Production method of heat exchange coil pipe with heat conduction profile with auxiliary fins

A technology for a heat exchange coil and a production method, applied in the field of heat exchange coils, can solve the problems of hindering the heat transfer of fluid heat to the heat exchange coil, reducing the heat exchange between the fluid and the heat exchange coil, etc. The speed of heat exchange, the increase of heat exchange area, and the effect of sufficient heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

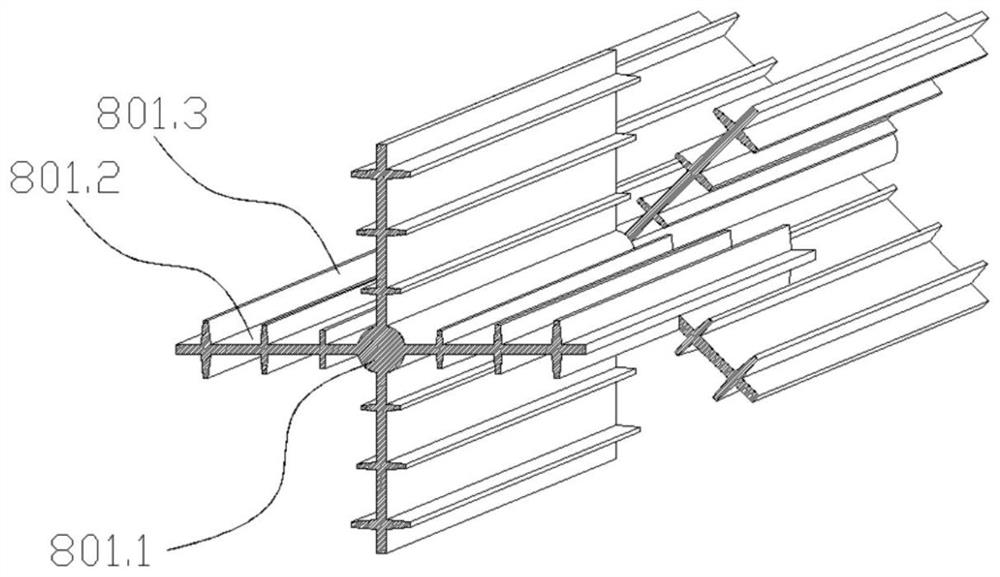

[0051] Embodiment 1, Figure 4 and Figure 5 There are two main fins 801.2 of the fin group on the heat conduction profile 801 with auxiliary fins, and three auxiliary fins on each main fin 801.2;

Embodiment 2

[0052] Embodiment 2, Figure 6 and Figure 7 There are four main fins 801.2 in the fin group on the heat conduction profile 801 with secondary fins, and there are five secondary fins on each main fin 801.2.

Embodiment 3

[0053] Embodiment 3, Figure 14 There are four main fins 801.2 of the fin group on the heat conduction profile 801 with auxiliary fins, and three auxiliary fins on each main fin 801.2, and there are also three main fins 801.2 on each fin group A plurality of holes are provided, preferably three holes.

[0054] Heat exchange coils with heat-conducting profiles with secondary fins are produced as follows:

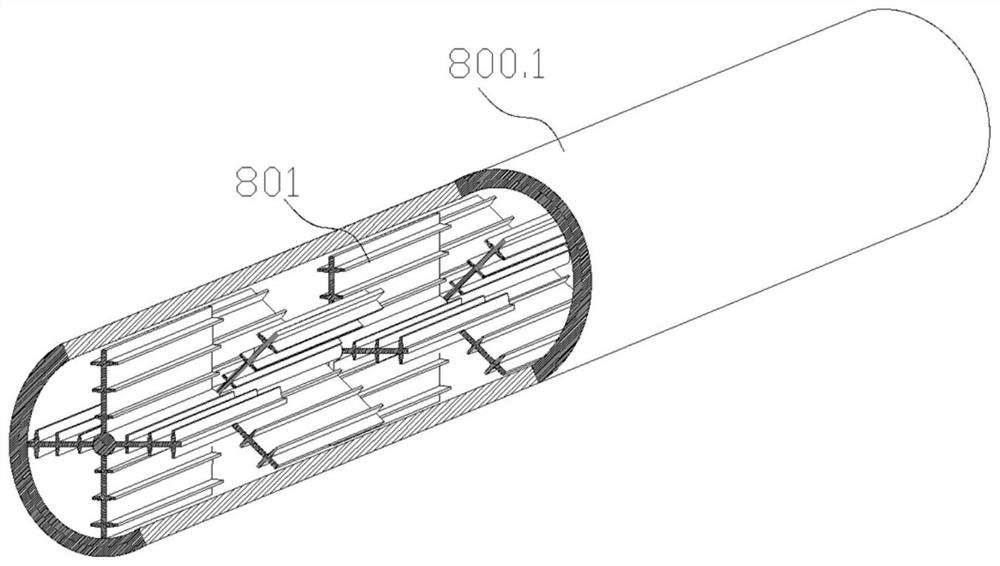

[0055] Step 1. Firstly, extrude and form a long section bar 910 that matches the cross-sectional shape of the fin group by using a mold, and then produce a full-length casing 909 with the same diameter as the main body of the heat exchange coil;

[0056] Step 2. Twisting the full-length profile into a heat-conducting profile with secondary fins and installing it in the full-length casing to form a straight pipe section;

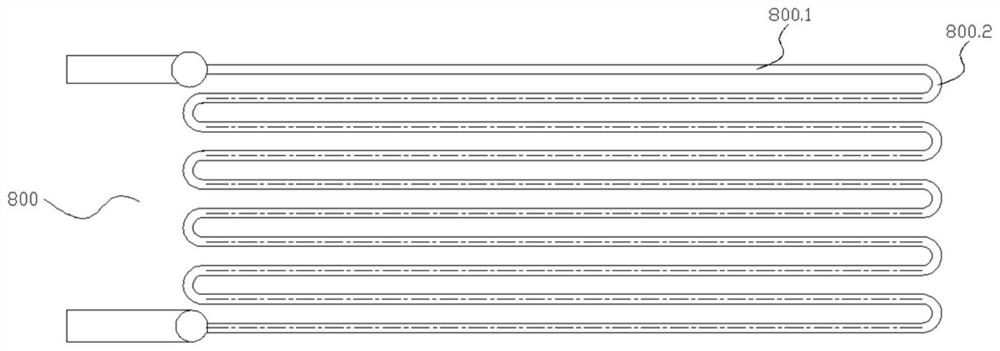

[0057] Step 3, connecting the straight pipe section and the bent pipe section to form a heat exchange coil with a heat-conducting profile with secondary f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com