Patents

Literature

54results about How to "Adequate heat conduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

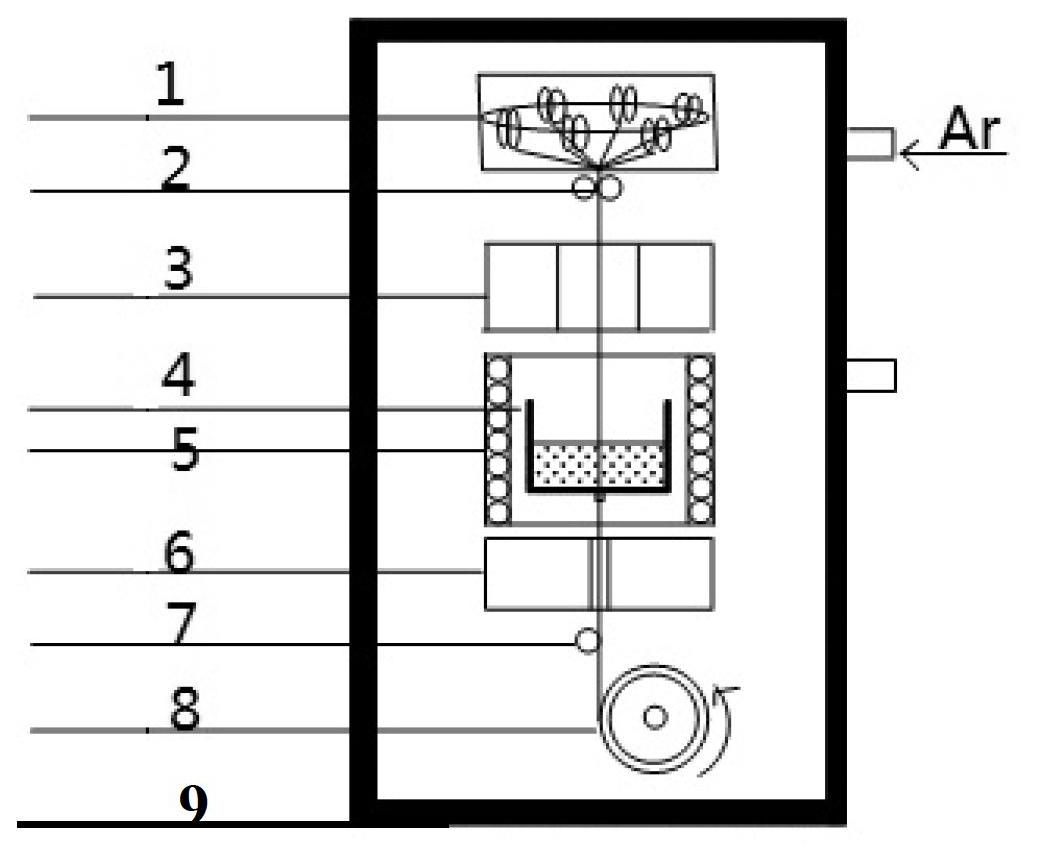

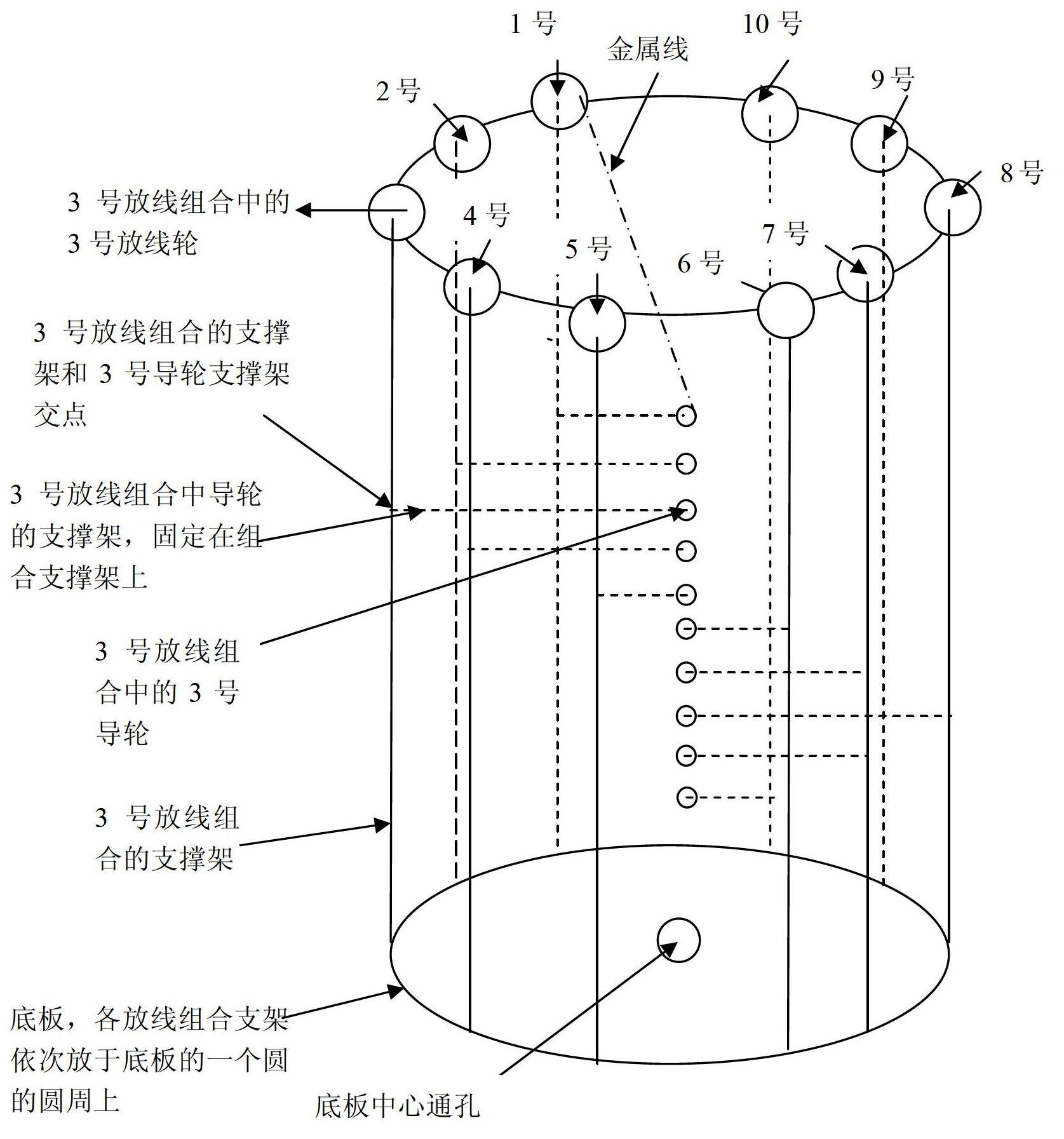

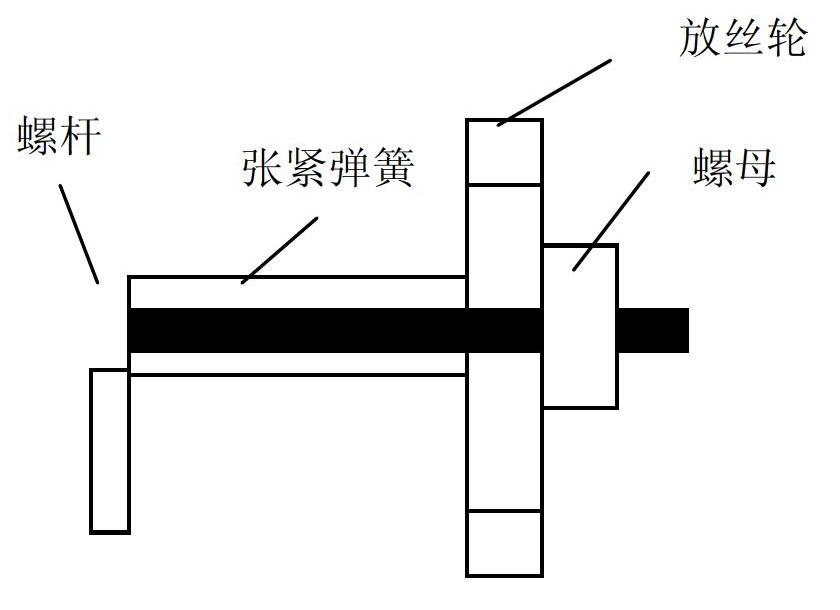

Continuous preparation equipment and process for fiber-reinforced metal glass composite filament

The invention provides continuous preparation equipment and a process for a fiber-reinforced metal glass composite filament, and belongs to the field of amorphous alloy (metallic glass). The continuous preparation equipment is composed of a vacuum system, a pay-off wheel set, a heating system, a cooling device and a dragging mechanism. A heating carrier is placed in the high vacuum system so as to obtain a composite interface with good bonding property, no blends and complete cleaning performance. By adopting the method for paying off, a double-guide-wheel device is used, the two guide wheels are tangent in the two guide wheels, and the lower guide wheel is connected with a motor so as to directly wind the prepared filament, thus realizing the continuous and large-scale production and achieving the purposes of short procedures and energy conservation and consumption reduction. The continuous preparation equipment and process are applied to preparation of armour piercing materials and other uses.

Owner:UNIV OF SCI & TECH BEIJING

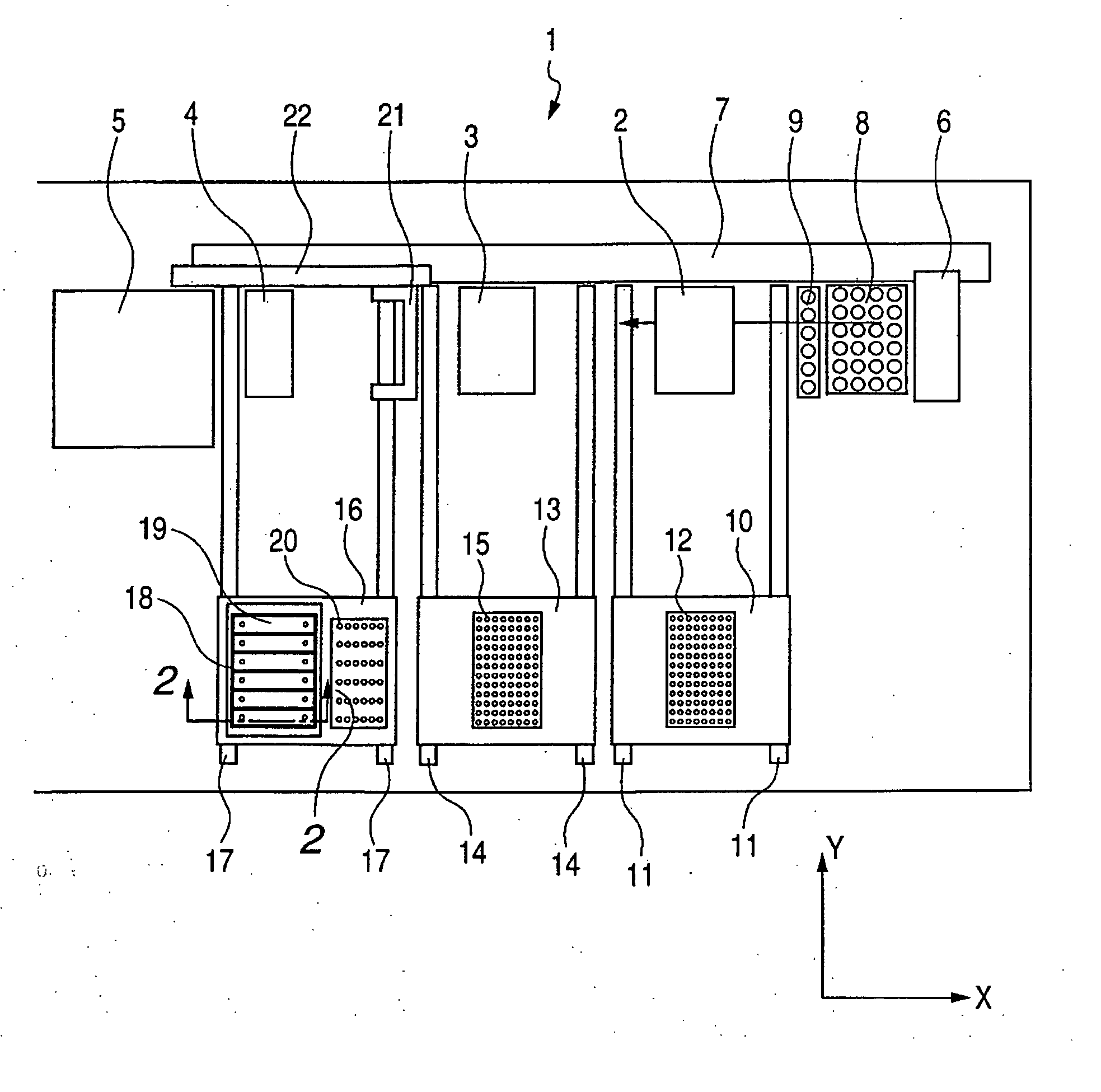

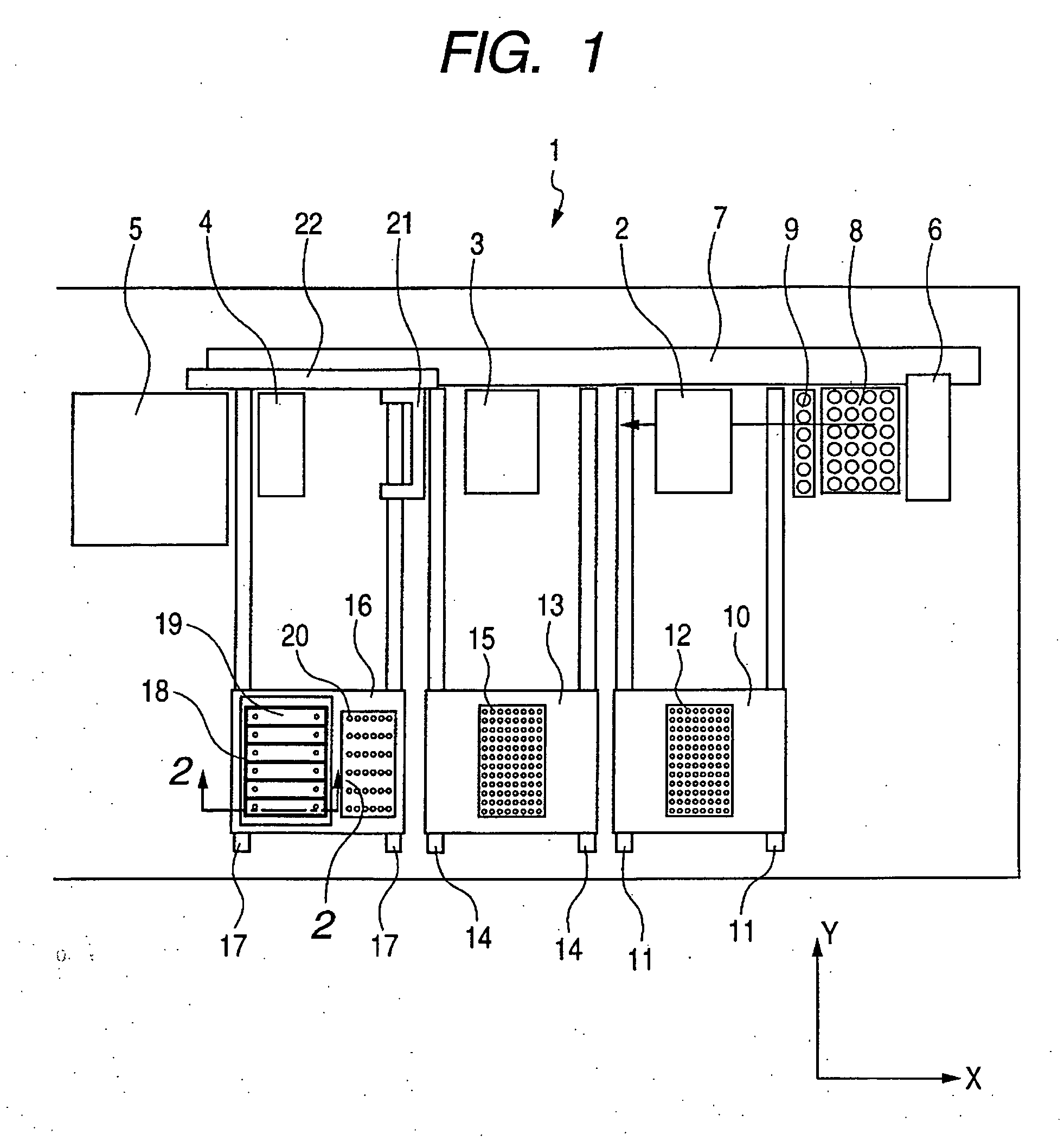

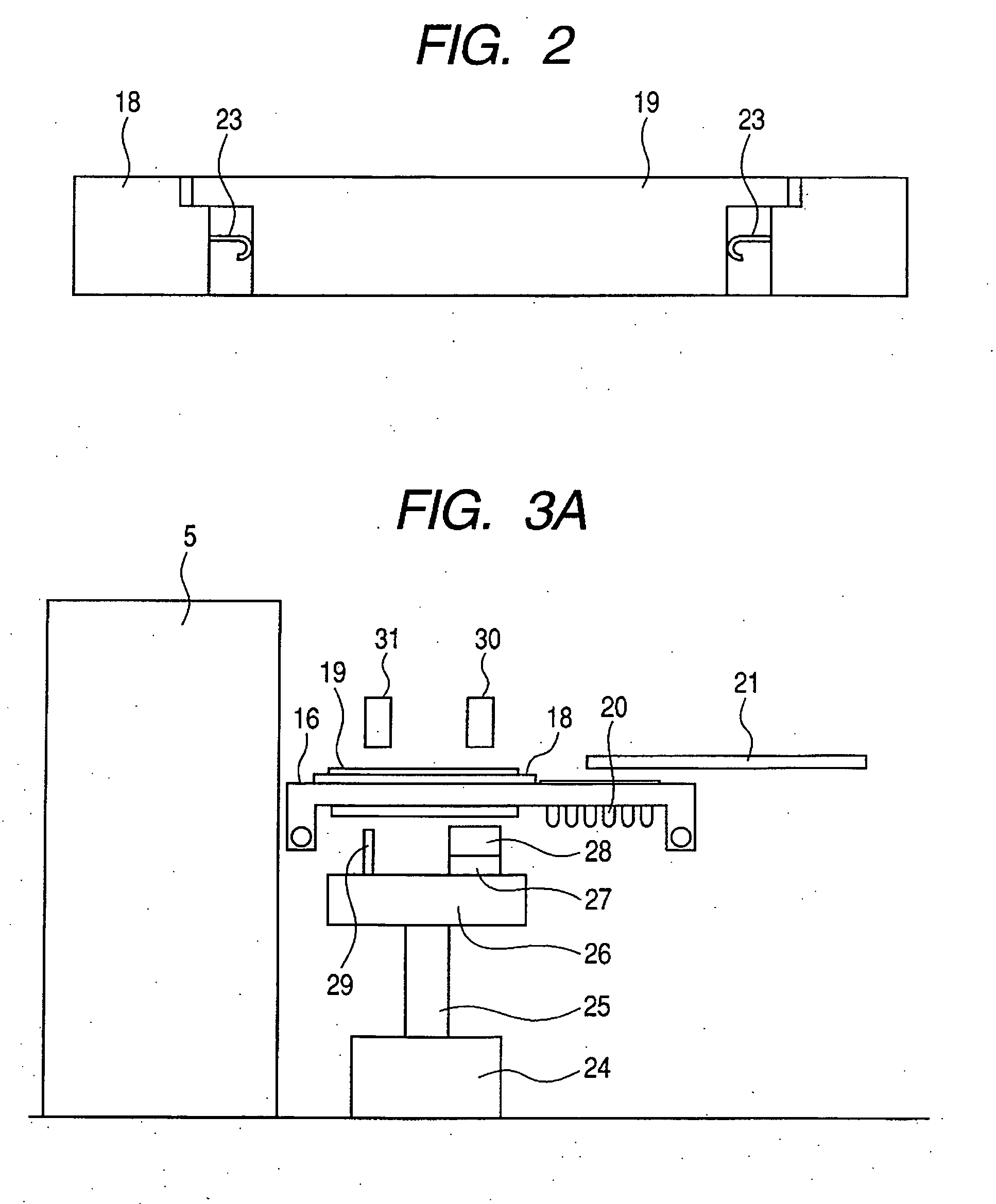

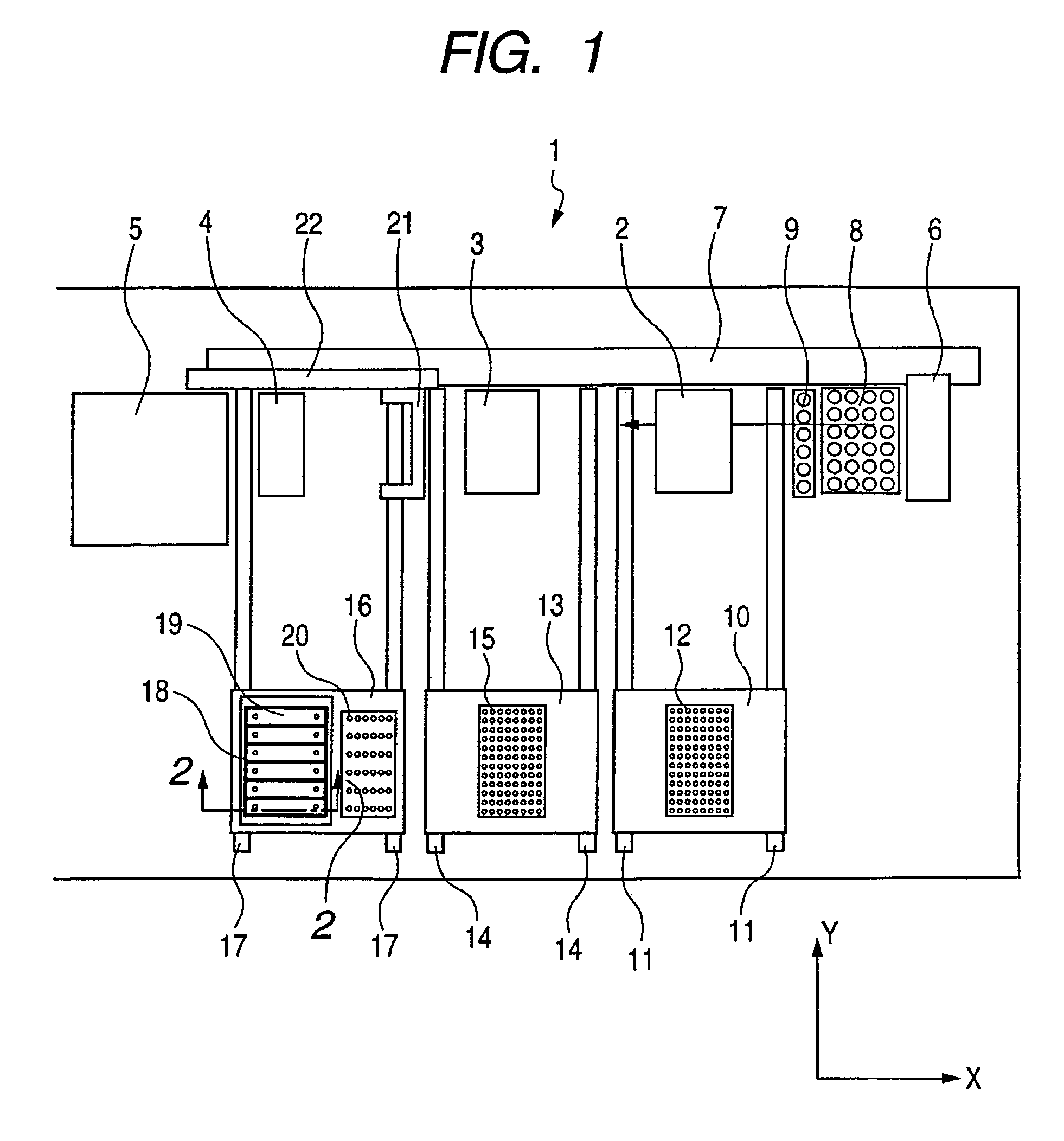

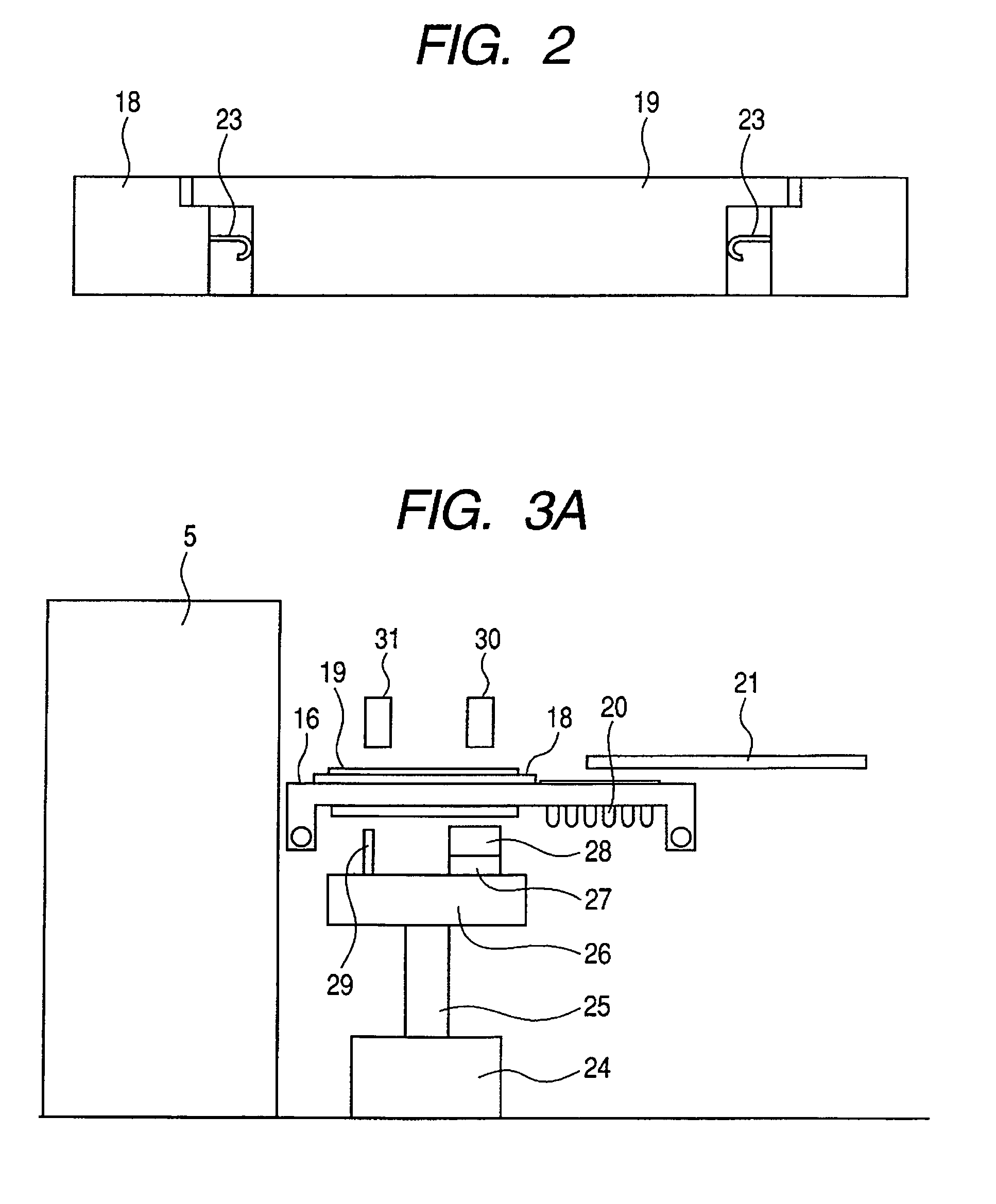

Temperature controller for structure

InactiveUS20070077647A1Keep postureUniform applicationBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlElectrical and Electronics engineering

Owner:CANON KK

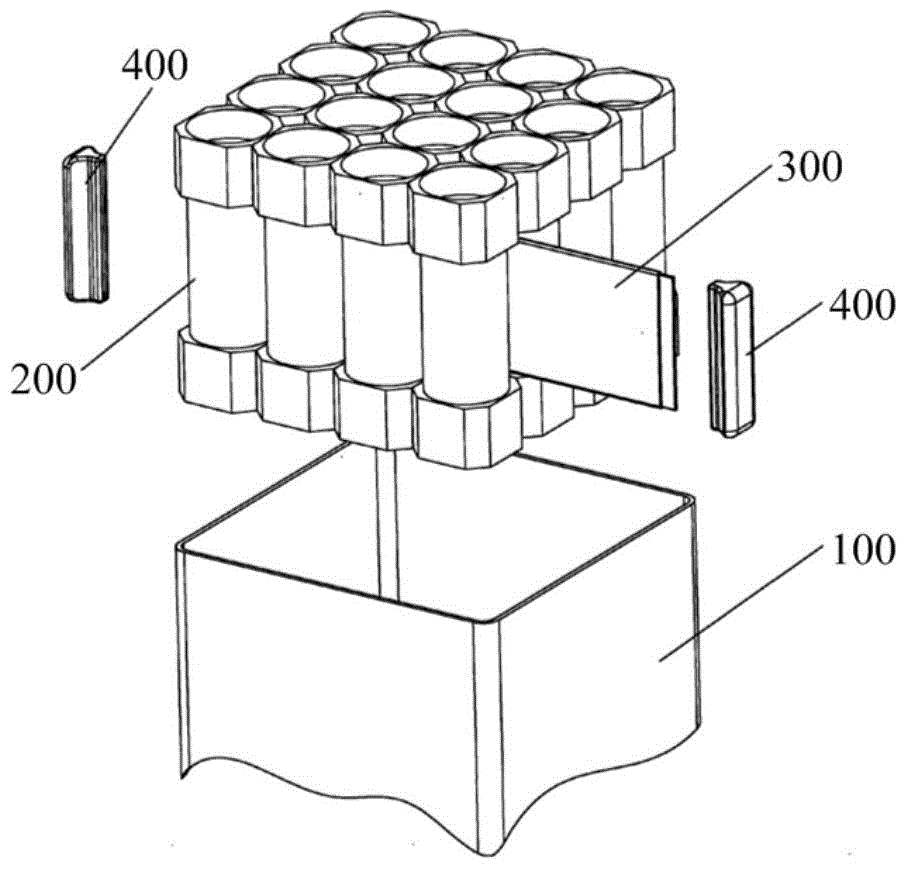

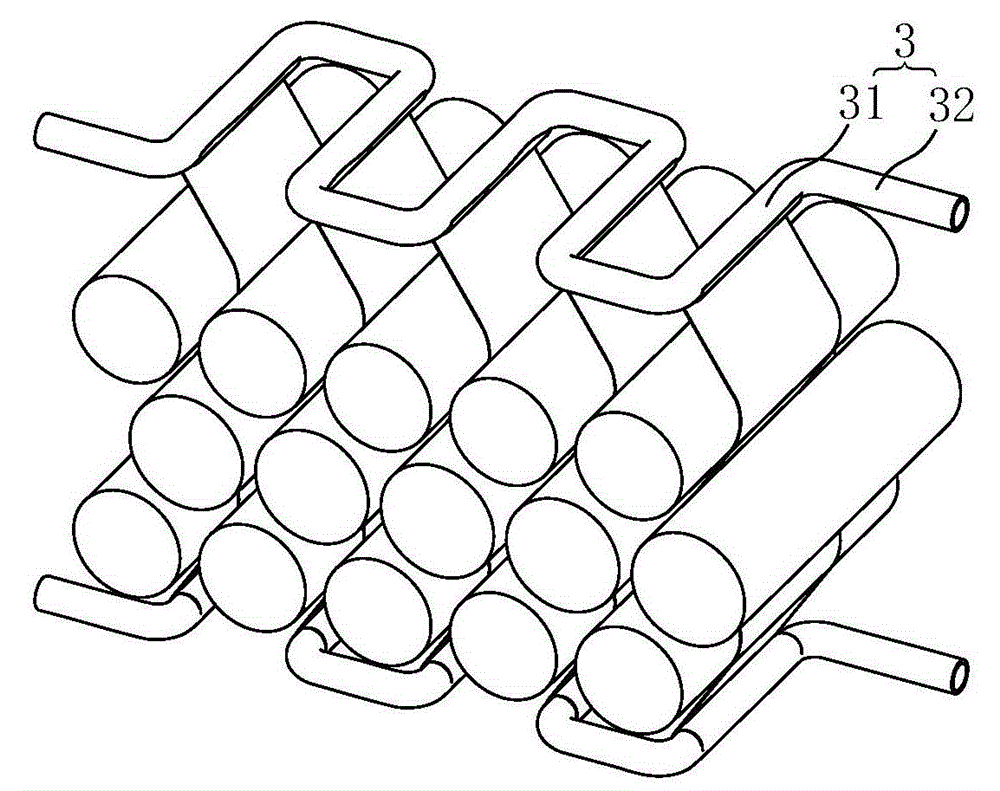

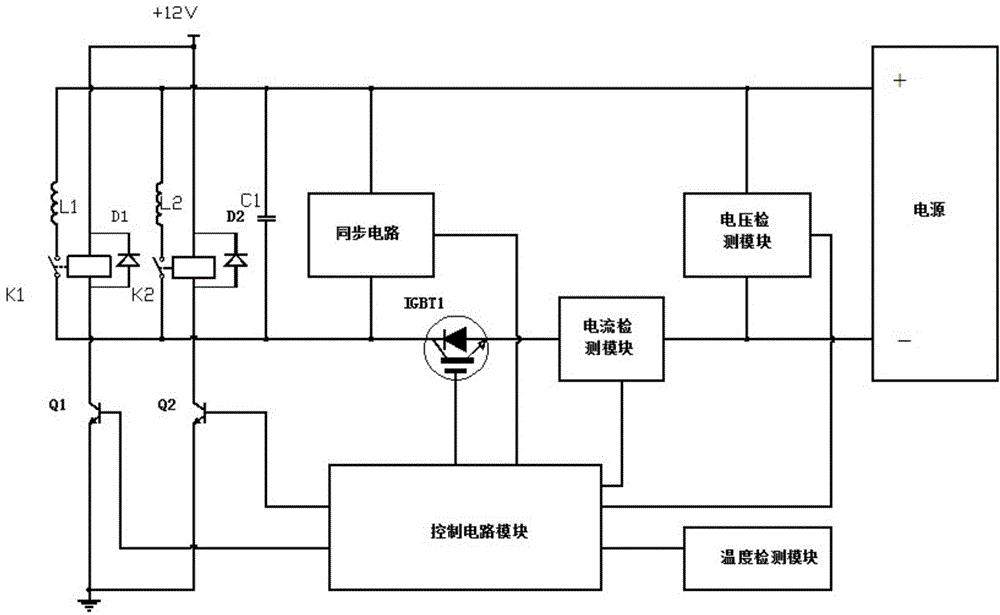

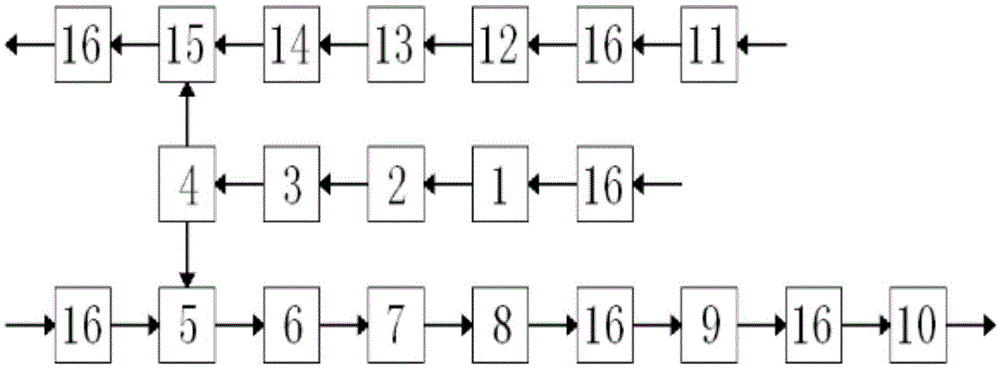

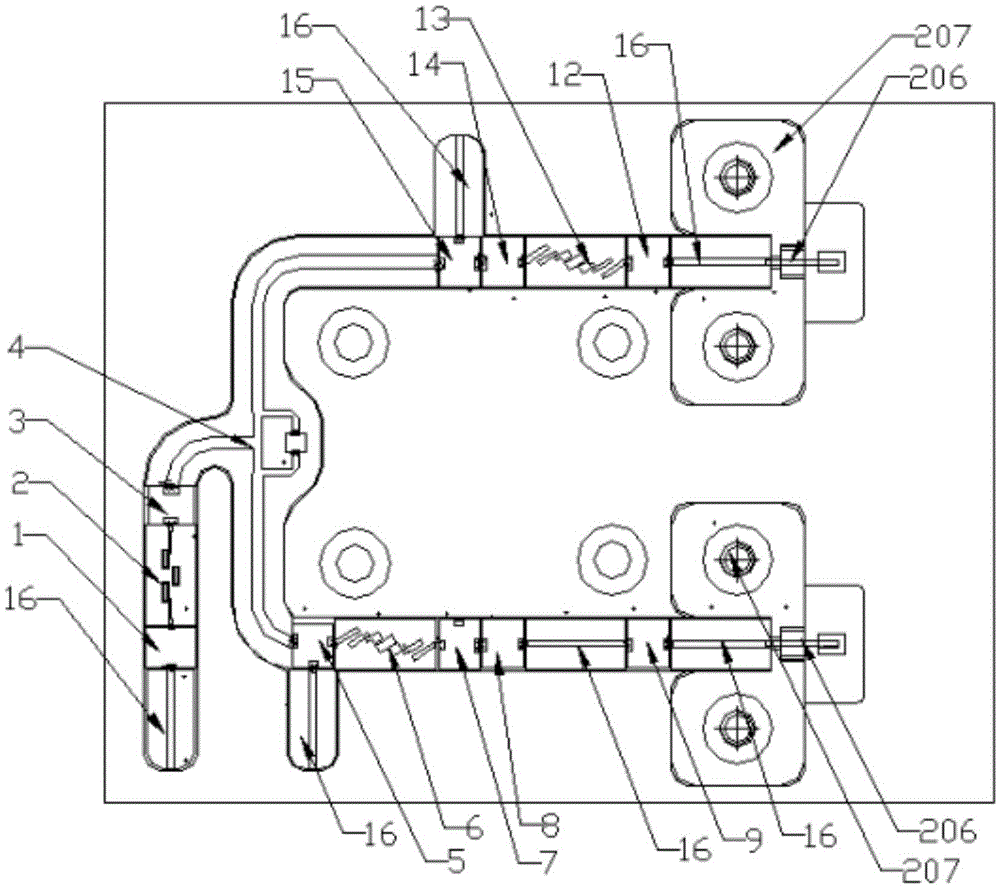

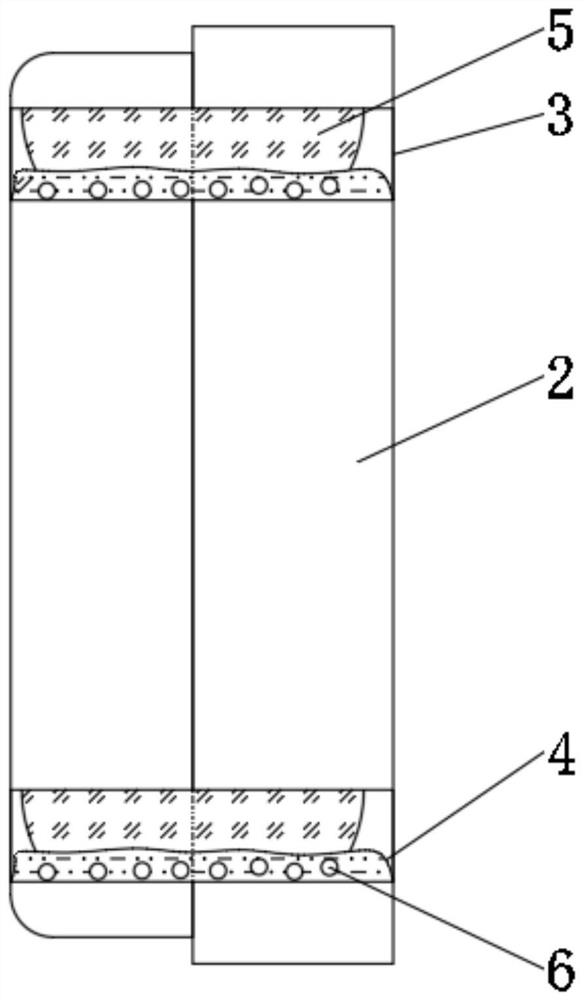

Battery module and cooling method thereof

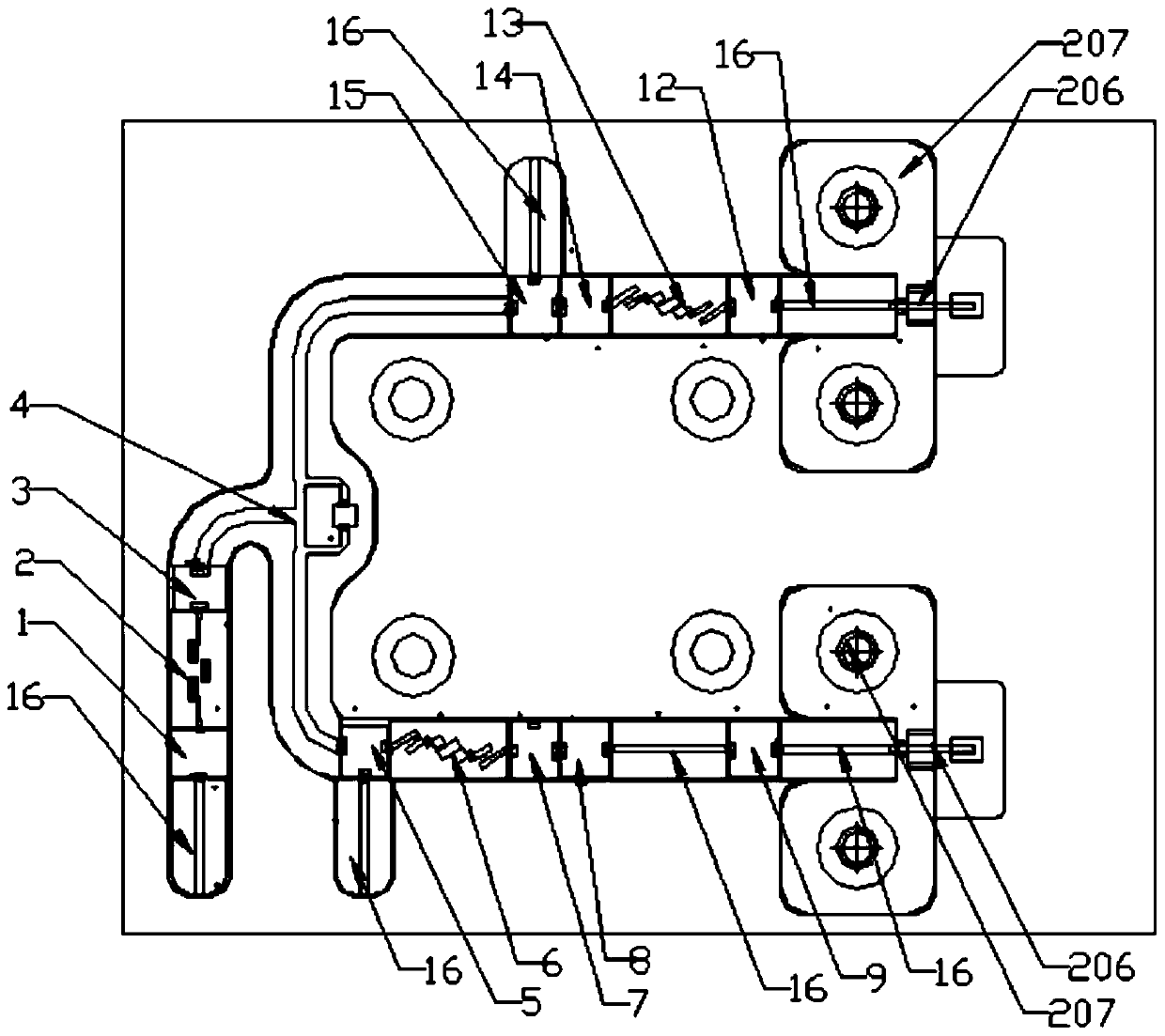

The invention discloses a battery module and a cooling method thereof. The battery module comprises a battery array mainly formed by a plurality of single batteries, cooling fins inserted into the battery array, and cooling pipes into which a refrigerant is introduced, wherein the cooling pipes are arranged at the two sides of the battery array, and the cooling fins are circuitously inserted into the battery array and penetrate out of the battery array to be fixedly arranged on the cooling pipes. According to the scheme, the cooling fins are circuitously inserted into the battery array, so that the contact areas of the cooling fins and batteries can be increased, the heat conduction is fully carried out, and heat is transferred to the cooling pipes to exchange heat with the refrigerant, and thus the cooling of the battery array is realized, and the cooling effect is good.

Owner:GUANGDONG YIWEI NEW ENERGY AUTOMOBILE CO LTD

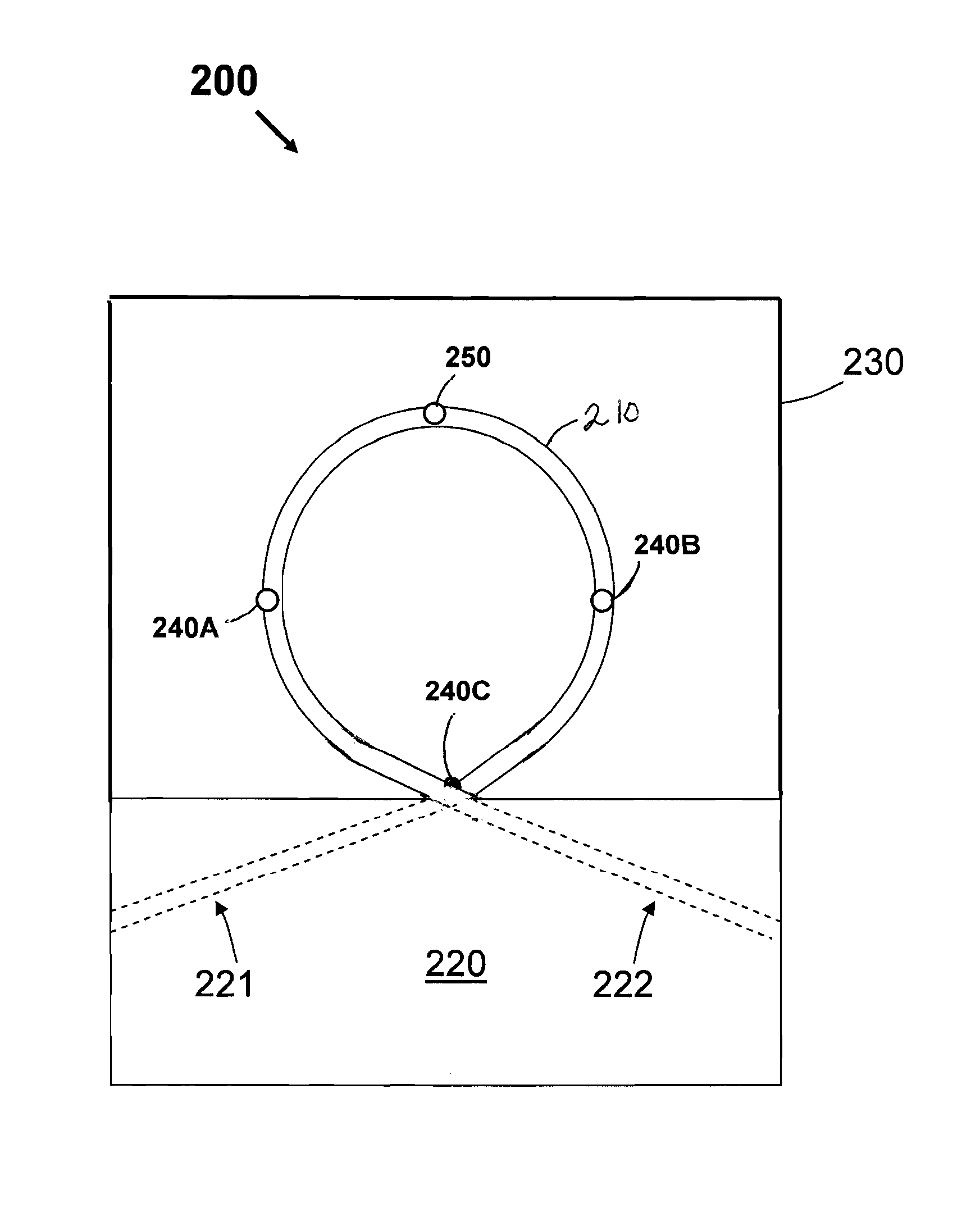

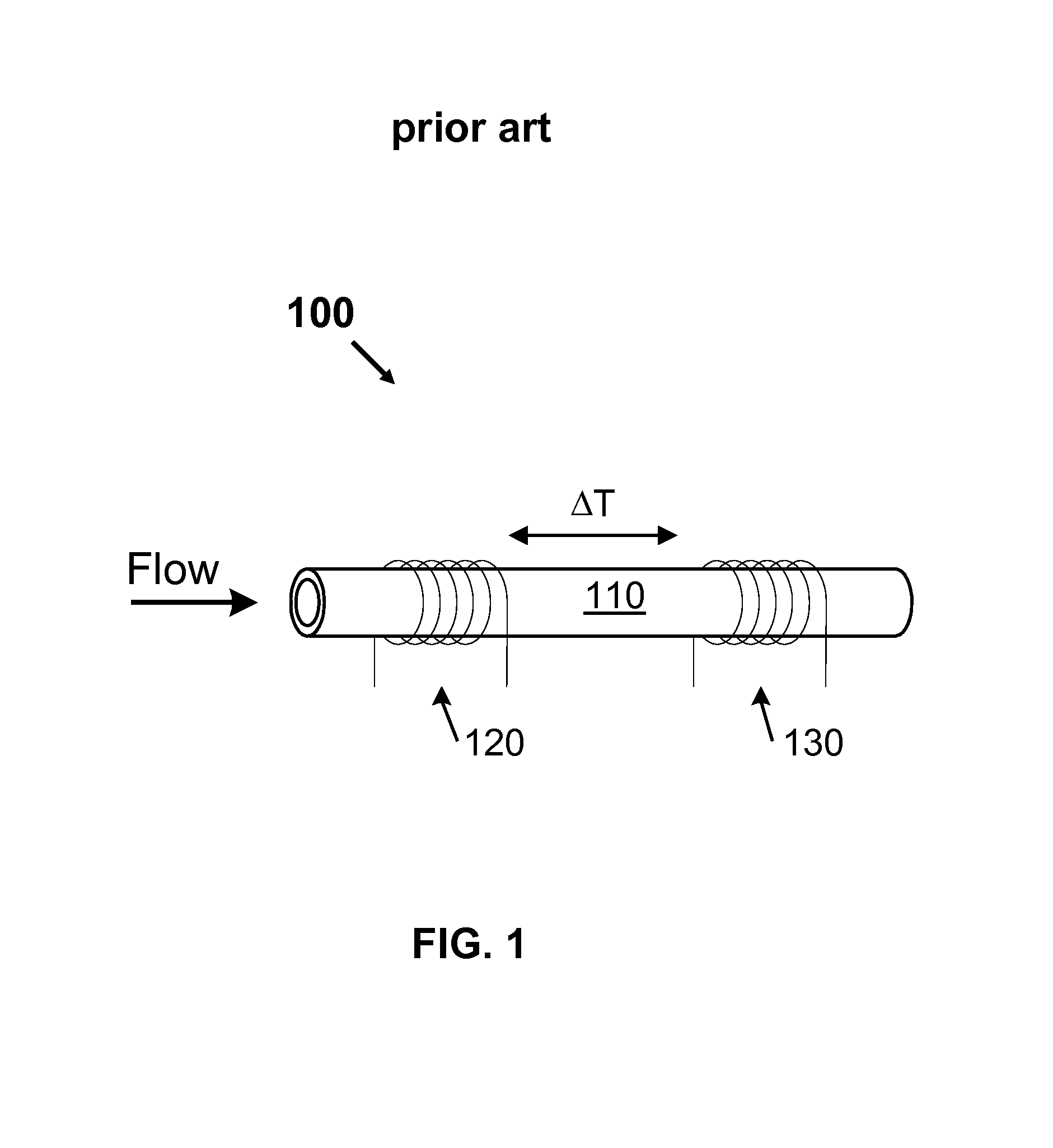

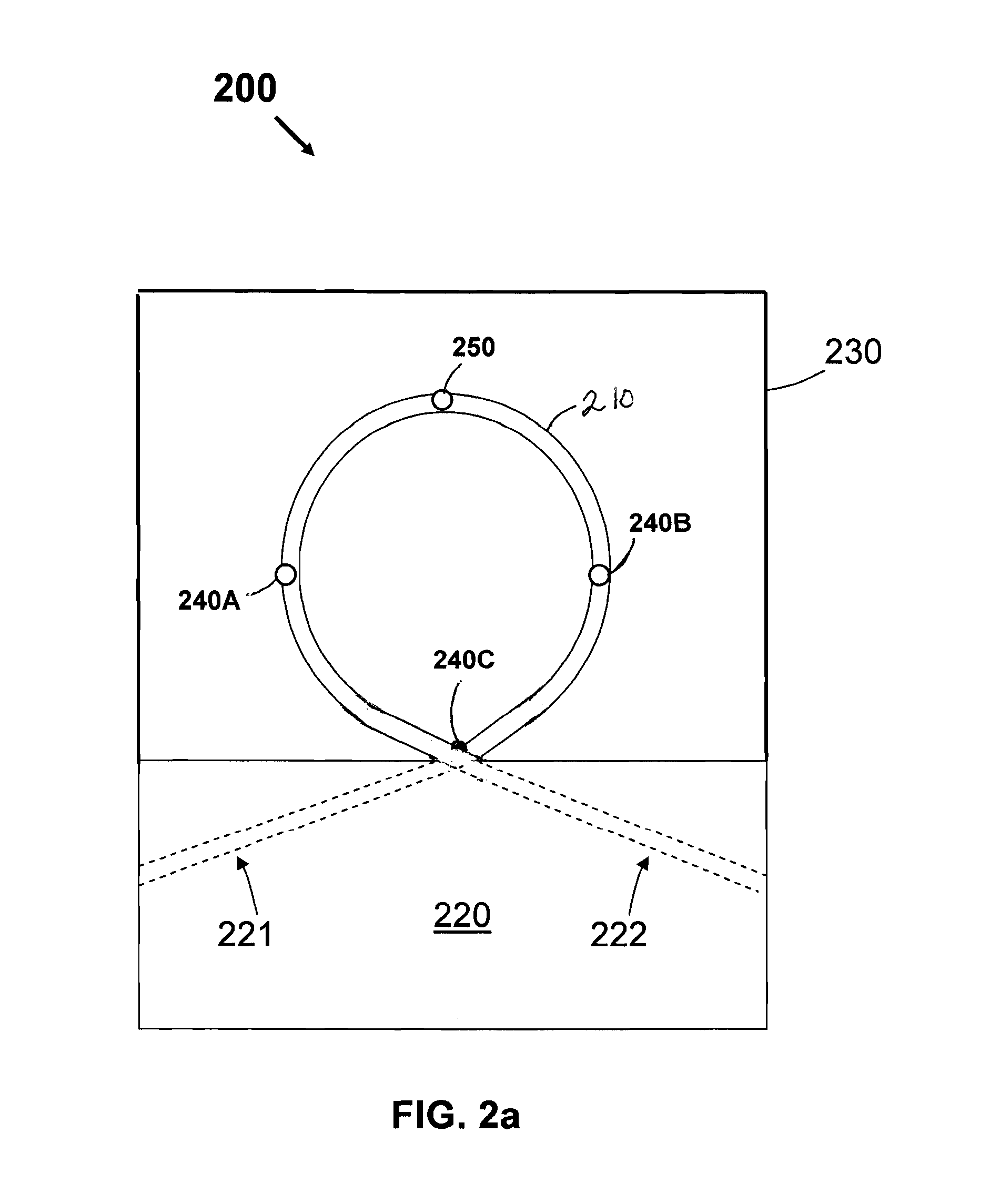

Thermal loop flow sensor

ActiveUS8485030B2Reduce impactAdequate heat conductionVolume/mass flow by thermal effectsVolume variation compensation/correction apparatusEngineeringStreamflow

Owner:WATERS TECH CORP

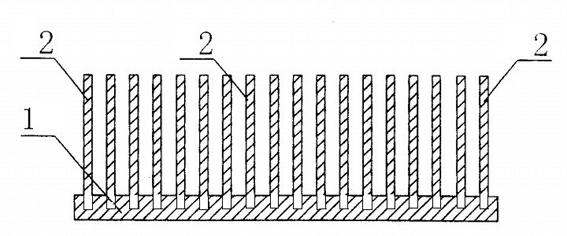

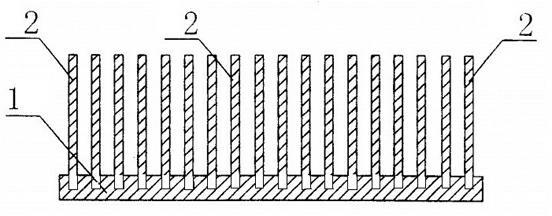

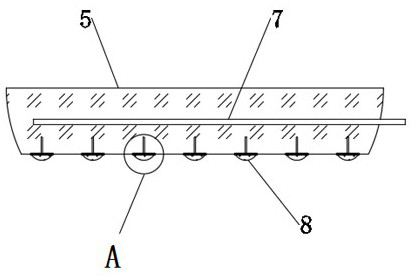

Radiating fin

InactiveCN102184900AStable structureAdequate heat conductionSemiconductor/solid-state device detailsSolid-state devicesHeat conductingHeat sink

The invention discloses a radiating fin comprising a substrate and a group of radiating fins, wherein the radiating fins are inserted into the substrate in a stamping mode and fixedly connected with the substrate; the space between adjacent radiating fins ranges from 3mm to 6mm; and the thickness of each radiating fin ranges from 5mm to 20mm, and the height range from 30mm to 250mm. The radiating fin enables the substrate and the radiating fins to be fixedly connected in the stamping mode, is simple in structure, stable and fully-fit in connection, sufficient in heat conduction and obvious in radiating effect, and does not have gaps, and the substrate and the radiating fins are made of aluminium alloy having good heat-conducting property, thus greatly improving the heat dispersion.

Owner:TAICANG XINGGANG METAL MATERIAL

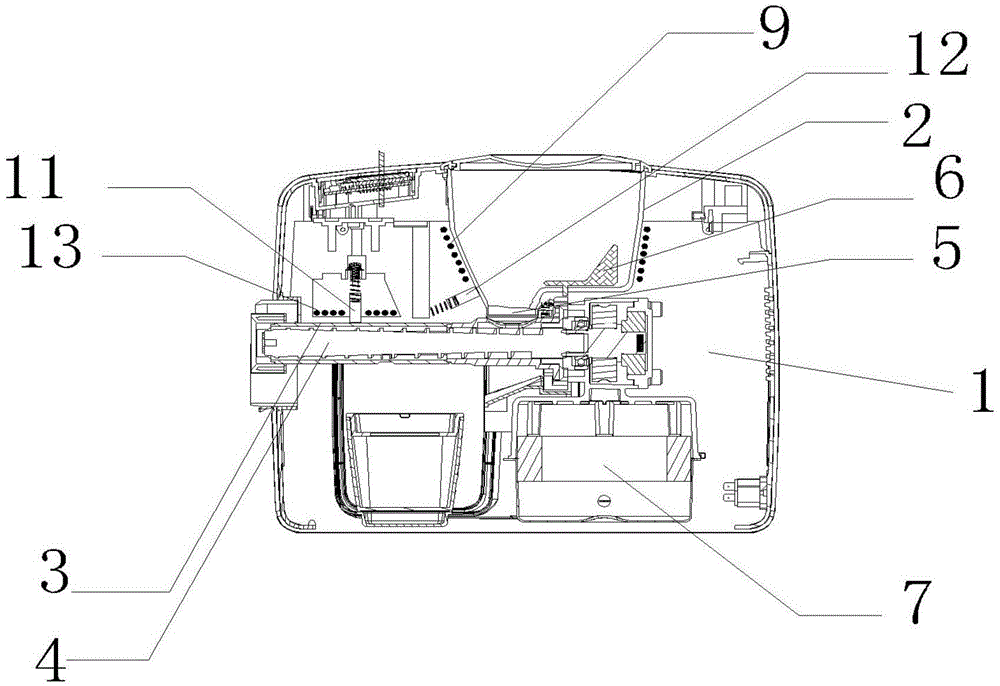

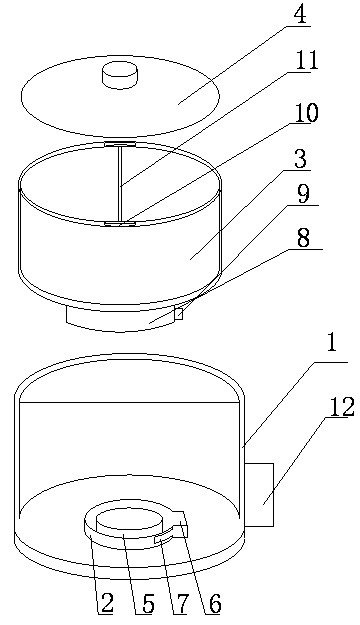

Domestic oil pressing machine and oil pressing method

The invention discloses a domestic oil pressing machine and an oil pressing method. The oil pressing method at least comprises the stages of material drying, preheating, material feeding and crushing for oil extraction; the stages of material drying and preheating can be carried out in a step-by-step mode or simultaneously; the two parts, namely a material hopper and a pressing barrel, are heated, and thus material drying and water evaporation before material feeding are realized; during the squeezing and crushing process, due to the heat conduction of the pressing barrel, the materials are crushed more thoroughly under the effect of high temperature, and thus the oil extraction rate is improved, residue and oil separation is better realized, a residue outlet is unlikely to block by residues, and the oil is strong in fragrance.

Owner:JOYOUNG CO LTD

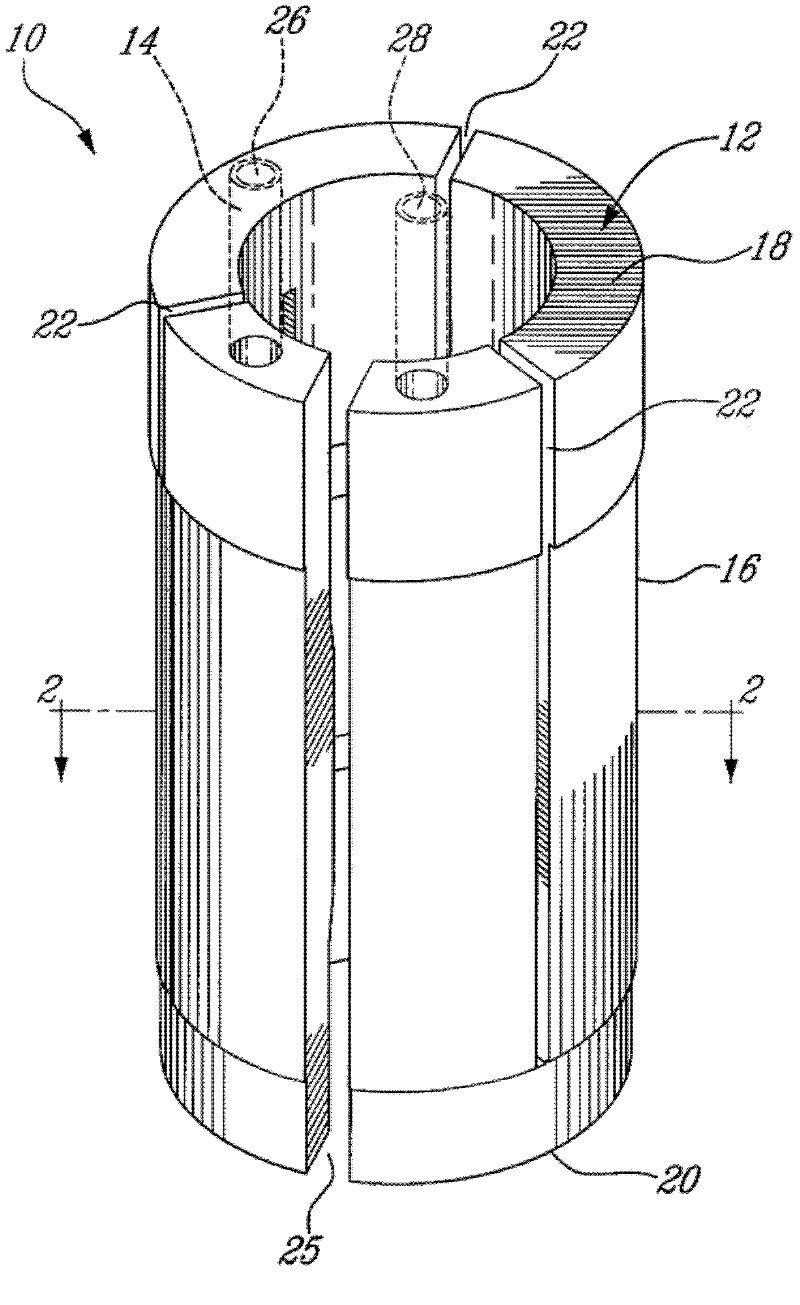

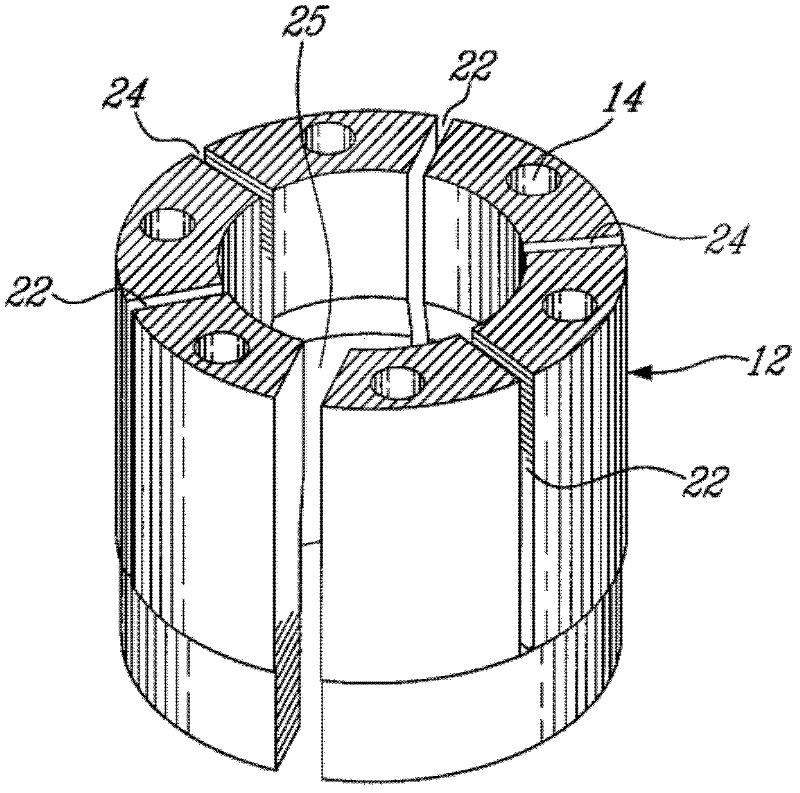

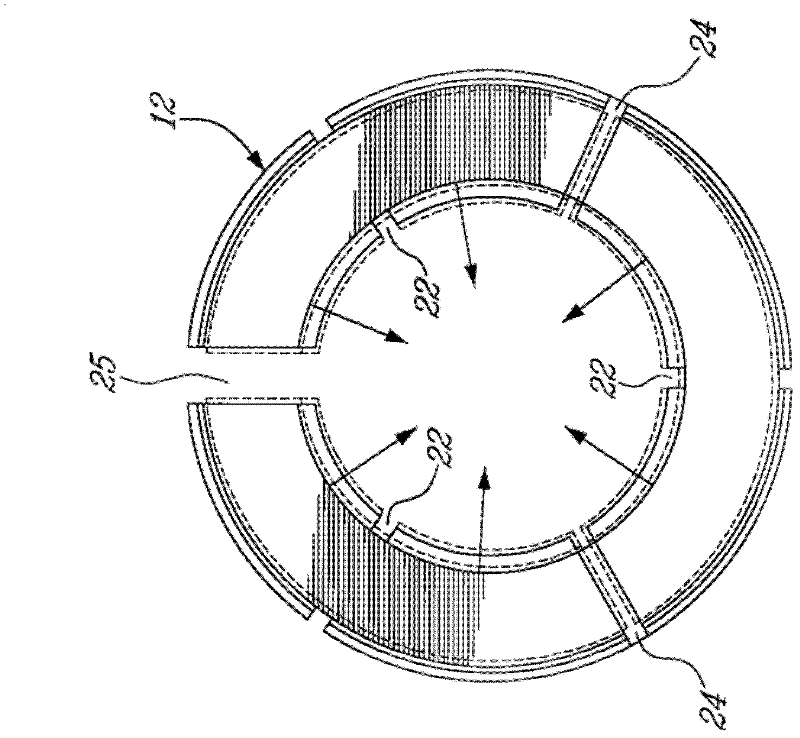

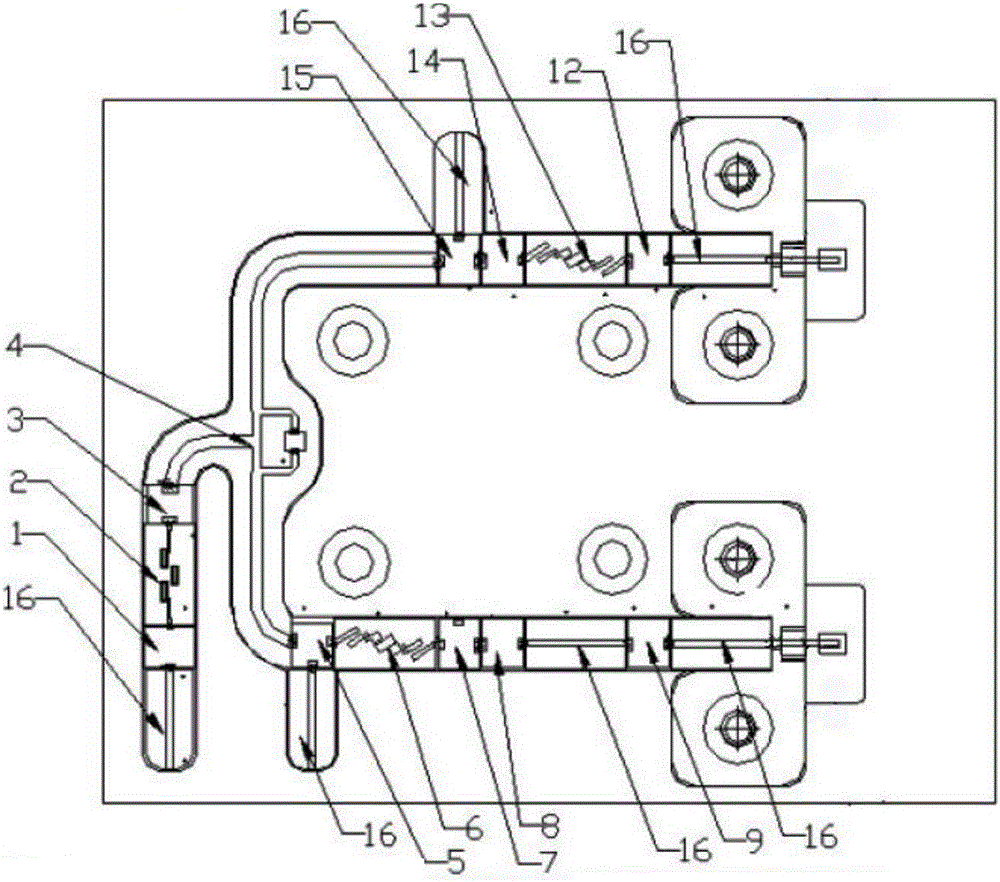

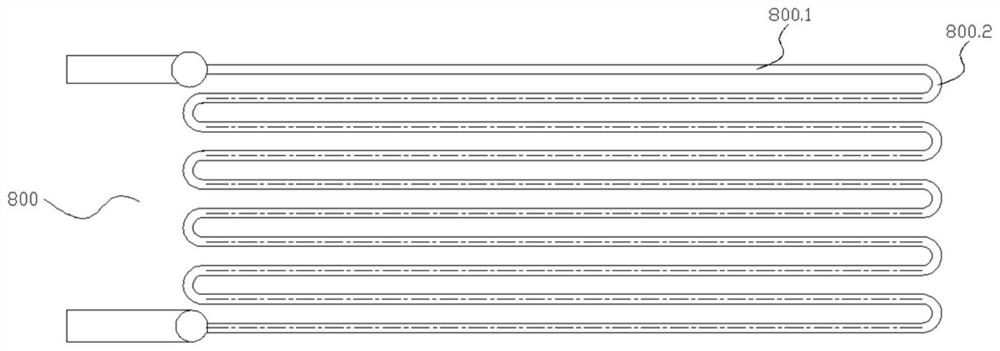

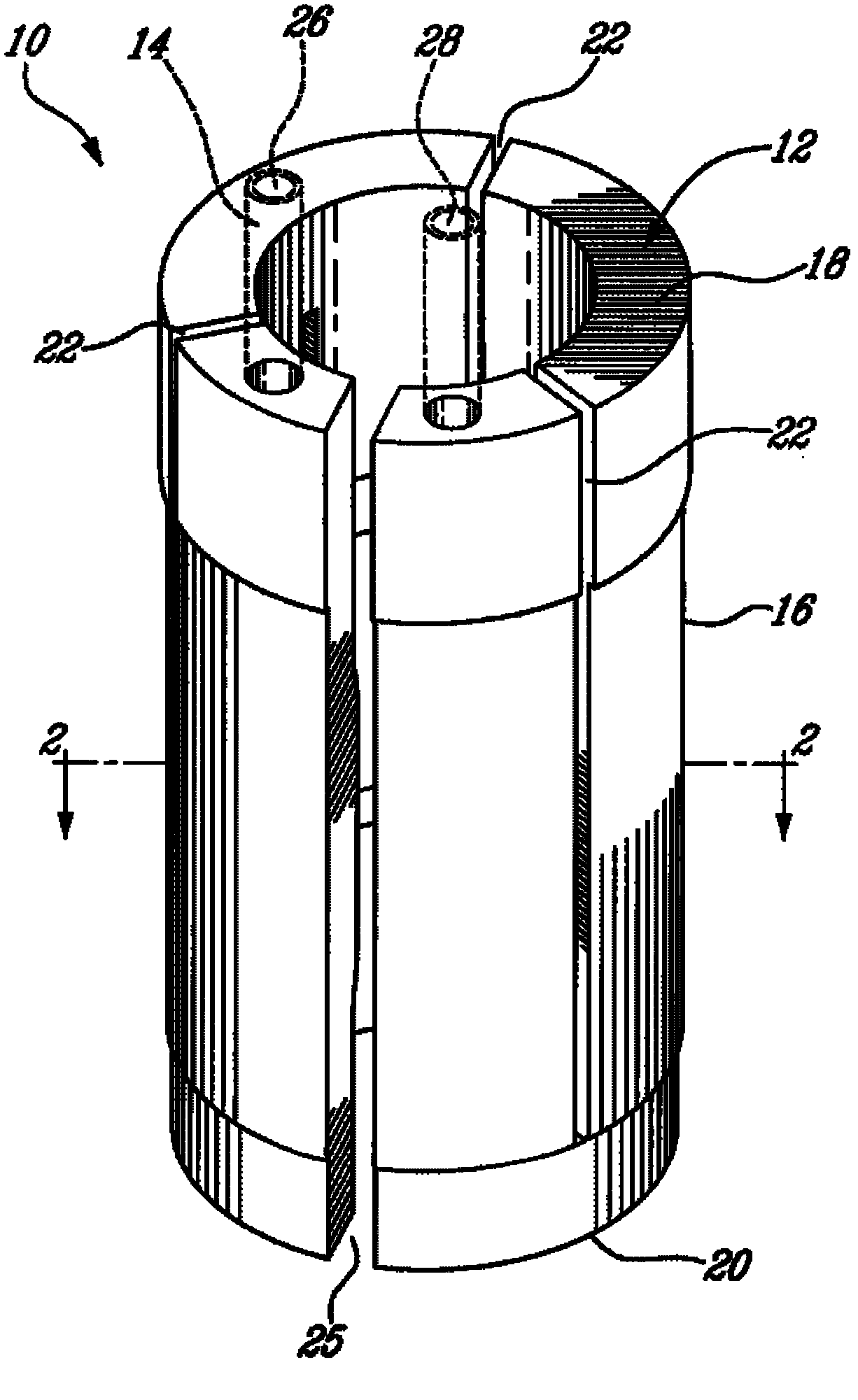

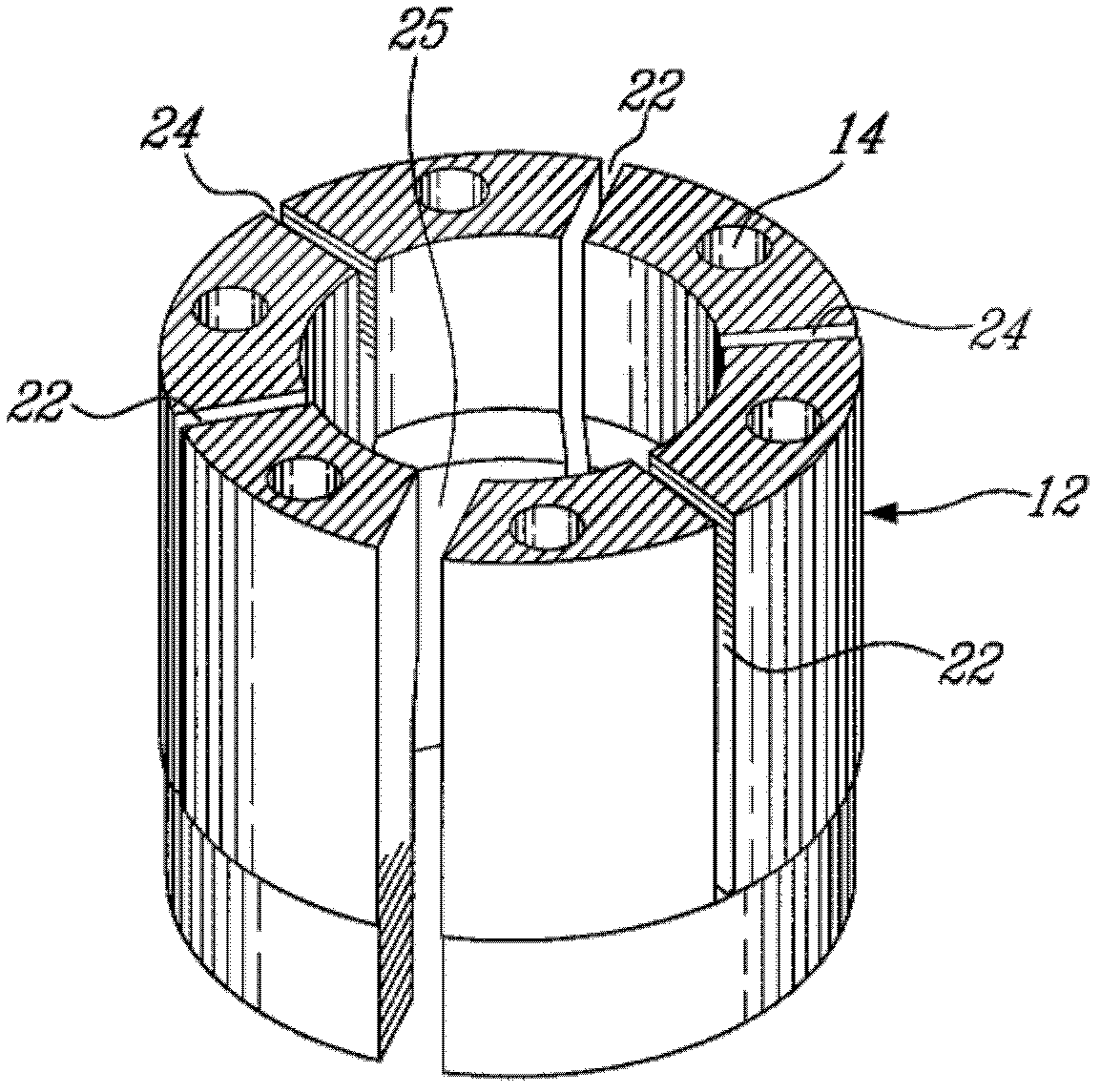

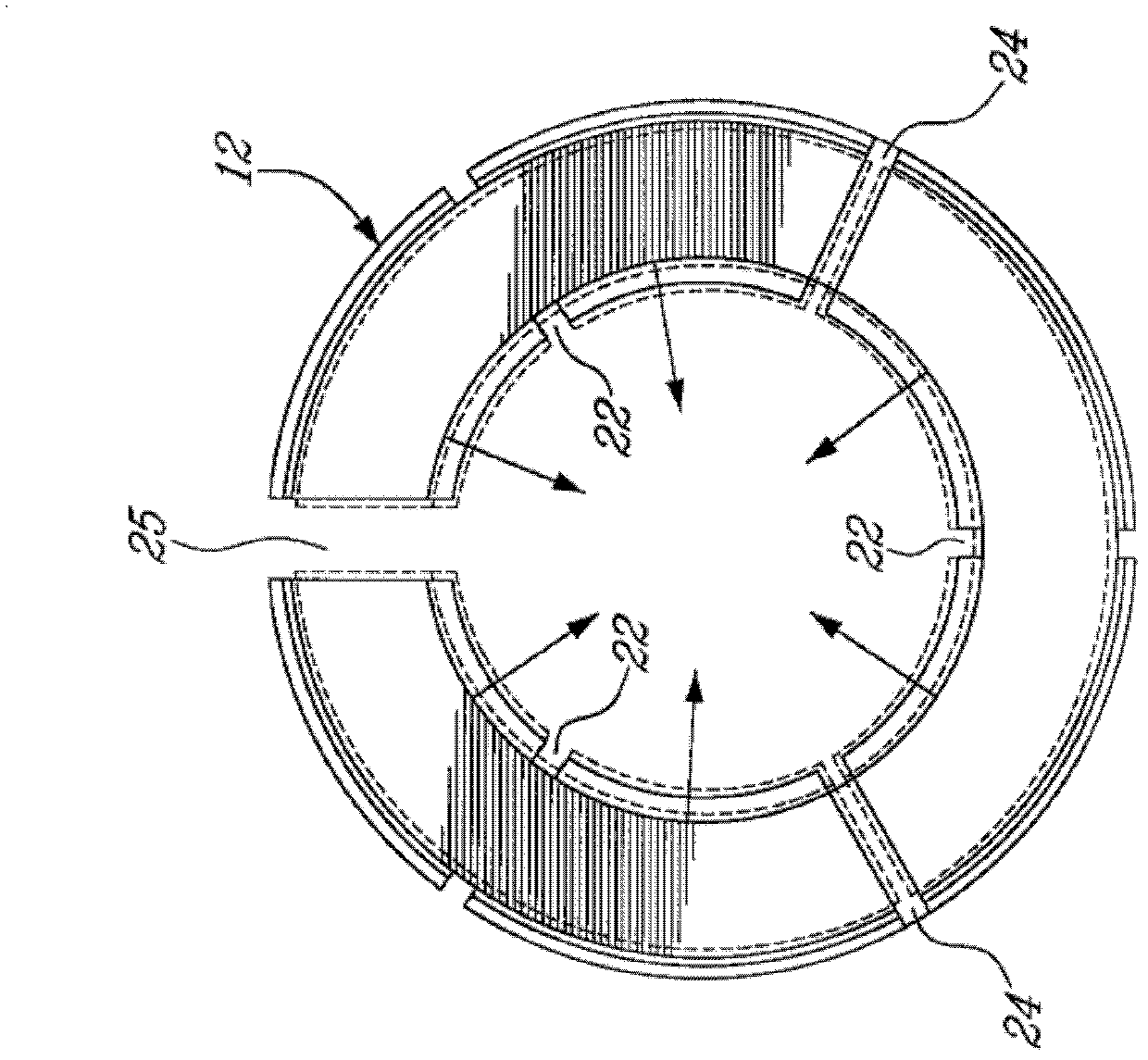

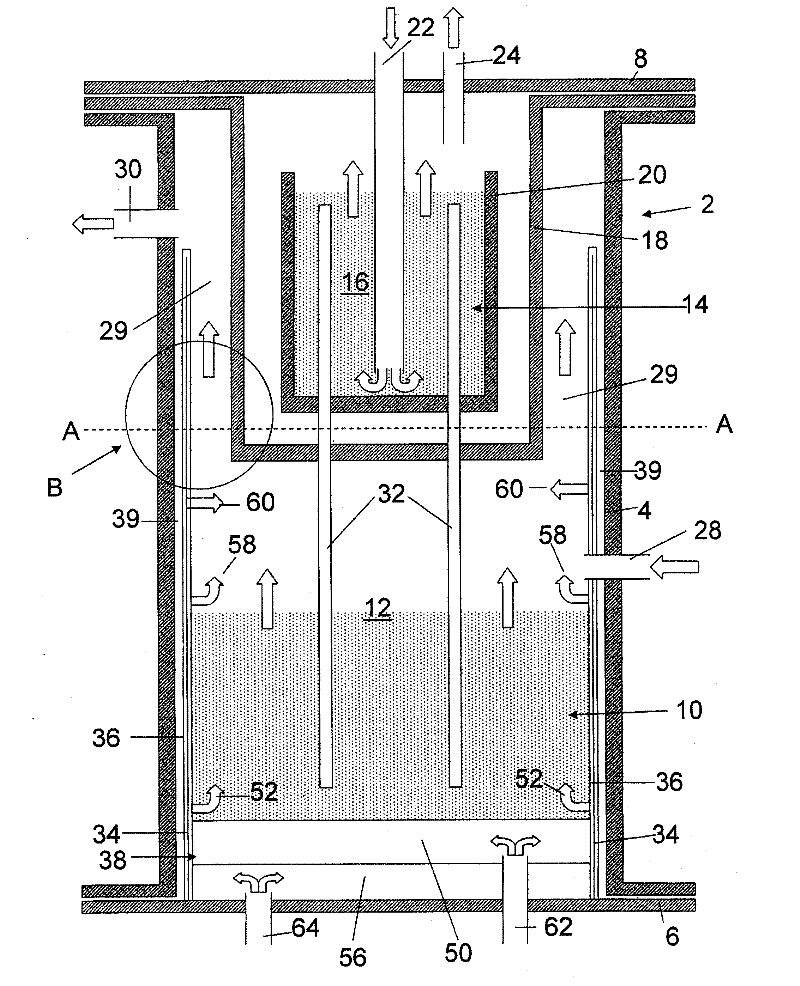

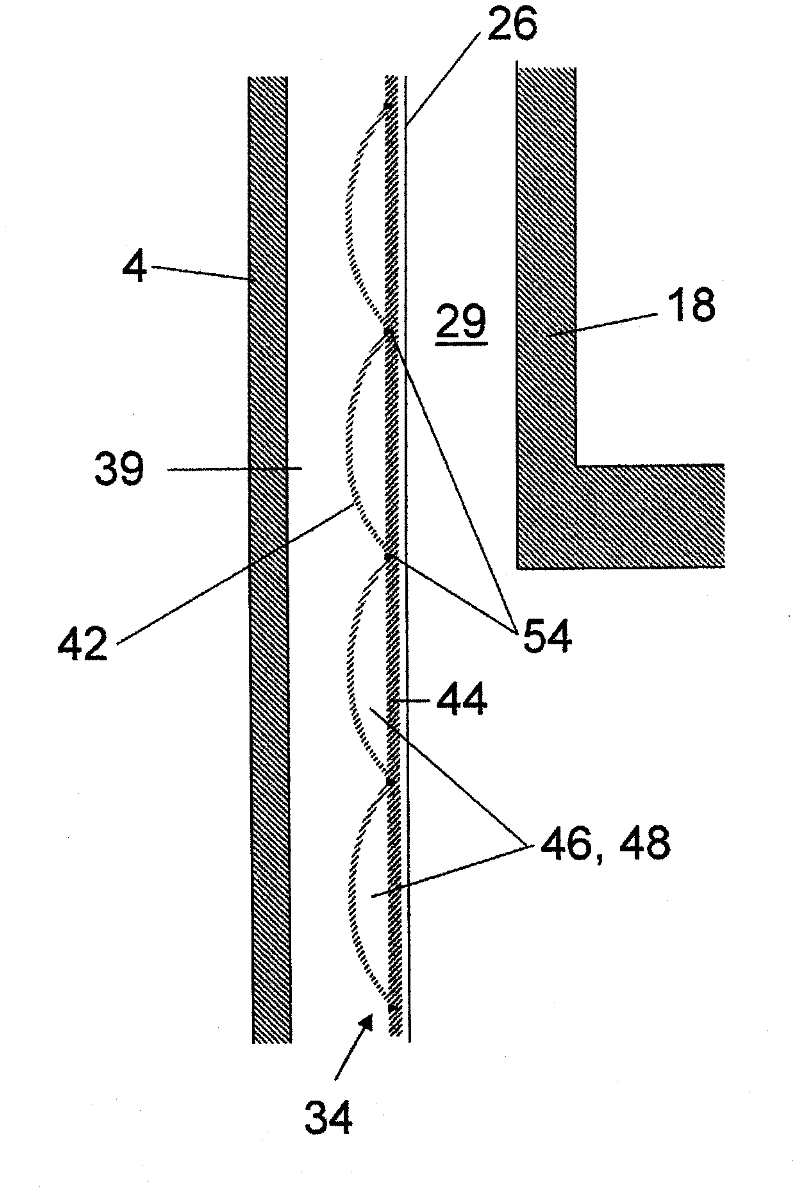

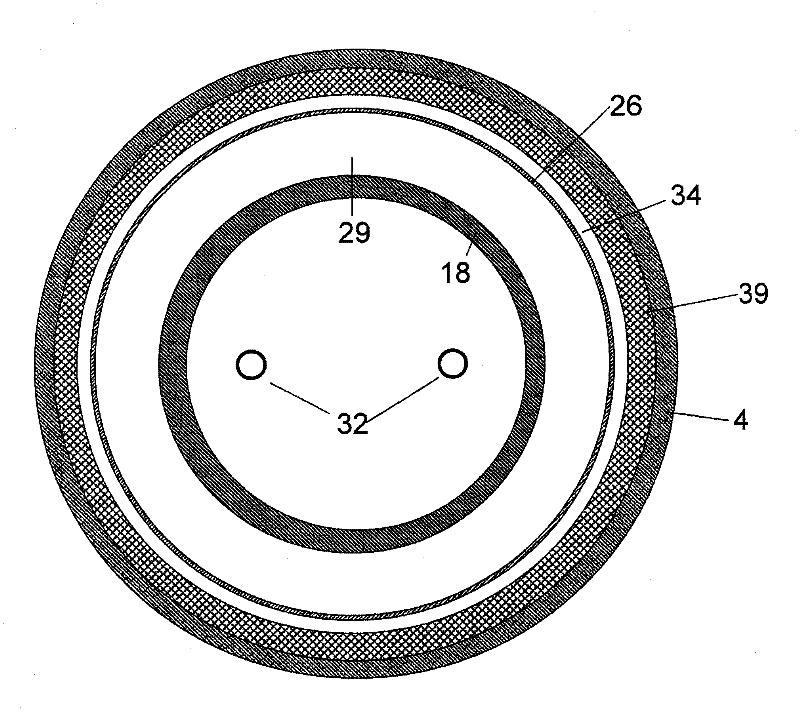

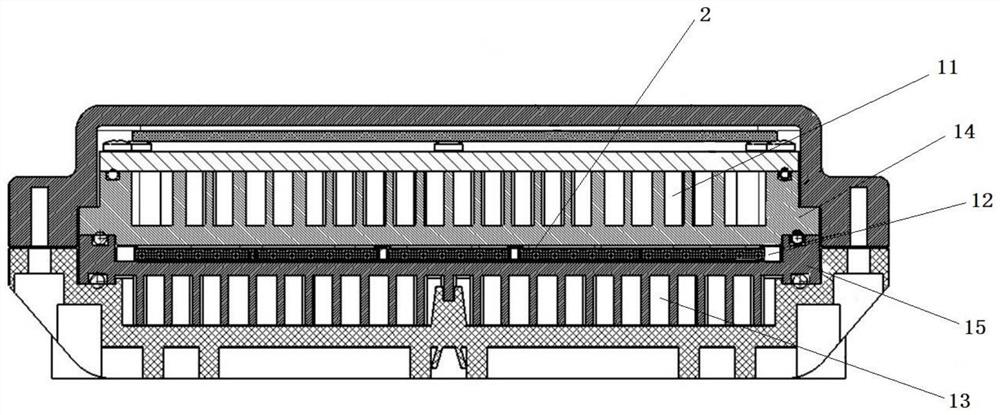

Liquid cooling arrangement for electric

ActiveCN102341999AAdequate heat conductionNo loss of contactMagnetic circuit stationary partsCooling/ventillation arrangementElectric machineEngineering

A liquid cooling arrangement for electric machines uses a continuous cooling tube associated with a heat storing element. The cooling tube has a serpentine configuration and the heat storing element includes longitudinal slots starting from both longitudinal ends of the heat storing element. Accordingly, it is possible to slightly deform the heat storing element to properly position it into the internal stator of an electric machine. An internal biasing assembly may be used to force the external surface of the heat storing element to the internal surface of the stator.

Owner:TM4 INC

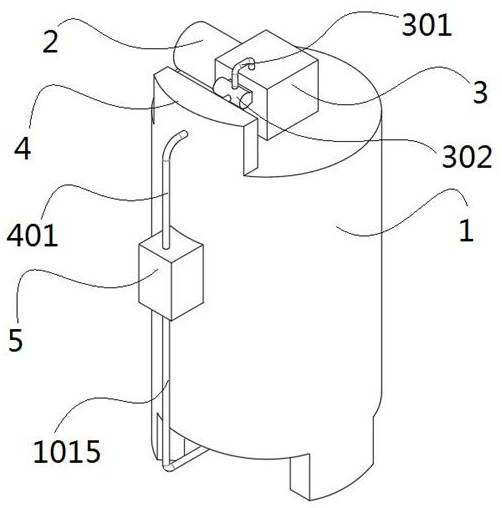

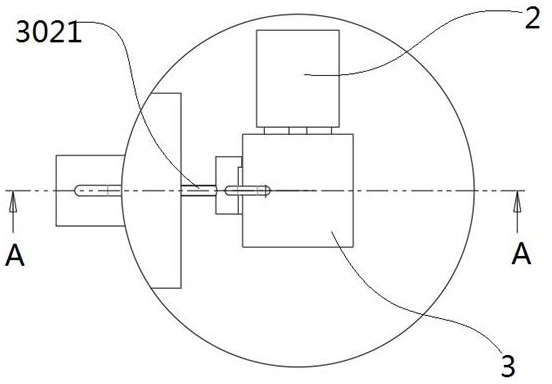

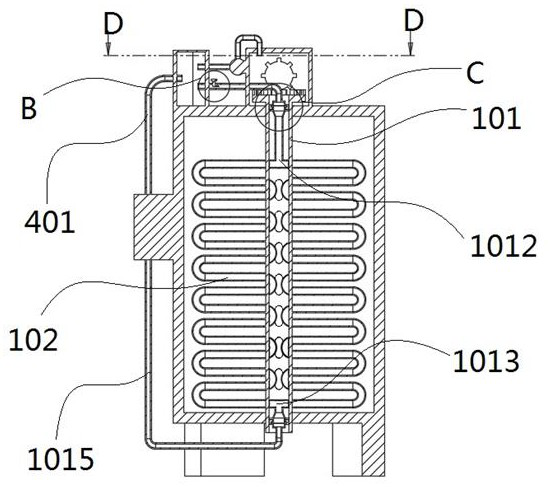

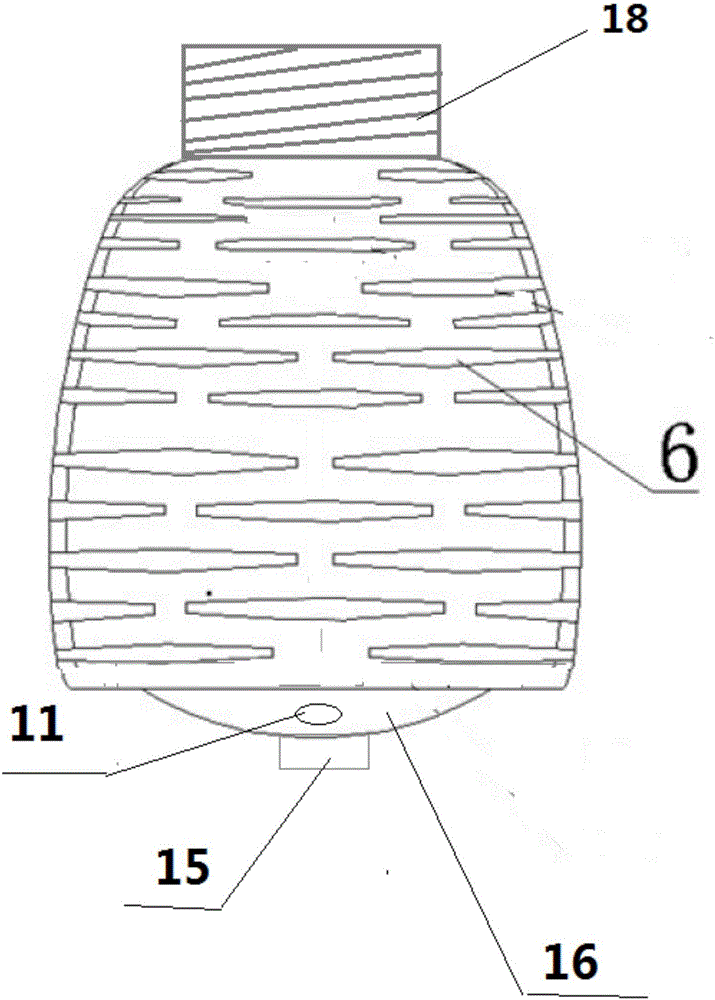

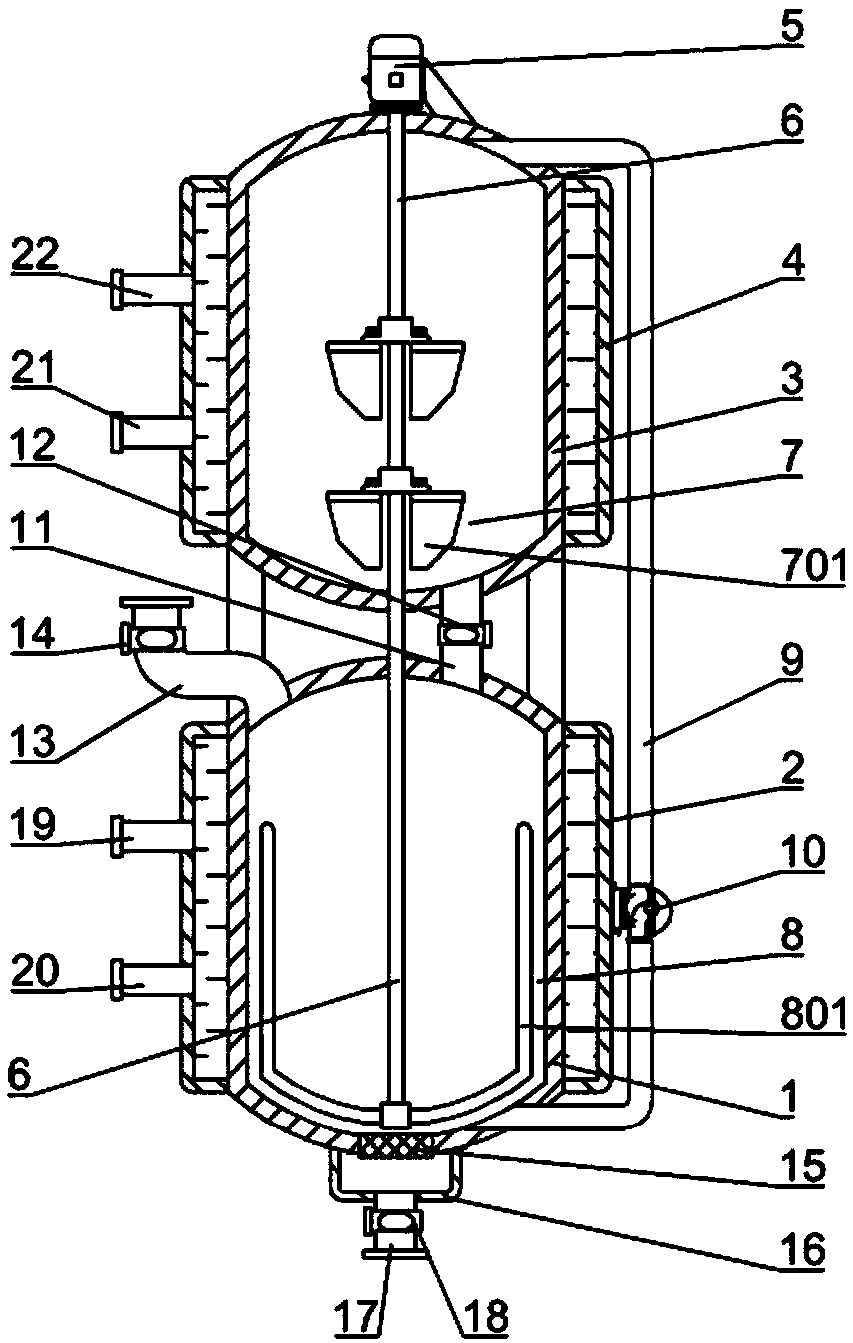

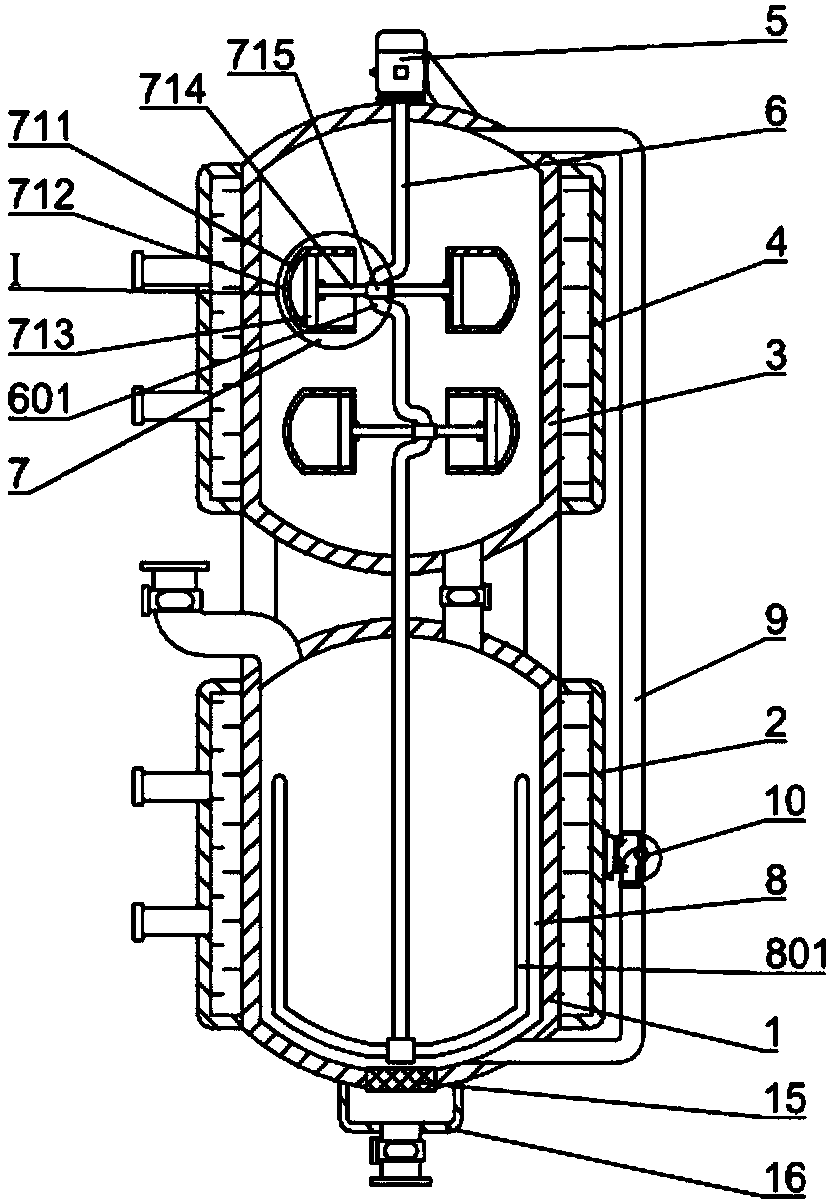

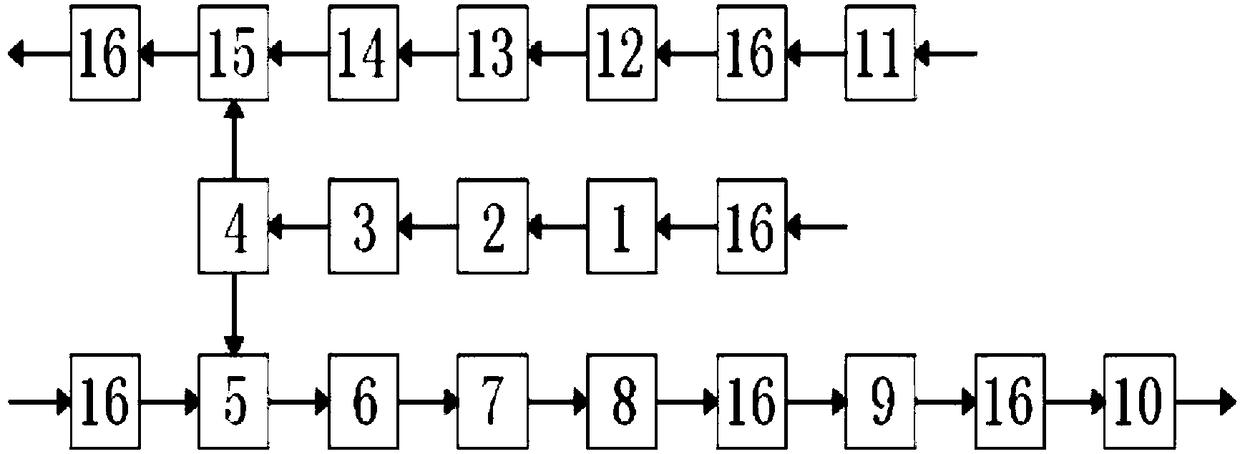

Distillation still capable of being heated by steam of stirring paddles

InactiveCN112337122AGuaranteed to workAdequate heat conductionDistillation regulation/controlTransportation and packagingElectric machineryDrive motor

The invention discloses a distillation still capable of being heated by steam of stirring paddles, and relates to the technical field of chemical processing equipment. The distillation still comprisesa tank body, a driving motor, a protective sleeve, a confluence box and an electric heating sleeve, the tank body, the protective sleeve, the confluence box and the electric heating sleeve are sequentially communicated, a stirring shaft is installed in the tank body, and a plurality of S-shaped pipe stirring paddles are installed on the peripheral side face of the stirring shaft. The stirring shaft and the stirring paddle of an S-shaped tubular structure are arranged in the tank body, and hot steam is introduced into the stirring paddle to heat materials in the tank body, so that direct and sufficient heat conduction in the stirring process is facilitated, and the heating efficiency and speed are improved; the protective sleeve, the confluence box and the electric heating sleeve are installed on the surface and the peripheral side face of the tank body, the steam exhaust pipe, the steam inlet pipe and other pipelines are communicated with one another to form a steam backflow channel,steam for heating can be recycled, and energy is saved.

Owner:PENGLAI LU HAO CHEM MACHINERY

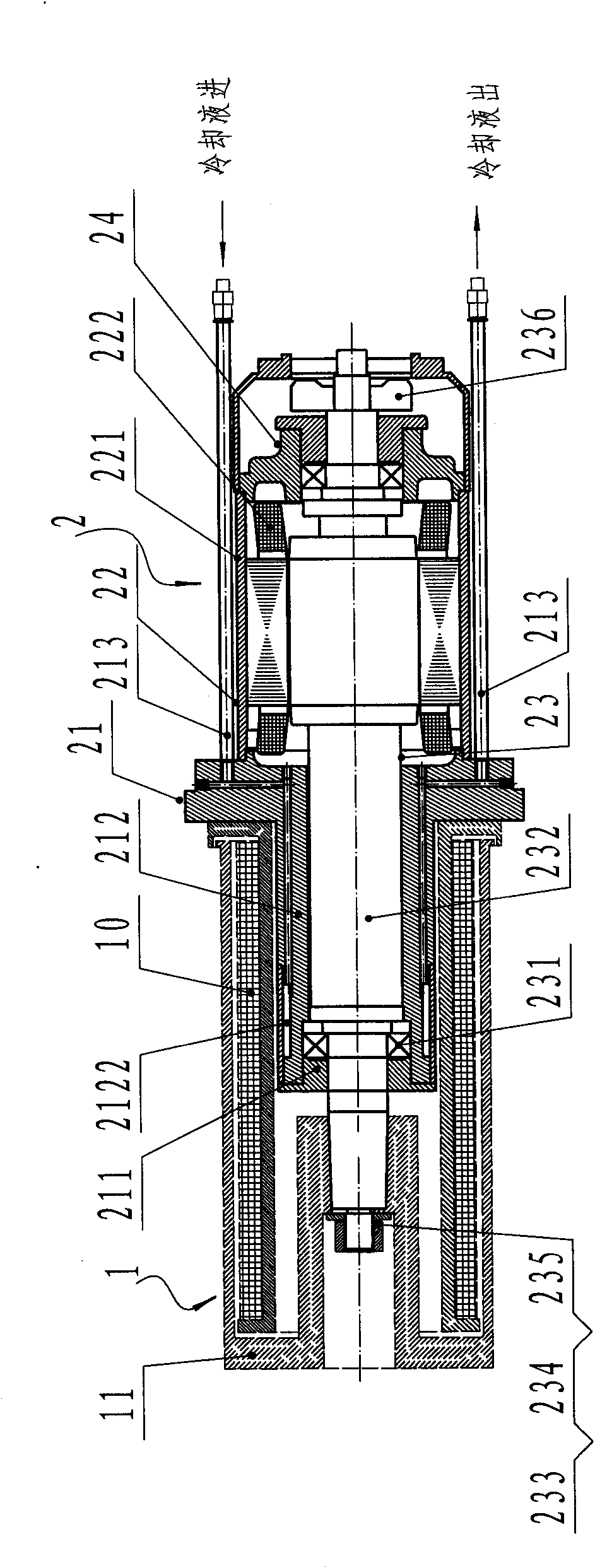

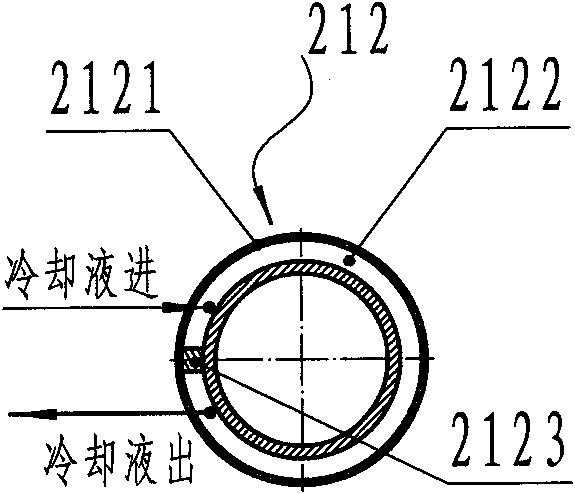

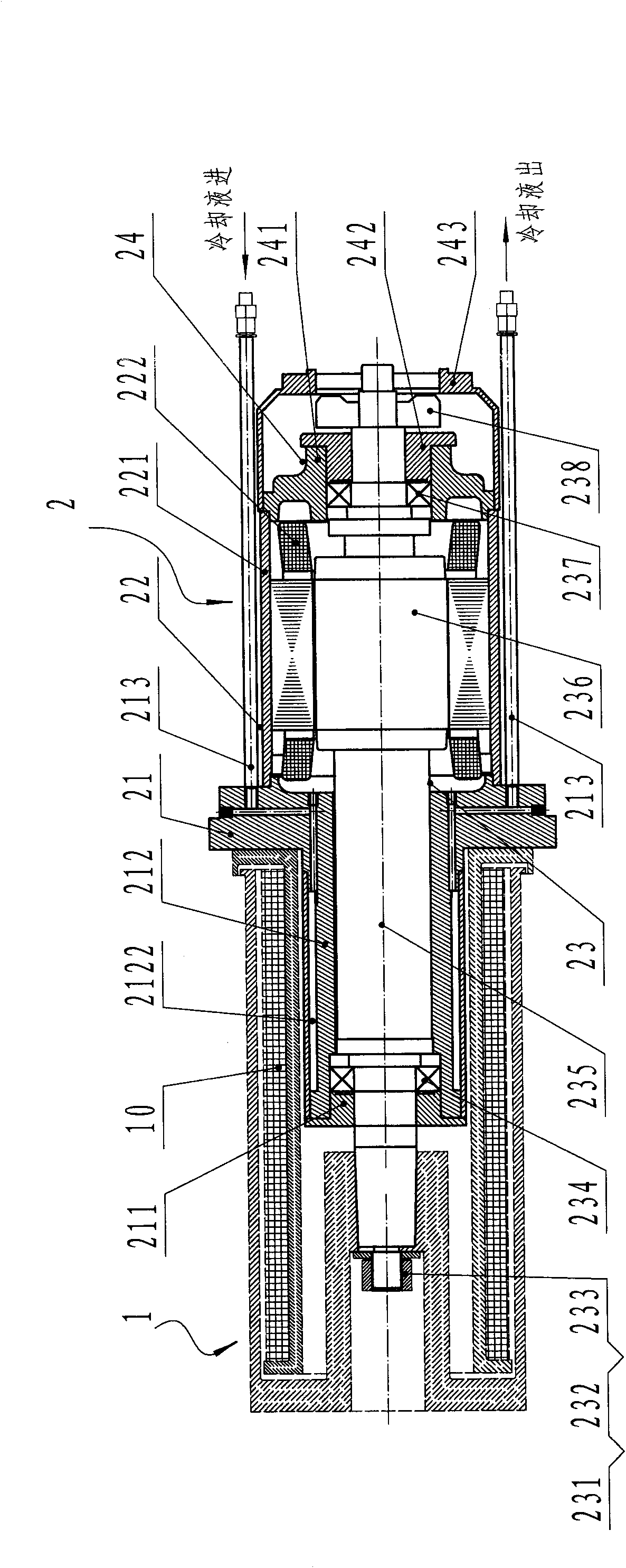

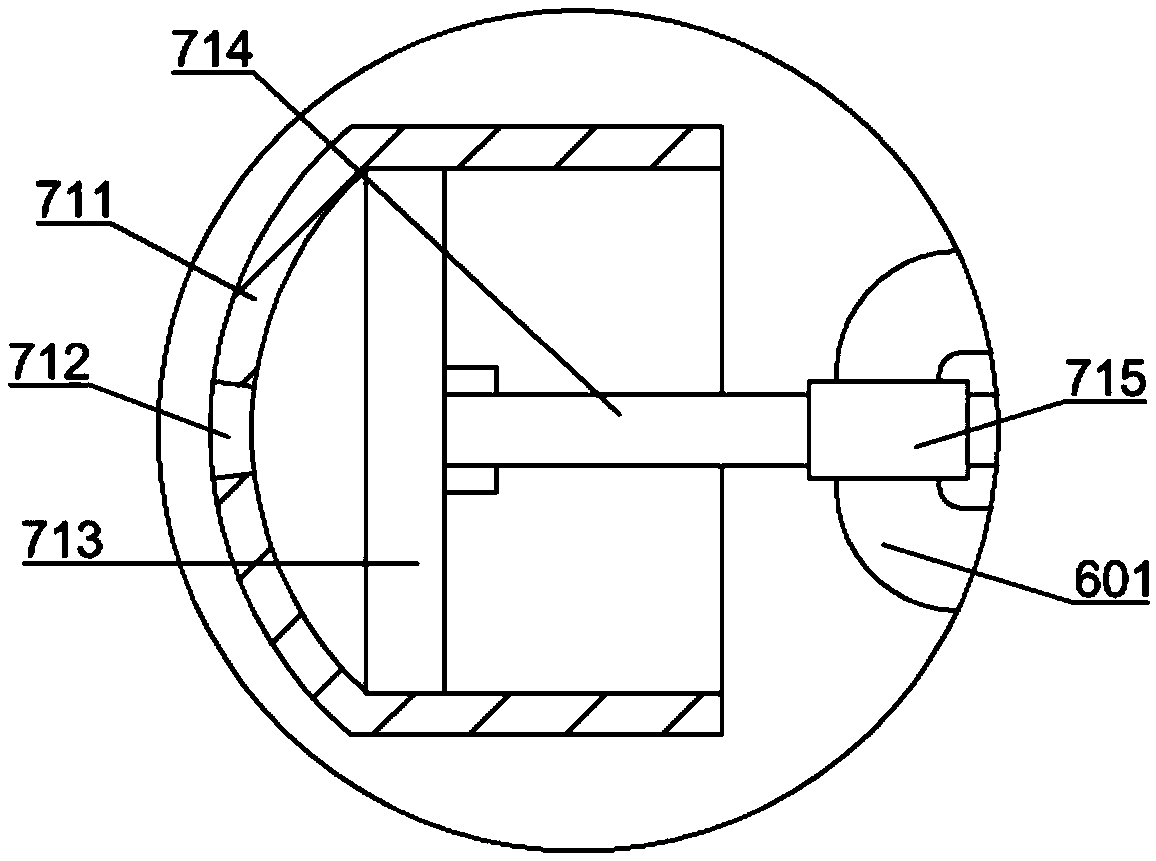

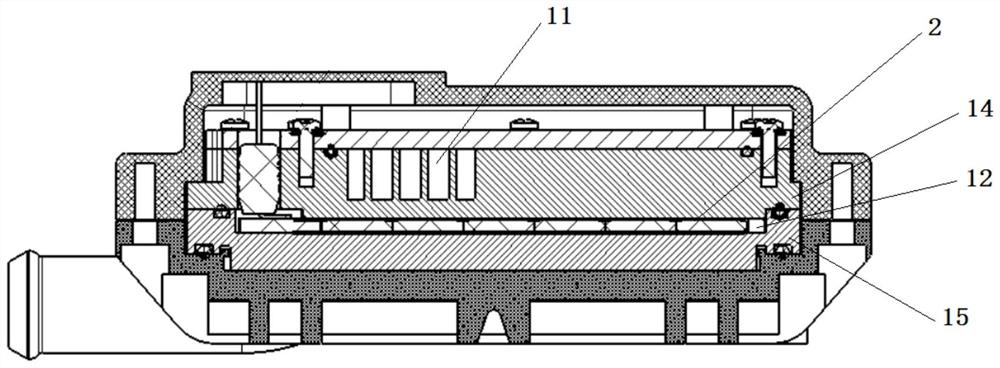

Permanently-magnetic synchronous heat-stretching roller motor

InactiveCN101917103AImprove cooling effectImprove reliabilitySynchronous machinesCooling/ventillation arrangementTextile yarnCooling effect

The invention discloses a permanently-magnetic synchronous heat-stretching roller motor, which can be used for a textile yarn and industrial yarn spinning and stretching combination machine. The motor consists of a hollow roller body part and a motor assembly, wherein the motor assembly consists of a back end cover part, a stator component, a rotor component and a front end cover part; the front end cover part consists of a front gland, a front end cover and an inlet and outlet cooling liquid pipe arranged on an engine base; the front end cover has a cylindrical structure extending into the roller body part; a heater is arranged in the roller body part along the axial length of the roller body part and fixed on the bottom end face of the front end cover; the inlet and outlet cooling liquid pipe is communicated with a cooling passage formed on the front end cover and is externally connected with a cooling loop; the cooling passage has an S-shaped end-to-end connected structure uniformly formed at the outer edge of the front end cover; a sealing barrel is packaged on the surface of the outer edge; and the axial length of the cooling passage is close to that of the front end cover. Due to the adoption of the technical scheme, the motor has the advantages of good cooling effect under a high-temperature and high-speed working environment, small temperature rise and long service life.

Owner:ZHEJIANG LANXIANG ELECTROMECHANICAL EQUIP MFG

High-temperature non-pressure seamless sintering technology-based miniaturized millimeter wave transmitting and receiving assembly

ActiveCN105743533AReduce lossSatisfy one-time process moldingMagnetic/electric field screeningTransmissionMillimeter wave communication systemsEngineering

The invention discloses a high-temperature non-pressure seamless sintering technology-based miniaturized millimeter wave transmitting and receiving assembly. The high-temperature non-pressure seamless sintering technology-based miniaturized millimeter wave transmitting and receiving assembly includes a shielding box body, a local vibration frequency multiplication link, a power allocation link, a receiving link and a transmitting link; the local vibration frequency multiplication link is connected with the power allocation link; the power allocation link is connected with the receiving link and the transmitting link; a 85:15 tungsten copper alloy shielding box body is adopted as the shielding box body; the links are in direct bonded connection with adjacent MMIC chips through 25 um golden wires; conversion can be realized through glass insulator and copper bar high-temperature sintered integrated probe waveguides. The high-temperature non-pressure seamless sintering technology-based miniaturized millimeter wave transmitting and receiving assembly of the invention has the advantages of compact structure and easiness in debugging, and can effectively meet the requirements of an ultra-wide-band and high-speed millimeter wave communication system.

Owner:NANJING CAIHUA TECH GROUP

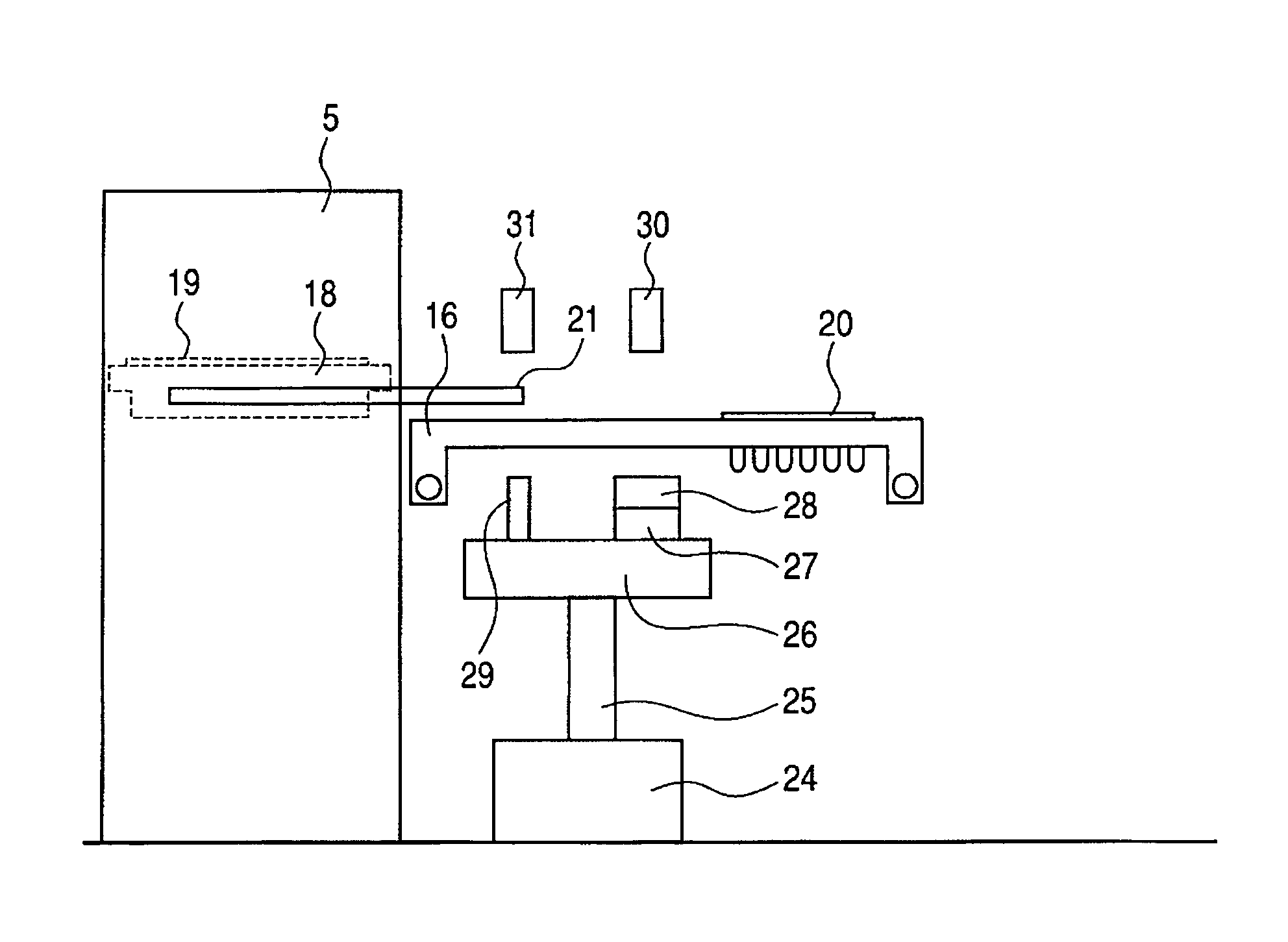

Temperature controller for structure

InactiveUS7816120B2Keep postureUniform applicationBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlEngineering

Owner:CANON KK

Miniature millimeter wave transceiver module

ActiveCN105530026AReduce lossSatisfy one-time process moldingTransmissionMillimeter wave communication systemsTransceiver

The invention provides a miniature millimeter wave transceiver module. By improving the structure and the process, the defects of complex structure, huge volume, large debugging amount, low reliability and narrow communication frequency band of an existing millimeter wave transceiver module are solved, the miniature millimeter wave transceiver module with excellent performance is provided, and the miniature millimeter wave transceiver module is compact in structure, easy to debug, capable of effectively meeting the demands of millimeter wave communication systems with ultra wide bands and high speeds.

Owner:NANJING CAIHUA TECH GROUP

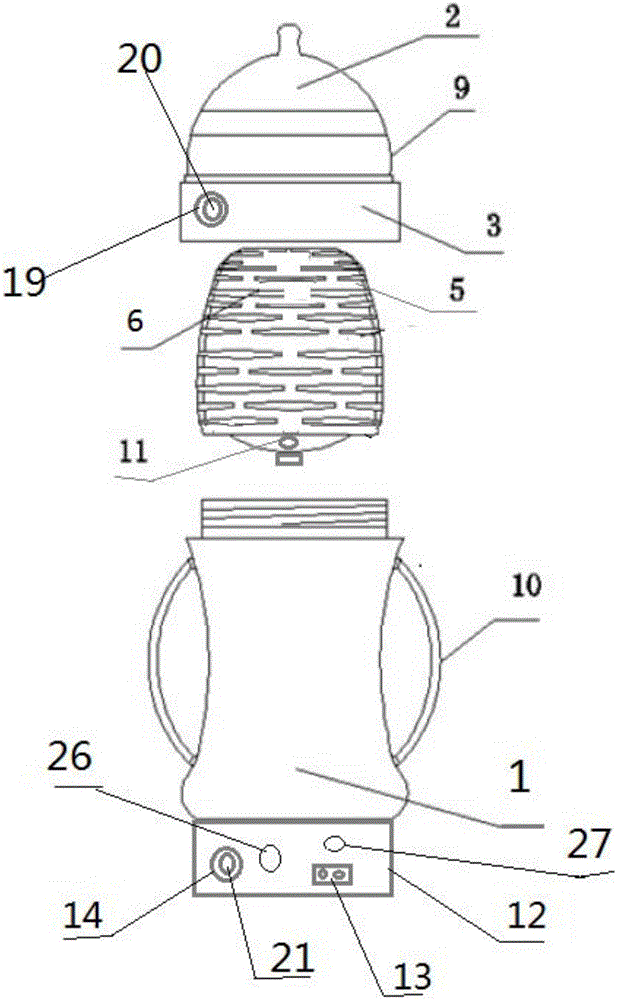

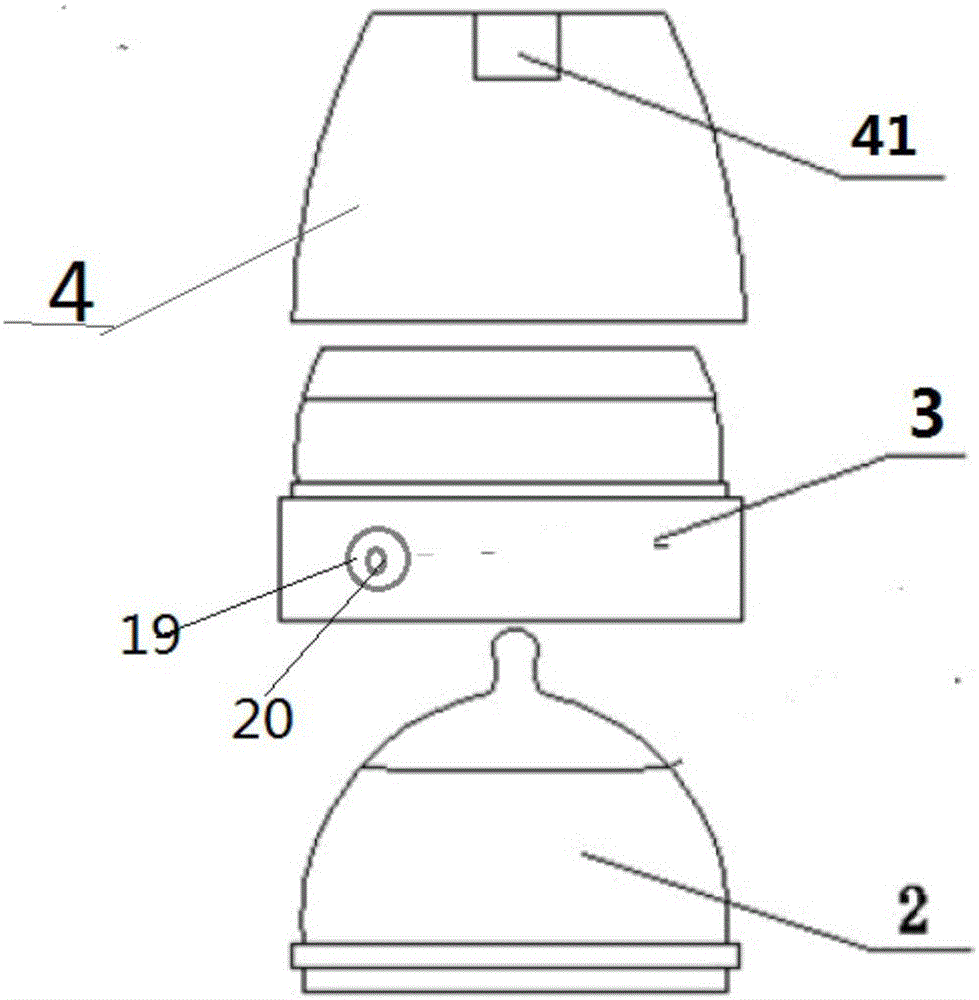

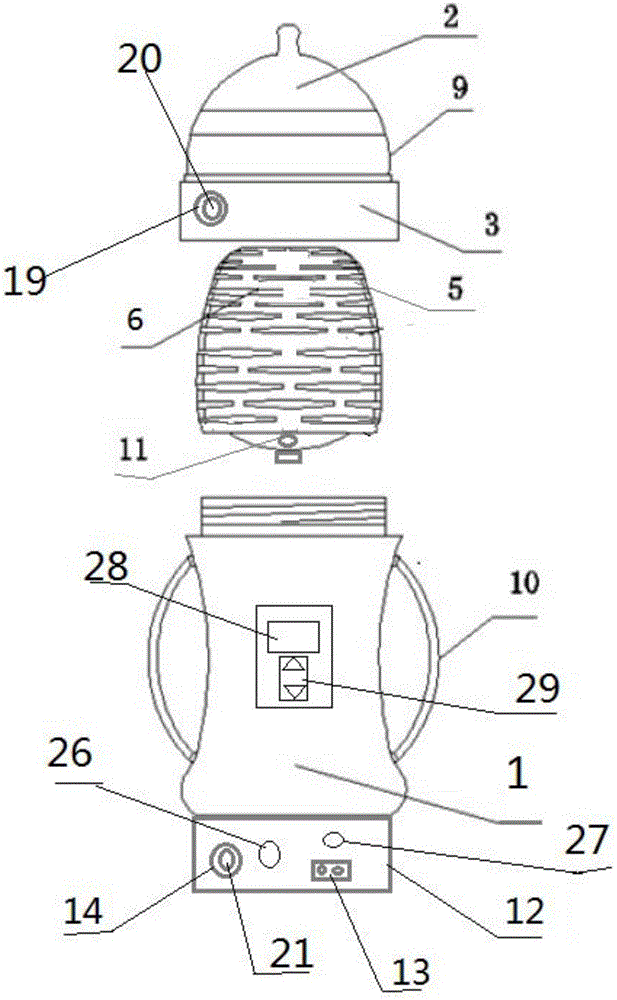

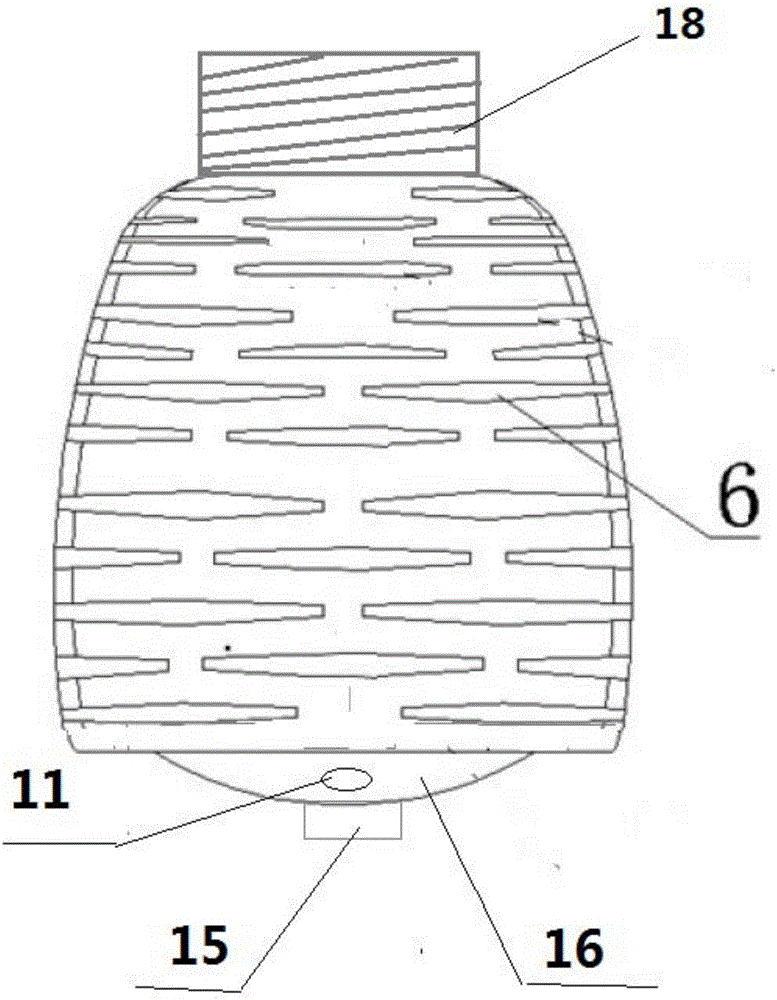

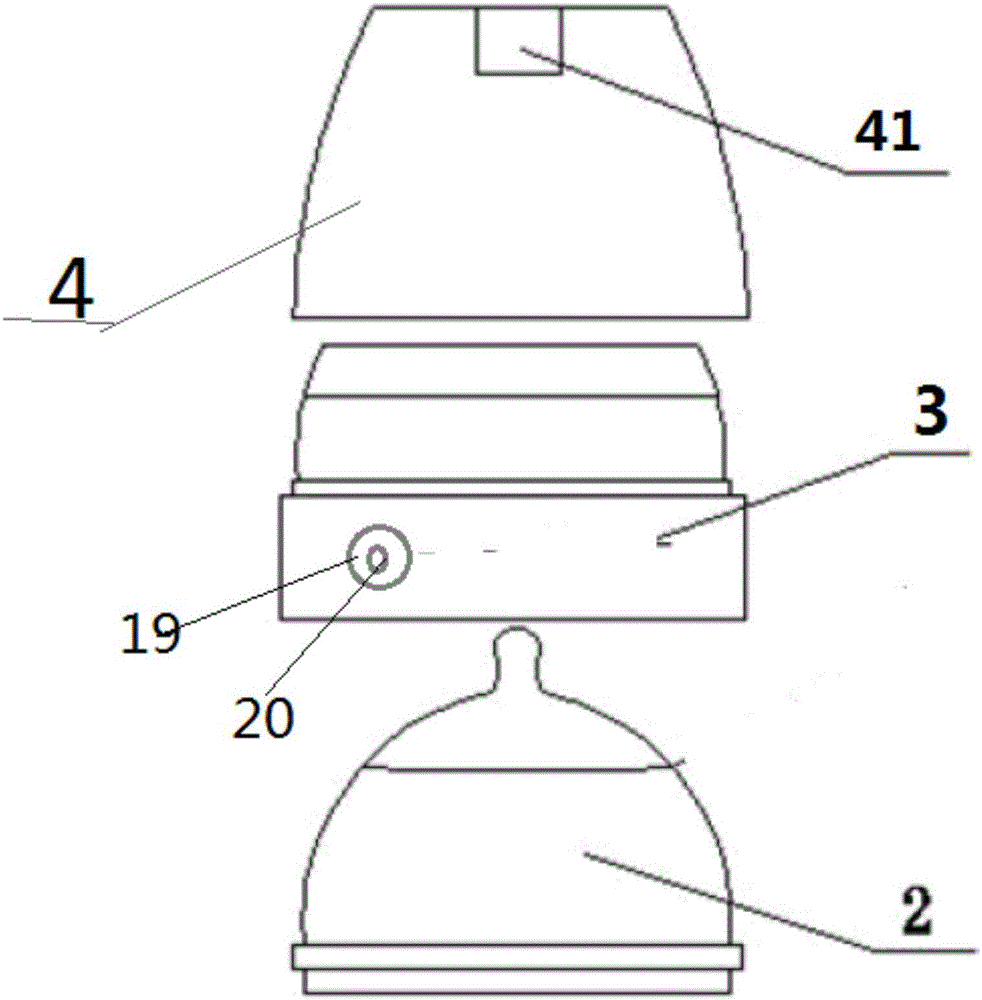

Temperature control feeding-bottle with disinfecting function

InactiveCN106038312AImprove insulation effectSensitive temperature monitoringOther dairy technologyFeeding-bottlesTemperature controlComing out

A temperature-controlled feeding bottle with a disinfection function, including a bottle body, a nipple, a nipple ring, a bottle cap, a temperature regulating device, an inner tank, and a base; diverter plates are evenly distributed around the outer layer of the temperature regulating device, and each diverter plate is up and down and There are distances on the left and right to form a fluid channel; the temperature sensor switch is set with a temperature control range value, the air pump is only in the open state when the temperature in the inner tank is higher or lower than the temperature control range value, and the heating device is only in the inner tank. When the temperature in the tank is lower than the temperature control range value, it is in the open state; when the air pump is turned on, the gas passes through the air inlet hole and the hole between the splitter plates, and then comes out of the air outlet hole, and is heated with the liquid in the inner tank. Exchange, to realize the function of heating or cooling the liquid in the inner tank; the bottom of the inner tank is transparent, and the ultraviolet rays can pass through the inner tank and inject into the liquid in the inner tank. The ultraviolet disinfection lamp on the base is powered by a lithium battery, and the ultraviolet rays can The disinfection lamp emits ultraviolet light to sterilize the liquid in the inner tank.

Owner:龙文凯

Slag discharging device used for aluminum smelting furnace combustion equipment

ActiveCN109628749ARapid precipitationSave human effortCharge manipulationCrucible furnacesCombustionSlag

The invention discloses a slag discharging device used for aluminum smelting furnace combustion equipment and relates to the technical field of metal smelting. The slag discharging device used for thealuminum smelting furnace combustion equipment comprises a stirring kettle, a stirring shaft arranged in the stirring kettle, a filtering net embedded in the bottom of the stirring kettle and a collecting box body connected to the lower surface of the stirring kettle and covering the filtering net. The slag discharging device further comprises a cooking kettle. The bottom of the cooling kettle communicates with the top of the stirring kettle through a switching-on pipe provided with a first electric control valve. The bottom end of the stirring kettle communicates with the top of the cookingkettle through a flow return pipe. A first pump body is installed on the flow return pipe. According to the slag discharging device, dross mixtures can flow cyclically in the stirring kettle and the cooling kettle, aluminum slag can be rapidly separated out, manual work is not needed for cooling and spreading of the dross mixtures, the dross obtained after cooling and spreading does not need to beadded into the stirring kettle through manpower, a large amount of labor is saved, workers also cannot make direct contact with the high-temperature dross, and the safety capability is improved.

Owner:四会市国耀铝业有限公司

Thermal expansive aluminum guide roller and production method thereof

InactiveUS20140100096A1Sufficient thermal expansion effectAdapt quicklyBearing assemblyVacuum evaporation coatingMaterials scienceMetallic Nickel

A thermal expansive aluminum guide roller includes: an aluminum guide roller base, wherein the aluminum guide roller base is coated by an irony layer, the irony layer is coated by a hard metallic layer. Preferably, the hard metallic layer is a nickel layer or a titanium layer. Aluminum is utilized because of a small density. With the light weight, inertia is small and a rotation speed can be adjusted rapidly for quickly adapting to different conditions while coating. A production method of the thermal expansive aluminum guide roller includes: a step of preparing the aluminum guide roller base, wherein the production method further includes steps of: A) preparing an irony sleeve; B) inserting the aluminum guide roller base into the irony sleeve; C) forming the irony layer; and D) forming a coating layer, wherein the irony layer is coated by a hard metallic layer.

Owner:SHANGHAI HONGHAO ENTERPRISE DEV

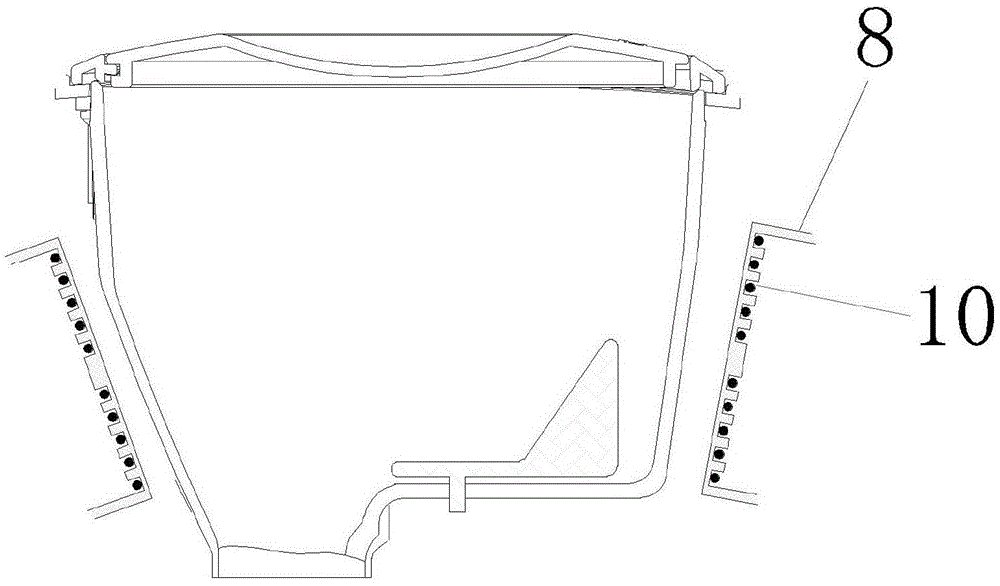

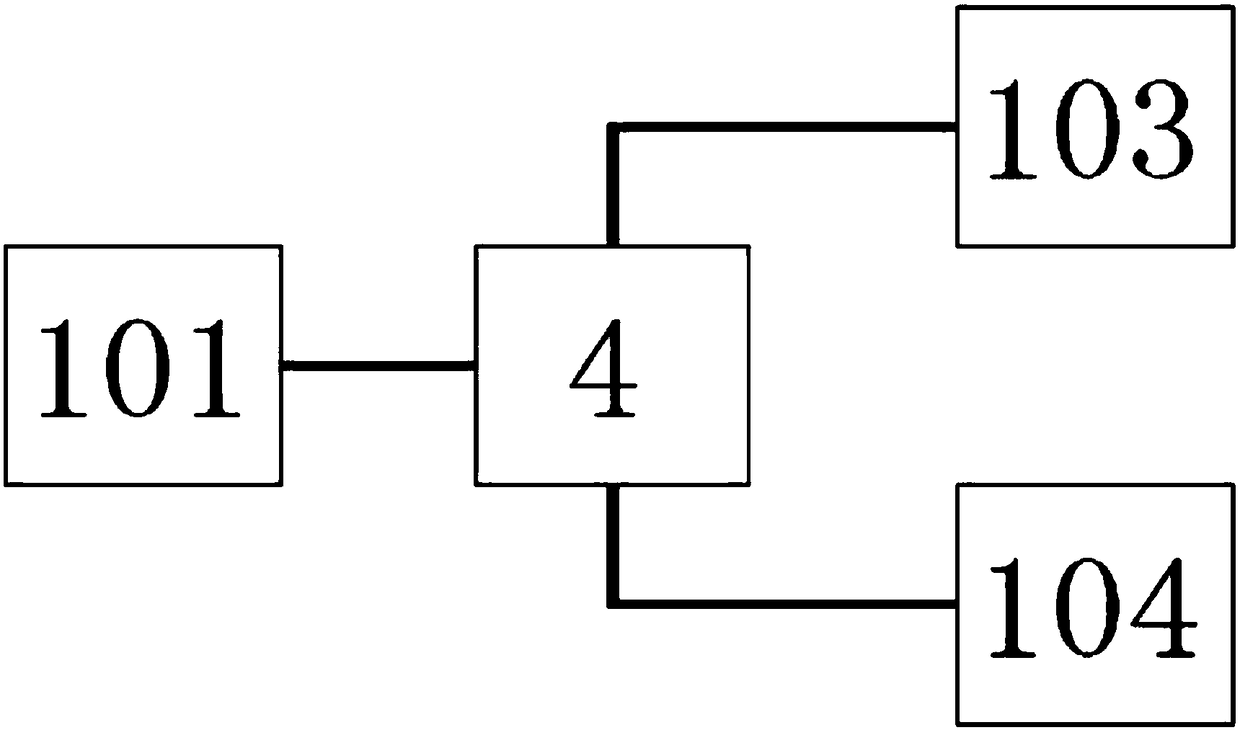

Feeding bottle with disinfection function and intelligent temperature adjustment

ActiveCN105943401AIncrease heat conduction areaAdequate heat conductionFeeding-bottlesTeatsProduct gasEngineering

The invention provides a feeding bottle with a disinfection function and intelligent temperature adjustment. The feeding bottle comprises a bottle body, a nipple, a nipple ring, a bottle cap, a temperature adjustment device, a liner and a base, wherein splitting plates are uniformly crosswise distributed on the periphery of the outer layer of the temperature adjustment device, and intervals are reserved among the splitting plates in up, down, left and right; a display screen and temperature adjustment buttons are arranged on the outer part of the bottle body; a CPU is arranged inside the base; the display screen, the temperature adjustment buttons and a temperature sensor switch are connected with the CPU, and a temperature controlled range value can be set for the CPU by virtue of the temperature adjustment buttons; an air pump is in an opened state only when the temperature in the liner is higher or lower than the temperature controlled range value, and the heating device is in an opened state only when the temperature in the liner is lower than the temperature controlled range value; under an air pump opened state, gas comes out from an air outlet through the air inlet and holes among the splitting plates, and the function of heating or cooling liquid in the liner can be achieved; and the liner bottom is transparent, an ultraviolet disinfection lamp on the base is used for disinfecting the liquid in the liner under a power supply opening state.

Owner:永康市超朗工贸有限公司

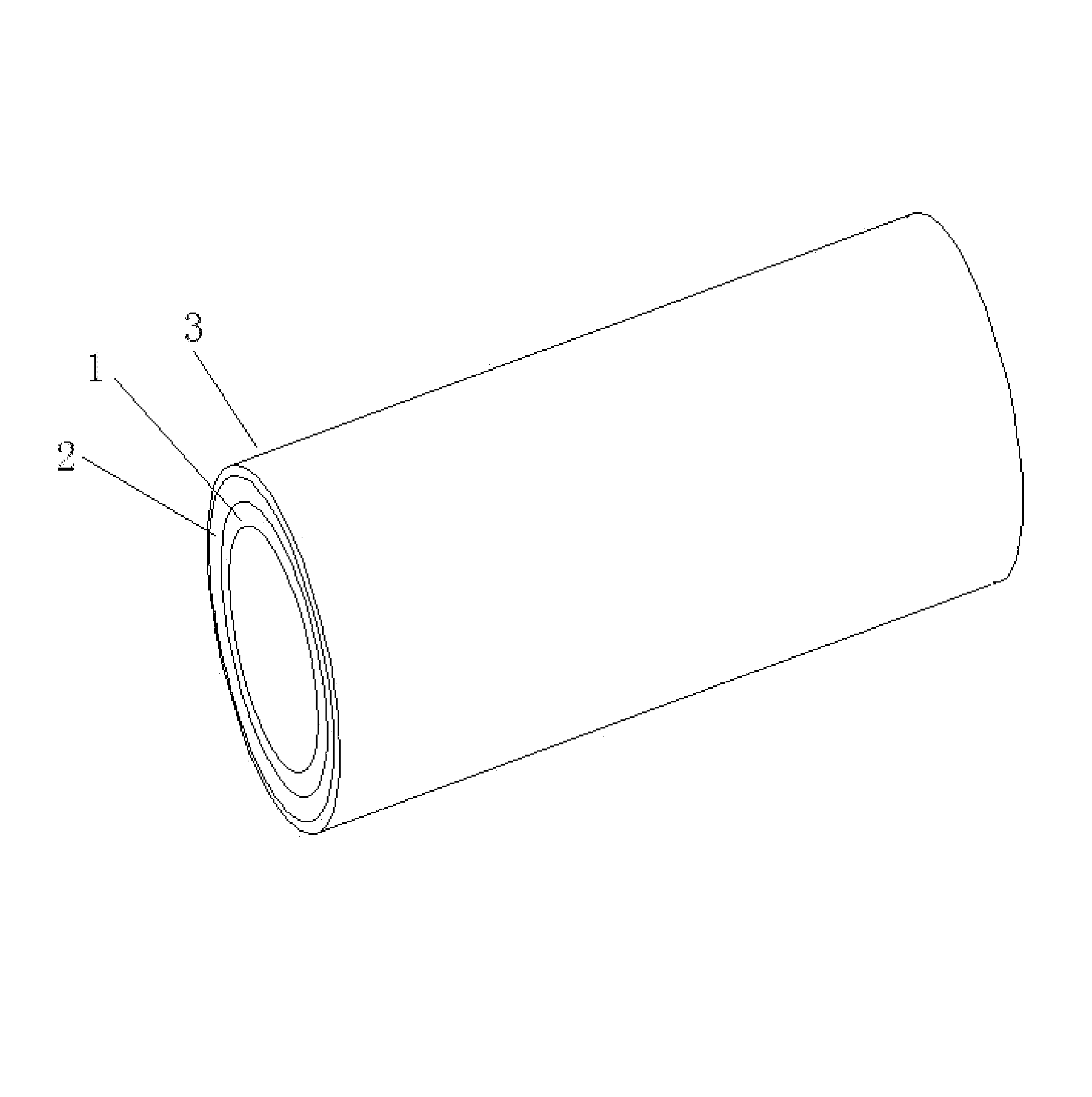

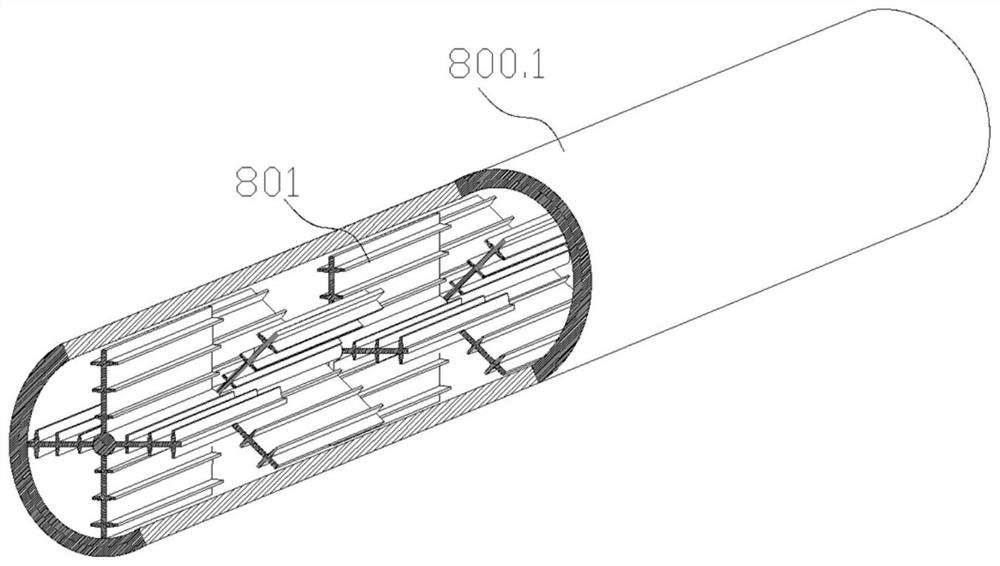

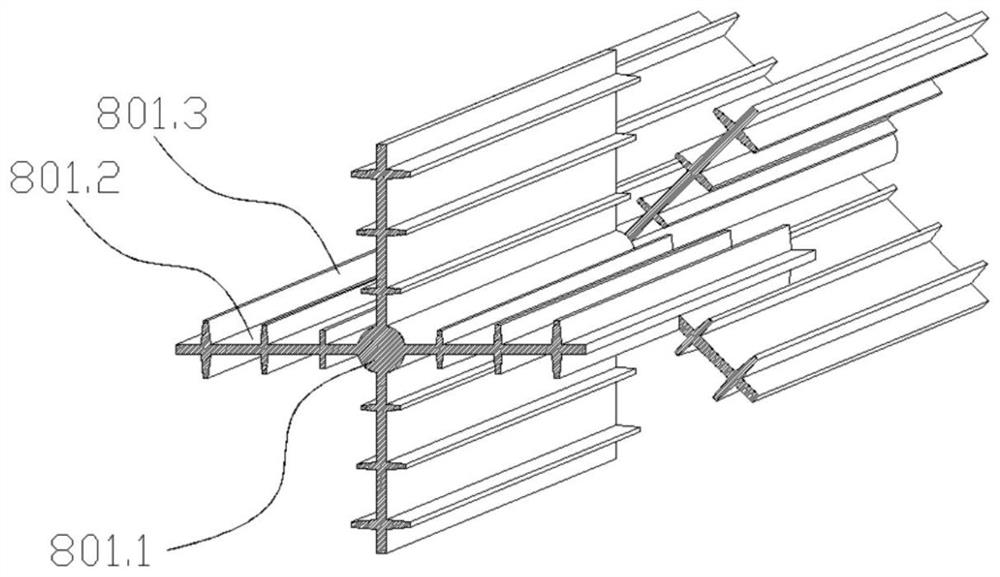

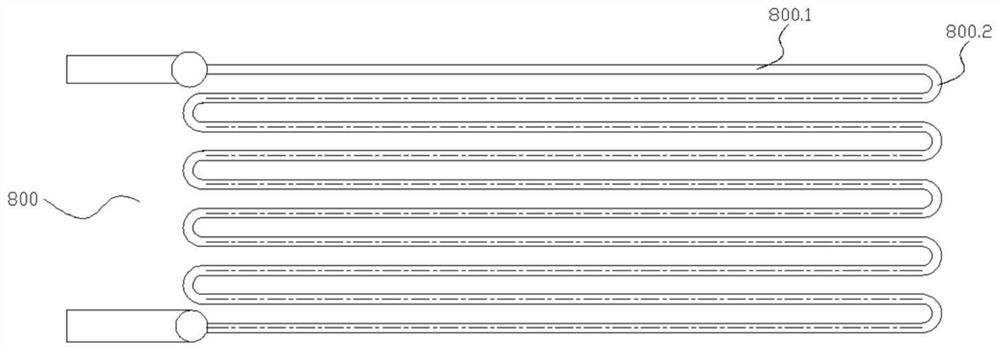

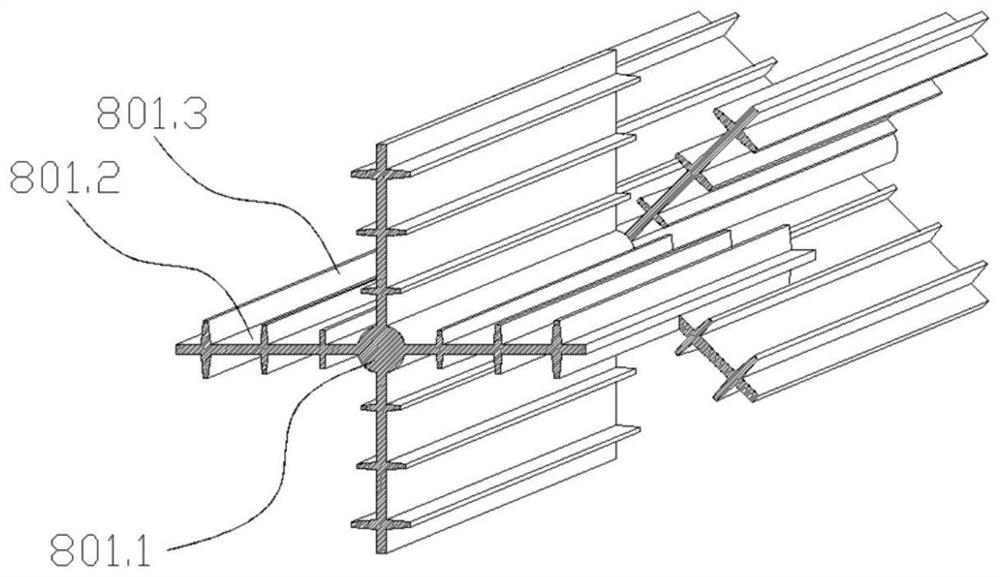

Production method of heat exchange coil pipe with heat conduction profile with auxiliary fins

The invention relates to a production method of a heat exchange coil pipe with a heat conduction profile with an auxiliary fin, which is characterized by comprising the following specific steps: step 1, firstly, extruding and molding a full-length profile which is matched with a fin group in section shape by adopting a die, and additionally, producing a full-length sleeve which is consistent with a heat exchange coil pipe main body in caliber; secondly, the full-length sectional material is twisted into a heat conduction sectional material with auxiliary fins, and the heat conduction sectional material is internally installed in the full-length sleeve to form a straight pipe section; and thirdly, the straight pipe sections and the bent pipe sections are connected to form the heat exchange coil pipe of the heat conduction sectional material with the auxiliary fins. According to the production method of the heat exchange coil pipe with the heat conduction sectional material with the auxiliary fins, fluid in a product can conduct heat to the heat exchange coil pipe body through the heat conduction sectional material arranged in the pipe with the excellent heat conduction performance, and therefore the heat exchange amount and the heat exchange speed are greatly increased.

Owner:江苏金荣森制冷科技有限公司

Molding device

PendingCN114290011AIncrease the heat exchange areaAdequate heat conductionMechanical engineeringMucous membrane

The forming device is characterized by comprising a rolling wheel set, the rolling wheel set comprises a rolling male die set and a rolling female die set which are arranged up and down, and protrusions matched with special-shaped structures in size are arranged on rolling male dies at intervals in the circumferential direction; and recesses matched with the special-shaped structures in size are formed in the rolling concave die in the circumferential direction at intervals. The special-shaped structures are arranged on the main fins of the heat conduction profile produced by the forming device, the special-shaped structures not only increase the heat exchange area of fluid in a pipe, but also can continuously break a liquid mucous membrane which prevents heat from being conducted to the inner pipe wall, and the heat exchange effect of the heat conduction profile is improved.

Owner:江苏金荣森制冷科技有限公司

Breathable head-mounted Bluetooth headset

ActiveCN113347521AEnables active ventilationImprove breathabilityHearing aid ventsSupra/circum aural earpiecesMechanical engineeringActive ventilation

The invention discloses a breathable head-mounted Bluetooth headset, and belongs to the technical field of Bluetooth headsets. A plurality of breathable air holes are formed in a receiver, then a breathable bag and a heat conduction bag are vertically distributed, the heat conduction bag is used for absorbing heat generated in the working process of the receiver, then the heat is transferred to an internal heat floating ball, the heat floating ball expands after absorbing certain heat, so that buoyancy is increased, the heat floating ball floats upwards, and the breathable bag on the upper side is extruded, air accumulated in the breathable bag is exhausted, active ventilation in the breathable air holes is achieved, and meanwhile heat on the heat floating ball is dissipated to the outside through a magnetic heat conduction umbrella and a outer heat conduction piece to achieve cooling. After cooling, the heat floating ball sinks and resets after restoring the original buoyancy, the breathable bag also restores the shape and absorbs external air for filling, the repeated breathable action of the breathable bag can be realized by repeating the actions, and the breathability of the receiver and the ears is obviously improved.

Owner:深圳市讴旎科技有限公司

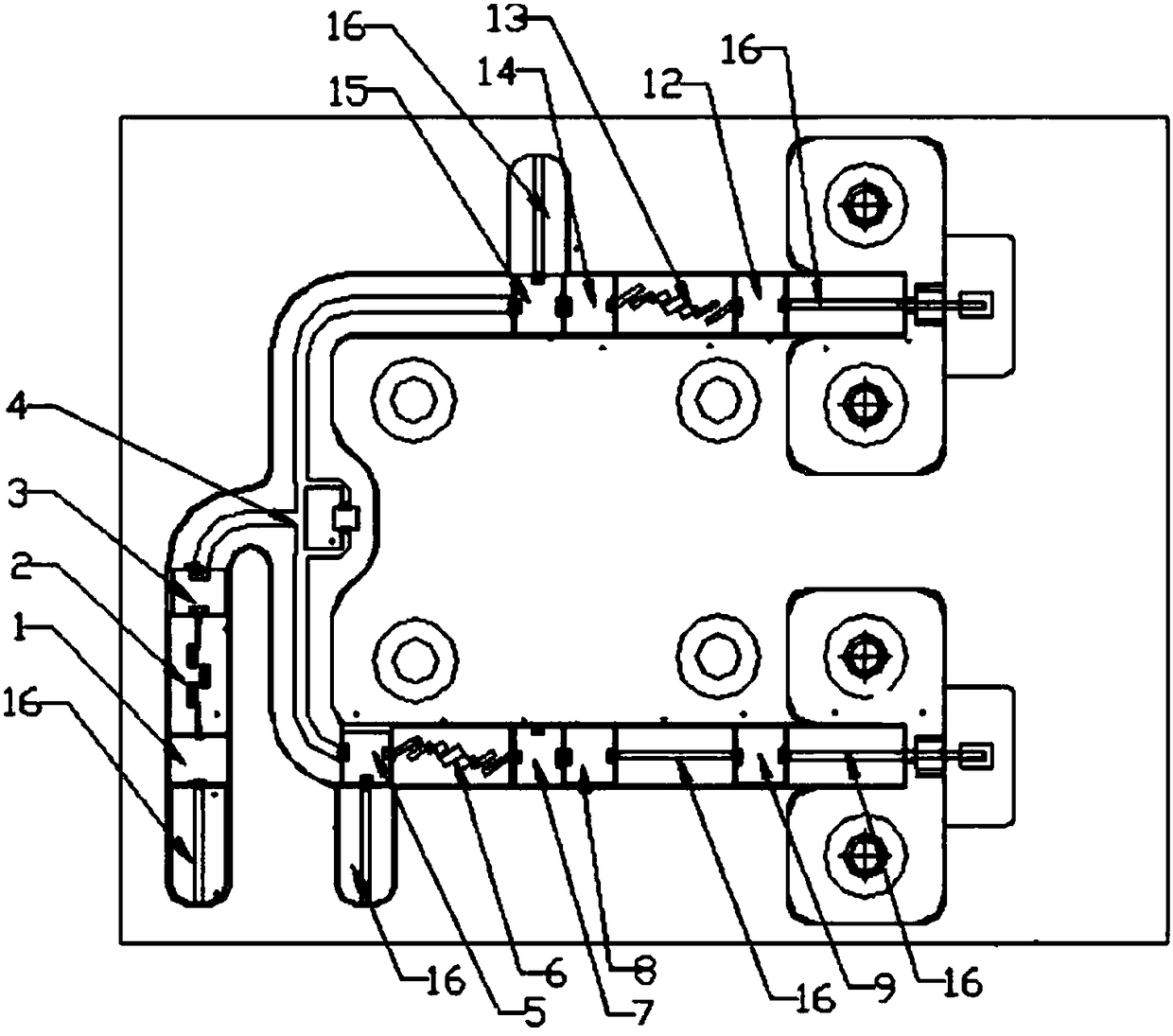

Liquid cooling arrangement for electric

ActiveCN102341999BAdequate heat conductionNo loss of contactMagnetic circuit stationary partsCooling/ventillation arrangementElectric machineMechanical engineering

A liquid cooling arrangement for electric machines uses a continuous cooling tube associated with a heat storing element. The cooling tube has a serpentine configuration and the heat storing element includes longitudinal slots starting from both longitudinal ends of the heat storing element. Accordingly, it is possible to slightly deform the heat storing element to properly position it into the internal stator of an electric machine. An internal biasing assembly may be used to force the external surface of the heat storing element to the internal surface of the stator.

Owner:TM4 INC

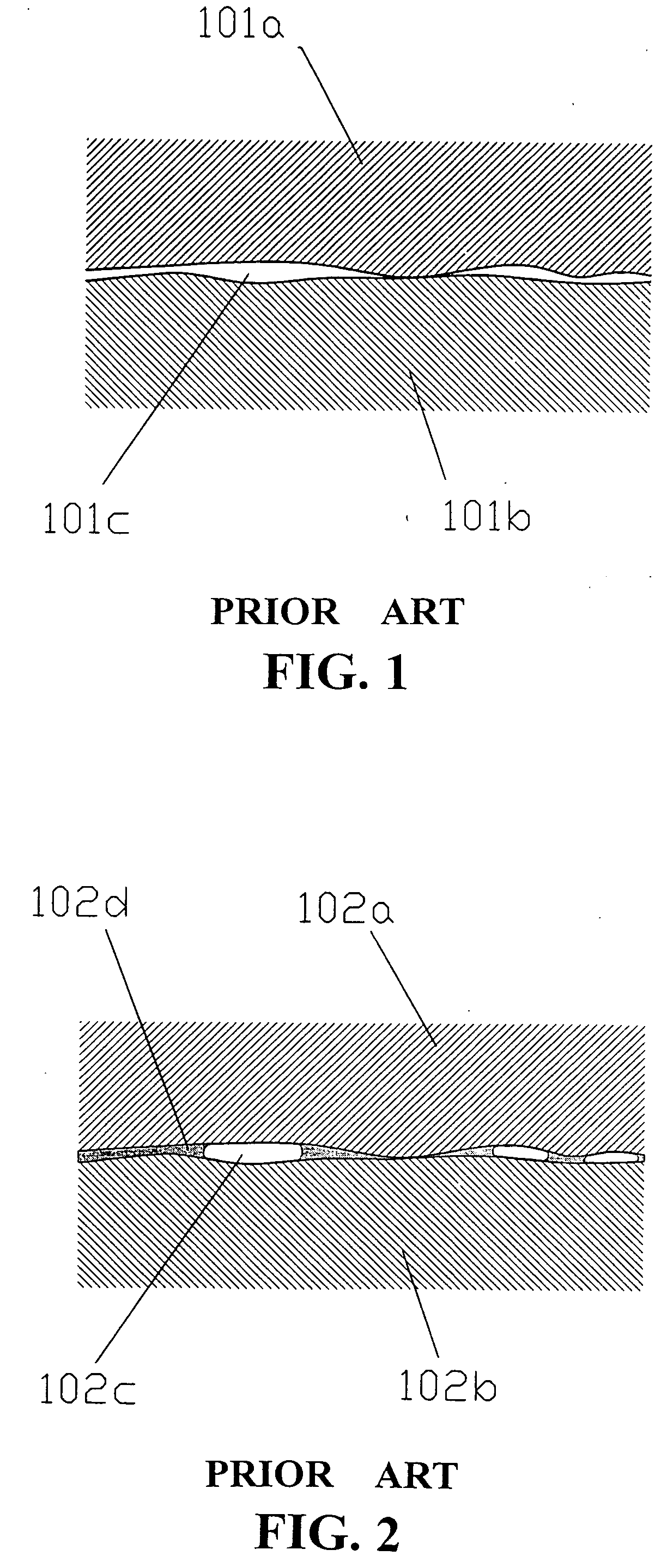

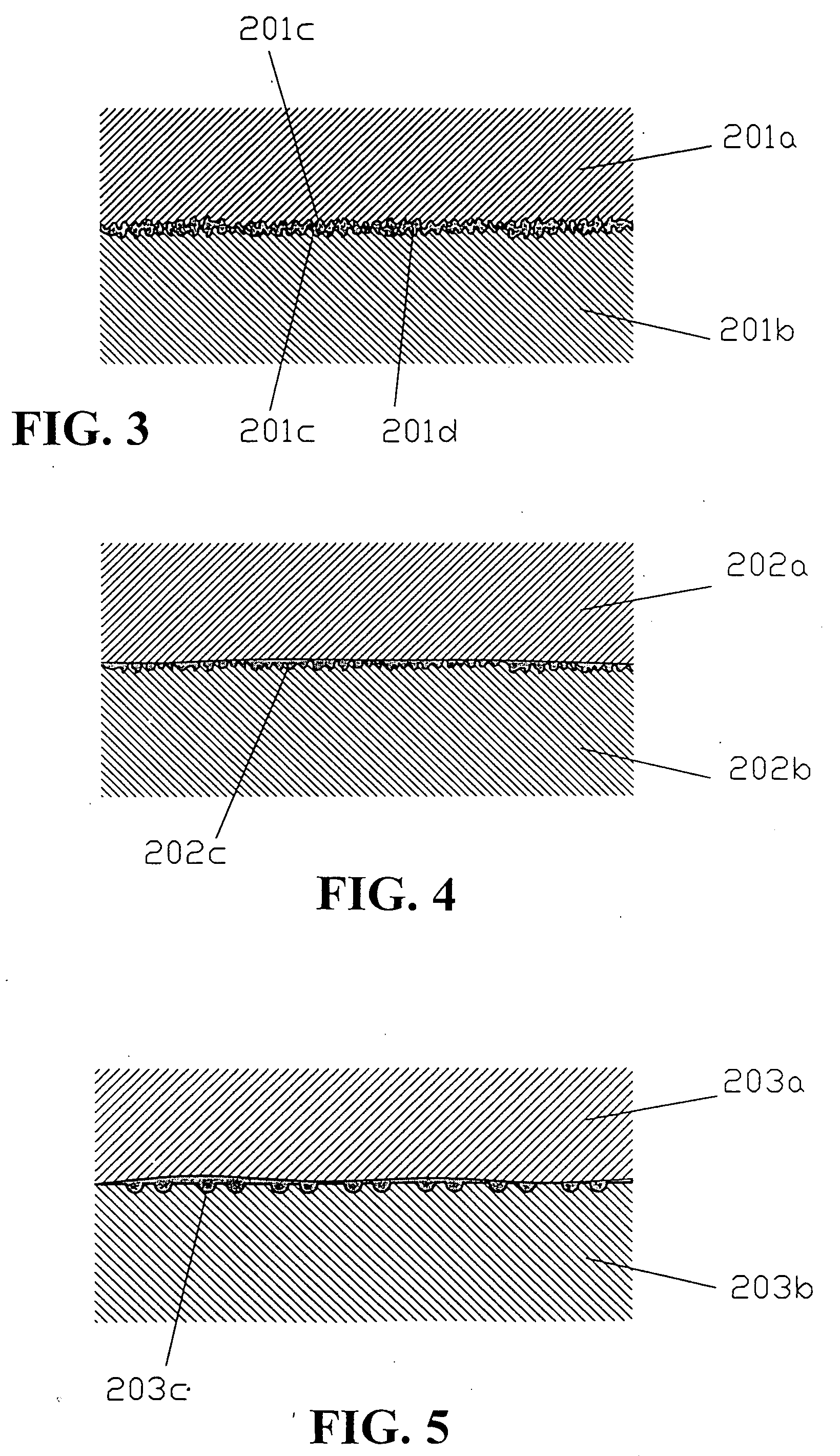

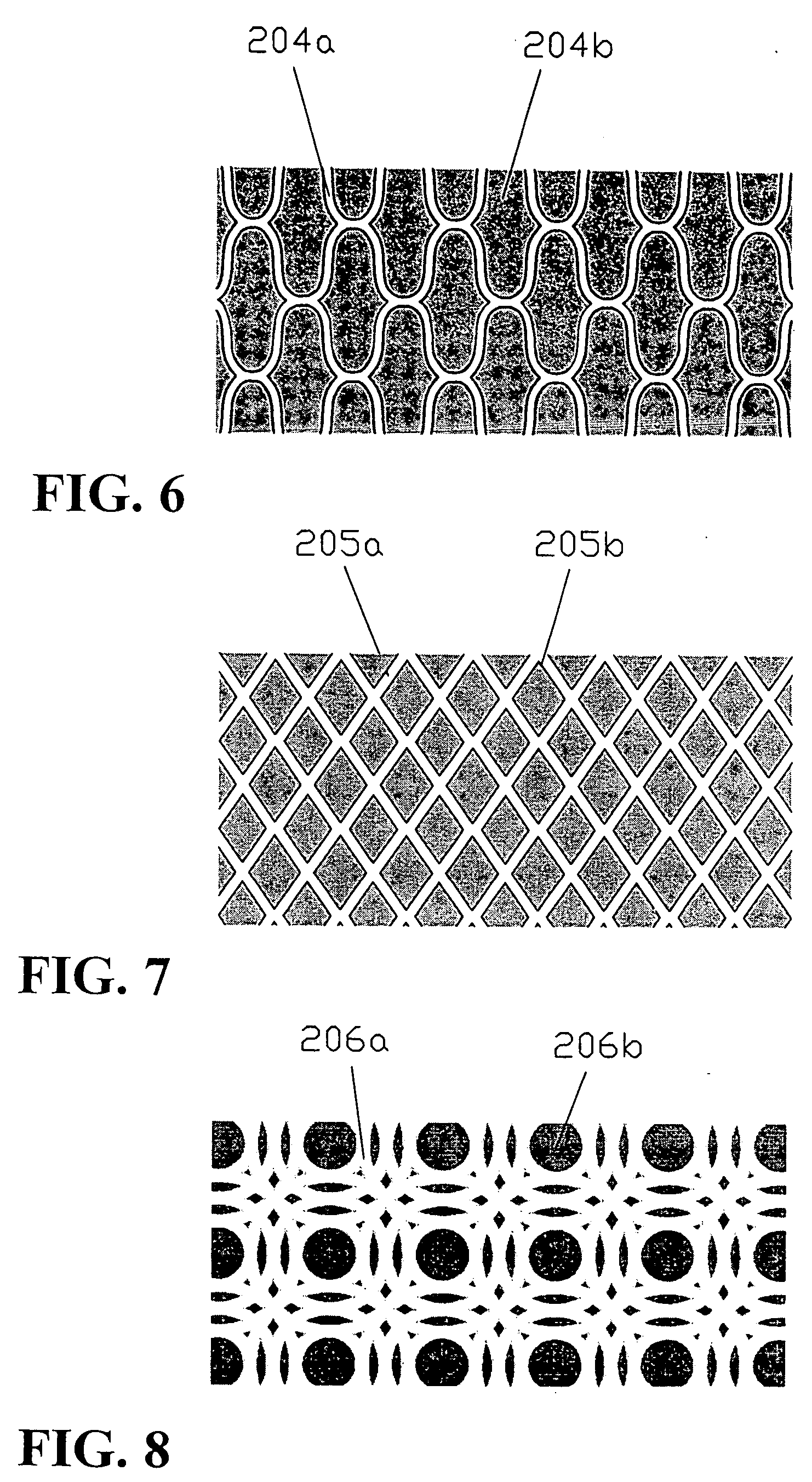

Low thermal resistance junction processing

InactiveUS20060131367A1Improve structural strengthImprove airtightnessSoldering apparatusMetal working apparatusMetallic materialsSolder paste

A method for reducing thermal resistance at a junction between two types of metallic material is provided. The method mainly forms a capillary structure between the two surfaces of the two identical or different types of metallic material. The method then adds and melts an appropriate amount of soldering paste at the junction so as to bind the two types of metallic material together. The invention could achieve superior structural strength and thermal conductivity at the junction.

Owner:LEE FREDERICK

Multifunctional electric cooker

InactiveCN103622533AClose contactMeet soft and hard requirementsCooking vesselsElectricityHeat conducting

The invention discloses a multifunctional electric cooker which comprises a cooker body. The multifunctional electric cooker is characterized in that a heating disc, a cooker container and a cooker cover are arranged in the cooker body. A groove is formed in the heating disc. A concave block is arranged on the groove. A concave strip connected with the concave block is arranged on the inner wall of the groove. A protruding groove matched with the groove is formed in the bottom of the cooker container. A protruding block matched with the concave block is arranged on the protruding groove. Wide-strip grooves are symmetrically formed in the inner wall in the cooker container. An H-shaped partitioning plate can be placed in the wide-strip grooves. The multifunctional electric cooker has the advantages that the protruding block on the bottom of the cooker container can be imbedded into the concave strip at the bottom of the cooker body, so that the cooker body and the cooker container are in tight contact, heat conducting is sufficient, electricity is saved, the H-shaped partitioning plate in the cooker container can isolate the cooker container, and meanwhile the requirement on food softness and hardness of people is met.

Owner:茅裕娟

A miniaturized millimeter-wave transceiver component based on high-temperature pressureless seamless sintering technology

ActiveCN105743533BReduce lossSatisfy one-time process moldingMagnetic/electric field screeningTransmissionMillimeter wave communication systemsTransceiver

The invention discloses a high-temperature non-pressure seamless sintering technology-based miniaturized millimeter wave transmitting and receiving assembly. The high-temperature non-pressure seamless sintering technology-based miniaturized millimeter wave transmitting and receiving assembly includes a shielding box body, a local vibration frequency multiplication link, a power allocation link, a receiving link and a transmitting link; the local vibration frequency multiplication link is connected with the power allocation link; the power allocation link is connected with the receiving link and the transmitting link; a 85:15 tungsten copper alloy shielding box body is adopted as the shielding box body; the links are in direct bonded connection with adjacent MMIC chips through 25 um golden wires; conversion can be realized through glass insulator and copper bar high-temperature sintered integrated probe waveguides. The high-temperature non-pressure seamless sintering technology-based miniaturized millimeter wave transmitting and receiving assembly of the invention has the advantages of compact structure and easiness in debugging, and can effectively meet the requirements of an ultra-wide-band and high-speed millimeter wave communication system.

Owner:NANJING CAIHUA TECH GROUP

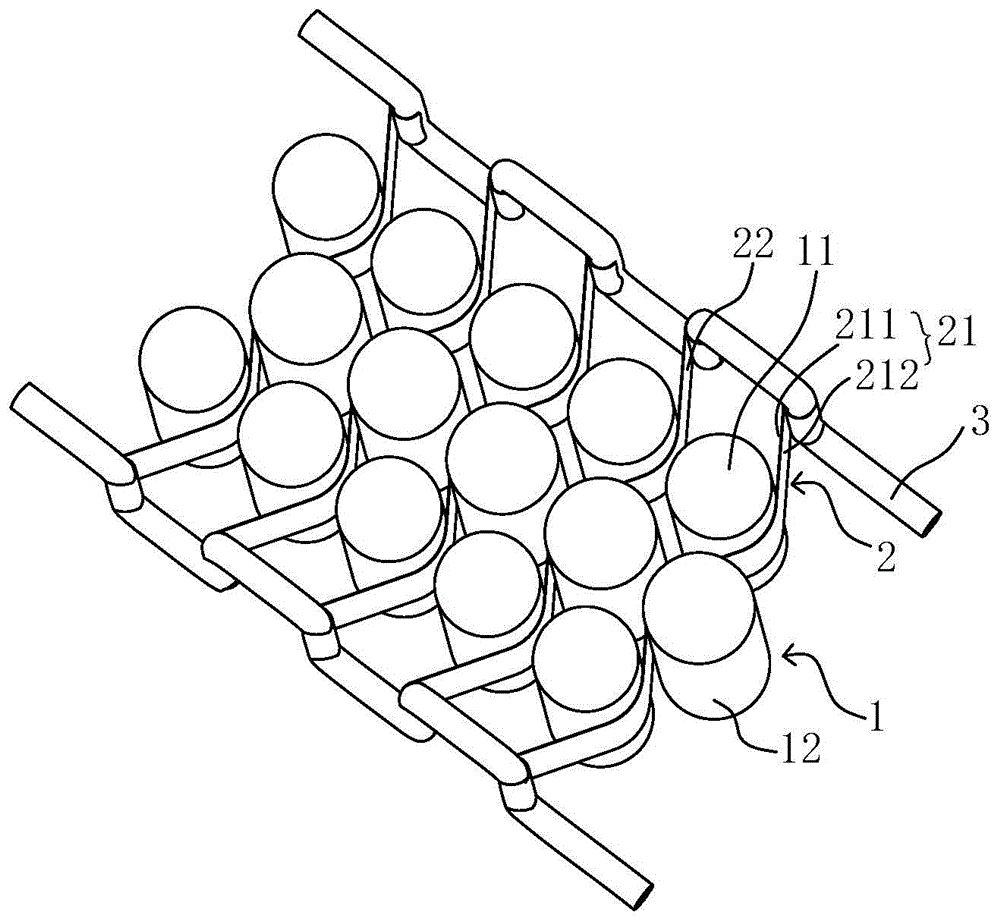

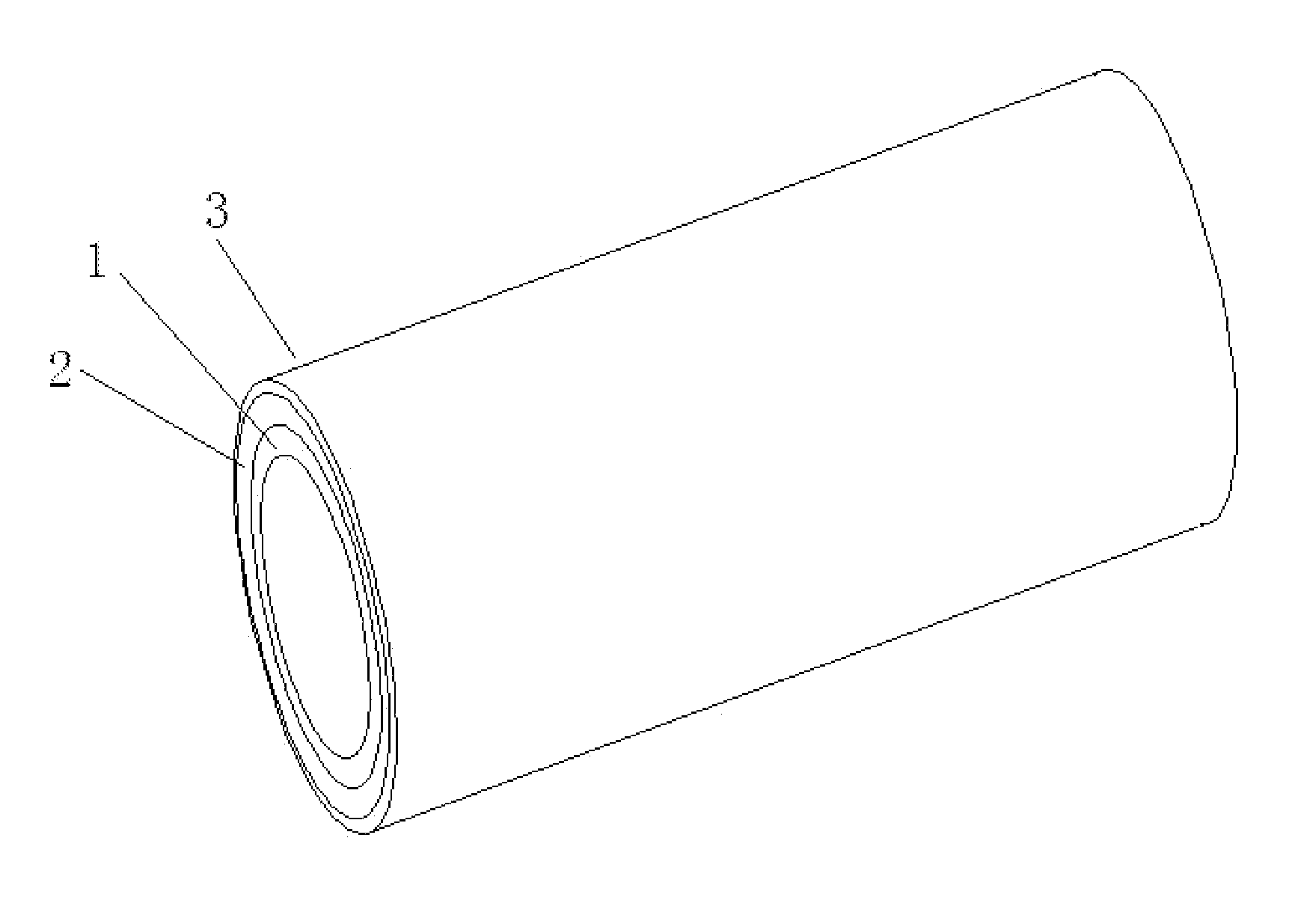

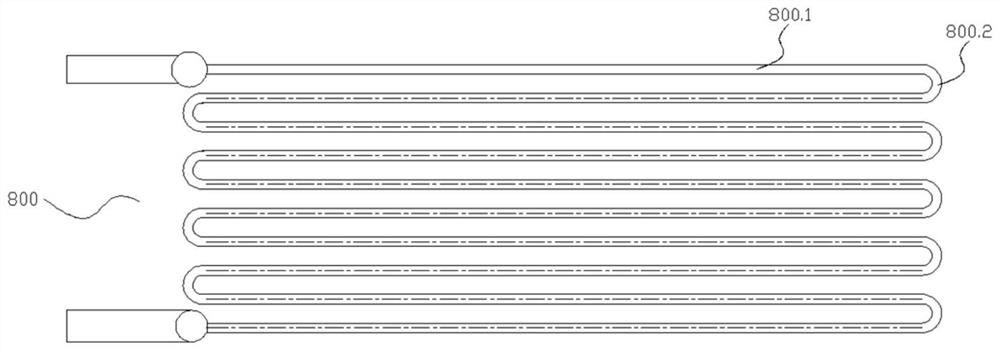

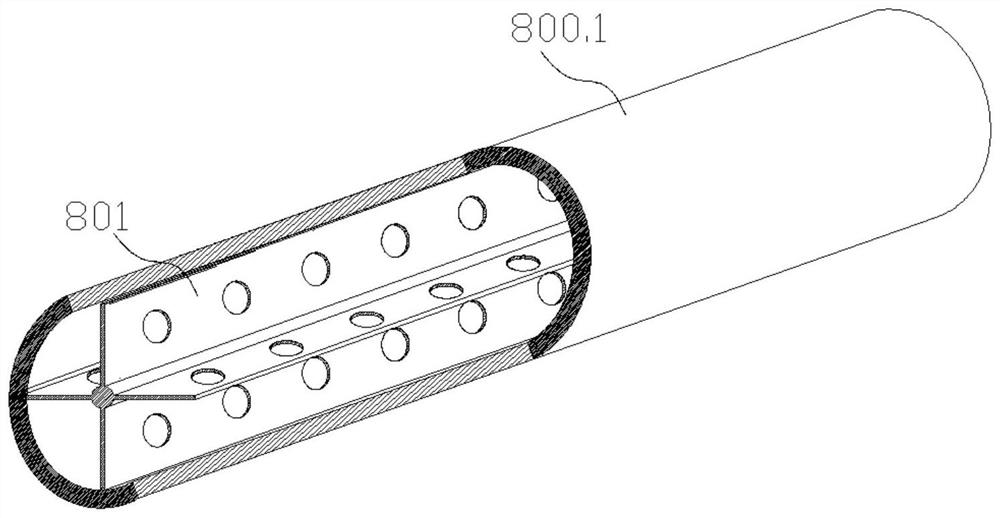

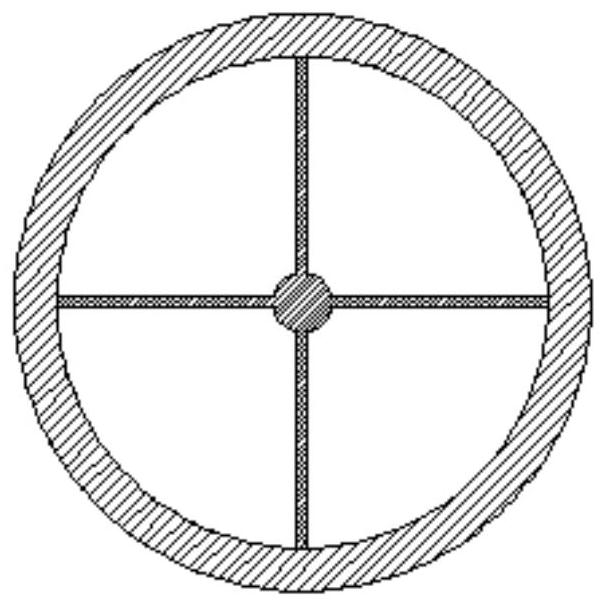

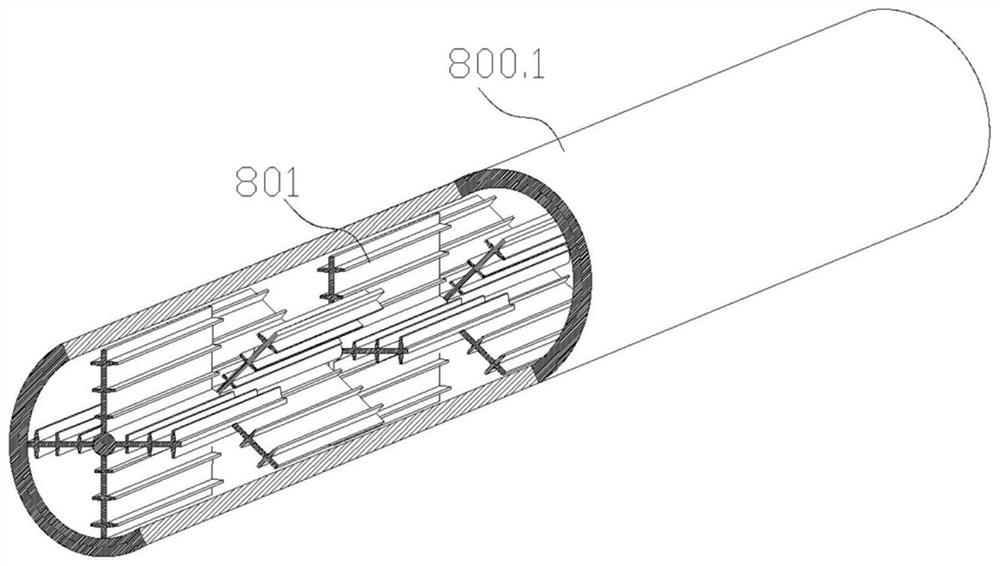

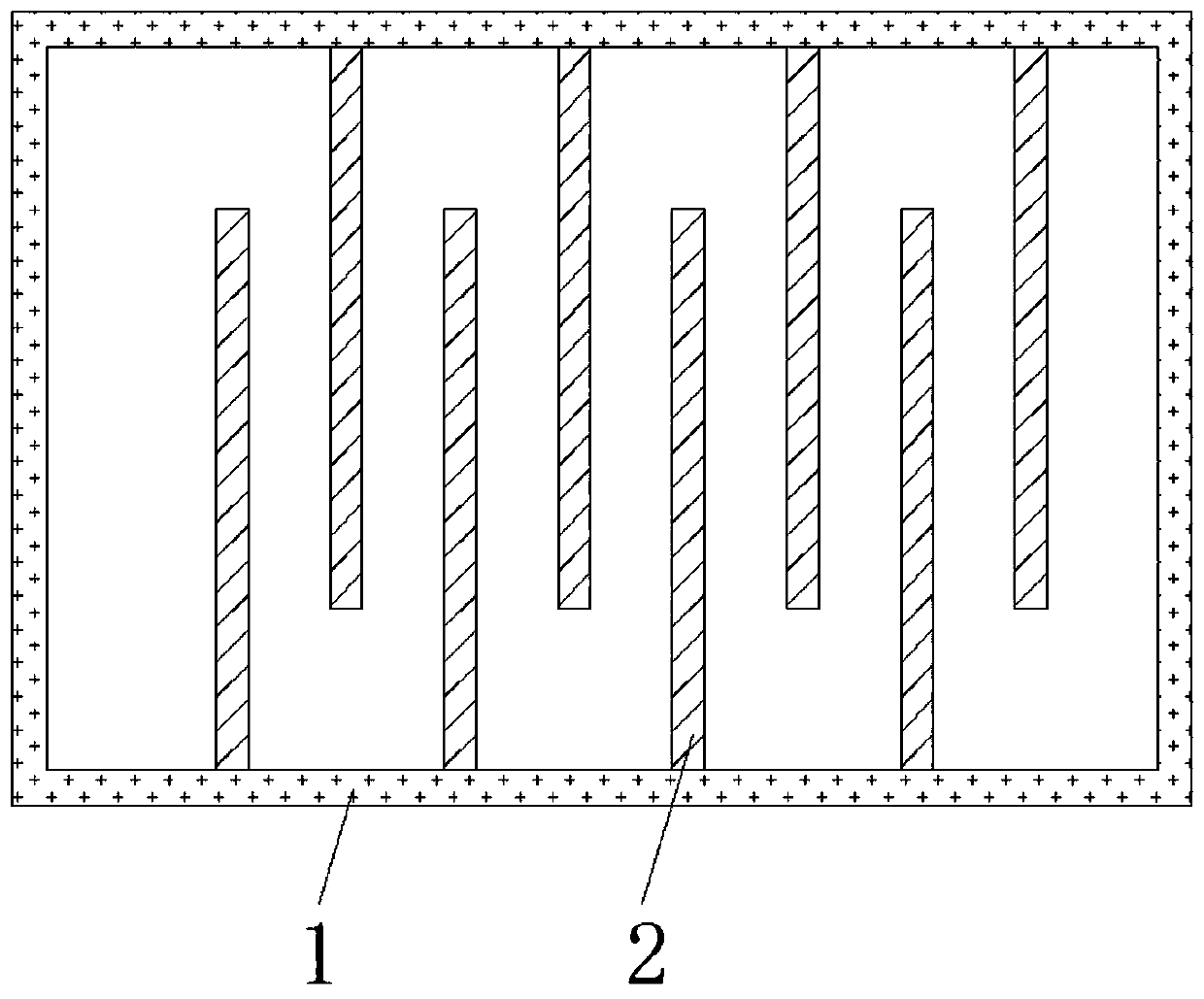

Heat exchange coil pipe with heat conduction section bar with auxiliary fins

PendingCN114353577AIncrease the heat exchange areaAdequate heat conductionTubular elementsStraight tubeMechanics

The heat exchange coil pipe comprises a heat exchange coil pipe main body, the heat exchange coil pipe main body comprises a straight pipe section and a bent pipe section, the straight pipe section of the heat exchange coil pipe main body is internally provided with the heat conduction profile with the auxiliary fins, and the bent pipe section of the heat exchange coil pipe main body is internally provided with the heat conduction profile with the auxiliary fins. The heat conduction profile with the auxiliary fins comprises a circular core rod arranged in the direction of the heat exchange coil body, main fins are arranged outside the core rod, and the auxiliary fins are arranged outside the main fins. Fluid in the heat exchange coil pipe with the heat conduction sectional material with the auxiliary fins can conduct heat to the heat exchange coil pipe body through the heat conduction sectional material arranged in the pipe with the good heat conduction performance, and therefore the heat exchange capacity and the heat exchange speed are greatly increased.

Owner:江苏金荣森制冷科技有限公司

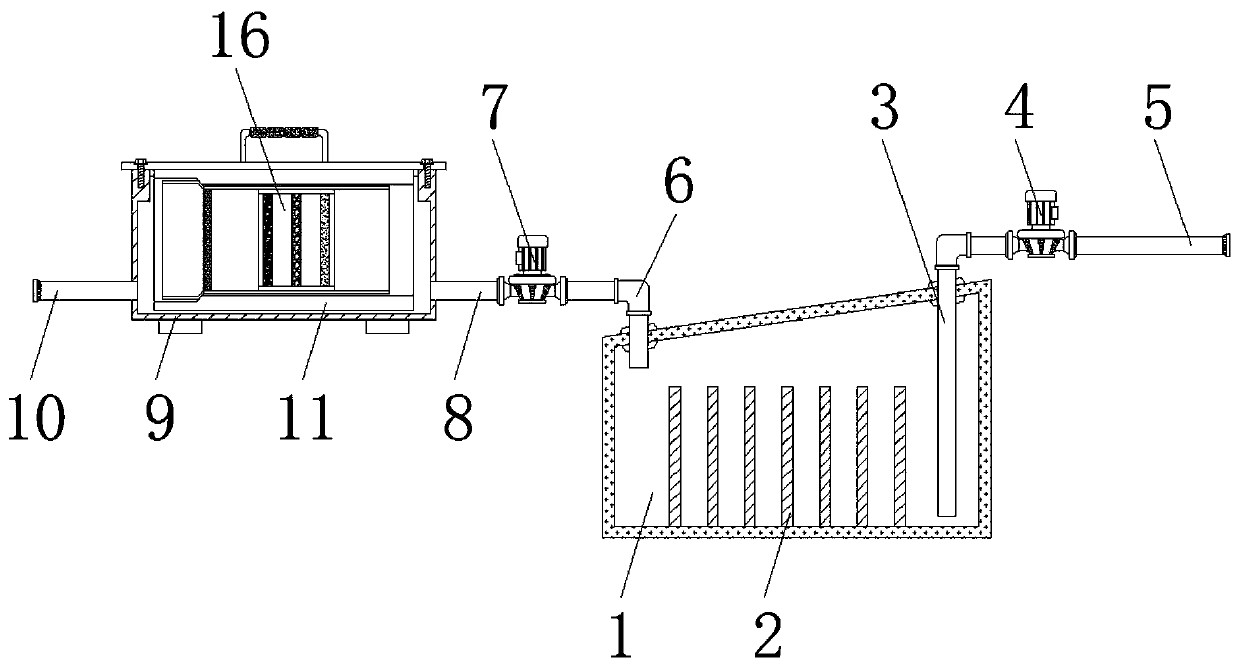

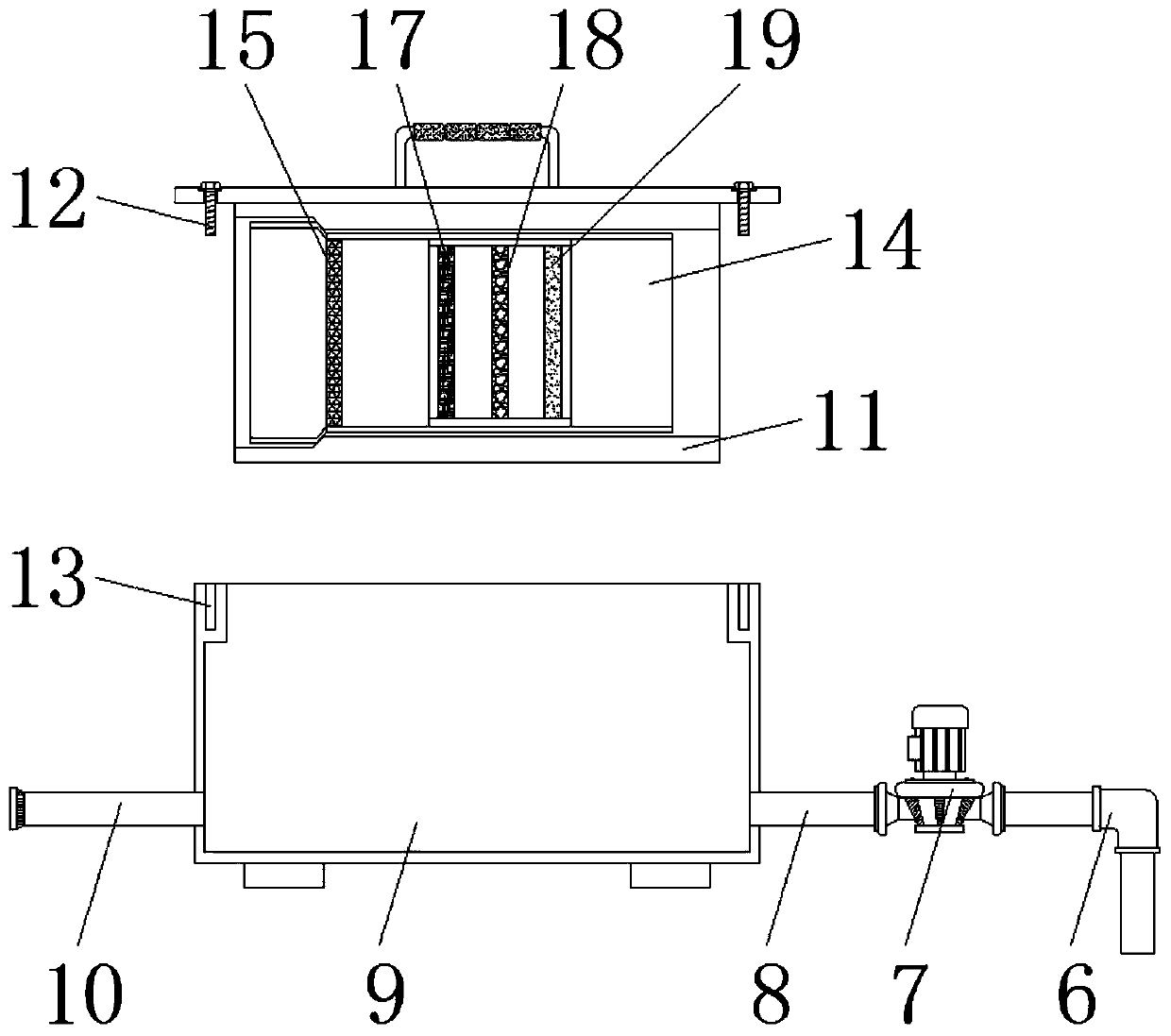

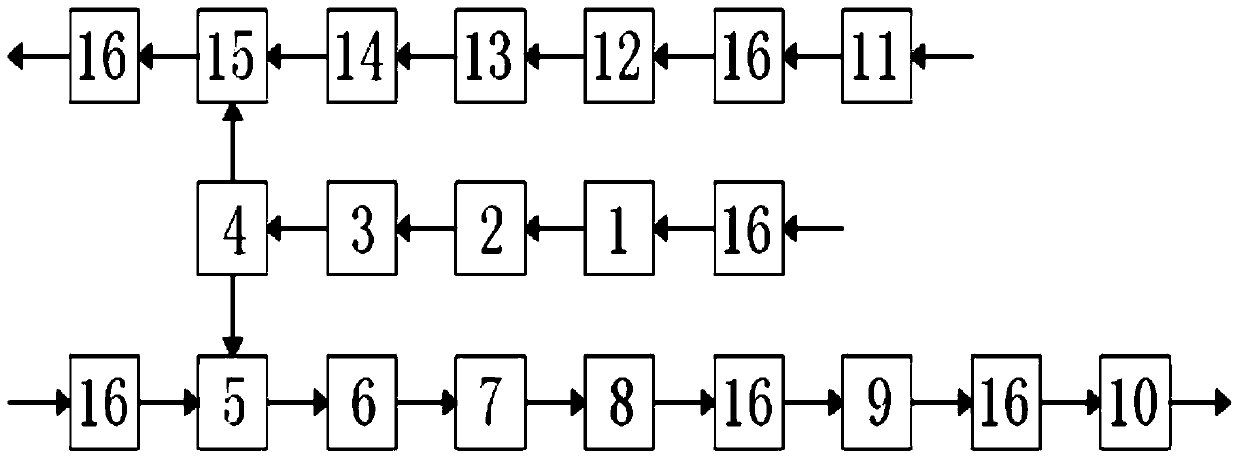

Cleaning ice water circulating system having filtering function and used for copper substrate production

InactiveCN111018161AConducive to heat dissipation and coolingReduce labor requirementsTreatment involving filtrationWaste water treatment from metallurgical processSlagWater reservoir

The invention discloses a cleaning ice water circulating system having a filtering function and used for copper substrate production. The cleaning ice water circulating system comprises a water storage pool, wherein water retaining walls are evenly arranged on the two sides of the inner bottom of the water storage pool in a staggered mode, one end of the top of the water storage pool communicateswith a cooling water outlet pipe, one end of the cooling water outlet pipe extends to the inner bottom of the water storage pool, a water pump A is arranged at the other end of the cooling water outlet pipe, and the output end of the water pump A communicates with a guide pipe A. The cleaning ice water circulating system is provided with a filter bin, a filter pipeline, a mounting pipe, a filter screen A, a mounting ring, a filter screen B, an activated carbon filter layer and a filter membrane, so cleaning sewage is continuously filtered and cleaned in the circulating process so as to allow the sewage to reach the recycling standard and prevent disintegrating slag from being attached to a copper substrate in the cleaning process; and fastening bolts and threaded grooves are employed for fixing and mounting, so the whole filter assembly is convenient to clean and replace, and thus, operation convenience is improved, and stability in the fixing process is improved.

Owner:安徽全照电子有限公司

A miniaturized millimeter wave transceiver component

ActiveCN105530026BReduce lossSatisfy one-time process moldingTransmissionMillimeter wave communication systemsTransceiver

The invention provides a miniature millimeter wave transceiver module. By improving the structure and the process, the defects of complex structure, huge volume, large debugging amount, low reliability and narrow communication frequency band of an existing millimeter wave transceiver module are solved, the miniature millimeter wave transceiver module with excellent performance is provided, and the miniature millimeter wave transceiver module is compact in structure, easy to debug, capable of effectively meeting the demands of millimeter wave communication systems with ultra wide bands and high speeds.

Owner:NANJING CAIHUA TECH GROUP

Fluidized-bed reactor and insert for said fluidized-bed reactor

InactiveCN102176962AHomogeneous heat loadAvoid deformationFluidized bed combustionGasifier feeding meansFluidized bedNuclear engineering

The invention relates to a fluidized-bed reactor having a higher power density and to an exchangeable insert for said fluidized-bed reactor, which insert makes the higher power density possible. The supply and pre-heating of the fluidizing agent, especially air, to the fluidized bed is combined with the cooling of the reactor vessel wall owing to the preferably exchangeable insert in the fluidized-bed reactor. The ''cold'' fluidizing agent is guided in at least one flow channel in the metal jacket surrounding the fluidized bed and is preheated and said channel and is then injected into the fluidized bed in an appropriate location. The reactor vessel wall is cooled by pre-heating the fluidizing agent.; The desired and required values for cooling the reactor vessel and the desired pre-heating of the fluidizing agent can be adjusted by suitably selecting the parameters 'length' and 'volume' of the flow channels in the insert and the flow rate of the fluidizing agent in the flow channels. The insert is used for supplying the fluidizing agent and for cooling the reactor vessel, thereby eliminating the need for a separate cooling device for the reactor vessel and for lining the reactor vessel with refractory clay. The reactor vessel according to the invention is compact, has a high power density and small thermal masses.

Owner:HIGHTERM RES

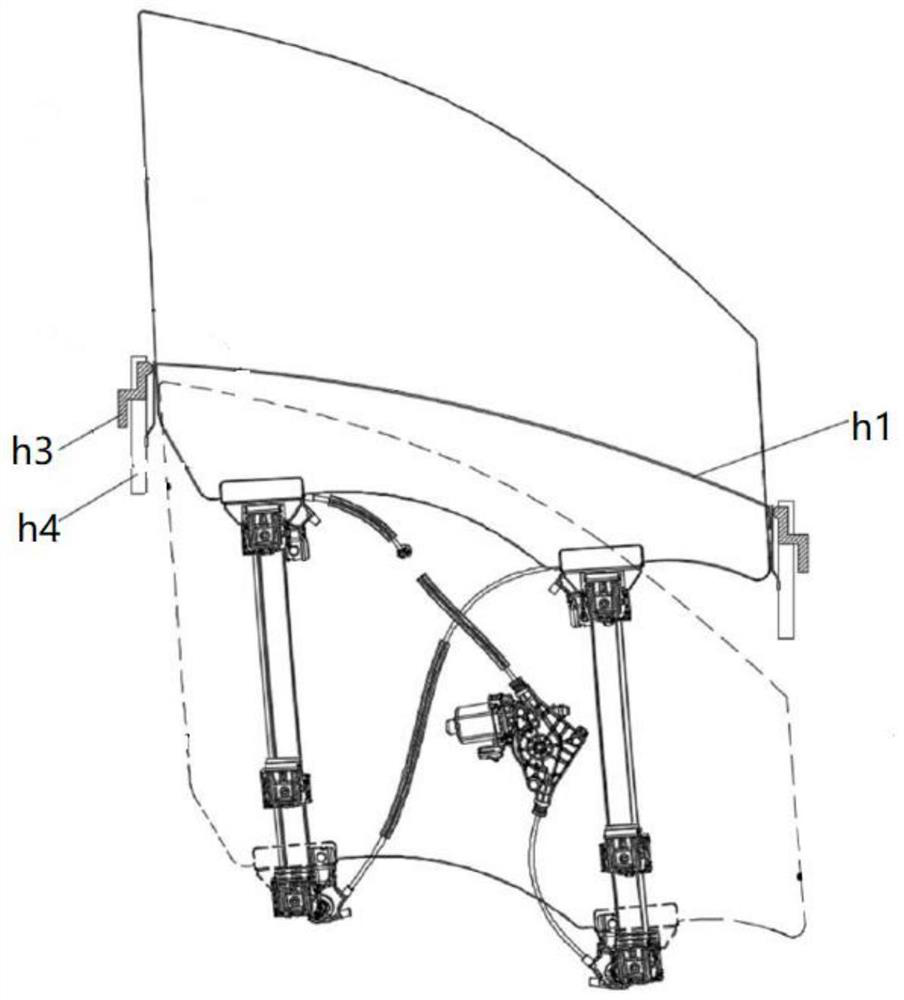

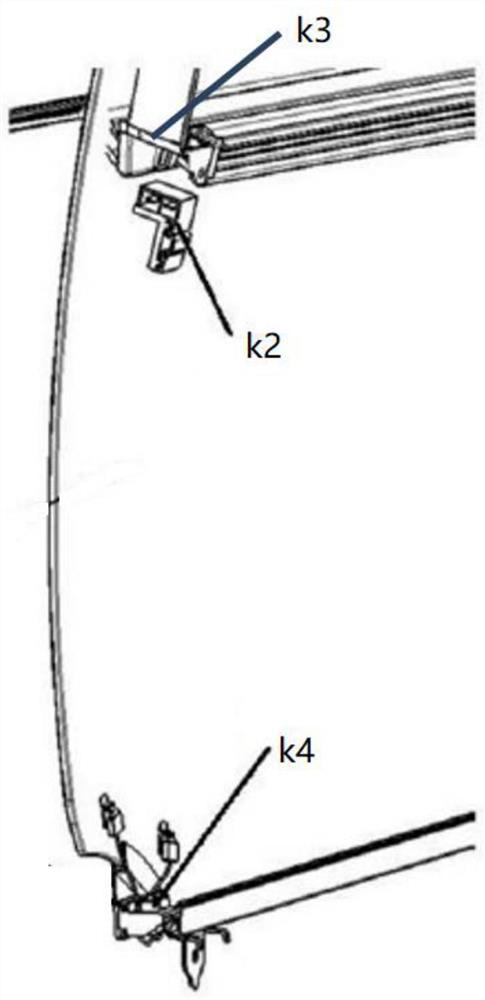

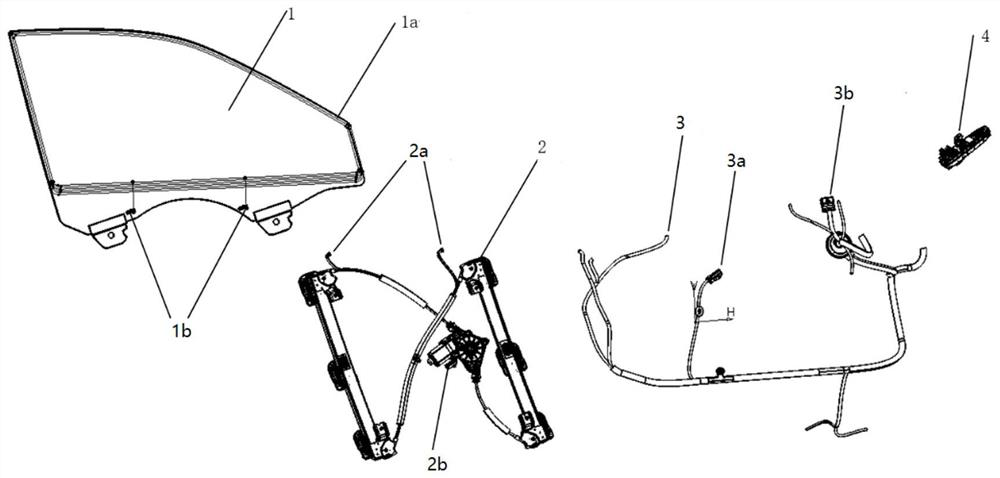

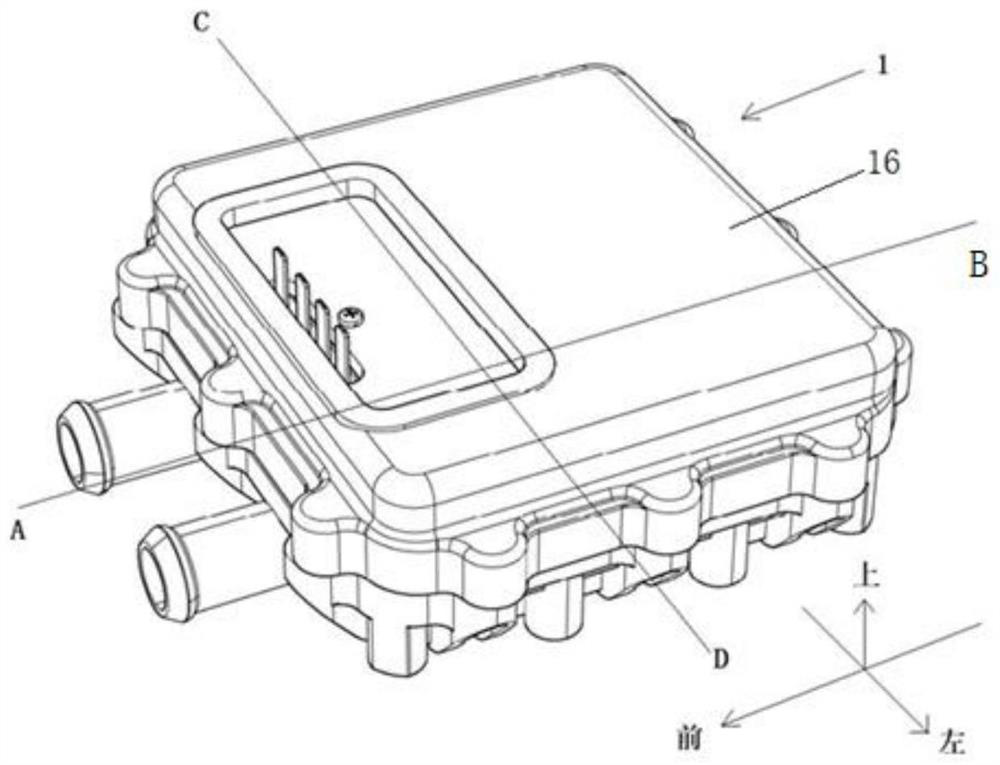

A glass heating and thawing device and automobile doors and windows

ActiveCN113401088BSimple structureNo risk of durability wear issuesWindowsWindscreensCommunication controlGate control

The application discloses a heating and defrosting device and automobile doors and windows, which relate to the technical field of automobile door and window design. The heating and defrosting device is used to heat the window glass in a cold environment. The heating and defrosting device includes: a heating wire, which is arranged around the vehicle The edge of the window glass has two glass heating conductive terminals at both ends; the two glass heating conductive terminals are arranged at the bottom of the window glass and connected to the vehicle power supply system; the door control button is used to control the lifting of the window glass, And the power on and off of the heating wire. The purpose of this application is to provide a glass heating and thawing device and automobile doors and windows, which adopts static communication control to realize the heating and thawing of the window glass without changing the design of the car door, and has strong durability and high reliability.

Owner:VOYAH AUTOMOBILE TECH CO LTD

Heat conduction structural member, heat conduction shell and heater

PendingCN114727433AImprove efficiencyImprove thermal efficiencyOhmic-resistance heating detailsThermodynamicsEngineering

The invention relates to a heat conduction structural member, a heat conduction shell and a heater. The heat conduction structural member comprises a structural member body and a heat conduction coating. The structural member body is provided with a surface; the heat conduction coating is arranged on the whole or part of the surface of the structural part body. According to the heat-conducting structural member, the heat-conducting shell and the heater, the heat-conducting coating is arranged on the surface of the heat-conducting structural member, the surface of the heat-conducting shell body and the surface of the positive plate or the negative plate, so that the heat-conducting property and the heat-conducting efficiency can be remarkably improved. Due to the arrangement of the heat-conducting coating, a heat-conducting film can be omitted, so that the cost can be obviously reduced, and compared with a scheme using the heat-conducting film, the cost can be reduced to be less than one fifth of the original cost by adopting the heat-conducting coating according to calculation.

Owner:浙江微燃电气科技有限公司

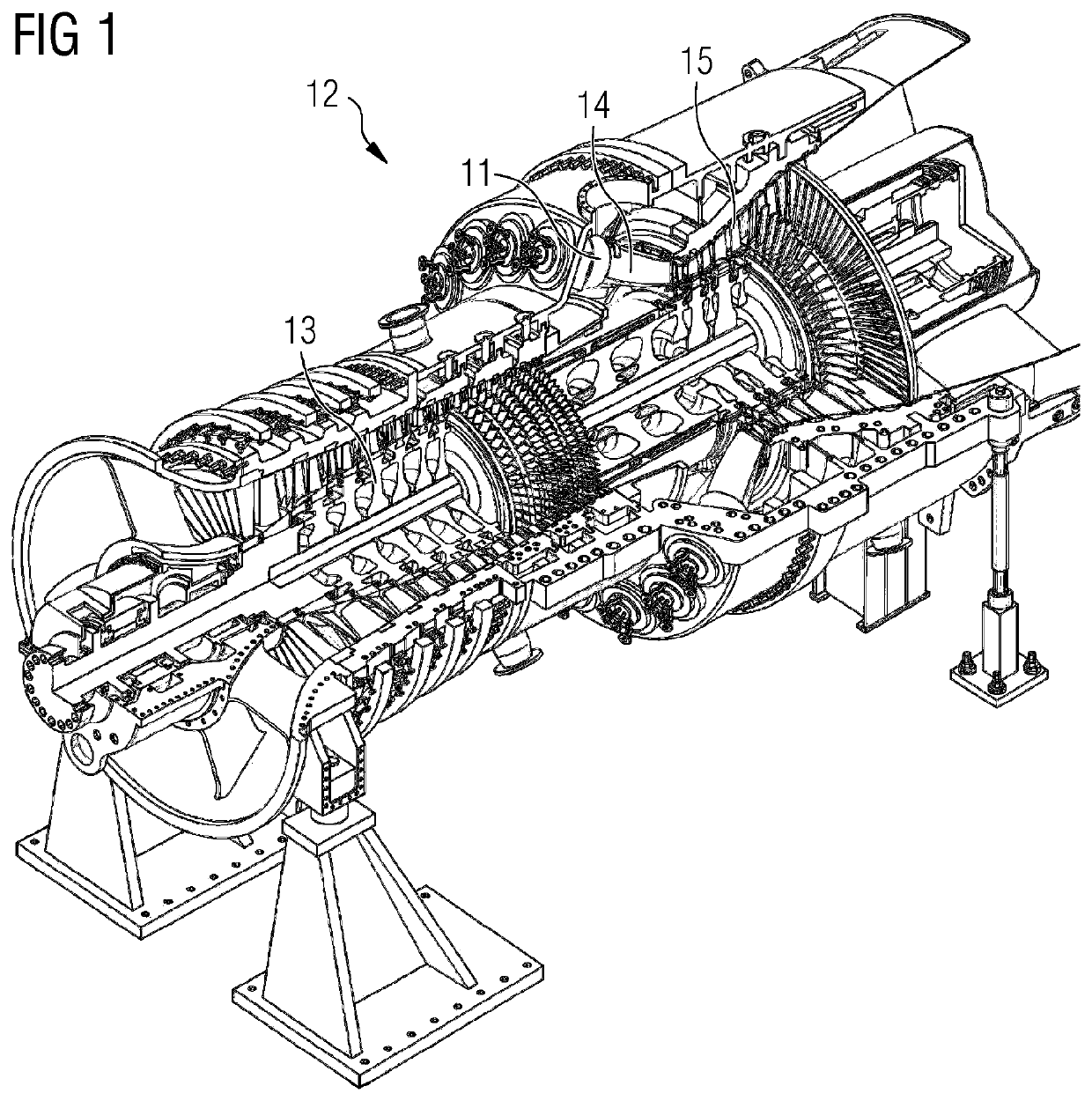

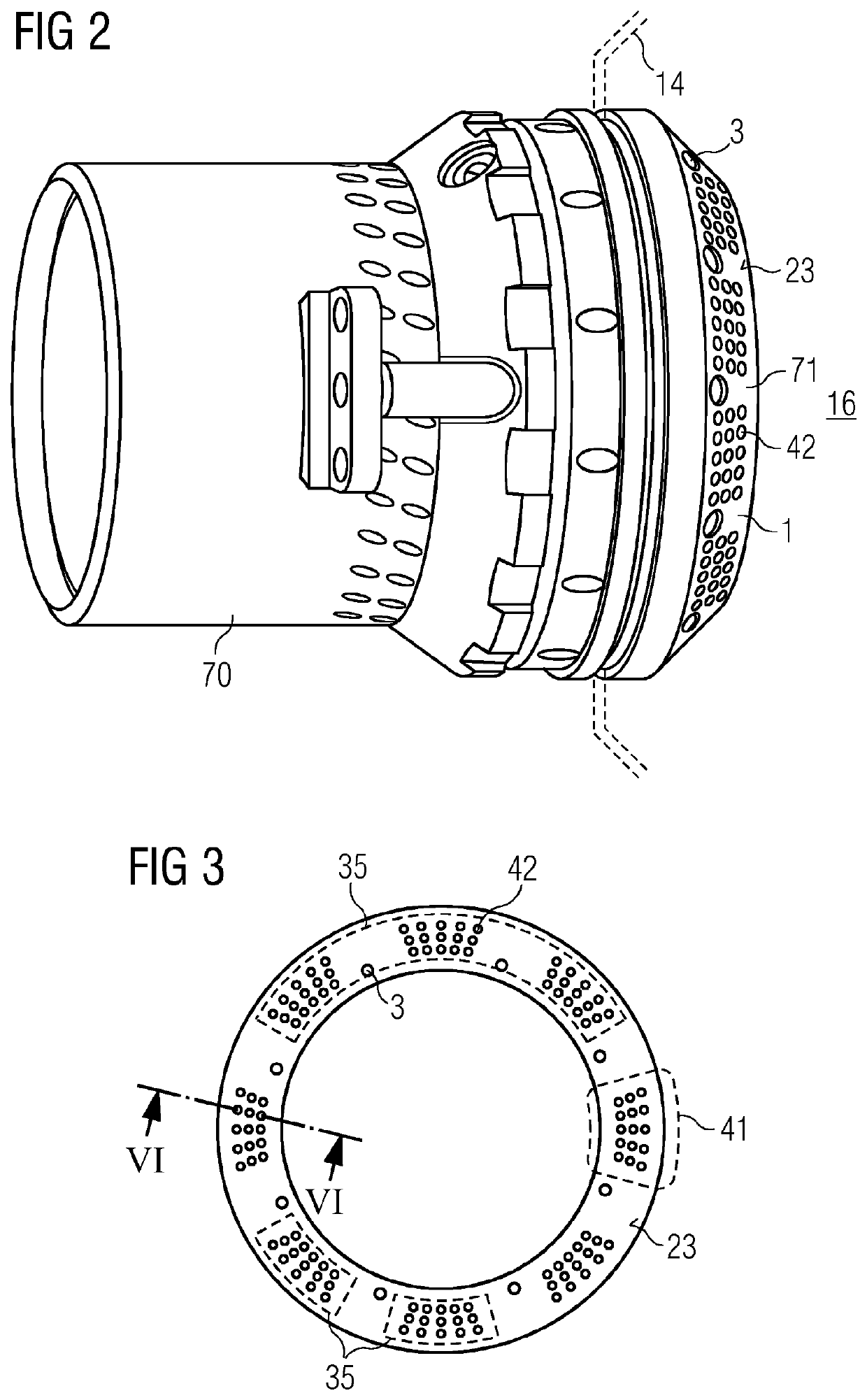

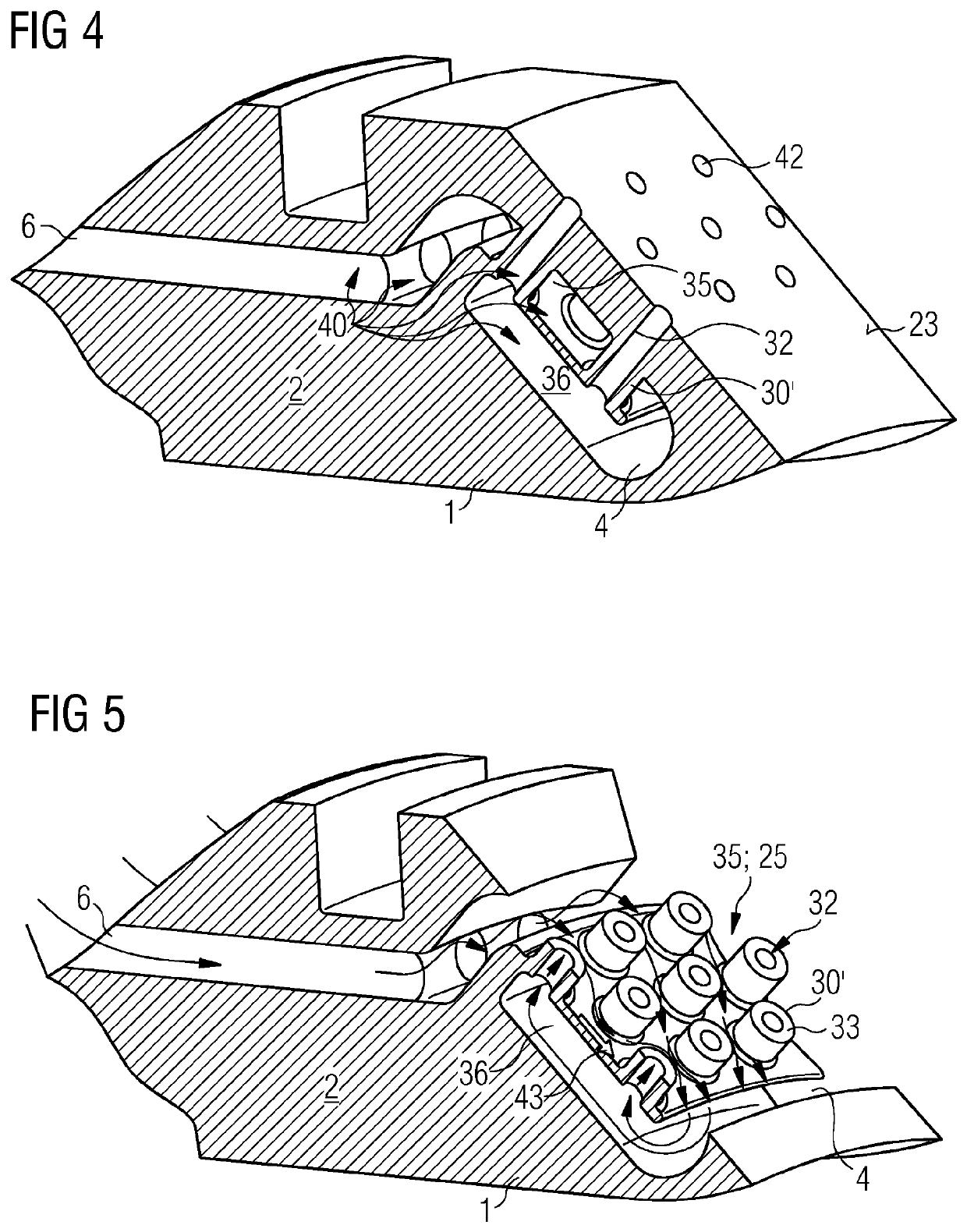

Machine component, particularly a turbomachine component, with cooling features and a method for manufacturing and of operation

ActiveUS11371438B2Avoid coolingImprove heat transfer performanceContinuous combustion chamberTurbine/propulsion engine coolingEngineeringMachine

A cooled machine component having a body with at least one integrated cooling channel having a lattice structure for guiding a cooling fluid through an interior, the lattice structure arranged as a void space penetrated by a plurality of hollow or solid struts. The lattice structure has an inlet for providing the cooling fluid to be guided through the void space of the lattice structure, and has an outlet for receiving the cooling fluid, the outlet being fluidically connected to a hollow interior of at least one of the plurality of hollow struts. At least a subset of the hollow struts provides a fluidic connection for cooling fluid from the outlet to a plurality of further downstream discharge ports. Walls of the body surrounding each of the plurality of further downstream discharge ports are physically connected to corresponding jackets of the at least one of the plurality of hollow struts.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com