Rivet pressing nut used for installing heat sink

A technology of pressure riveting nuts and heat sinks, which is applied in the direction of nuts, threaded fasteners, connecting components, etc., which can solve the problems of bolts losing their locking function, bolts not connecting with nuts, and thread teeth being damaged, so as to improve the heat dissipation effect, The effect of increasing the contact area and increasing the heat exchange rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, specific embodiments will be described in detail below in conjunction with the accompanying drawings.

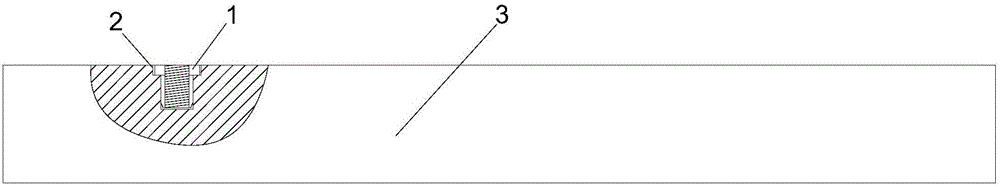

[0022] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the present invention, including a nut body 1 and a plate 3 with a riveting hole 2 .

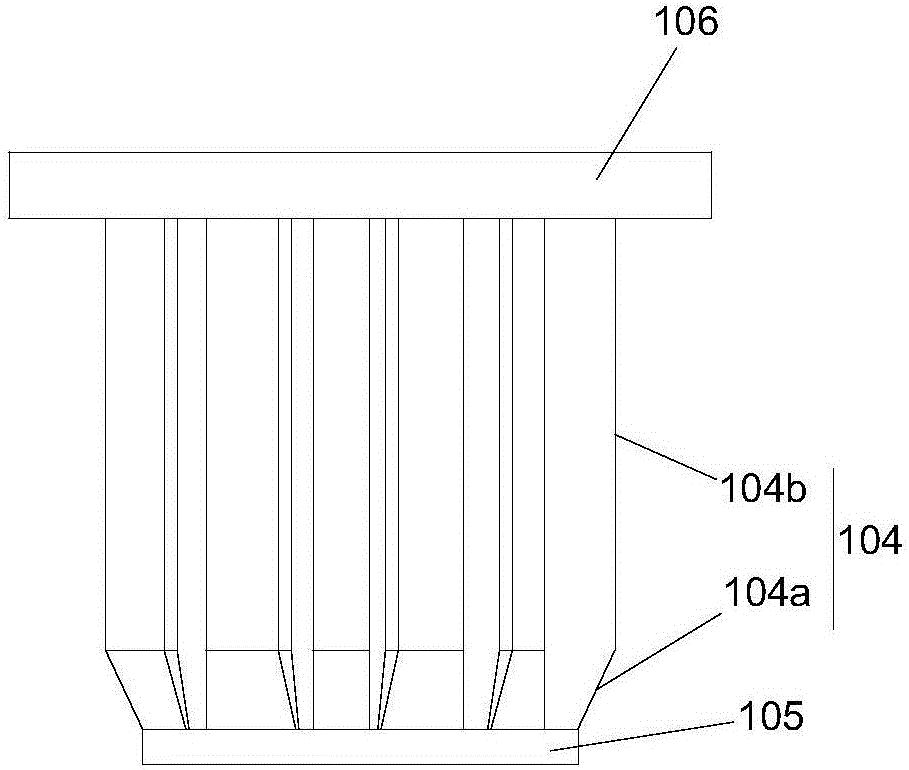

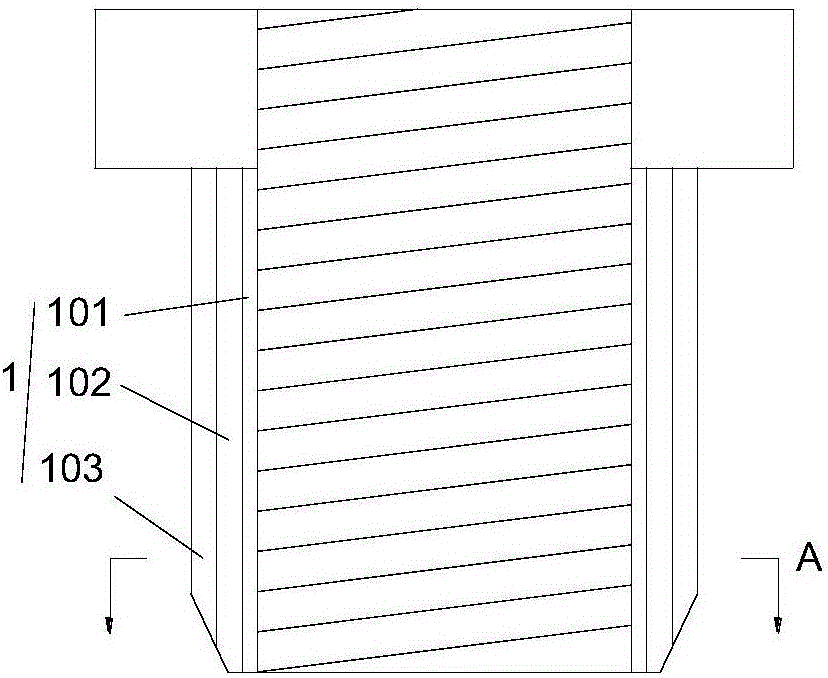

[0023] Such as Figure 2-3 as shown, figure 2 It is the front view of the nut body proposed by the present invention, image 3 for figure 2 sectional view of Figure 4 for image 3 The A-direction sectional view in. The nut body 1 sequentially includes a thread layer 101 , a body layer 102 and a riveting layer 103 from inside to outside. The outer periphery of the riveting layer 103 is provided with a plurality of crests 104 , and the plurality of crests 104 are evenly distributed on the outer periphery of the riveting layer 103 . During specific implementation, the thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com