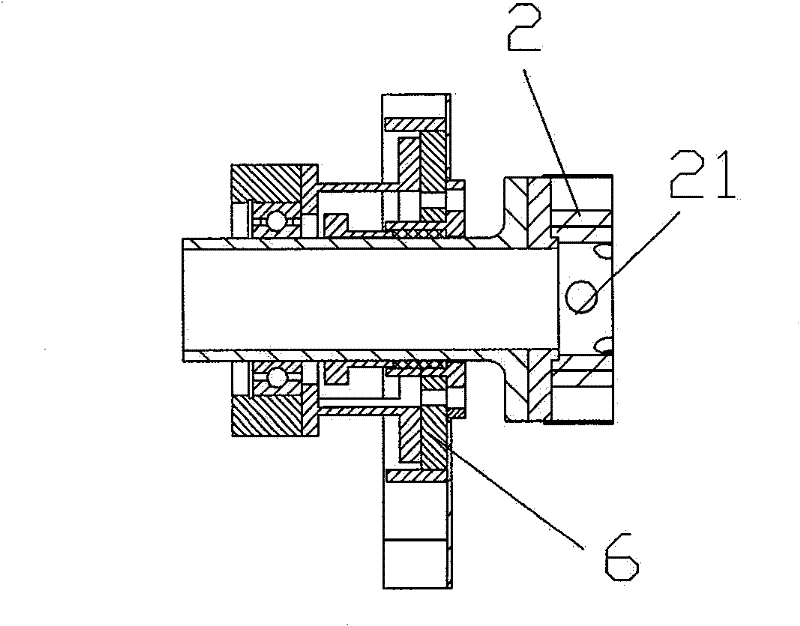

Twisting and jacking device

The torsion jacking and stretching device comprises a push rod transversely arranged leftwards, a transversely-arranged profile outer sleeve is arranged on the left side of the push rod, a profile cover die is arranged on the left side of the profile outer sleeve, and an electromagnetic brake is arranged outside the profile cover die; a profile gear cover die is arranged on the left side of the profile cover die, and a sleeve rotating seat is arranged on the left side of the profile cover die. A first fin set and a second fin set are arranged on a core rod of a heat conduction profile produced by the torsion jacking device in a staggered mode in the length direction of the core rod, so that fluid flowing from the front can be continuously divided, heat conduction of the fluid is more sufficient and even, the flow direction of the fluid in a pipe can be changed, and the heat conduction efficiency is improved. The heat exchange coil pipe is more beneficial to breaking and hindering heat conduction to the inner pipe wall mucous membrane, so that fluid in the heat exchange coil pipe can conduct heat to the heat exchange coil pipe body through the heat conduction profile arranged in the pipe with excellent heat conduction, and the heat exchange amount and the heat exchange speed are greatly increased.

Owner:江苏金荣森制冷科技有限公司

A steam desuperheating system

ActiveCN104501132BVaporization speed is fastWell mixedSuperheating controlEngineeringSteam temperature

Owner:HANGZHOU WORLDWISE VALVE

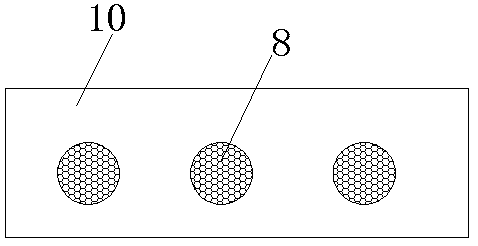

Grinding material forming mold with rapid heat dissipation function

PendingCN108381737AIncrease heat exchange speedSimple structureMould auxillary partsEngineeringCooling speed

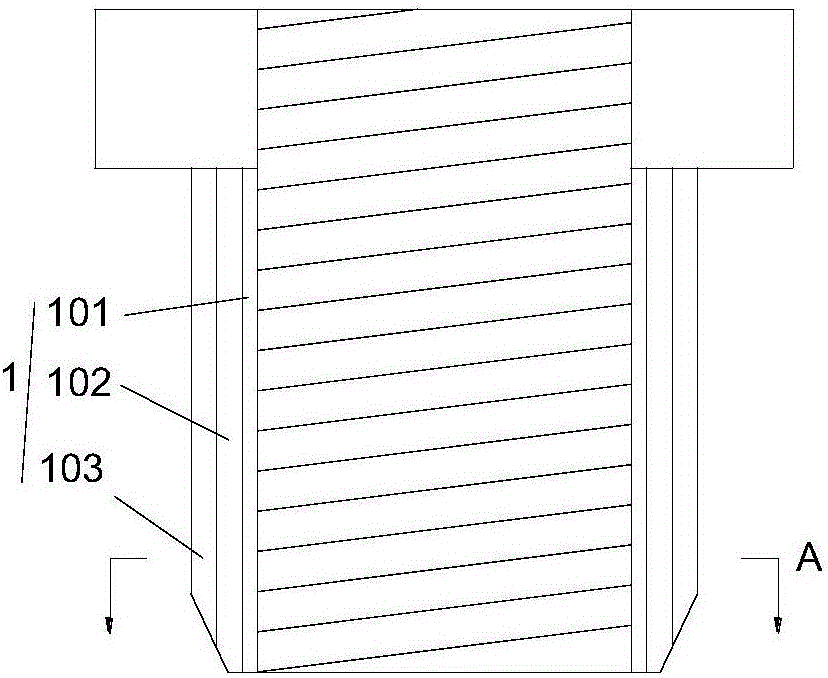

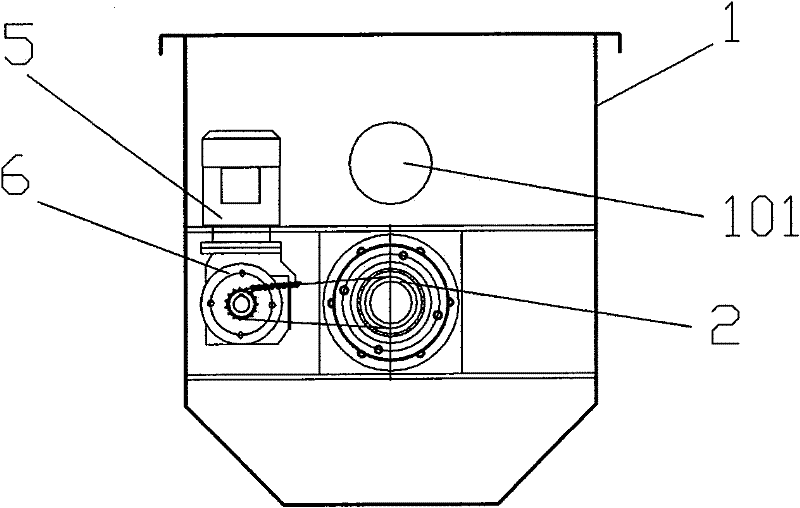

The invention discloses a grinding material forming mold with the rapid heat dissipation function. The forming mold comprises an upper mold plate and a lower mold plate, an upper circulation groove ofan inverted concave structure is formed in the upper mold plate, a vertical water inlet is formed in the outer wall of the top end of the upper mold plate, the interior of the water inlet communicates with the interior of the upper circulation groove, groove openings in the two ends of the upper circulation groove are welded with vertical connecting casing pipes correspondingly, heat dissipationholes which are distributed at equal distance are formed in the outer wall of one side of the upper mold plate, the middle of the outer wall of the bottom end of the upper mold plate is sunken inwardsto form an upper mold groove, and a lower circulation groove of a concave structure is formed in the lower mold plate. The forming mold is simple in structure, high in heat dissipation speed, and beneficial to product rapid forming, the cooling speed of the mold is accelerated, the upper circulation groove, the lower circulation groove, an air inlet groove, an air outlet groove and the heat dissipation holes are arranged, the whole weight of the upper mold plate and the lower mold plate is reduced, and the mold can be more easily carried.

Owner:FORTURE TOOLS CO LTD

Energy-saving waste liquid heat exchange treatment device

InactiveCN101876514BSluggish outflow velocityPrevent scalingStationary conduit assembliesHeat transfer modificationLiquid wasteWastewater

Owner:浙江永洋复合材料科技有限公司

Production method of torsion jacking device

The invention relates to a production method of a torsion jacking device. The production method comprises the following steps: step 1, feeding; step 2, carrying out first-time top extension; step 3, cutting; 4, second-time jacking and stretching are carried out; step 5, twisting; and the step 2 to the step 5 are repeated, and cutting of gaps of the multiple sections of fin sets and twisting between the adjacent fin sets are completed. The first fin group and the second fin group are arranged on the core rod of the heat conduction profile produced by the production method of the torsion jacking device in the length direction in a staggered manner, so that fluid flowing from the front can be continuously divided, the heat conduction of the fluid is more sufficient and uniform, the flow direction of the fluid in a pipe can be changed, and the heat conduction efficiency is improved. The heat exchange coil pipe is more beneficial to breaking and hindering heat conduction to the inner pipe wall mucous membrane, so that fluid in the heat exchange coil pipe can conduct heat to the heat exchange coil pipe body through the heat conduction profile arranged in the pipe with excellent heat conduction, and the heat exchange amount and the heat exchange speed are greatly increased.

Owner:江苏金荣森制冷科技有限公司

A built-in air conditioner

ActiveCN105371458BReduce thicknessLower lifting heightLighting and heating apparatusAir conditioning systemsAir conditioningAerospace engineering

The embodiment of the invention discloses an embedded air conditioner. The embedded air conditioner comprises an air port body, a complete machine and an air feeding pipeline. The air port body is provided with an air feeding hole exhausting air to the indoor space. The whole machine is used for generating air adjusting air flow, and the air port body and the complete machine are used for being fixed to different positions respectively. One end of the air feeding pipeline is communicated with the air feeding hole of the complete machine, and the other end of the air feeding pipeline is communicated with an air inlet of the air port body. According to the embedded air conditioner, the air port body and the complete machine are separated, the thickness of the embedded air conditioner is reduced, the hoisting height of a user is reduced, and therefore the height of a suspended ceiling is reduced. According to the embedded air conditioner, the air port body is installed at any position of a room, the air port body, the complete machine and the air feeding pipeline can be installed as a whole in a hoisted mode at the same time, and the embedded air conditioner has the advantages of the air port installing position of a courtyard machine and also has the advantage that an air duct machine can be hoisted as a whole. According to the embedded air conditioner, air feeding position is moved forwards, heat exchange speed is increased, and the comfort degree is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Production method of automatic forming device for forming, twisting, jacking and stretching

According to the production method of the automatic forming device for forming, twisting and jacking, a full-length profile moves to the left end from the right end of the forming device, when the full-length profile passes through a rolling wheel set, a main fin is rolled into a special-shaped structure by the rolling wheel set in a rolling gap, the full-length profile continues to move leftwards, and the cutting and twisting steps are repeated; and after blanking, spot welding is carried out on the heat conduction profile of the special-shaped fin and the full-length casing pipe to form a straight pipe section after cutting and twisting of the whole full-length profile are completed and the full-length profile enters the full-length casing pipe. The first fin group and the second fin group are arranged on the core rod of the heat-conducting profile produced by the production method of the automatic forming device for forming, twisting, jacking and stretching in the length direction of the core rod in a staggered manner, so that fluid flowing from the front can be continuously segmented, and the heat exchange capacity and the heat exchange speed are greatly increased.

Owner:江苏金荣森制冷科技有限公司

Aluminum finned type heat exchanger

ActiveCN105928389AEnhanced convectionImprove ventilationStationary conduit assembliesLaminated elementsEngineeringHeat exchanger

The invention provides an aluminum finned type heat exchanger. The aluminum finned type heat exchanger comprises a plurality of heat radiating and flow guiding pipes arranged at intervals, a first flow converging pipe and a second flow converging pipe, wherein aluminum fins are separately arranged on the outer surfaces of the heat radiating and flow guiding pipes, and space settings are kept between the aluminum fins on the heat radiating and flow guiding pipes arranged at intervals; one ends of the heat radiating and flow guiding pipes separately communicate with an inner cavity of the first flow converging pipe, and the other ends of the heat radiating and flow guiding pipes separately communicate with an inner cavity of the second flow converging pipe; and the two ends of the first flow converging pipe and the second flow converging pipe are separately hermetically arranged, the middle parts of the first flow converging pipe and the second flow converging pipe are all piecewise isolated to block flow, and liquid inlet ends and / or liquid outlet ends are arranged on the first flow converging pipe or the second flow converging pipe. The aluminum finned type heat exchanger has the advantages that through arranging the heat radiating and flow guiding pipes, the first flow converging pipe and the second flow converging pipe, arranging the aluminum fins on the outer surfaces of the heat radiating and flow guiding pipes, and piecewise isolating the middle parts of the first flow converging pipe and the second flow converging pipe to block flow, the heat radiating path is prolonged, the heat radiating area is increased, and the heat exchange quantity and the heat exchange speed are comprehensively increased.

Owner:宁波长发电器科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com