Temperature control feeding-bottle with disinfecting function

A functional and feeding bottle technology, applied in feeding bottles, household appliances, other household appliances, etc., can solve the problems of unsanitary, single function, and inability to measure the temperature of milk, and achieve the effect of sufficient heat conduction and increase of heat conduction area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings.

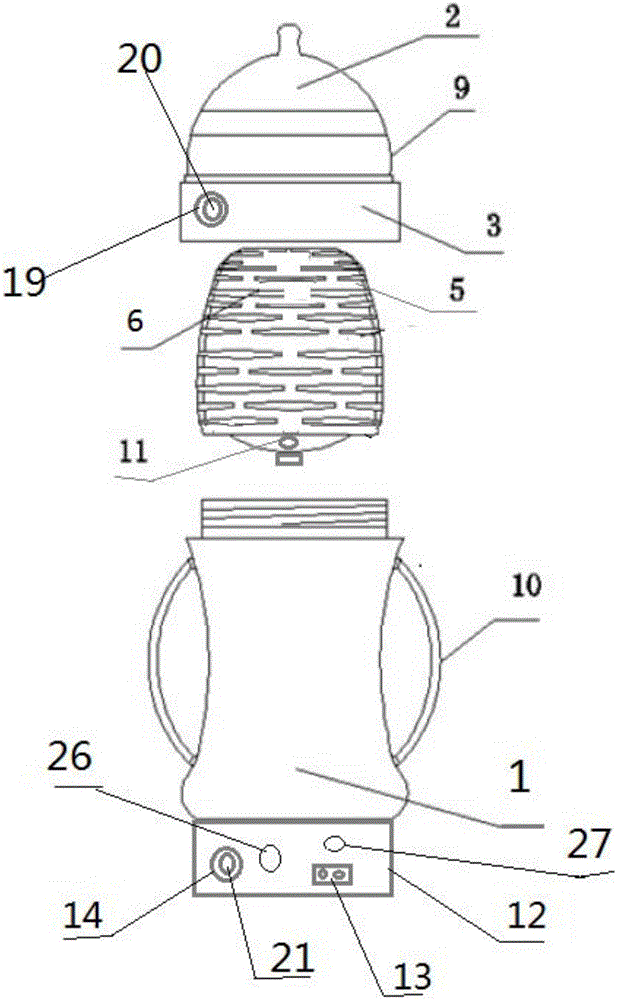

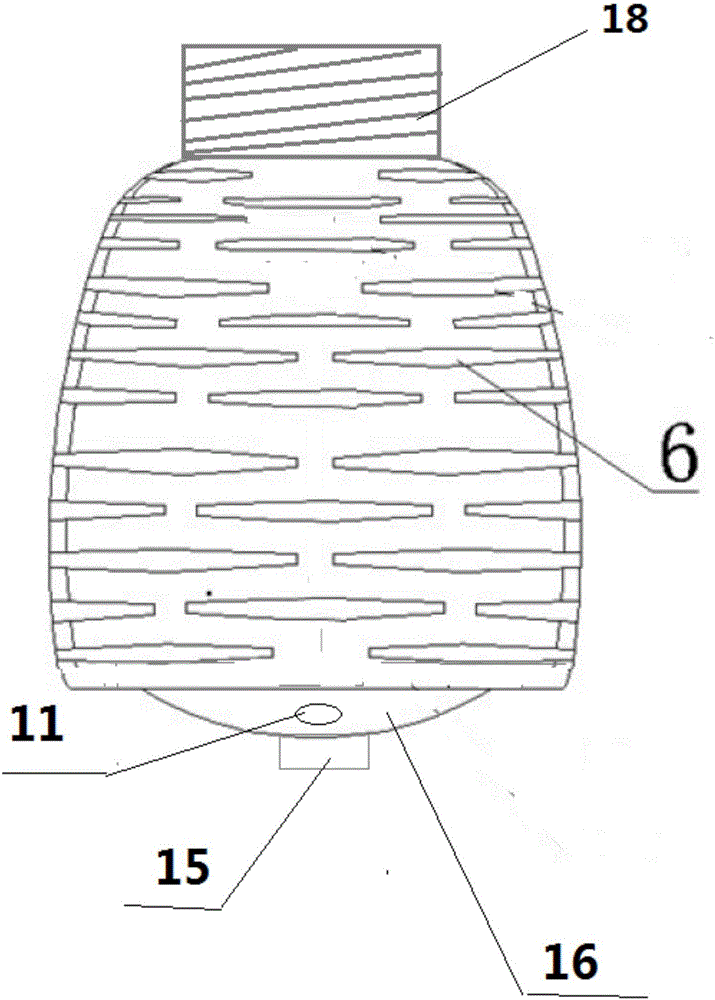

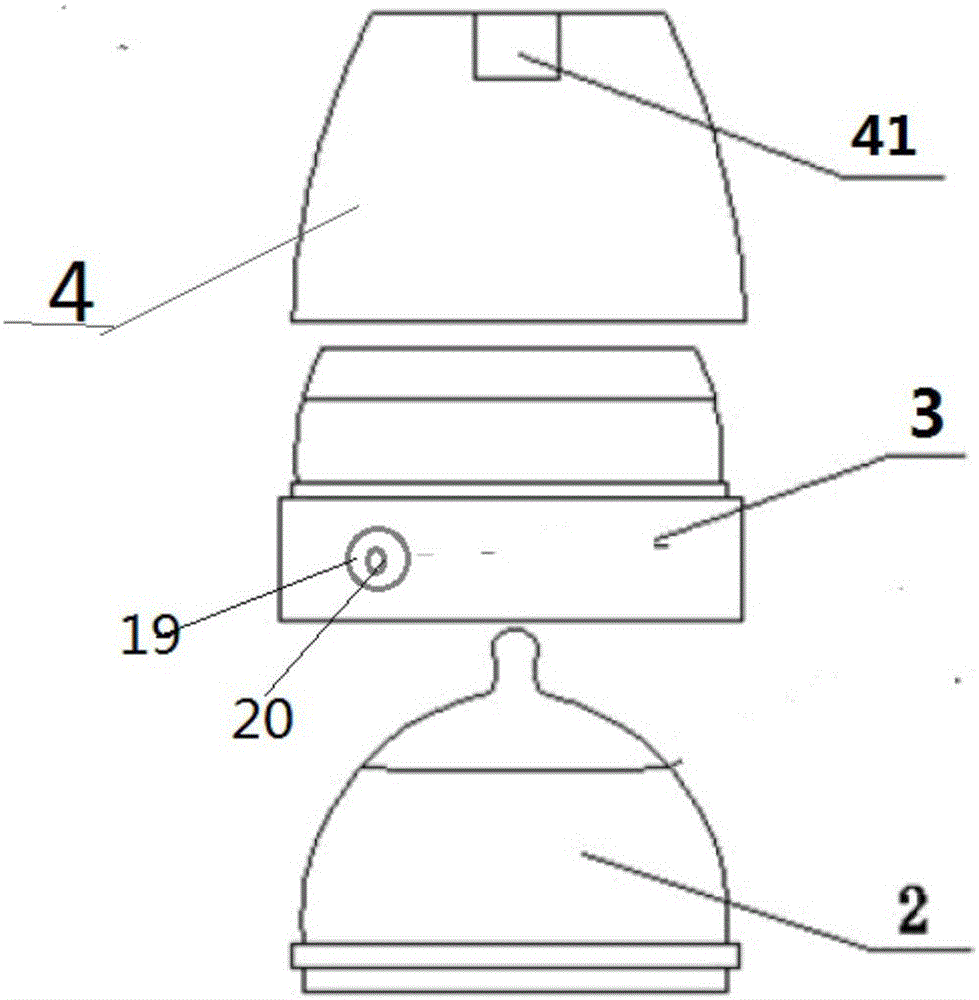

[0023] Such as figure 1 , 2, 3, 4, 5, 6, 7, a temperature-controlled feeding bottle with disinfection function, including bottle body (1), nipple (2), nipple ring (3), bottle cap (4), temperature adjustment device (5), liner (16), base (12); temperature regulating device (5) uniformly cross-distributed divider plates (6) around the outer layer, and each divider plate (6) has distances up and down, left and right, thereby forming a fluid passage; base (12) is provided with air pump (22), lithium battery (24), heating device (23), and base (12) is provided with jack (13) and air inlet (14) outside, air inlet ( 14) It communicates with the air pump (22) air inlet, and the jack (13) can be connected with an external charger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com