High-temperature non-pressure seamless sintering technology-based miniaturized millimeter wave transmitting and receiving assembly

A technology of transmitting and receiving components and millimeter waves, which is applied in the directions of electrical components, transmission systems, magnetic field/electric field shielding, etc., can solve the problems of narrow communication frequency band, complex structure, and large amount of debugging, etc. secondary damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

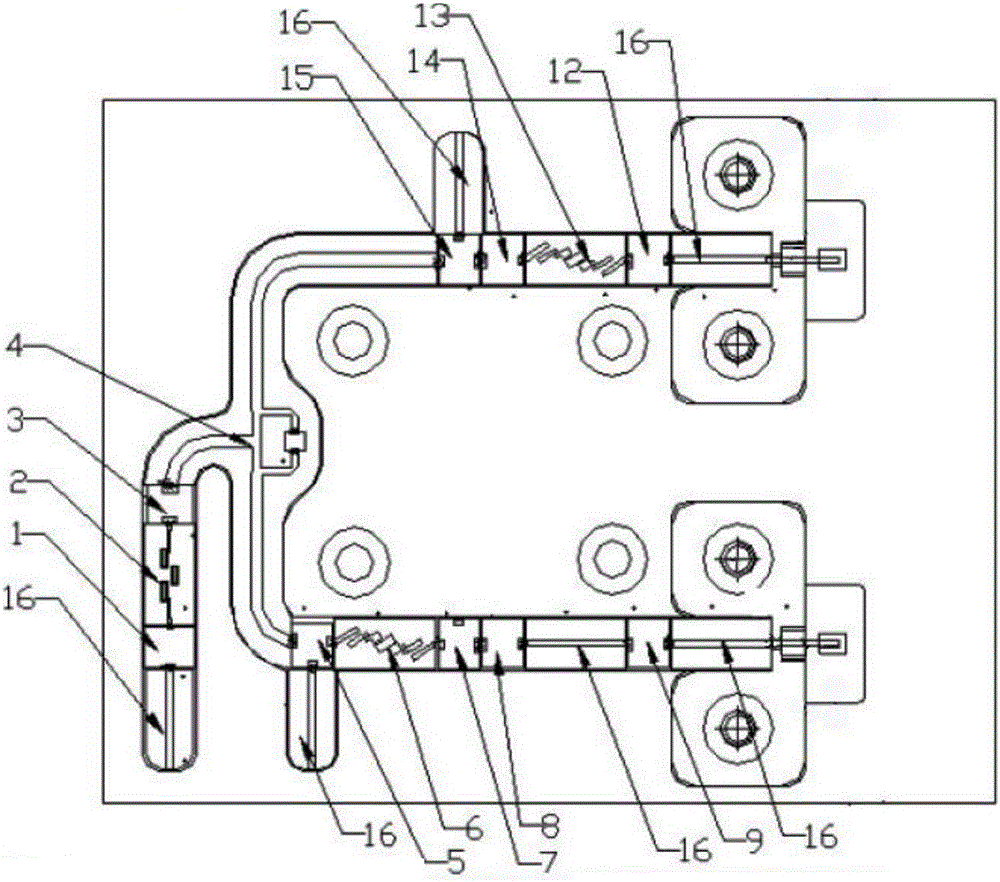

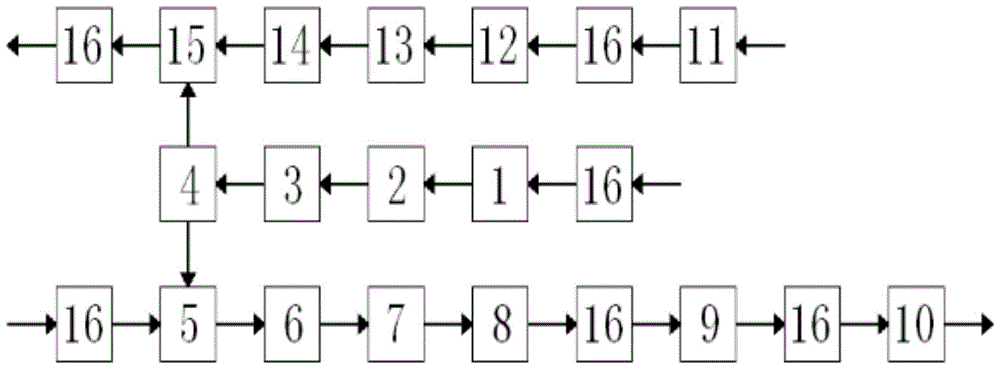

[0017] Below in conjunction with accompanying drawing and embodiment, content of the invention will be further described:

[0018] In the existing technology, this product uses more MMIC chips, and the MMIC chips are all made of 99.6% aluminum oxide substrate material. The expansion coefficient of the substrate material is 7.5. The shielding box selected by the existing millimeter wave transceiver components is basically For copper or aluminum alloy, the expansion coefficient of the profile is about 20, which is quite different from the expansion coefficient of the substrate material, so it is difficult to carry out high-temperature seamless sintering. At the same time, the MMICs of the existing millimeter-wave transceiver components are connected by a microstrip printed board. The microstrip printed board and the MMIC chip are pasted on the shielding box body through conductive silver paste. The conductive silver paste is unevenly coated, and the thickness of the MMIC chip ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com