Patents

Literature

117results about How to "Fully grounded" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

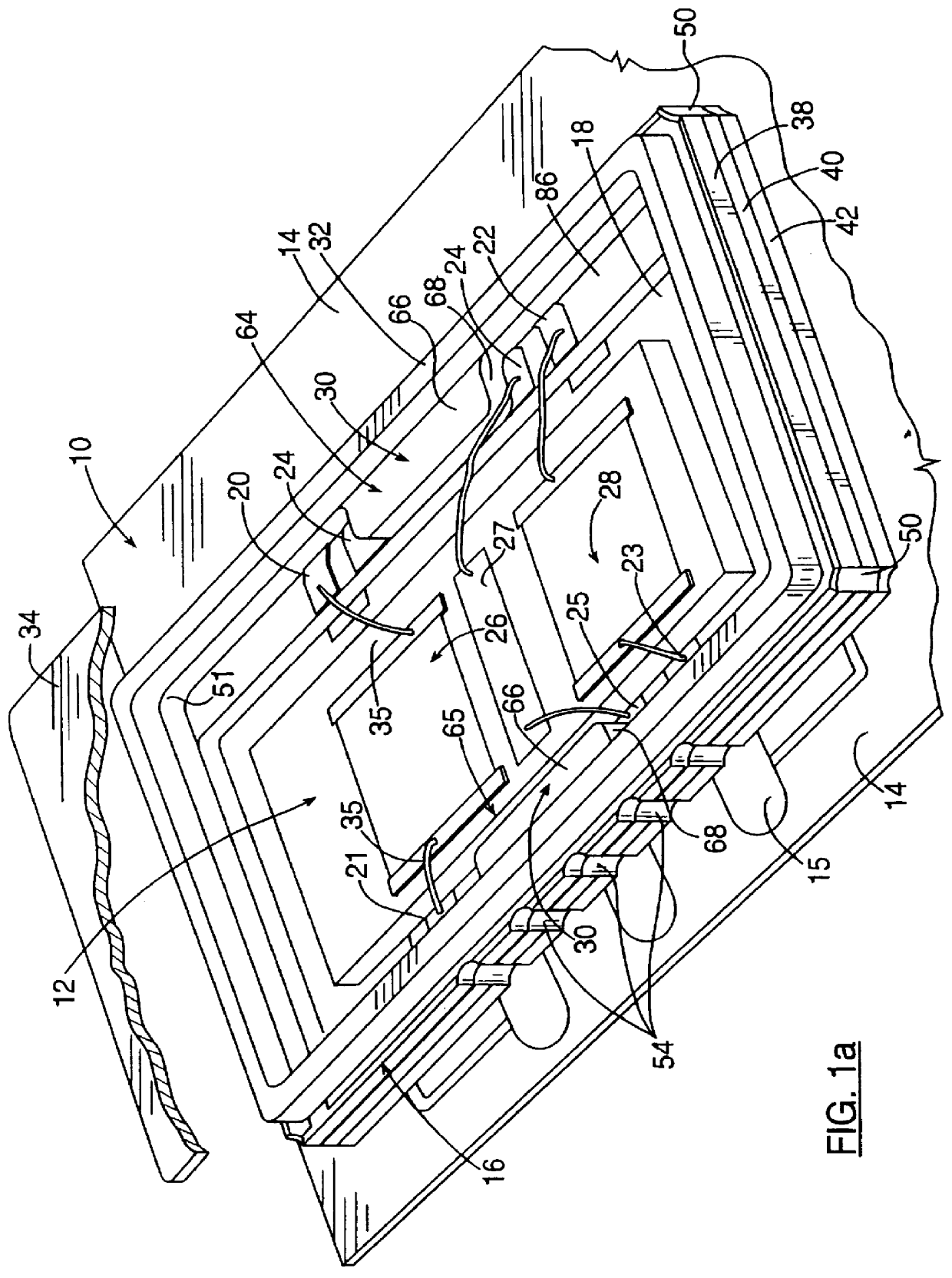

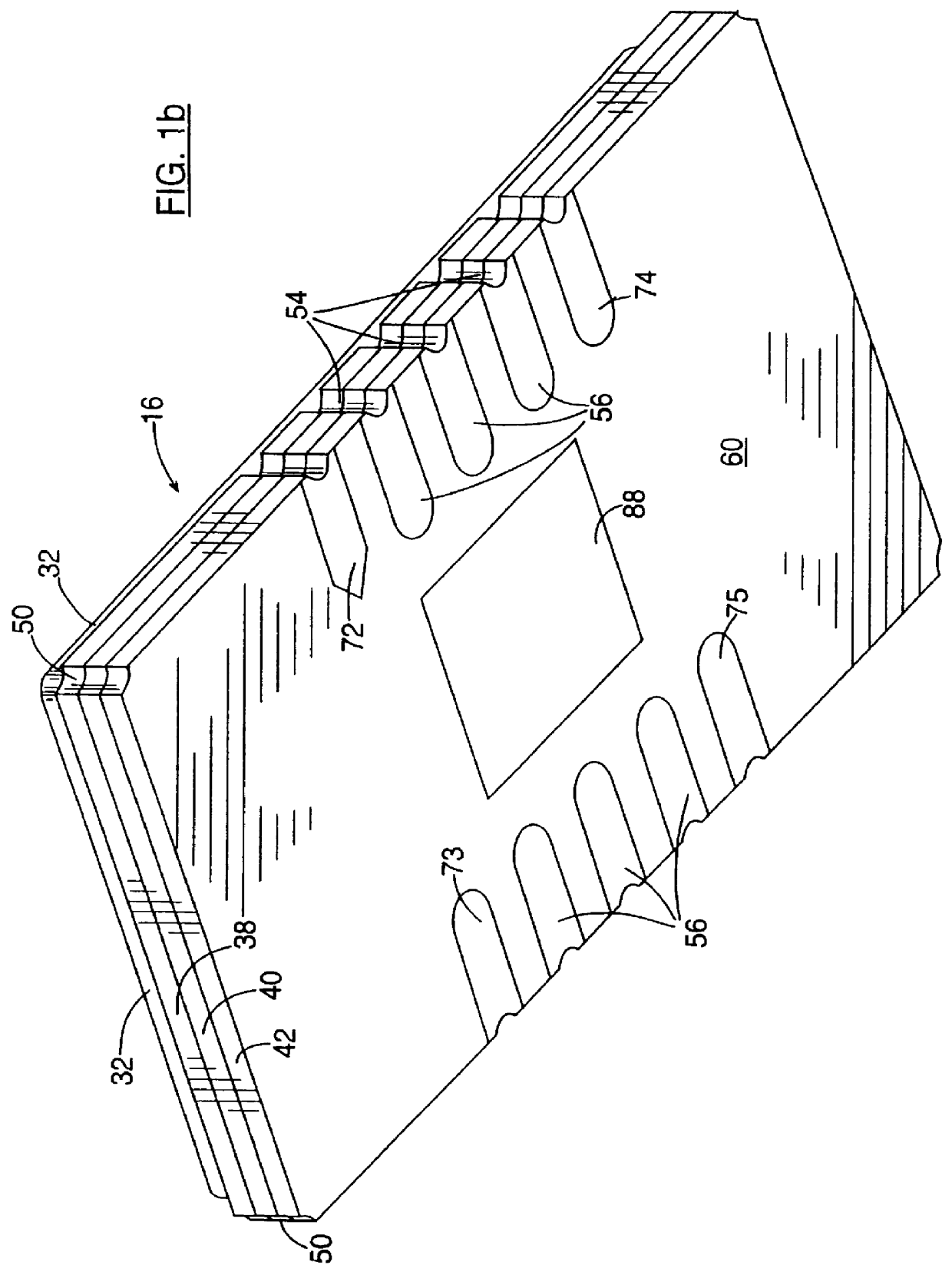

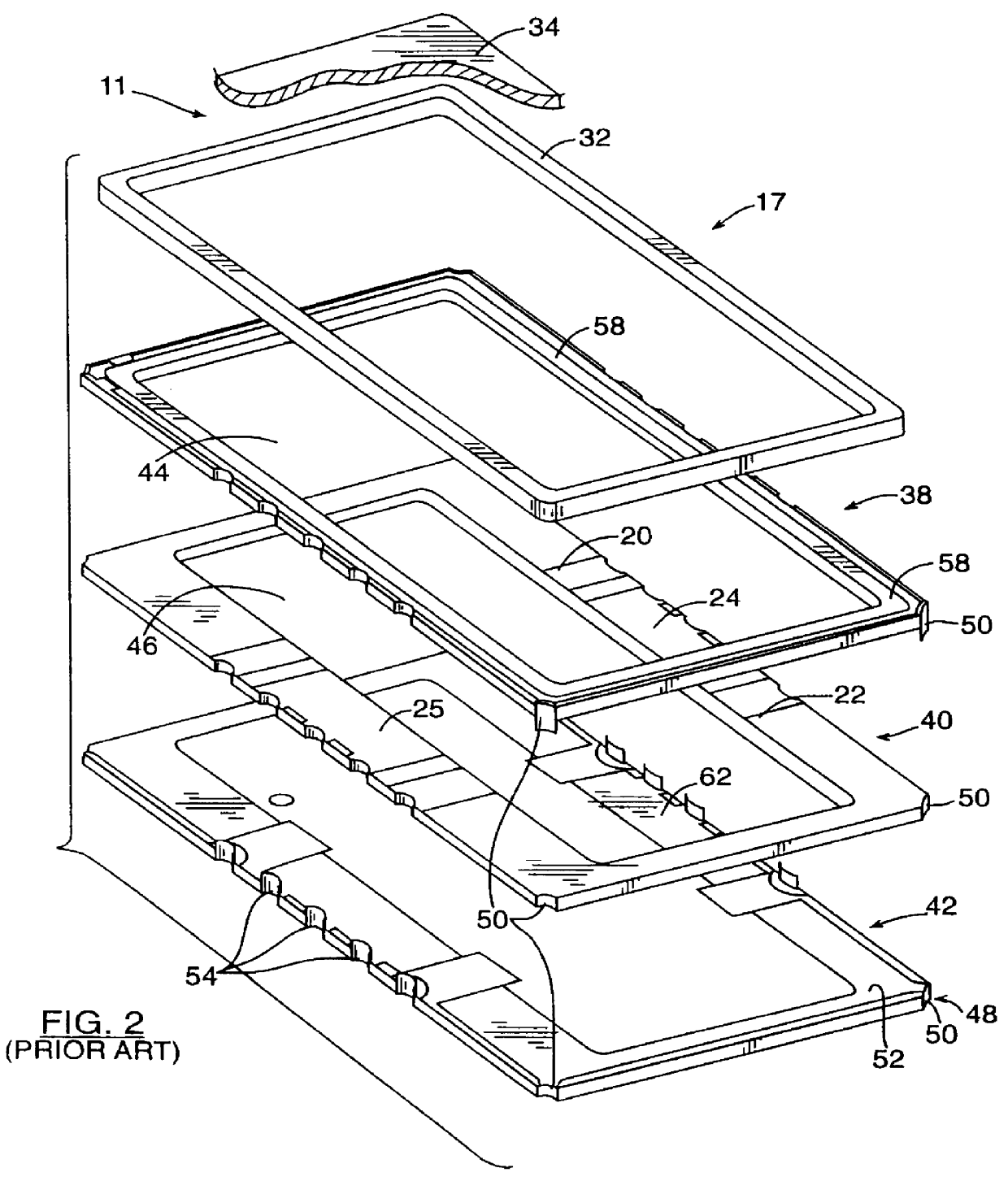

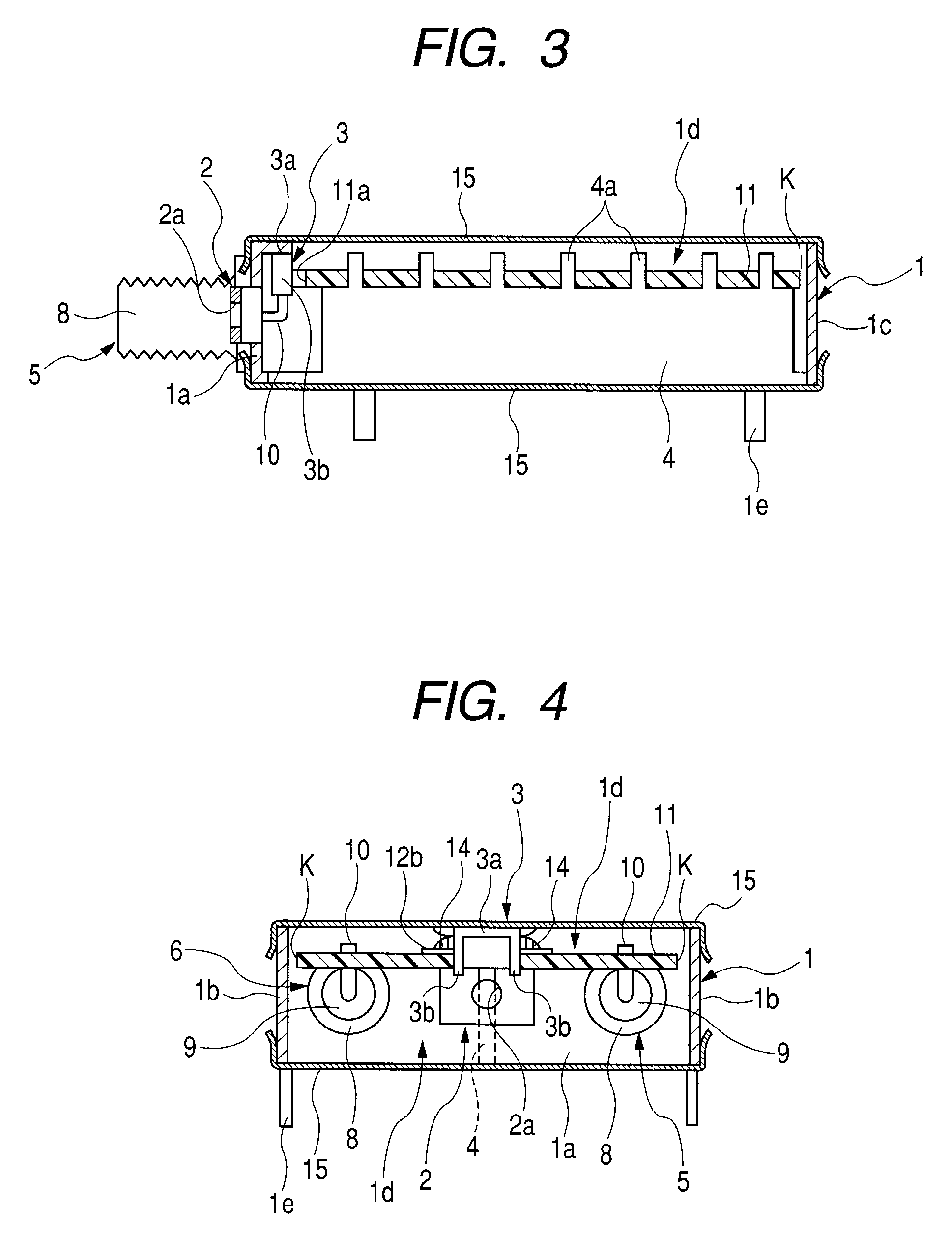

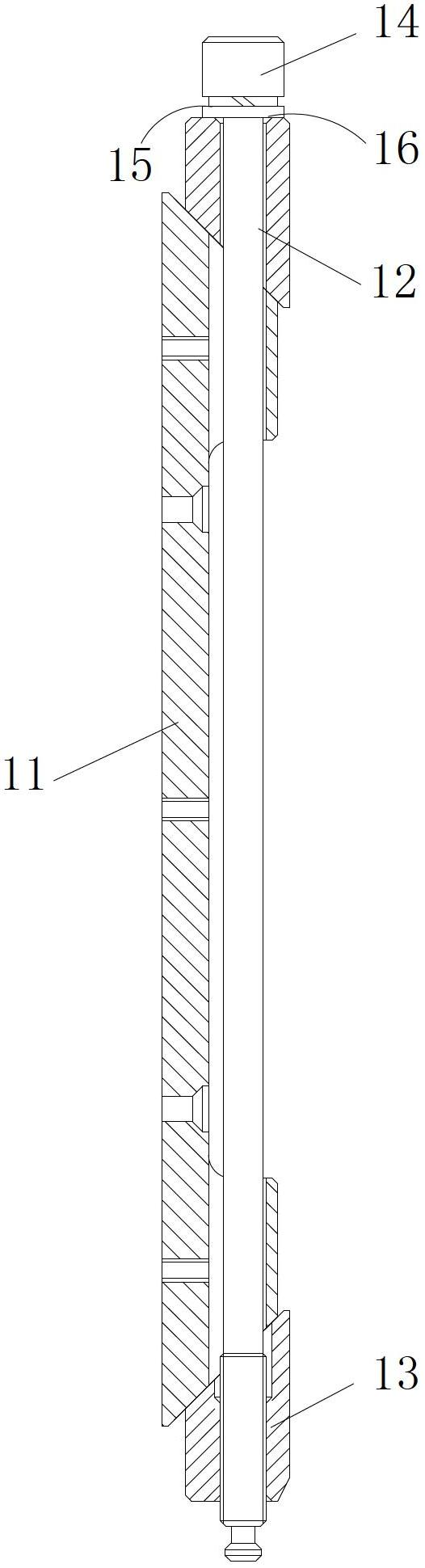

Leadless ceramic chip carrier crosstalk suppression method

InactiveUS6105226AReduce electromagnetic signal effectReduce crosstalkPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblySurface mountingElectrical connection

A leadless ceramic chip carrier useful in surface mounting of SAW devices includes electrically conductive vias and metalization between input and output bond pads for improved crosstalk suppression between input and output device connections. A protrusion extending from a top layer of a multilayer ceramic carrier provides additional electrical contact to a package seal brazed thereto. The vias are positioned between input and output bond pads and connect the metalized protrusion to package ground pads through contact with multiple metalized layers of the package for enhancing the electrical connection between the package Kovar seal ring and customer accessed ground pads. For further suppression of crosstalk, bond pads within the package for connection to the SAW device are spaced at a greater distance from each other than their corresponding pads on the package bottom surface thus maintaining an optimum spacing for package connection to printed circuit board pads for minimizing thermal mismatch effects.

Owner:TRIQUINT

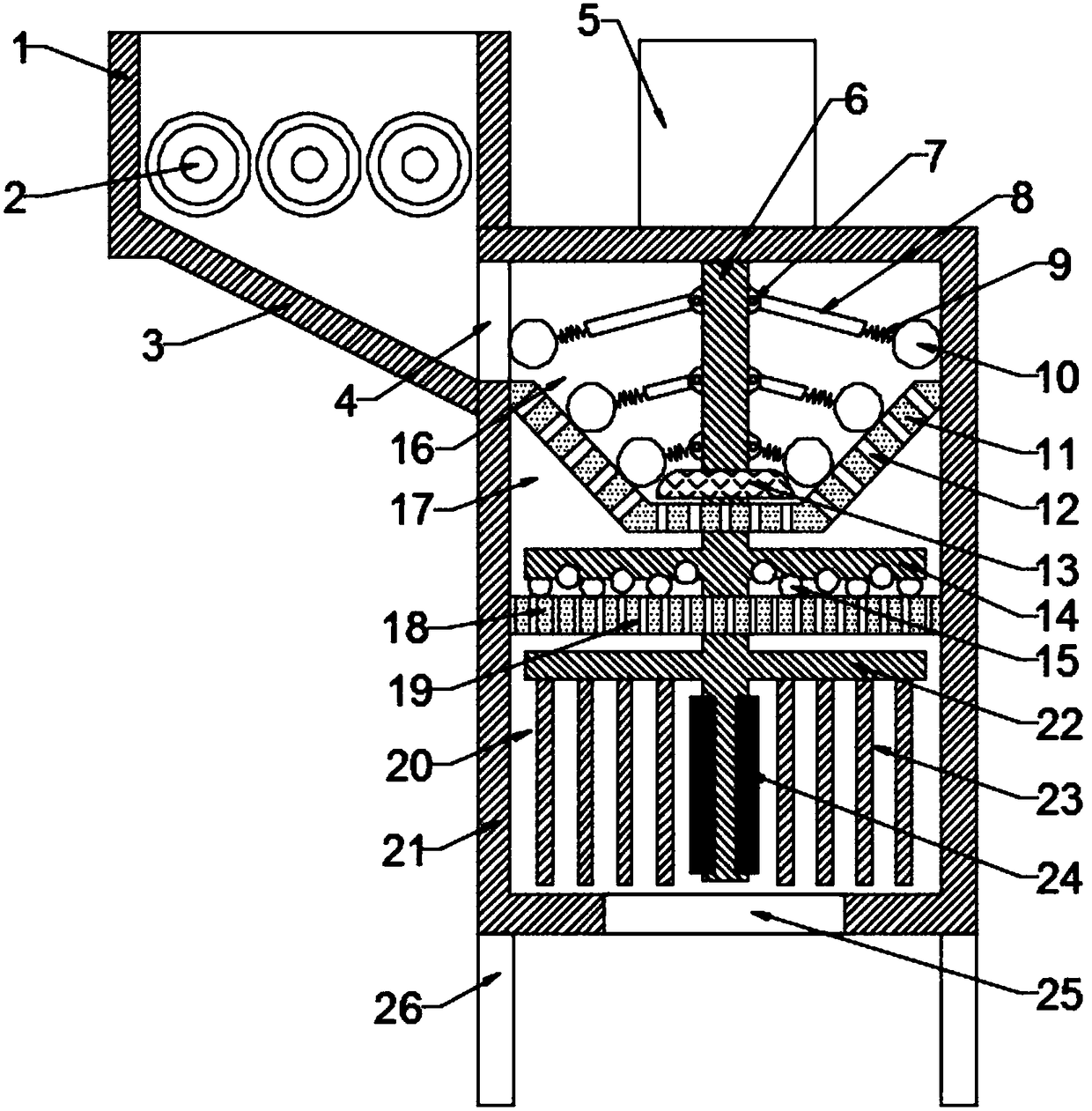

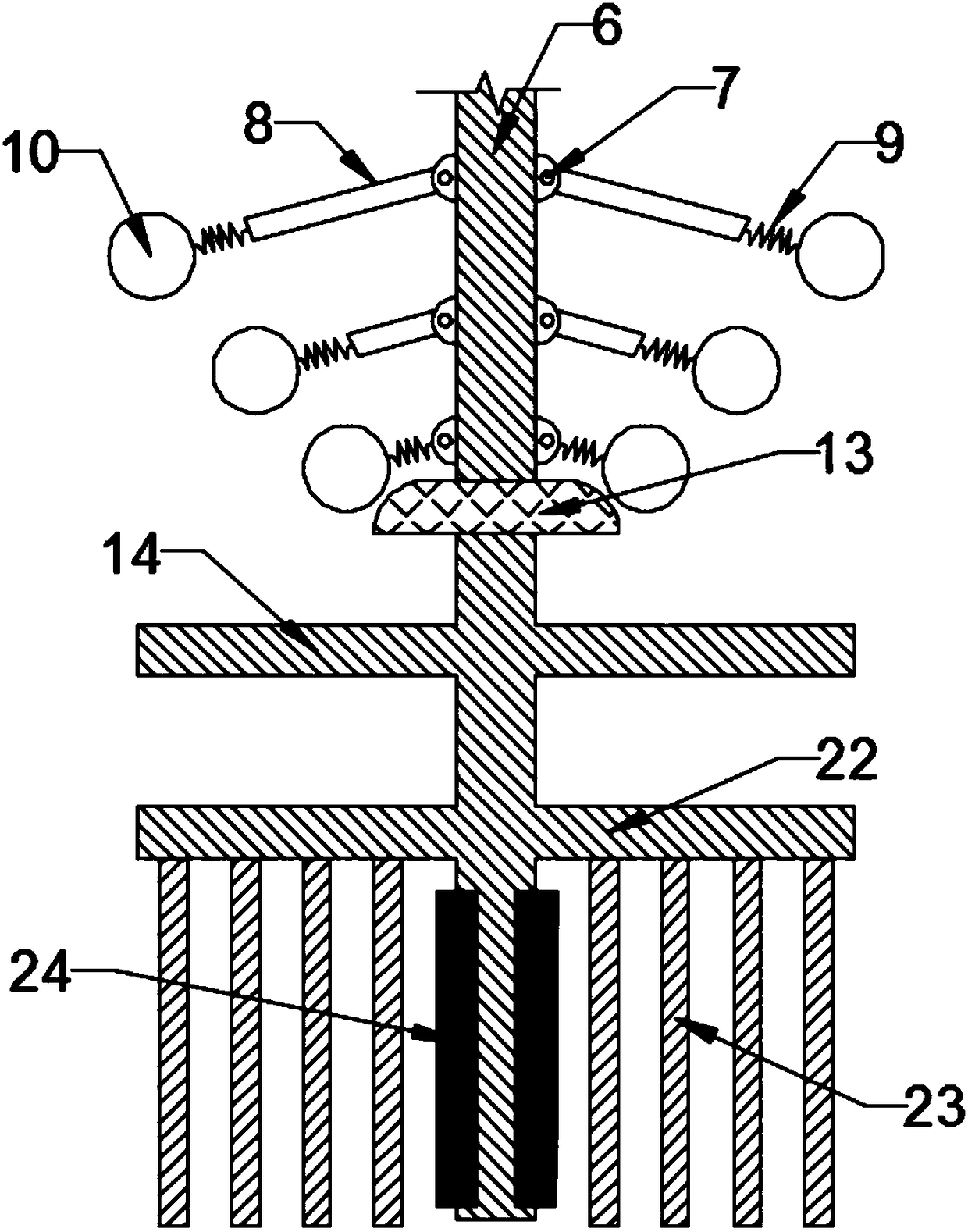

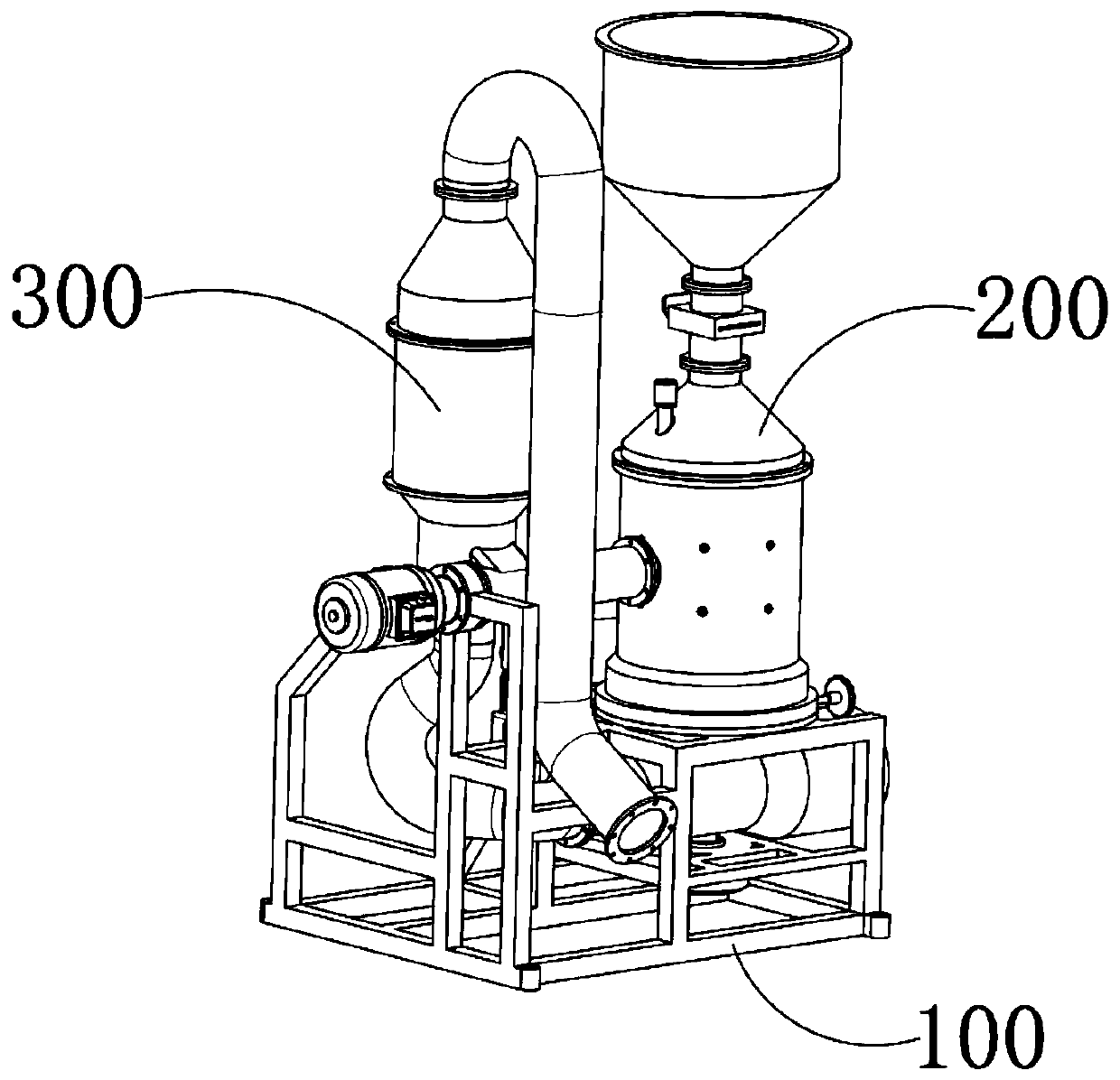

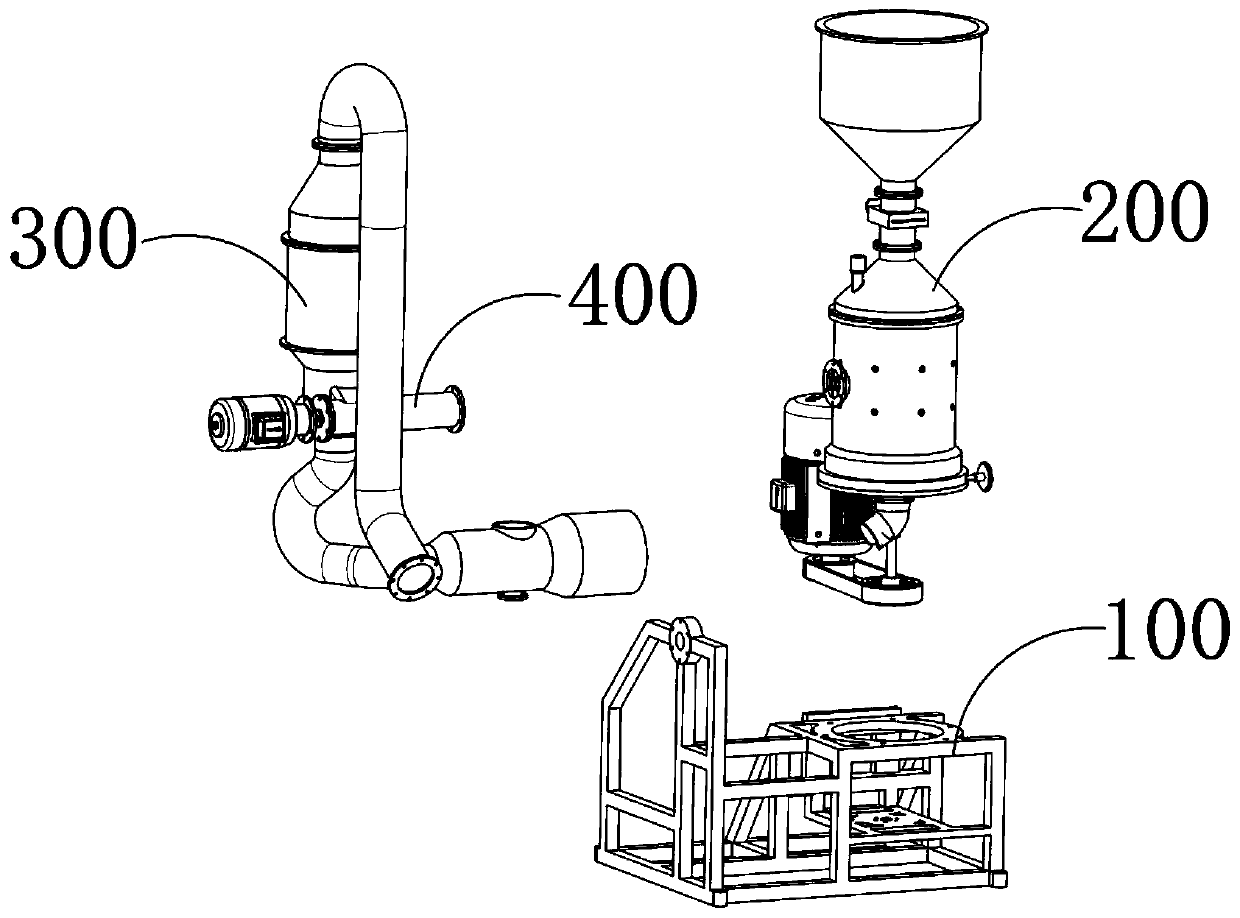

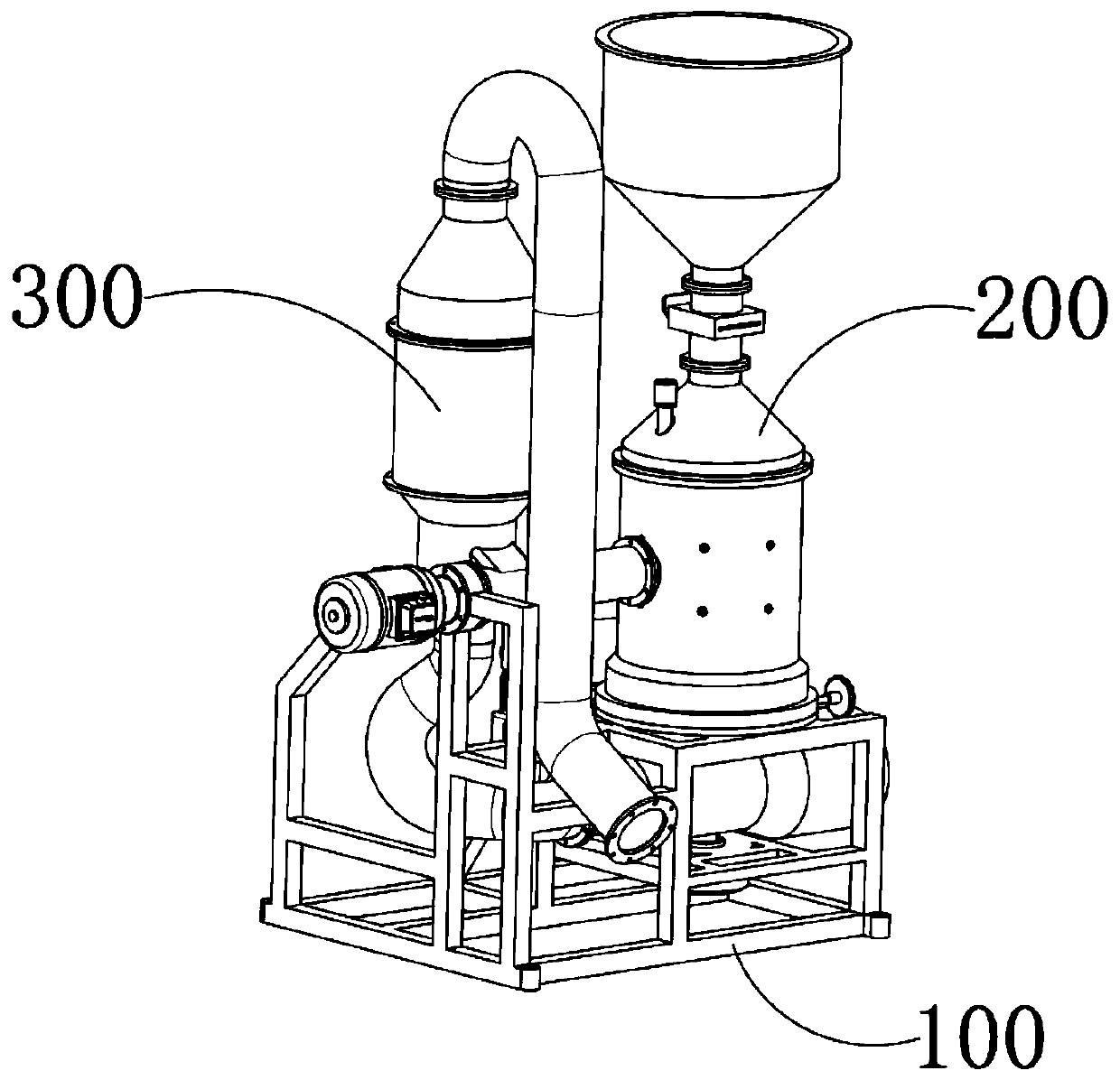

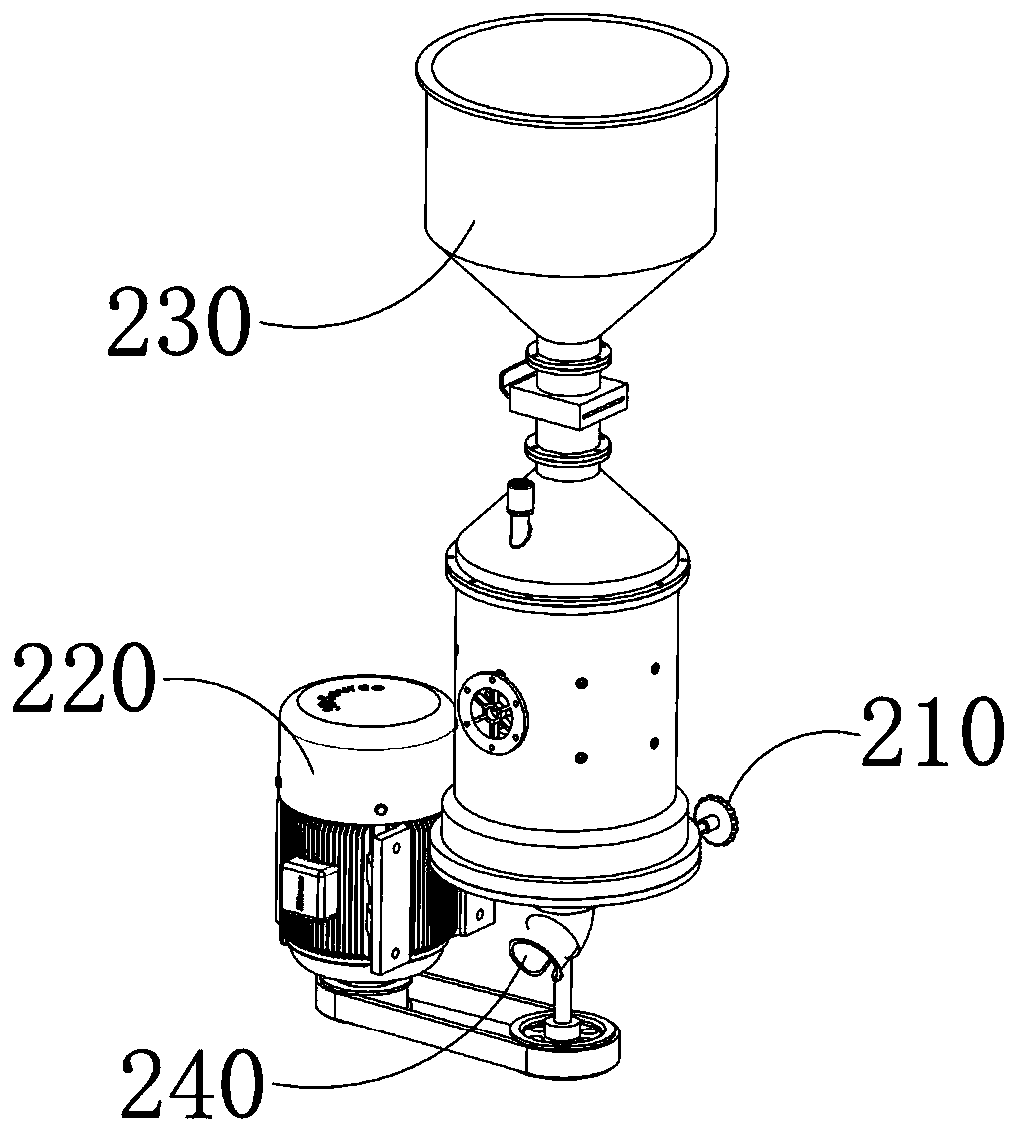

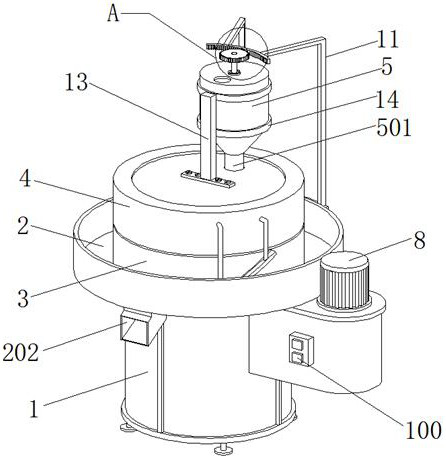

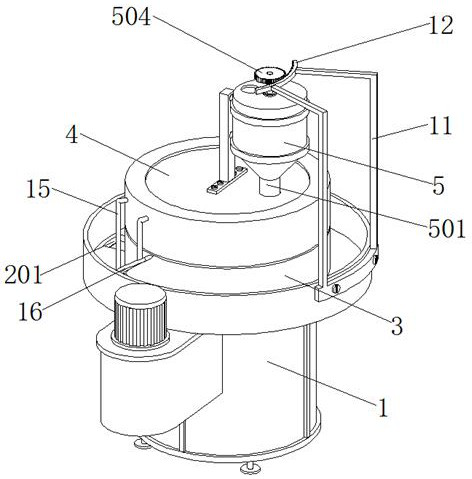

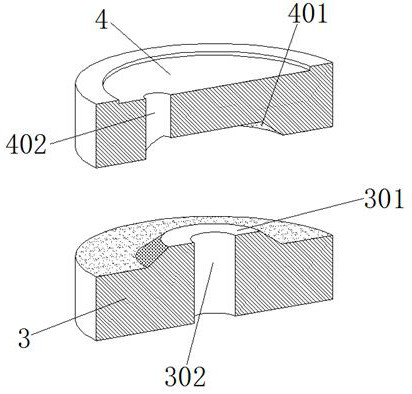

Integrated crushing and grinding equipment for cement raw material

InactiveCN108579983AEasy to addFully groundMixing operation control apparatusPretreatment controlEngineeringRaw material

The invention discloses integrated crushing and grinding equipment for a cement raw material, and aims to solve the problem of inconvenient raw material processing of a existing cement plant in the prior art. The integrated crushing and grinding equipment is technically characterized in that the integrated crushing and grinding equipment comprises a feeding hopper, a crushing mechanism, grinding balls, grinding pills and a tank body, wherein a grinding hopper and a filter plate are connected to the interior of the tank body and sequentially divide the interior of the tank body into a first grinding cavity, a second grinding cavity and a mixing cavity from top to bottom; hinged seats are fixed on side walls of a rotating shaft of the first grinding cavity and connected to one ends of connecting rods; the other ends of the connecting rods are connected to one ends of springs; the other ends of the springs are connected to the grinding balls; the grinding balls are propped against the inner wall of the grinding hopper; a pushing rod is fixedly connected to a rotating shaft in the second grinding cavity; the plurality of grinding pills are arranged in the second grinding cavity. The integrated crushing and grinding equipment has the advantages that the structure is stable, the crushing effect is good, it is guaranteed that a material is fully ground and processed, the grain sizes of the ground material are the same, and raw material production and processing by the cement plant are facilitated.

Owner:王少平

Surface processing process of aluminum and aluminum alloy workpieces

InactiveCN103624636ASurface crystal structure vibrationNot easy to scratchPolishing machinesElectrophoretic coatingsSteel ballDrying time

The invention discloses a surface processing process of aluminum and aluminum alloy workpieces, and has the advantages that the process operation is simple and easy, the cost is low, and the noise and dust pollution is low. The surface processing process is realized through the following steps that firstly, a plurality of stainless steel balls are poured into a grinding chamber of a vibration grinding machine for forming stainless steel bead balls, then, clean water is poured into the grinding chamber of the vibration grinding machine, in addition, stainless steel ball piles are immersed by the poured clean water, finally, aluminum and aluminum alloy workpieces to be processed are poured into the grinding chamber of the vibration grinding chamber, aluminum alloy cleaning agents are added into the grinding chamber of the vibration grinding machine for carrying out grinding vibration cleaning, and the grinding vibration cleaning time is 3 to 5 minutes; aluminum alloy brightening agents are added into the grinding chamber of the vibration grinding machine for carrying out grinding and brightening treatment, and the grinding and brightening time is 8 to 12 minutes; the aluminum and aluminum alloy workpieces processed in the third step are taken out to be subjected to cleaning treatment, the aluminum and aluminum alloy workpieces processed in the fourth step are placed into a drying box to be dried, the drying temperature is 130 to 150 DEG C, and the drying time is 5 to 8 minutes.

Owner:福建天广消防有限公司

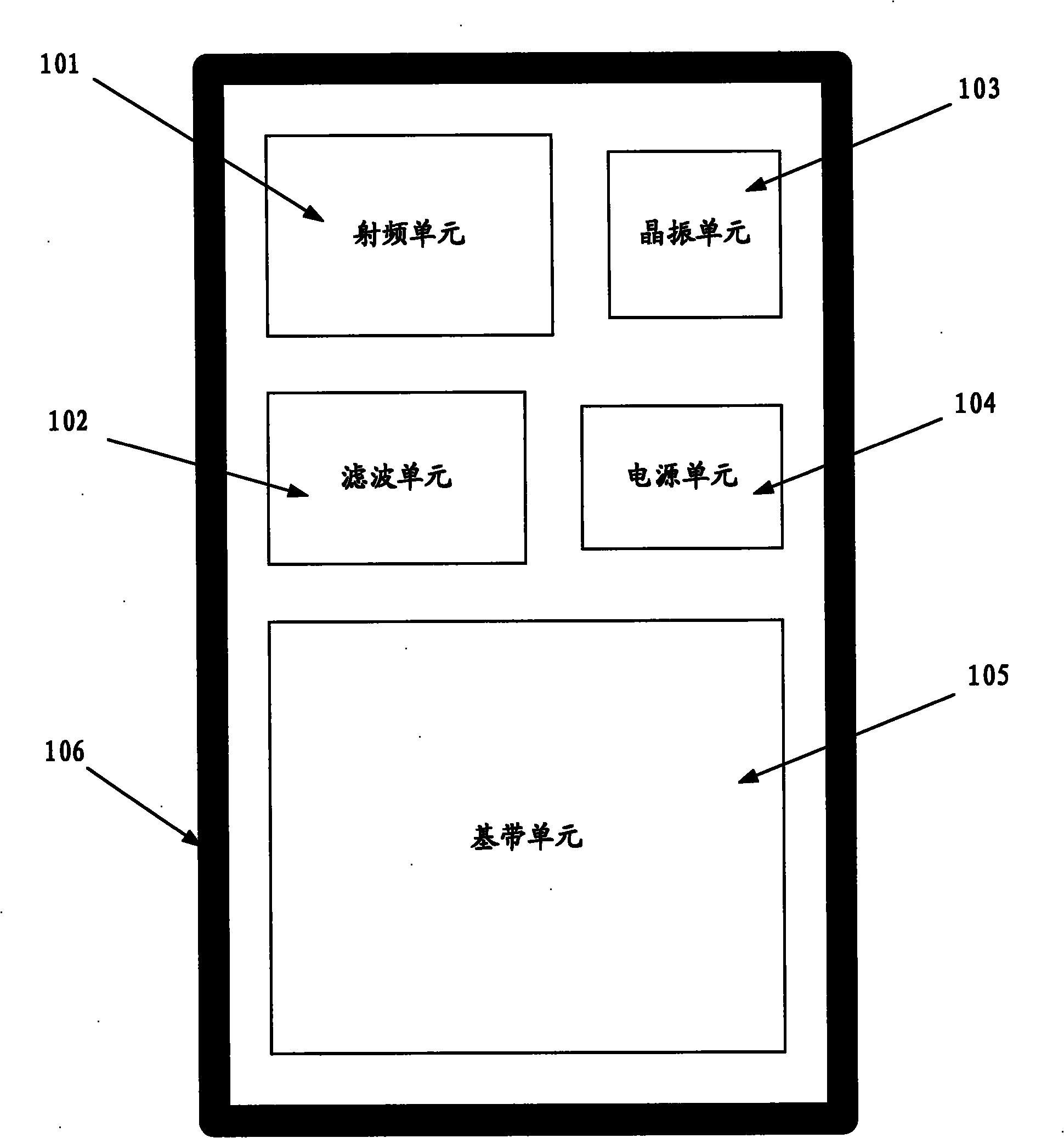

Radio frequency unit

InactiveUS7466564B2Improve isolationFully groundedDiscontinuous tuningResonant circuit detailsEngineeringElectronic component

Owner:ALPS ALPINE CO LTD

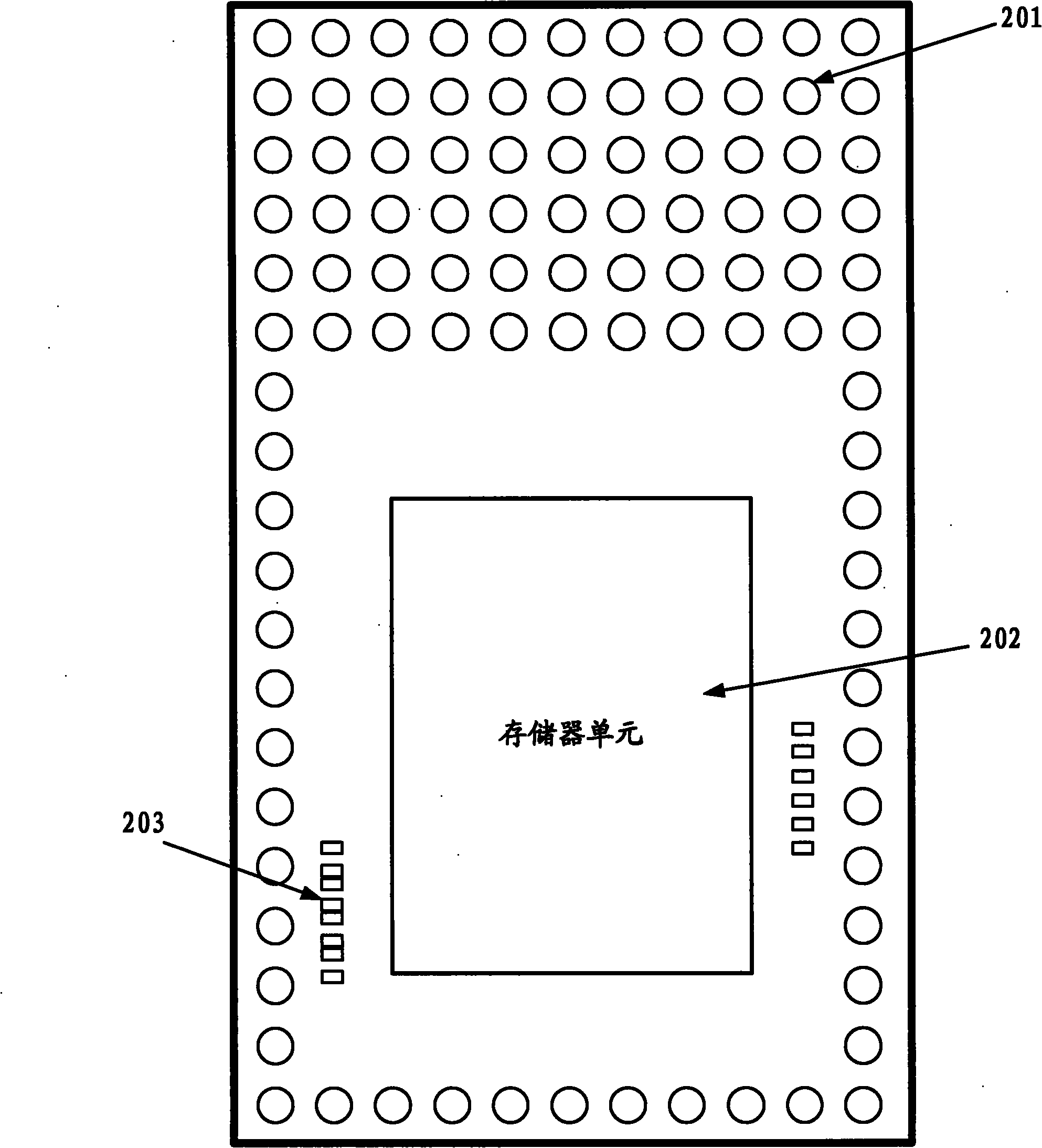

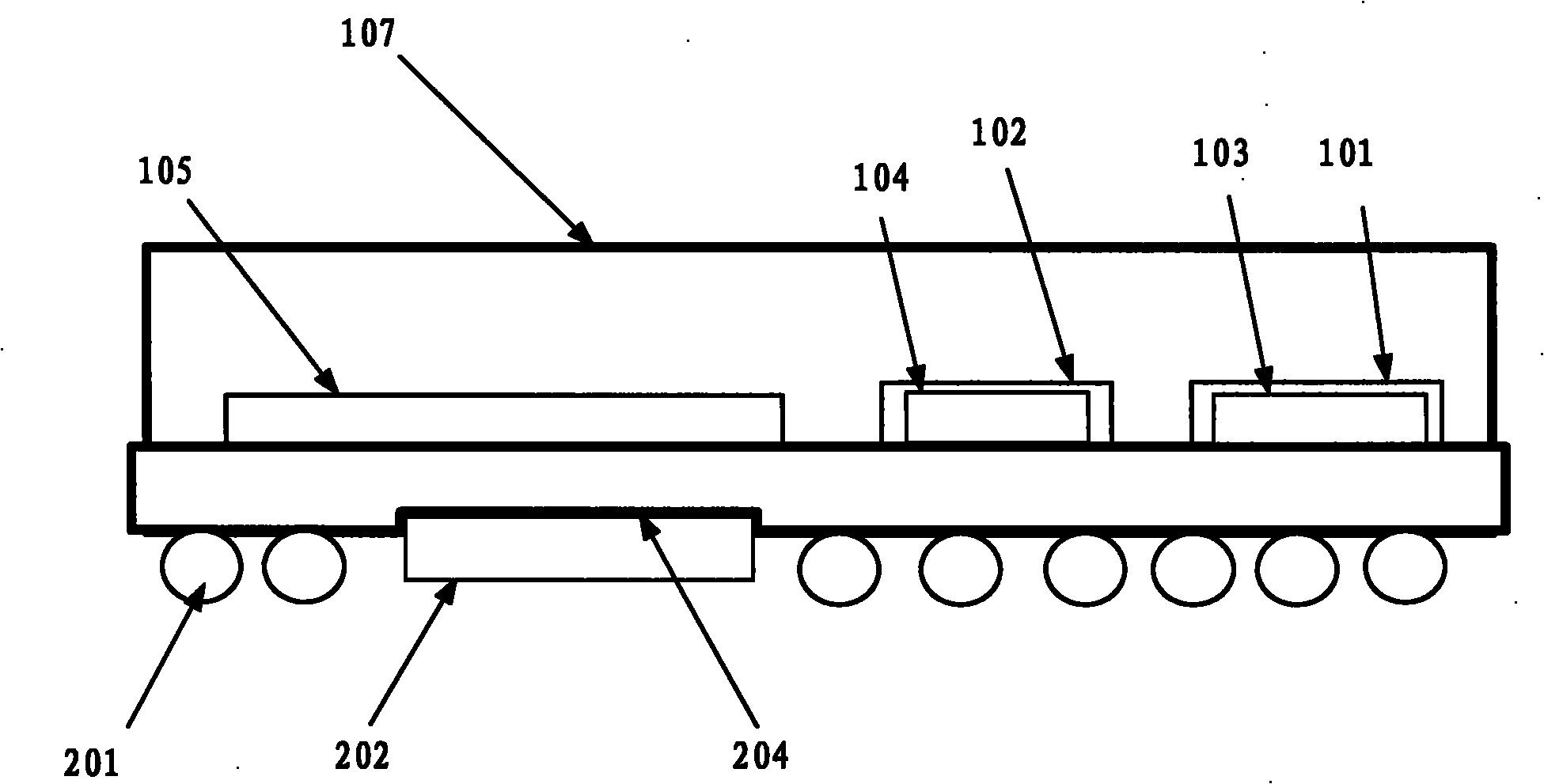

Wireless communication module

InactiveCN102215043AEasy to integrateReduce volumeTransmissionWireless communicationEvolution-Data OptimizedCode division multiple access

The invention belongs to the field of mobile communication, and relates to a wireless communication module, in particular to a high-performance small-sized module of a code division multiple access (CDMA) evolution-data optimized (EV-DO) mobile terminal. The small-sized module is applicable to a third generation (3G) user terminal. The wireless communication module is characterized in that: board-level connection is carried out by ball grid array (BGA) package; the level of integration is high; the size is small; good electrical performance and an external interface function are realized; and requirements of a customer can be well met. The wireless communication module comprises a radio frequency front end, a transmitting and receiving channel, a base band processing part, a memory and a power manager, wherein the base band processing part and the radio frequency front end are placed on a top layer of a circuit board; a shielding cover is arranged on the top layer to guarantee an excellent electromagnetic compatibility function of the module; the memory is placed on a bottom layer of the circuit board; and the bottom layer adopts an advanced BGA technology to guarantee reliable connection during the application of the module.

Owner:NATIONZ TECH INC

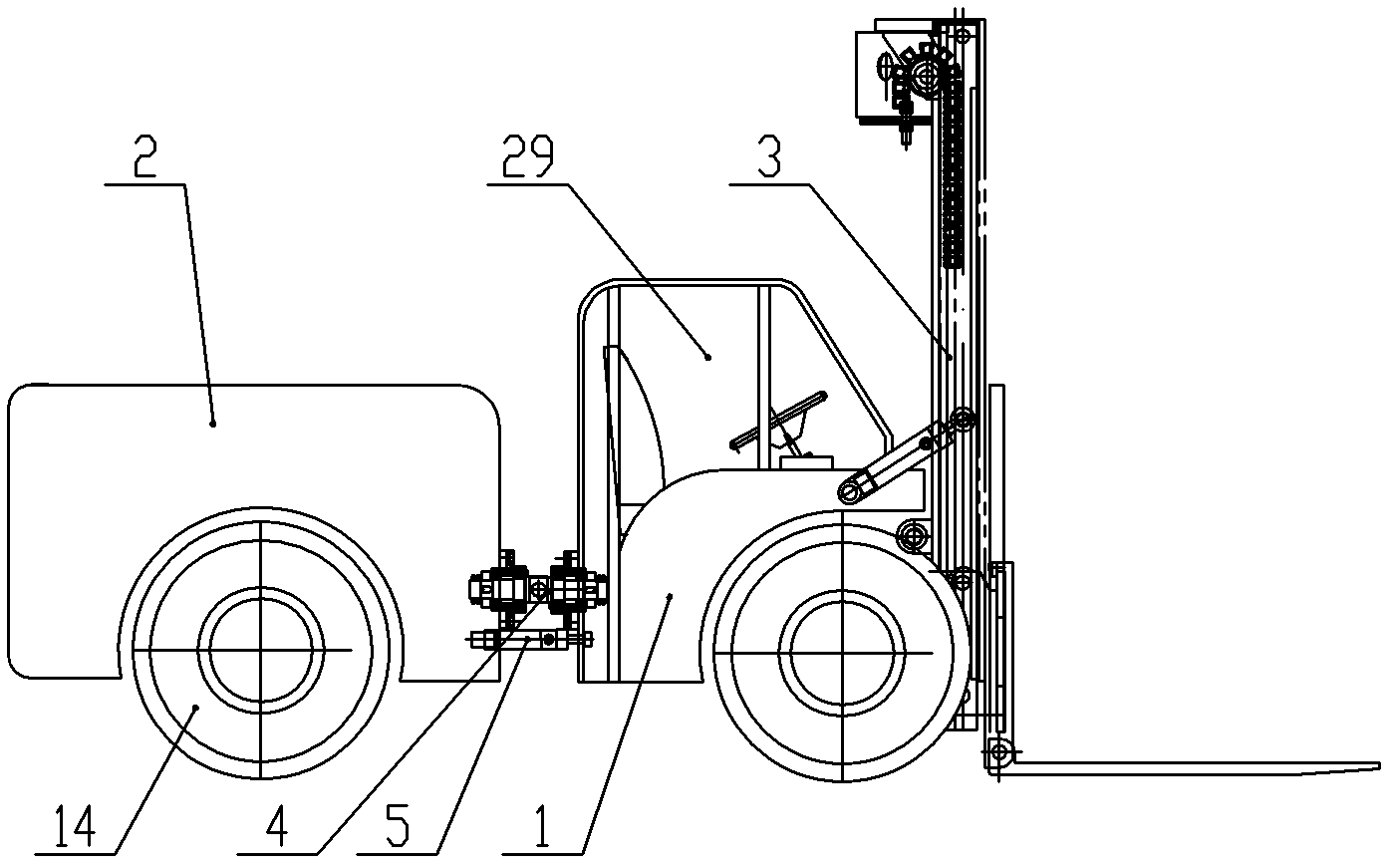

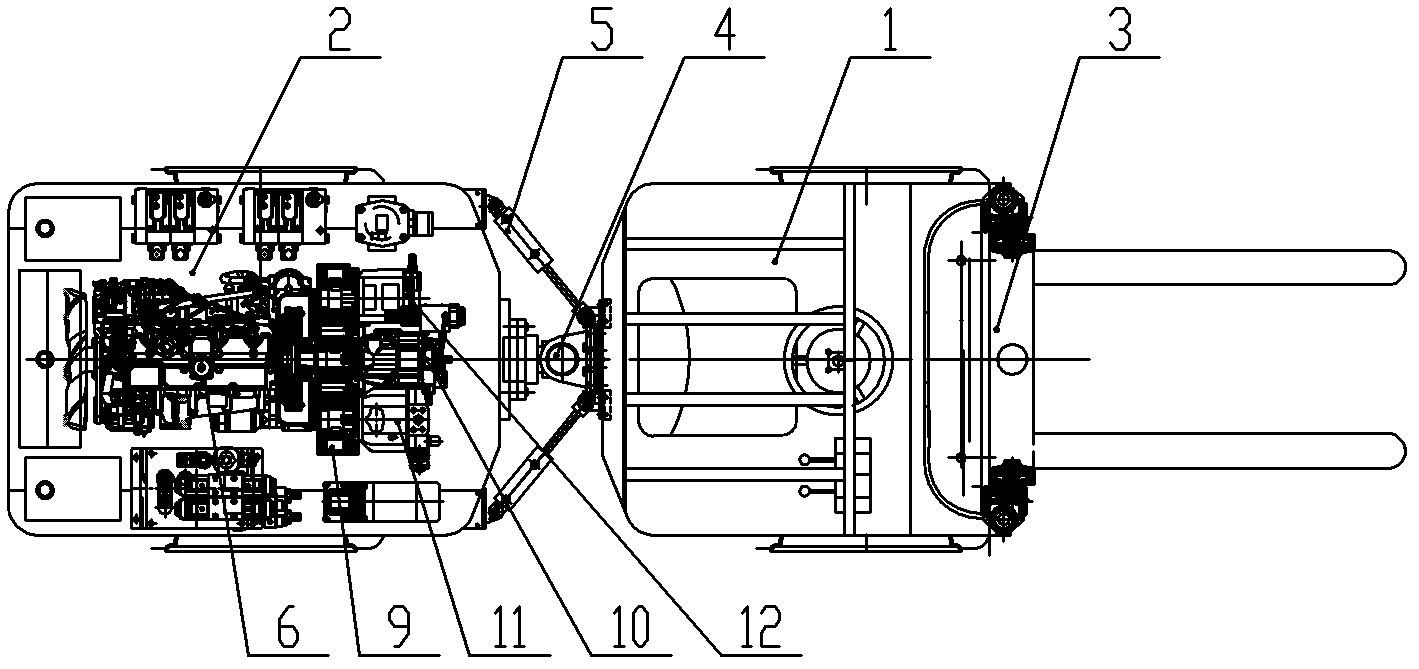

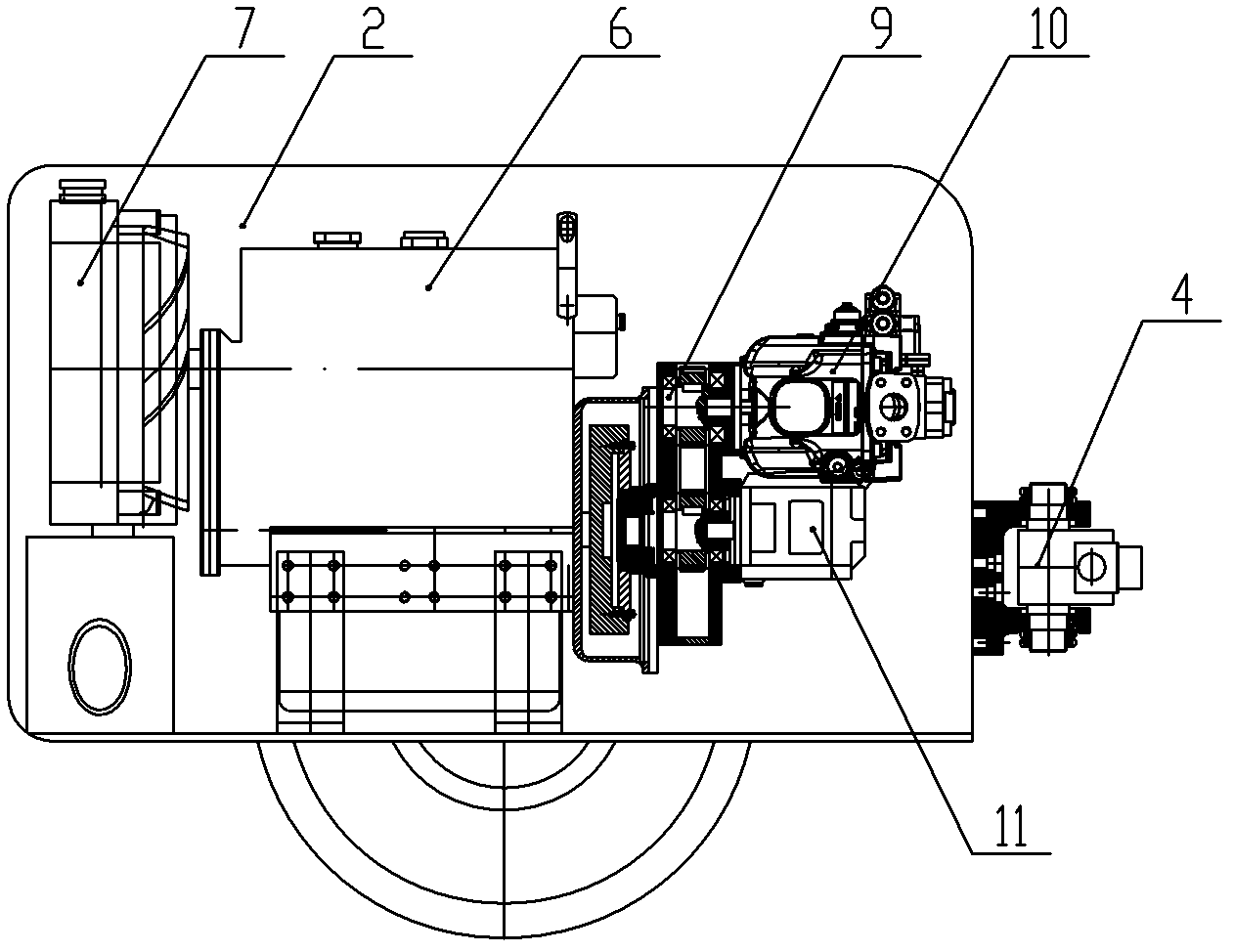

Off-road type forklift with hydrostatic four-wheel drive and articulated frame

InactiveCN102583193ASmall turning radiusHigh steering sensitivityUnderstructuresLifting devicesTransfer caseFour-wheel drive

The invention relates to an off-road type forklift with hydrostatic four-wheel drive and an articulated frame. The forklift comprises a front forklift body and a rear forklift body, which are connected through an articulation mechanism and a steering cylinder, wherein two wheels are respectively arranged on the front forklift body and the rear forklift body; each wheel is arranged at the output end of one hydraulic motor; a drive cabin is arranged on the front forklift body; a lifting mechanism is connected at the front side of the front forklift body; an engine is arranged on the rear forklift body; a transfer case is connected at the flying wheel end of the engine; three oil pumps, namely a variable pump, a first constant pump and a second constant pump are connected at the output end of the transfer case; the variable pump is connected with four hydraulic motors; the first constant pump is connected with the lifting mechanism; and the second constant pump is connected with a steering system. According to the forklift, the articulated frame and the hydrostatic four-wheel drive are adopted, the wheels can be ensured to be fully grounded, and the maximal wheel side thrust of the hydraulic motors is brought into play; and the off-road performance of the forklift is good, so that the application range of the forklift is greatly expanded.

Owner:缪慰时

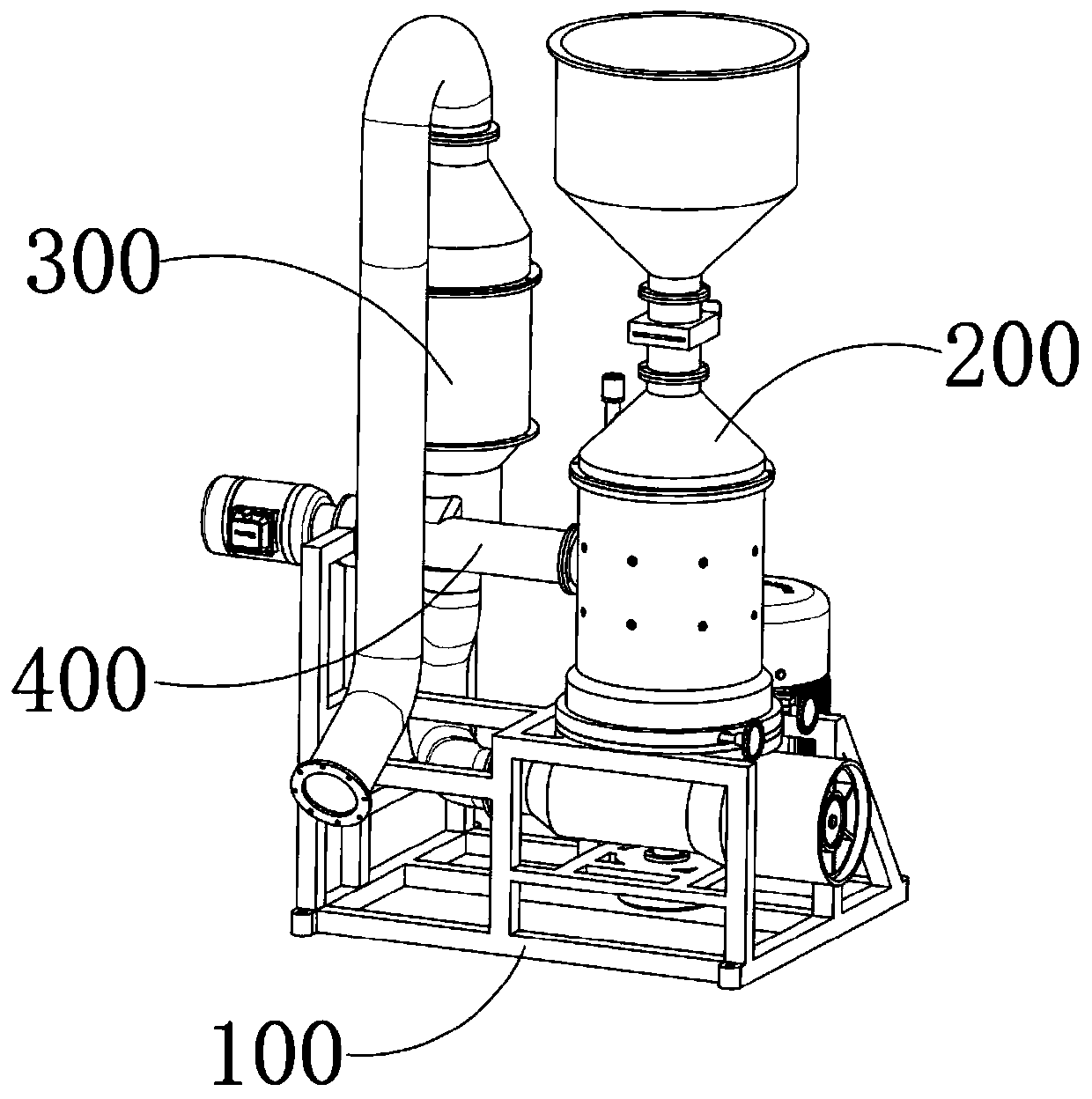

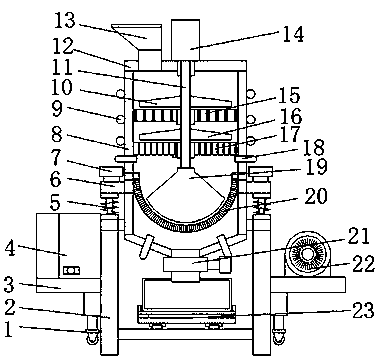

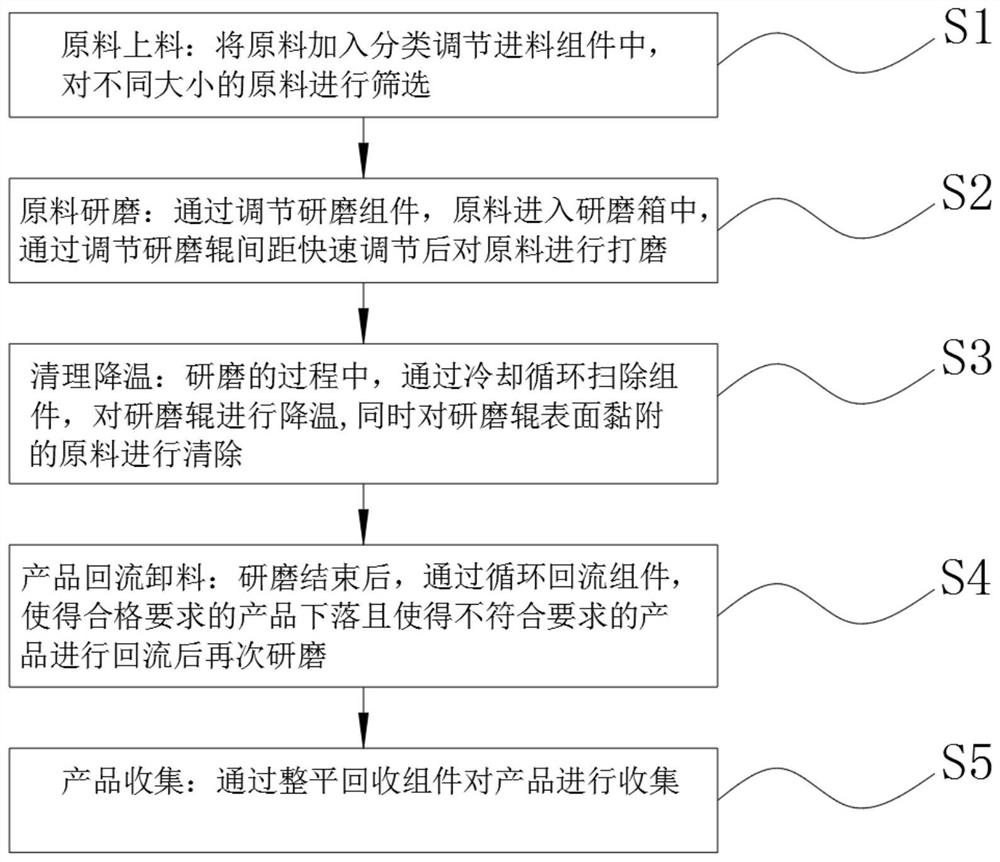

Rice fine grinding and milling process

The invention provides a rice fine grinding and milling process. The process includes the steps of adding rice in a feeding mechanism into the top of a pulverizing tank, allowing the rice to evenly flow into the space between an upper grinding plate and a lower grinding plate under the guidance effect of a guiding plate, grinding the broken rice into rice powder to enter an inner cylinder throughthe cooperation of the upper grinding plate and the lower grinding plate, discharging the rice powder into a collecting cylinder of a suspension separating device through a discharging channel, blowing the rice powder in the collecting cylinder into a suspension tank from bottom to top through an air blowing mechanism so that the rice powder can suspend in the suspension tank, discharging and collecting suspending rice powder through the suspension tank, discharging fallen rice powder particles to an input end of a circulating pipeline in a circulating device, rotating an auger to convey the rice powder particles to a pulverizing tank, and making the rice powder particles fall into the gap between the upper grinding plate and the lower grinding plate again to be ground again by the upper grinding plate and the lower grinding plate.

Owner:山东久信食品有限公司

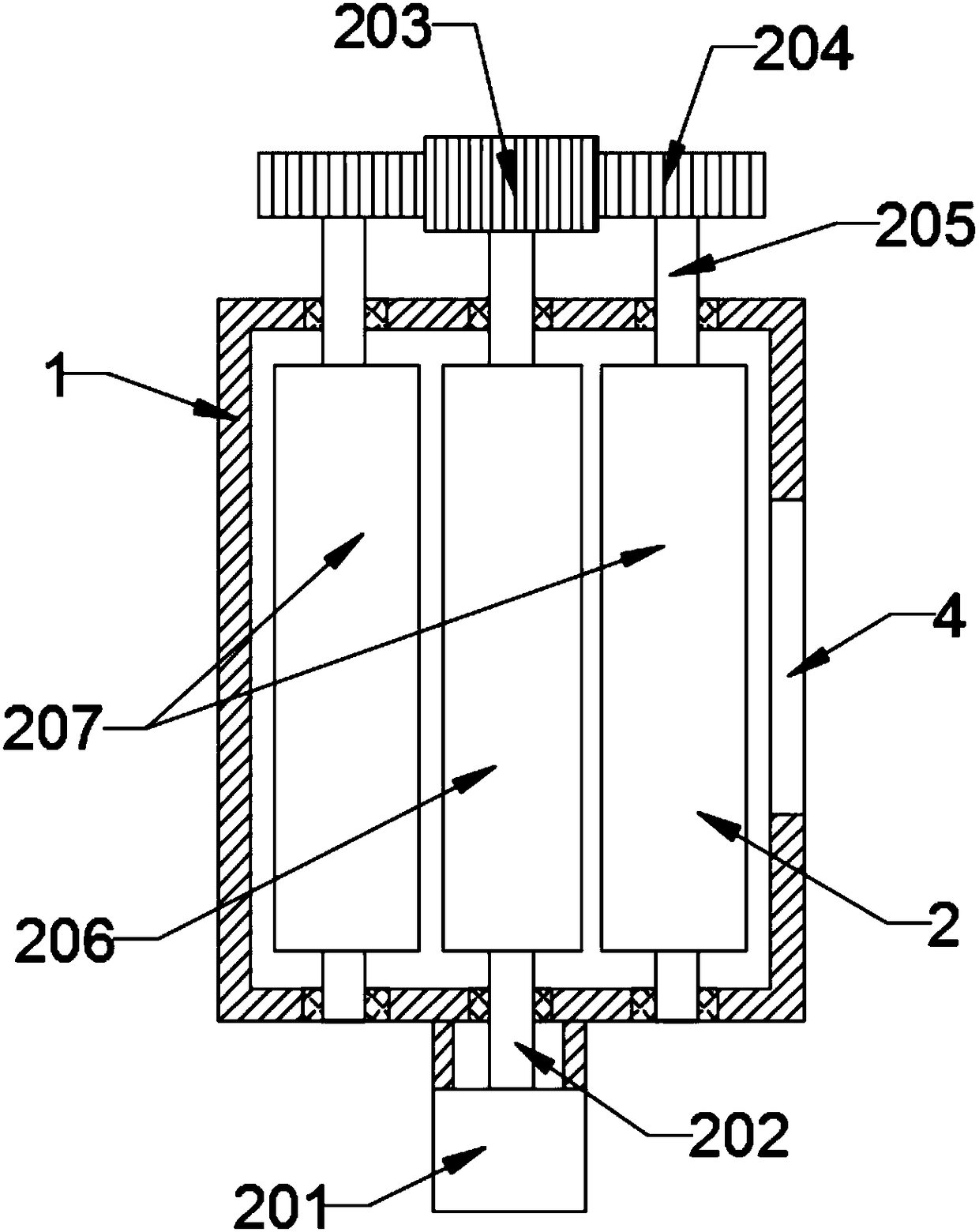

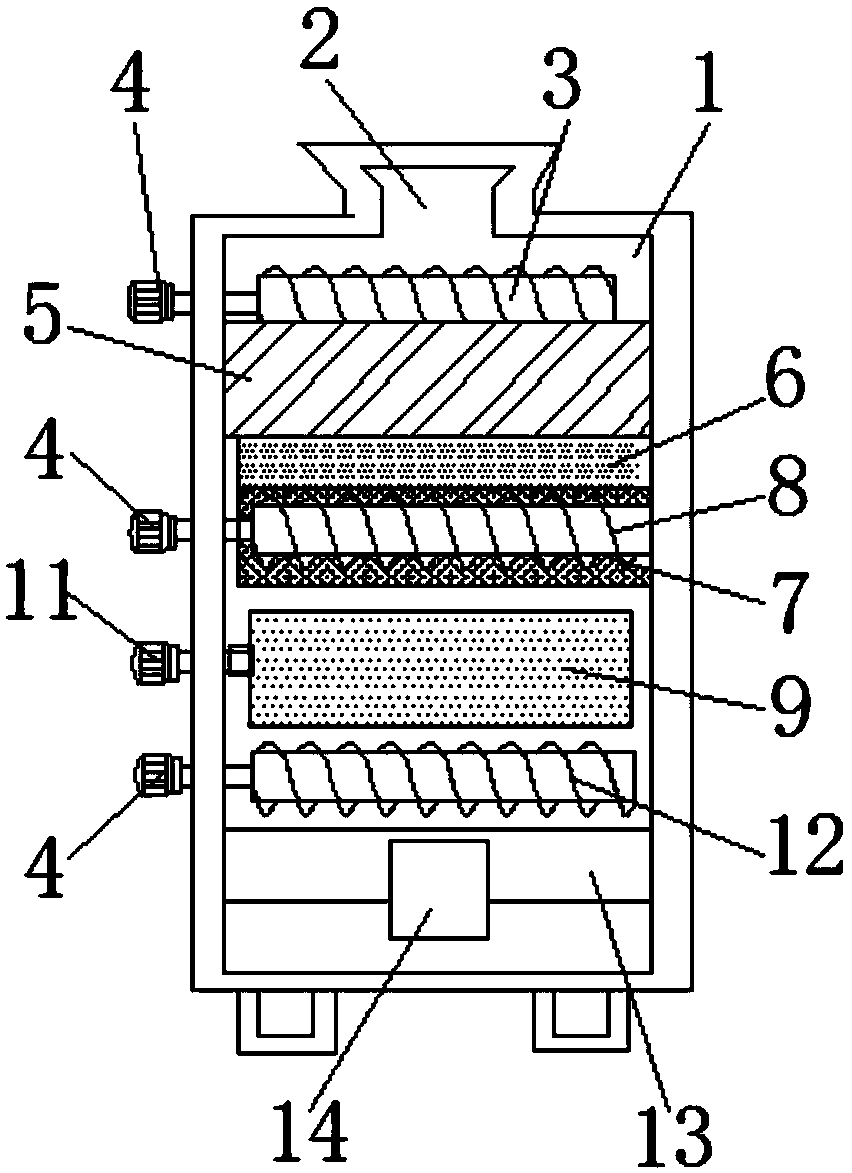

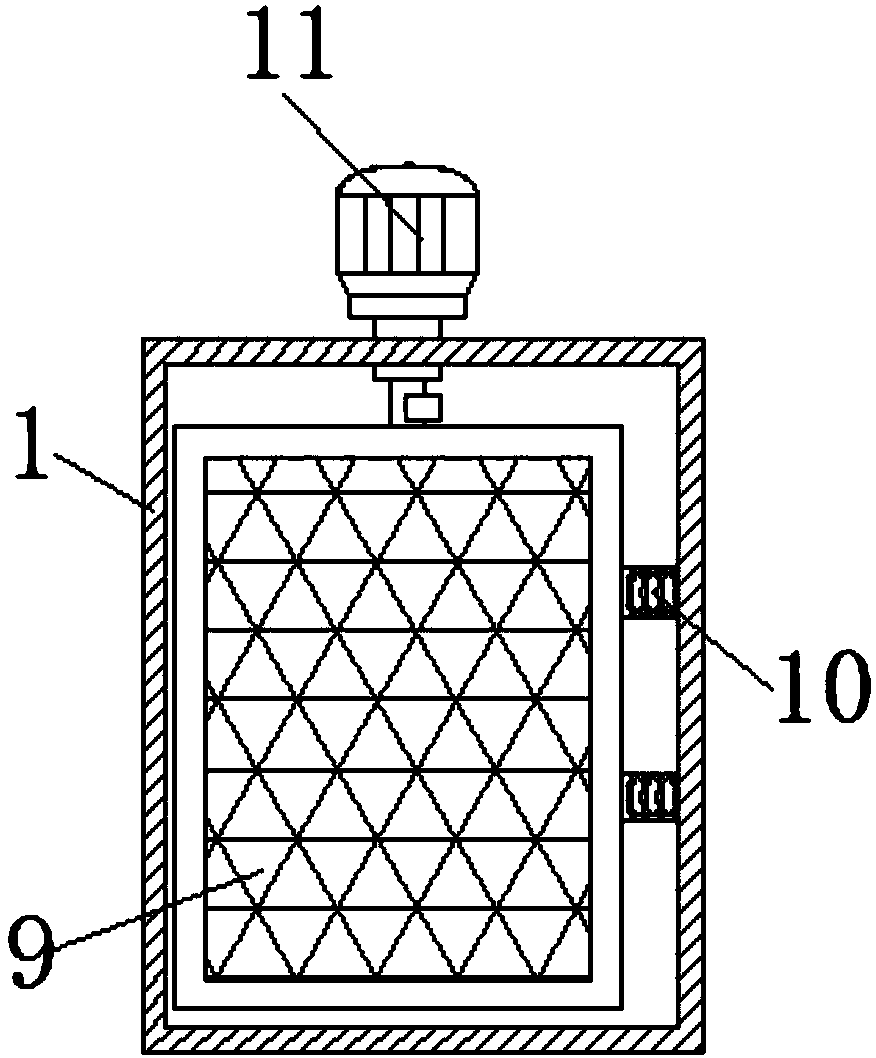

Multistage milling device for polymer chemical material particles

PendingCN108405063AGuaranteed grinding effectAvoid quality degradationHollow article cleaningCocoaCompound (substance)Engineering

The invention belongs to the technical field of medical equipment and particularly relates to a multistage milling device for polymer chemical material particles. The multistage milling device aimingat solving the problems that an existing milling device is difficult to clean, meanwhile the heat generated during milling is not completely dissipated, and damage to the milling device is caused easily. According to the multistage milling device, the following scheme is provided, the multistage milling device comprises a support frame, vertically-arranged shock absorbers are connected to the fourcorners of the top of the support frame through bolts, and the tops of the four shock absorbers are all connected with mounting blocks through bolts, and the same milling box is welded to the ends, close to each other, of the four mounting blocks. According to the multistage milling device, the polymer chemical material particles are milled by a first milling disc and a second milling disc and then ball-milled by a ball milling head and a third milling disc, so that the milling effect of the polymer chemical material particles can be ensured, the milling device is easy and convenient to clean, and the corrosion of the residual polymer chemical material to the milling device can be effectively avoided.

Owner:LINYI UNIVERSITY

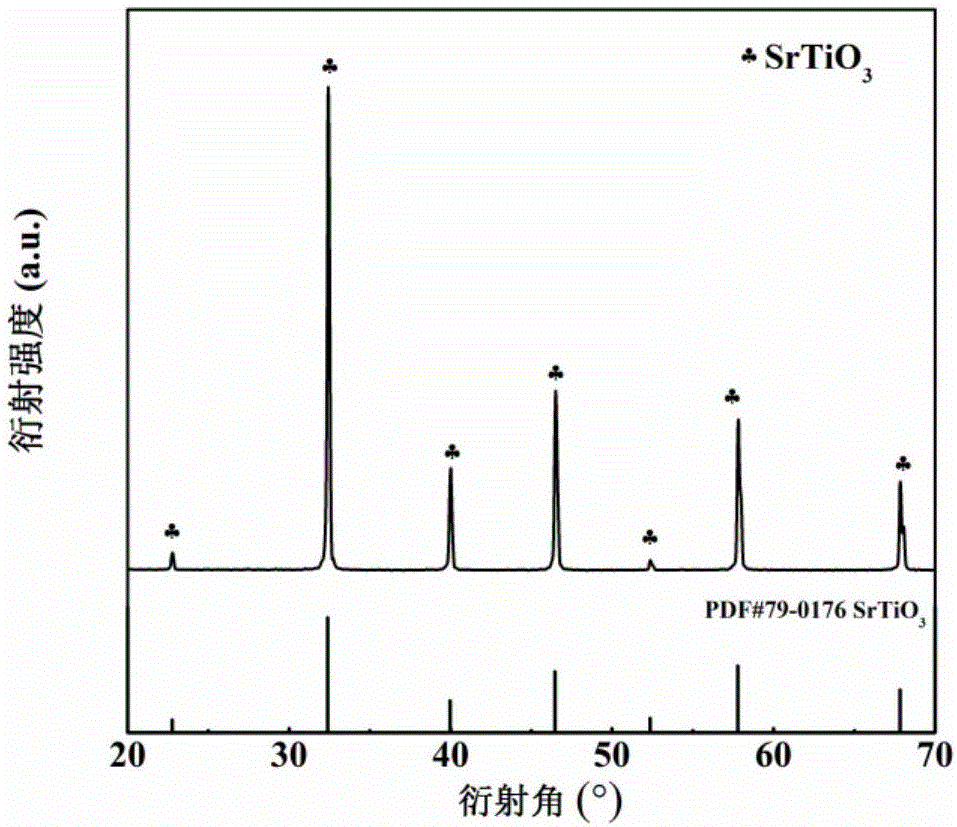

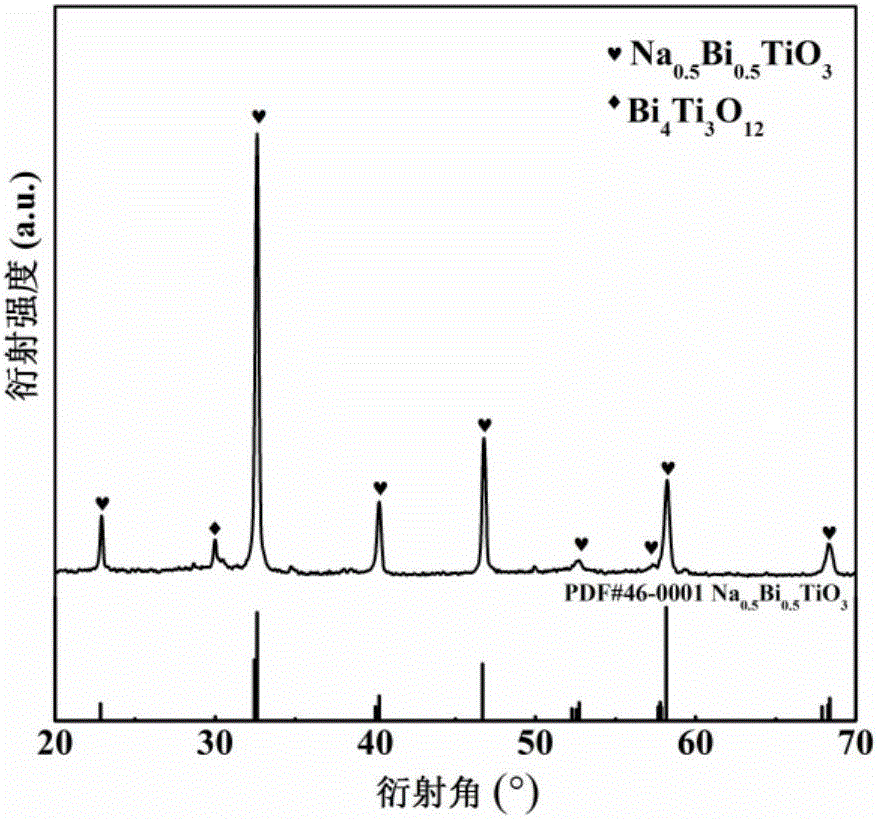

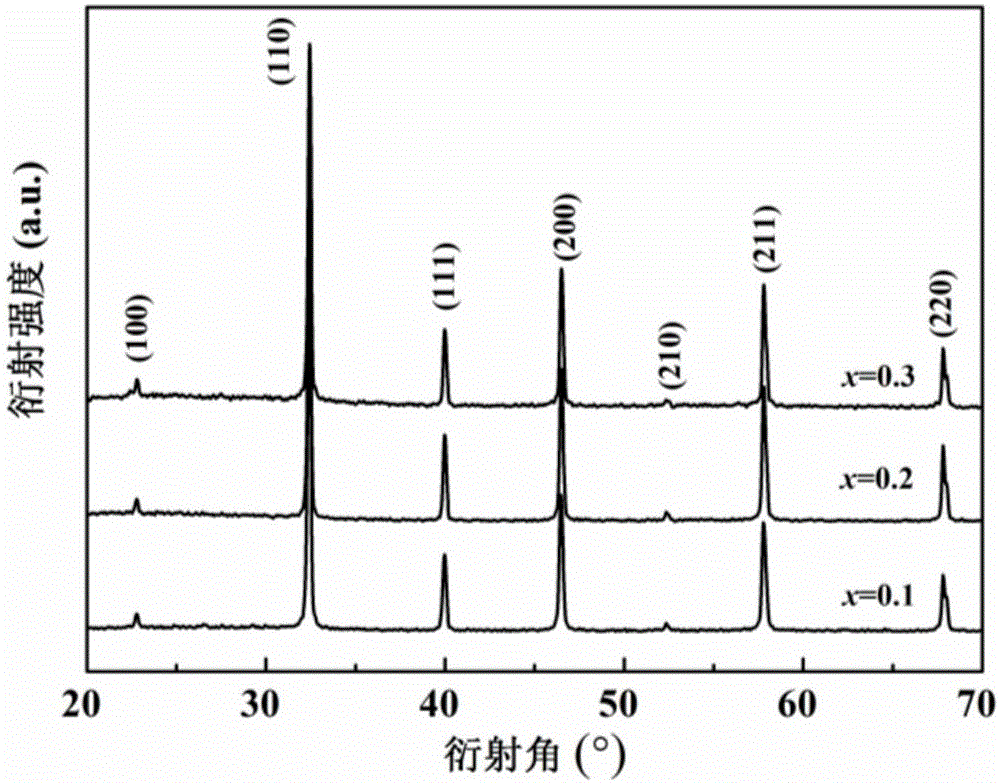

SrTiO<3>-based lead-free high-energy-density ceramic material and preparation method thereof

InactiveCN106587997AHigh polarizationHigh energy storage densityFixed capacitor dielectricMaterials preparationSilver electrode

The invention discloses an SrTiO<3>-based lead-free high-energy-density ceramic material and a preparation method thereof, and belongs to the technical field of material preparation. According to the method, firstly, 10 to 30 mol percent of Na<0.5>Bi<0.5>TiO<3> powder is added into SrTiO<3> powder to form a mixture; the mixture is subjected to ball milling and drying to obtain dried materials; then, the dried materials are sequentially granulated and sieved to form granulation materials; the granulation materials are made into test specimens; then, sintering is performed to obtain sintering test specimens; grinding and cleaning are performed on the obtained sintering test specimens; the front side and the back side of the ground and cleaned sintering test specimens are uniformly coated with silver electrode slurry; then, sintering is performed; and (1-x)SrTiO<3>-xNa<0.5>Bi<0.5>TiO<3> ceramics are obtained. The high-energy-density ceramic material obtained by using the method provided by the invention has the advantages that the preparation process is simple; the material cost is low; and the mass production can be realized, so that an effective path is provided for the application of the high-energy-density ceramic material.

Owner:SHAANXI UNIV OF SCI & TECH

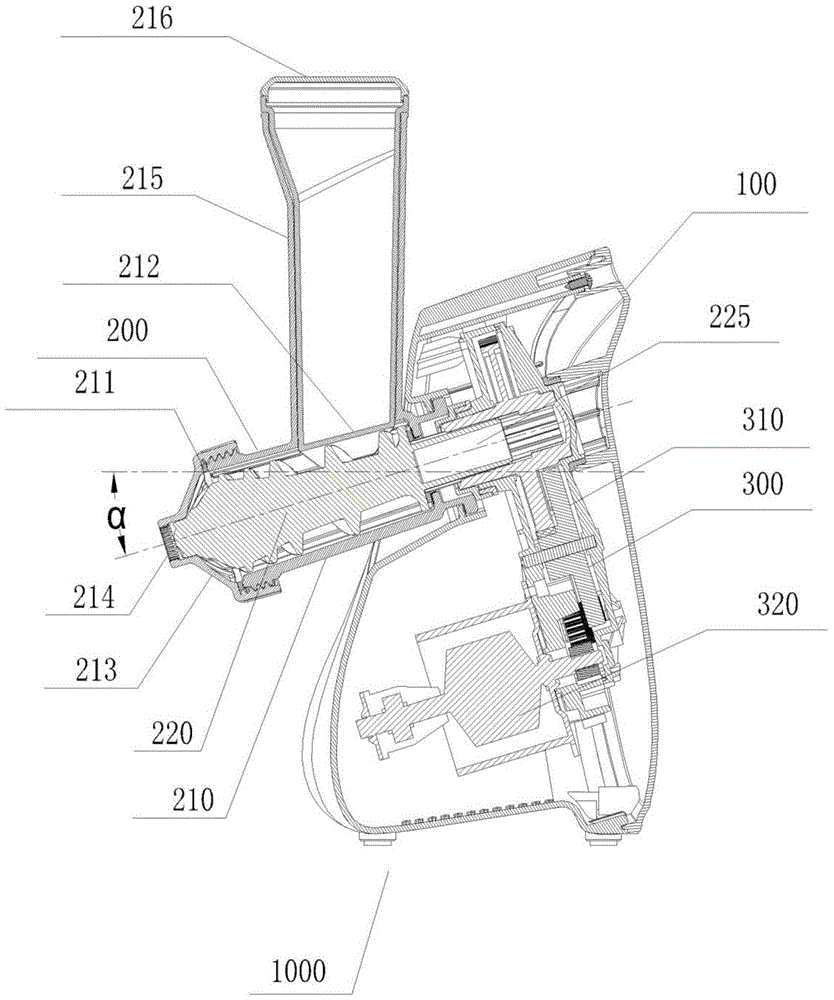

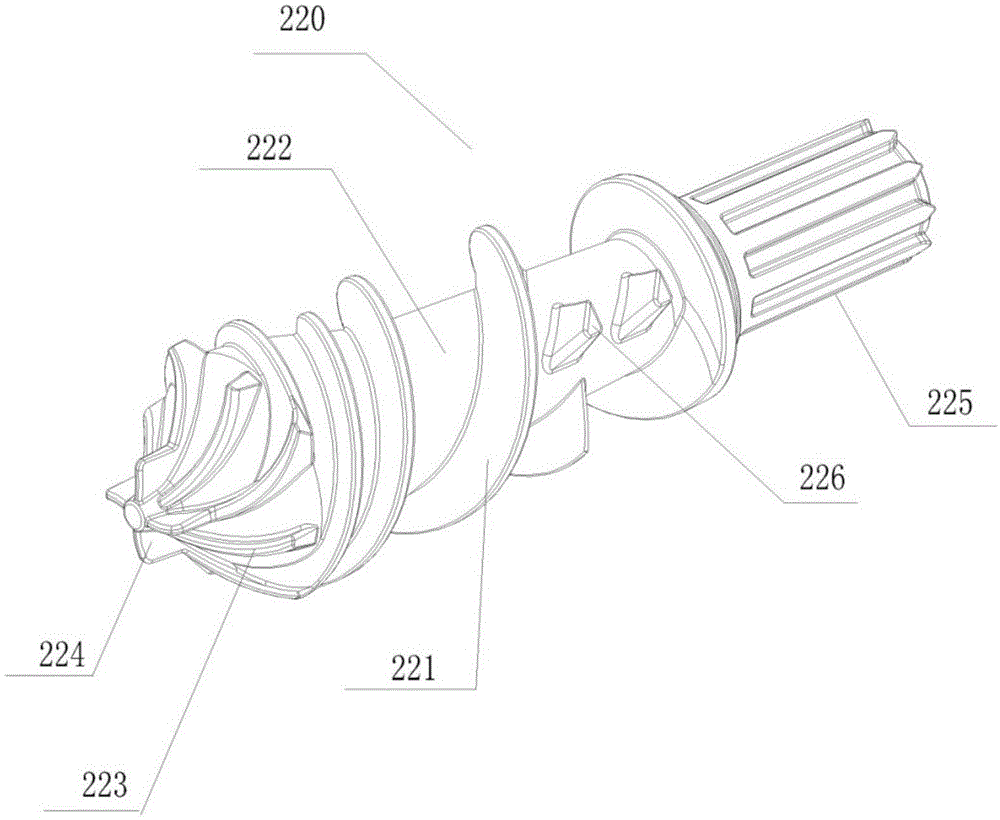

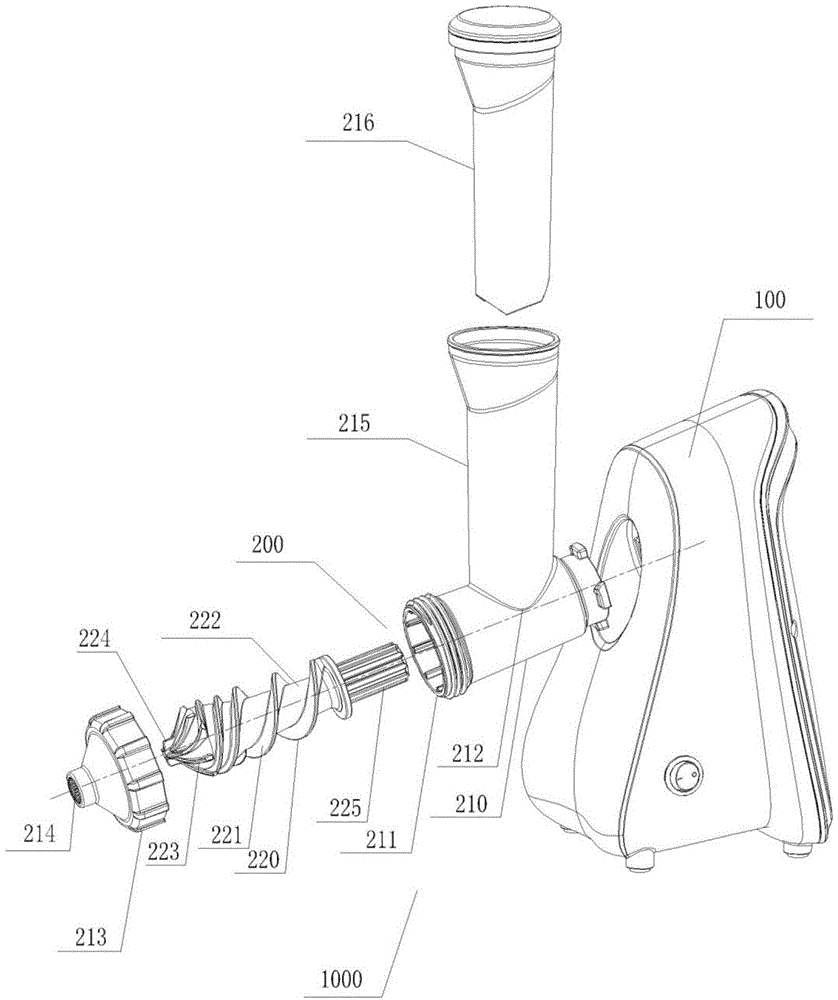

Screw type food processing device

ActiveCN105433824AFully groundedPrevent splashKitchen equipmentDischarge efficiencyMechanical engineering

The invention relates to a screw type food processing device comprising a housing and a screw extrusion assembly arranged on the housing; the screw extrusion assembly comprises an extrusion pipe and a screw rod coaxially arranged in the extrusion pipe; the axis of the extrusion pipe leans against the horizontal line; one end, having a discharge port, of the extrusion pipe is lower than the other end; the screw type food processing device can effectively prevent juice of extruded food from flowing into a drive mechanism, can reduce device center of gravity, is better in stable performance, and can increase discharge efficiency.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

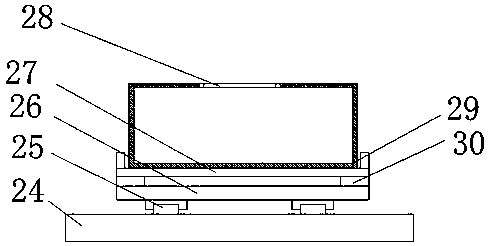

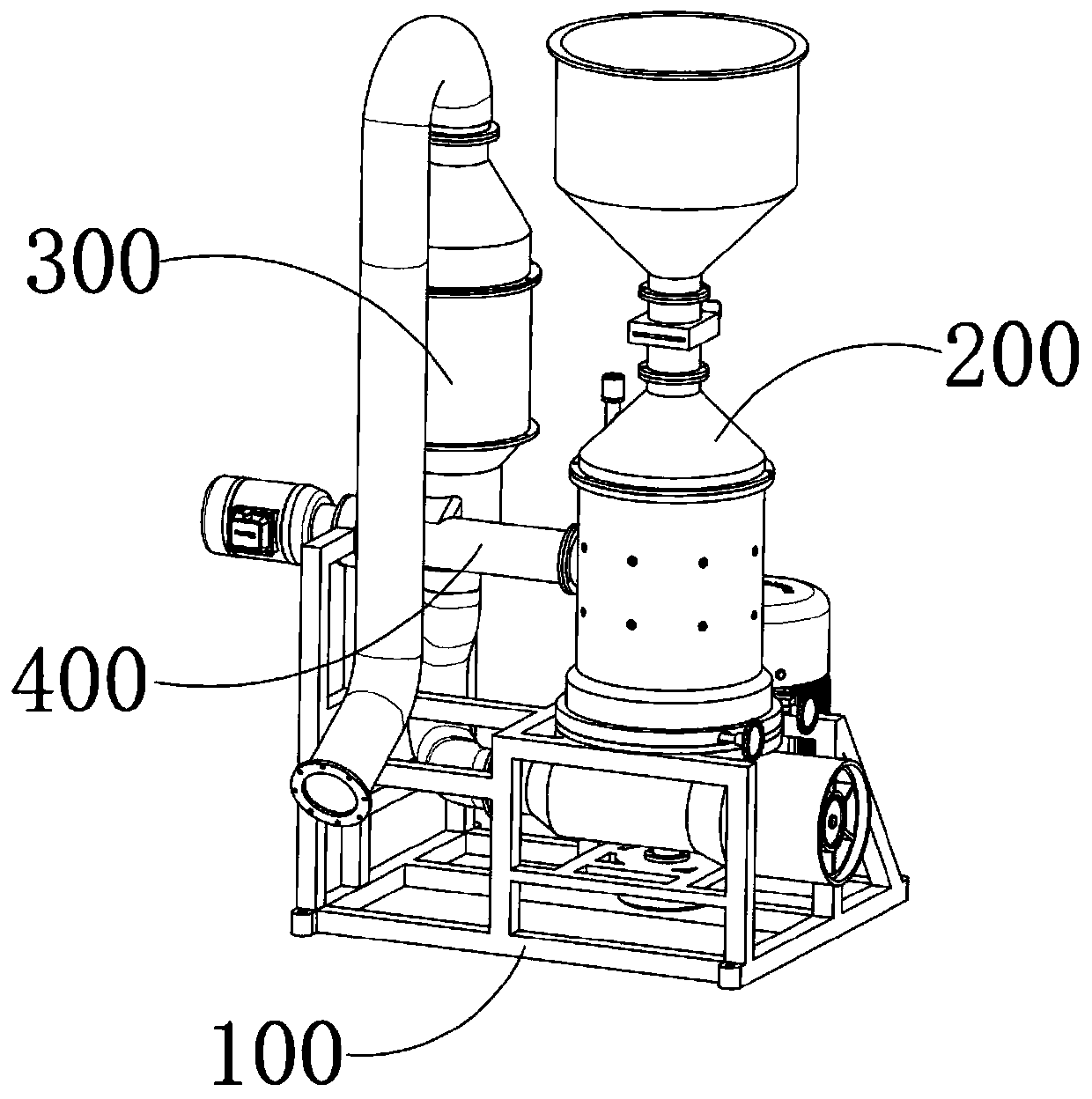

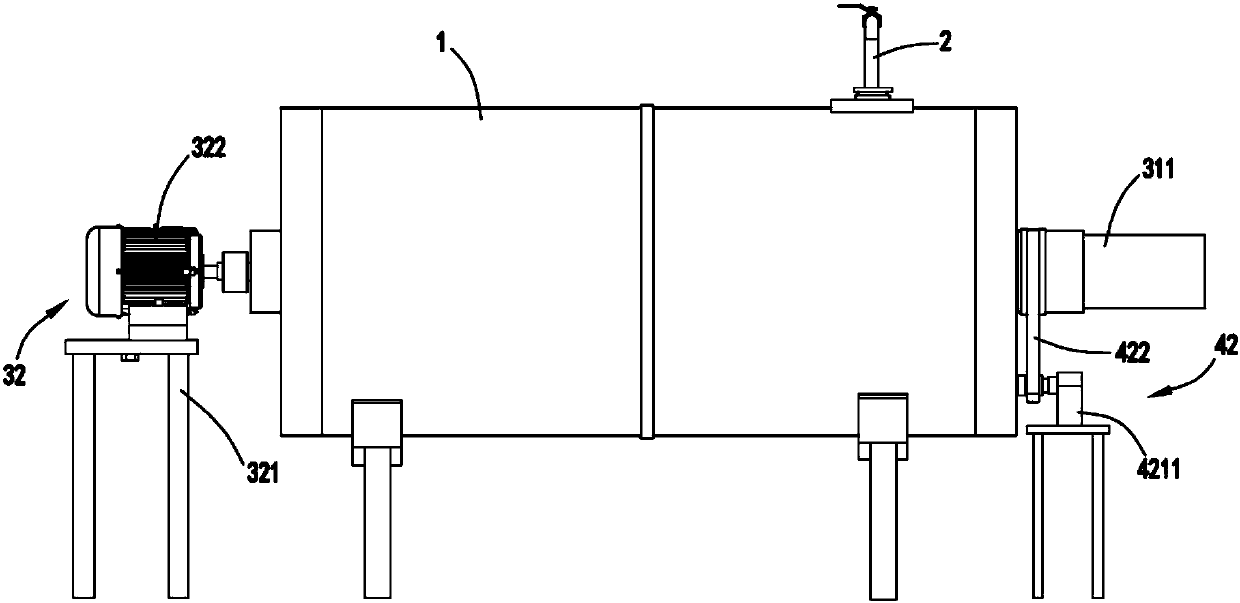

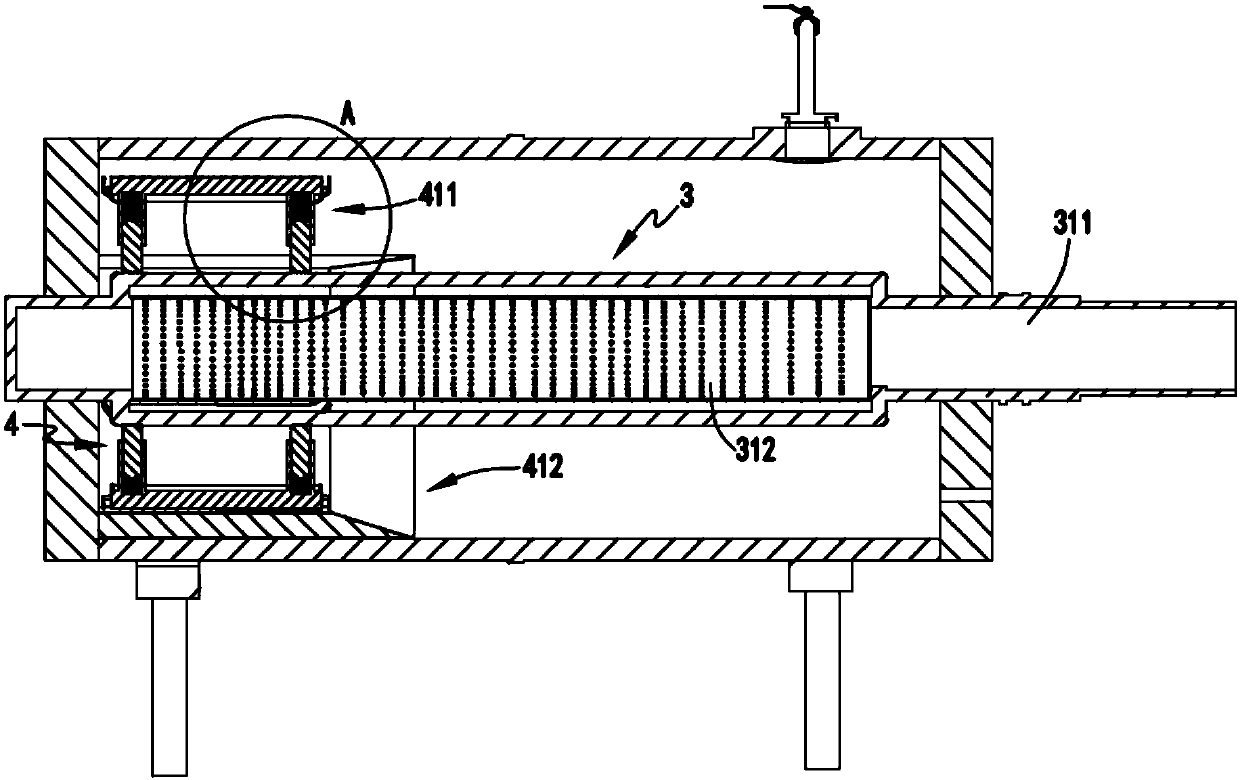

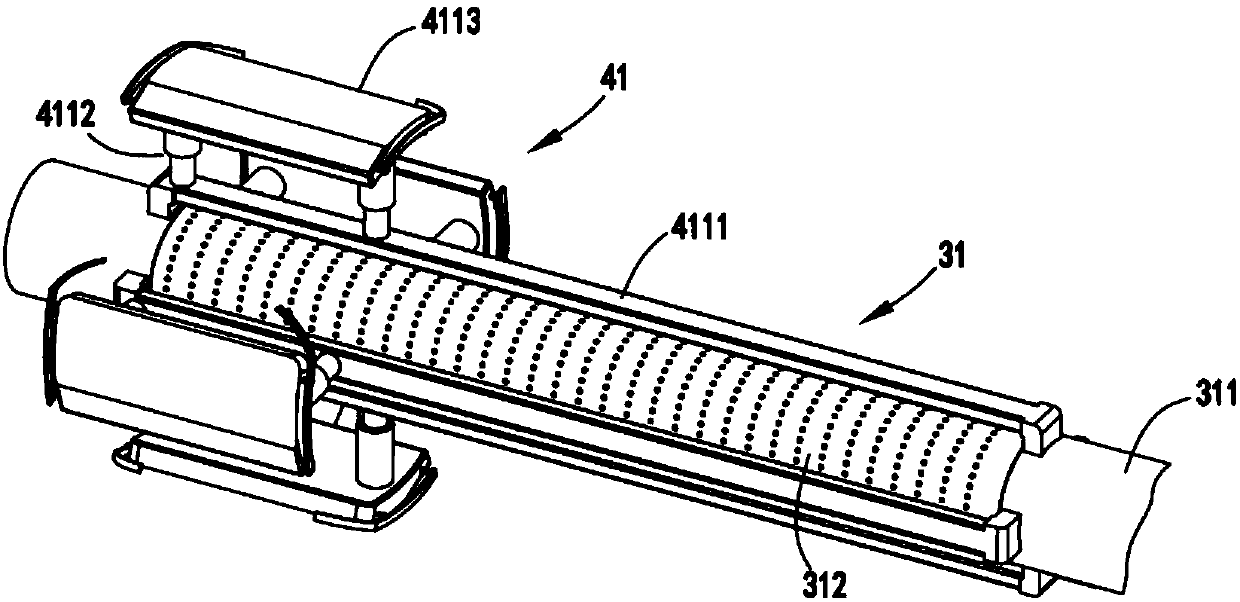

Rice processing equipment

ActiveCN110586272AIngenious structureThe principle is simpleCocoaGrain treatmentsEngineeringAir suspension

The invention provides rice processing equipment, which includes a grounded mounting rack, as well as a grinding device, a suspension separation device and a circulation device all fixedly mounted onthe mounting rack, wherein the grinding device is used for grinding rice into rice flour and discharging the rice flour to the suspension separation device; the suspension separation device is used for air suspension separation for rice flour and enables the rice flour to be discharged to outside for collection, and enables the rice particles to be discharged to the circulation device; the circulation device is used for receiving the rice particles discharged from the suspension separation device and conveying the rice particles into the grinding device for secondary grinding processing. The rice processing equipment has the significance that air suspension is used for suspension, separation and screening the mixture of rice flour and rice particles subjected to primary grinding, so that the separated rice flour is directly discharged and collected, and the separated rice particles is subjected to circular secondary grinding processing, as a result, rice is completely ground.

Owner:邵阳市厚土生态农业有限公司

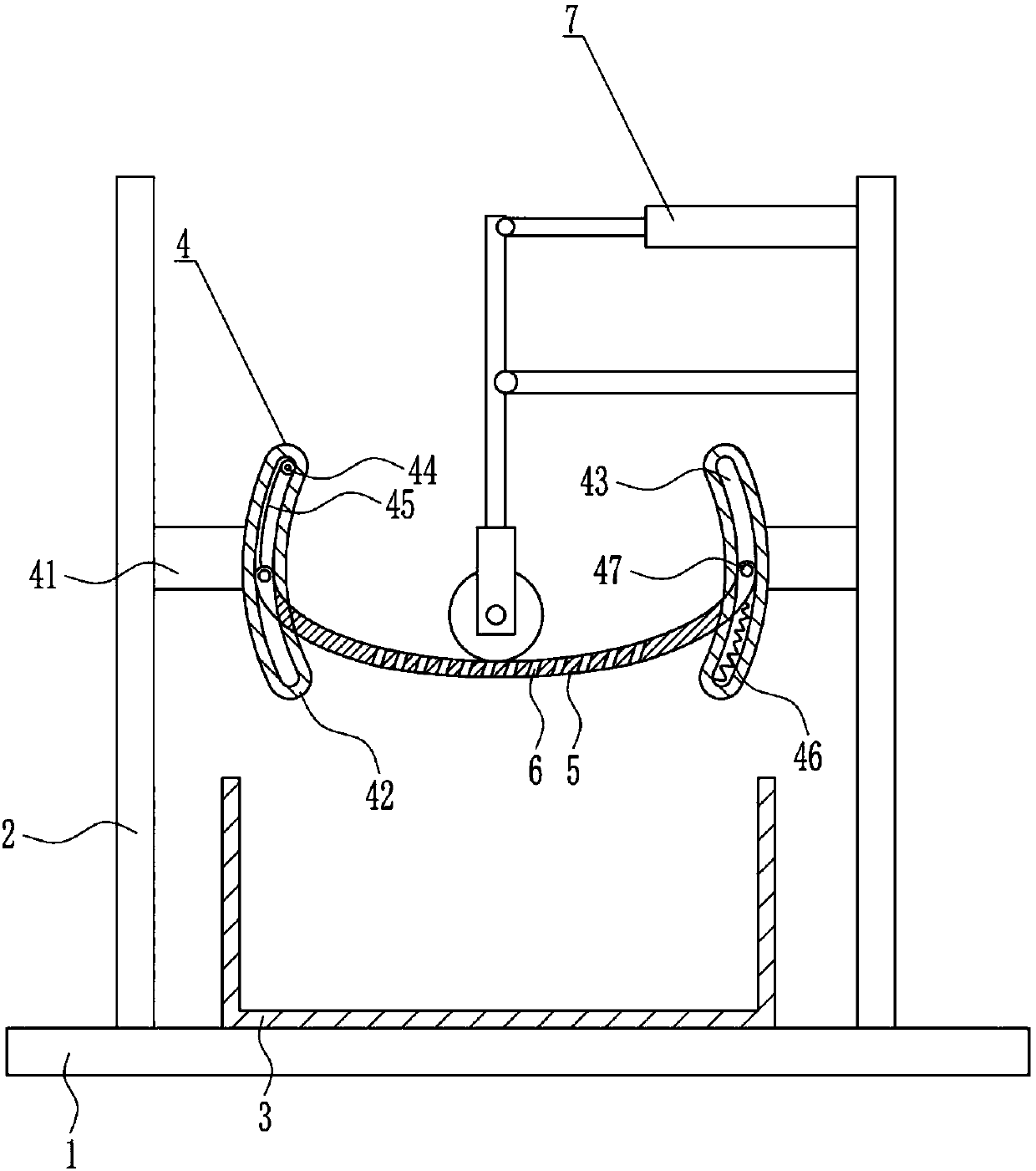

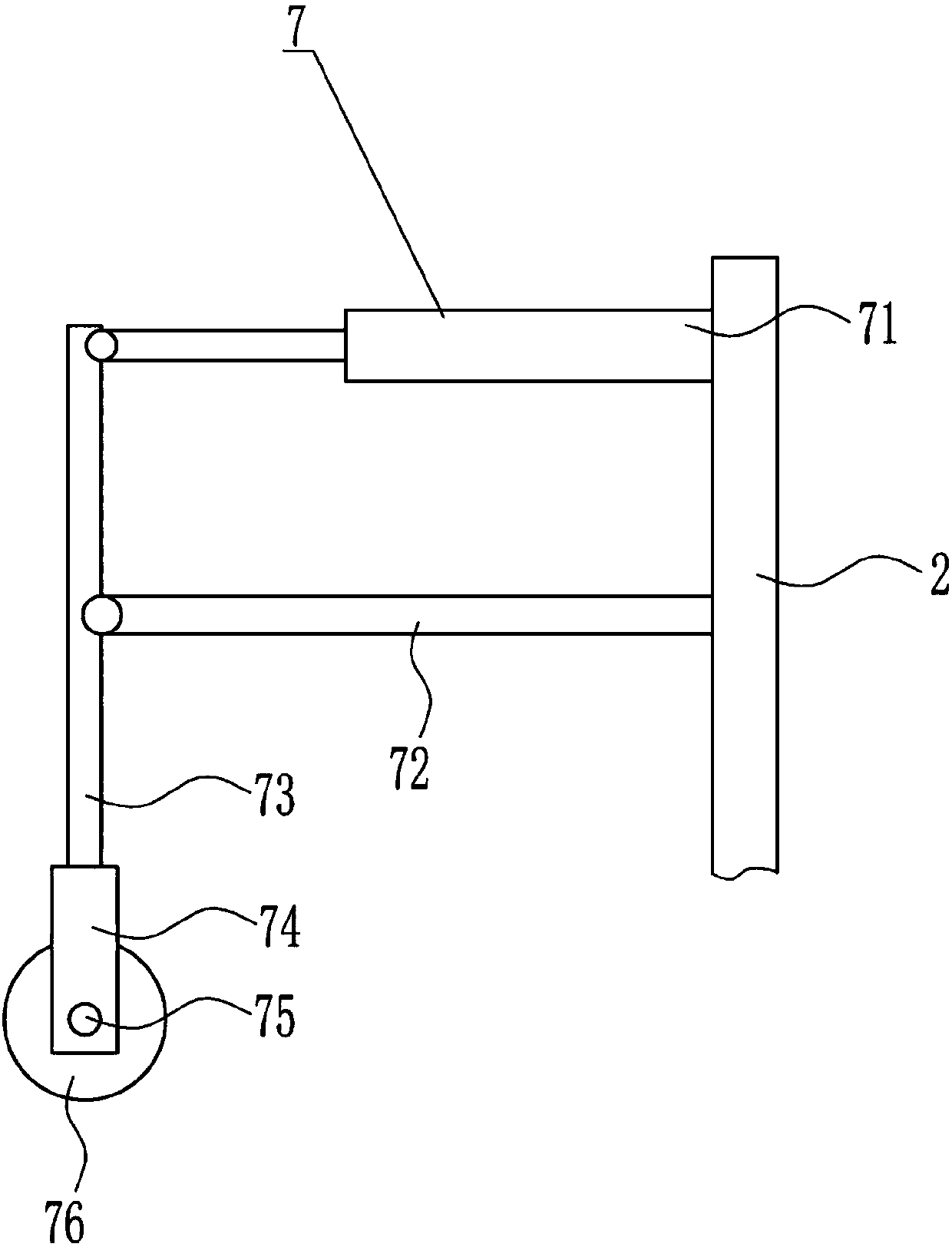

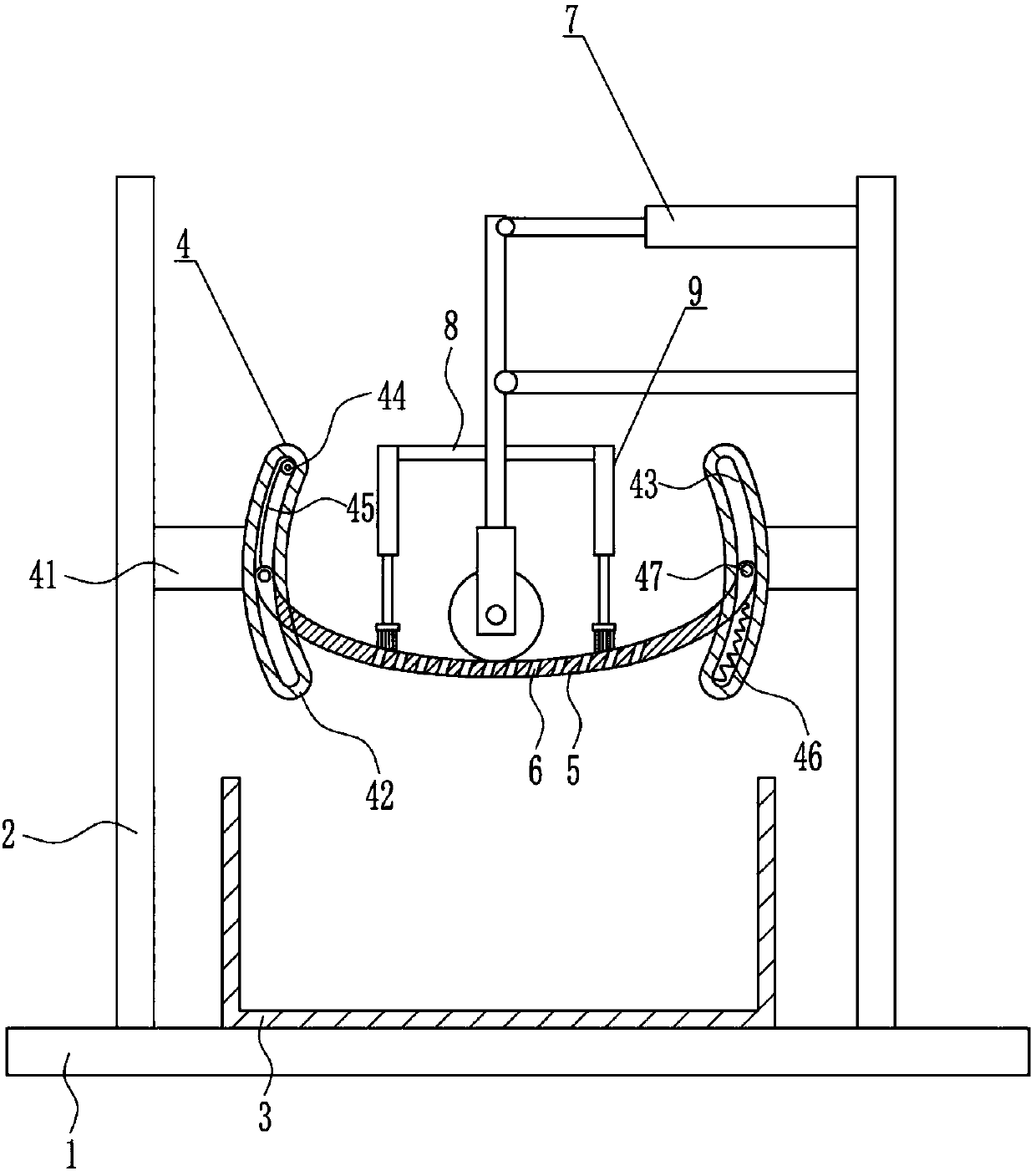

Wheat grinding device for food processing

ActiveCN107899669AFully groundedGood grinding effectGrain treatmentsEngineeringMechanical engineering

The invention discloses a wheat grinding device for food processing, and belongs to the technical field of food processing. The wheat grinding device is capable of being simple in operation, comprehensive in grinding and high in working efficiency. The grinding device for food processing comprises a bottom plate, supports, a collecting frame, a swing device, a loading plate and a grinding device body; the supports are symmetrically and vertically arranged on two ends of the bottom plate, and the collecting frame is arranged on the position, between the two supports, of the bottom plate; the swinging device is fixedly arranged on the supports, the loading plate is arranged on swinging parts of the swinging device and is located above the collecting frame, and multiple discharging holes areformed in the loading plate; and the grinding device body is fixed on the support on one side, and a grinding part of the grinding device body is in contact with the upper surface of the loading plate. The wheat grinding device has the advantages that the grinding effect is good, and the effects of simple operation, comprehensive grinding and the high working efficiency are achieved.

Owner:SHAANXI UNIV OF SCI & TECH

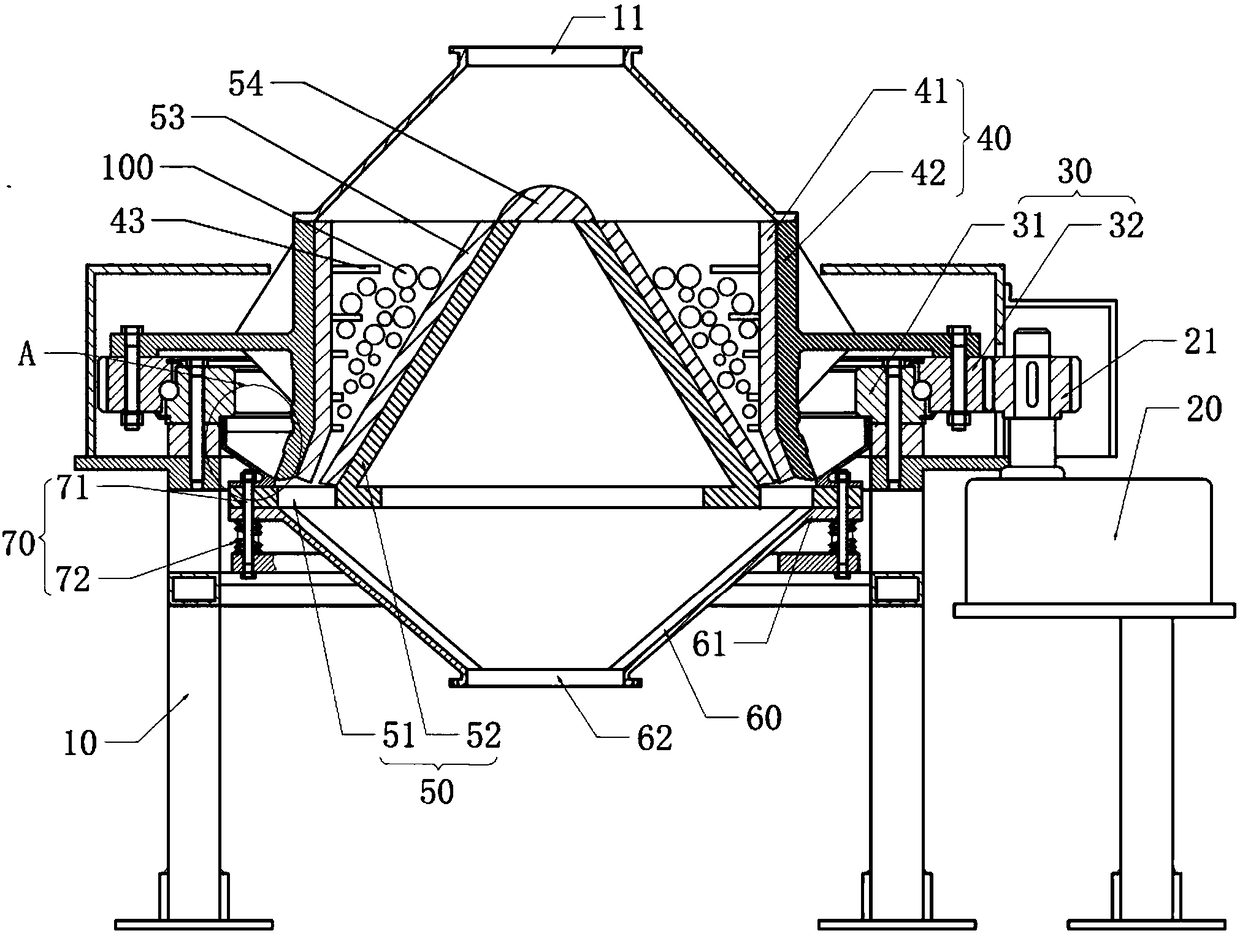

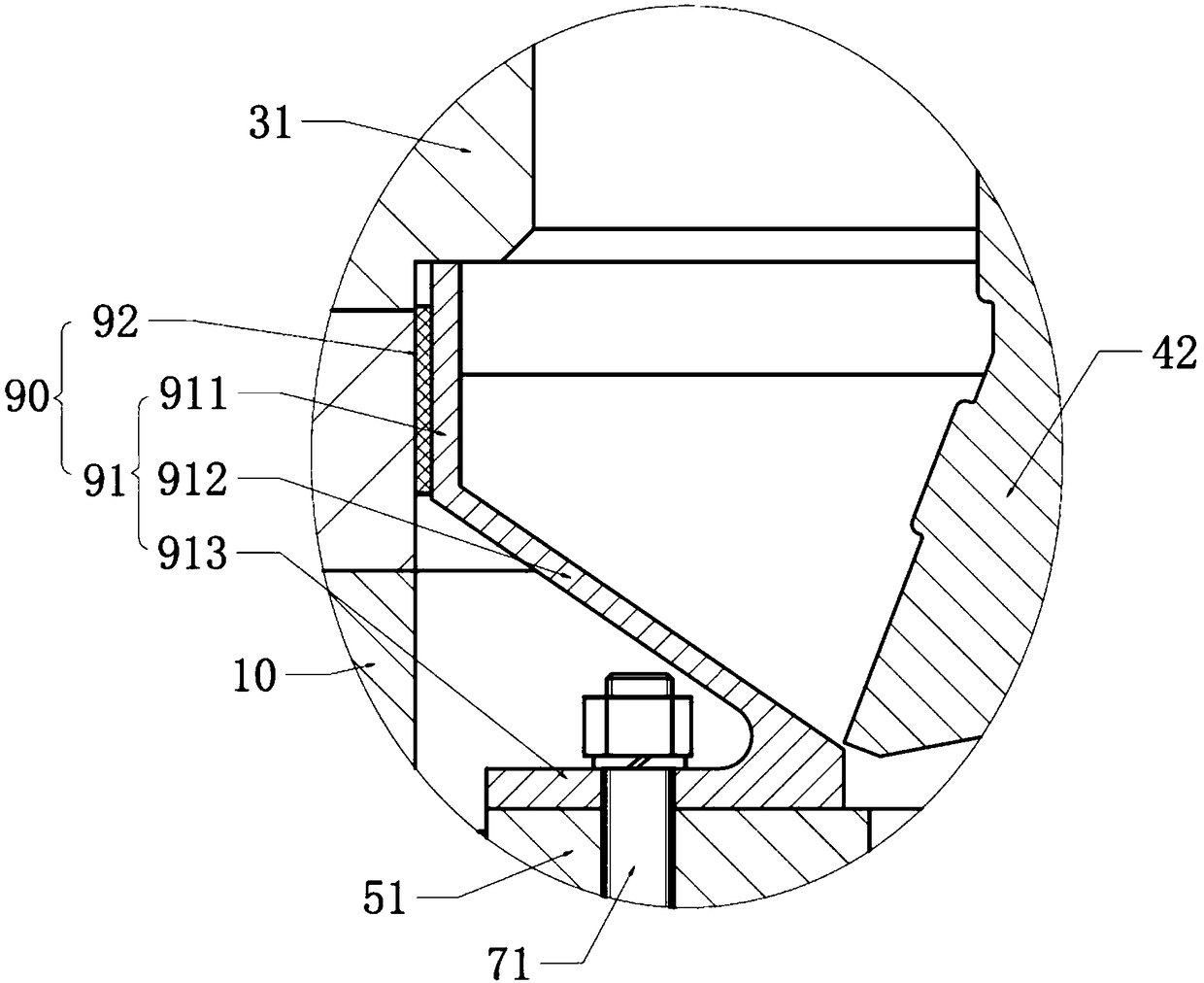

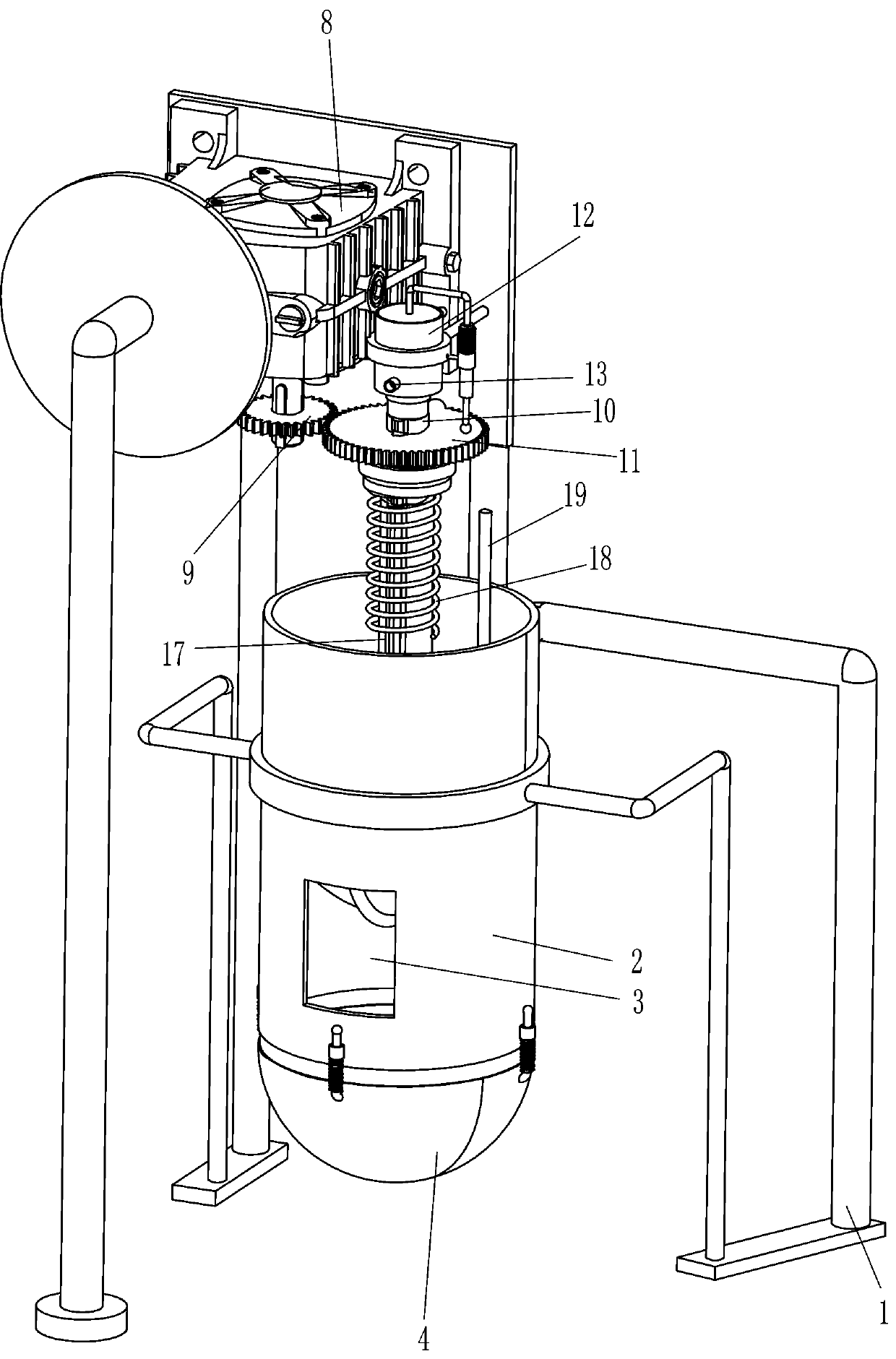

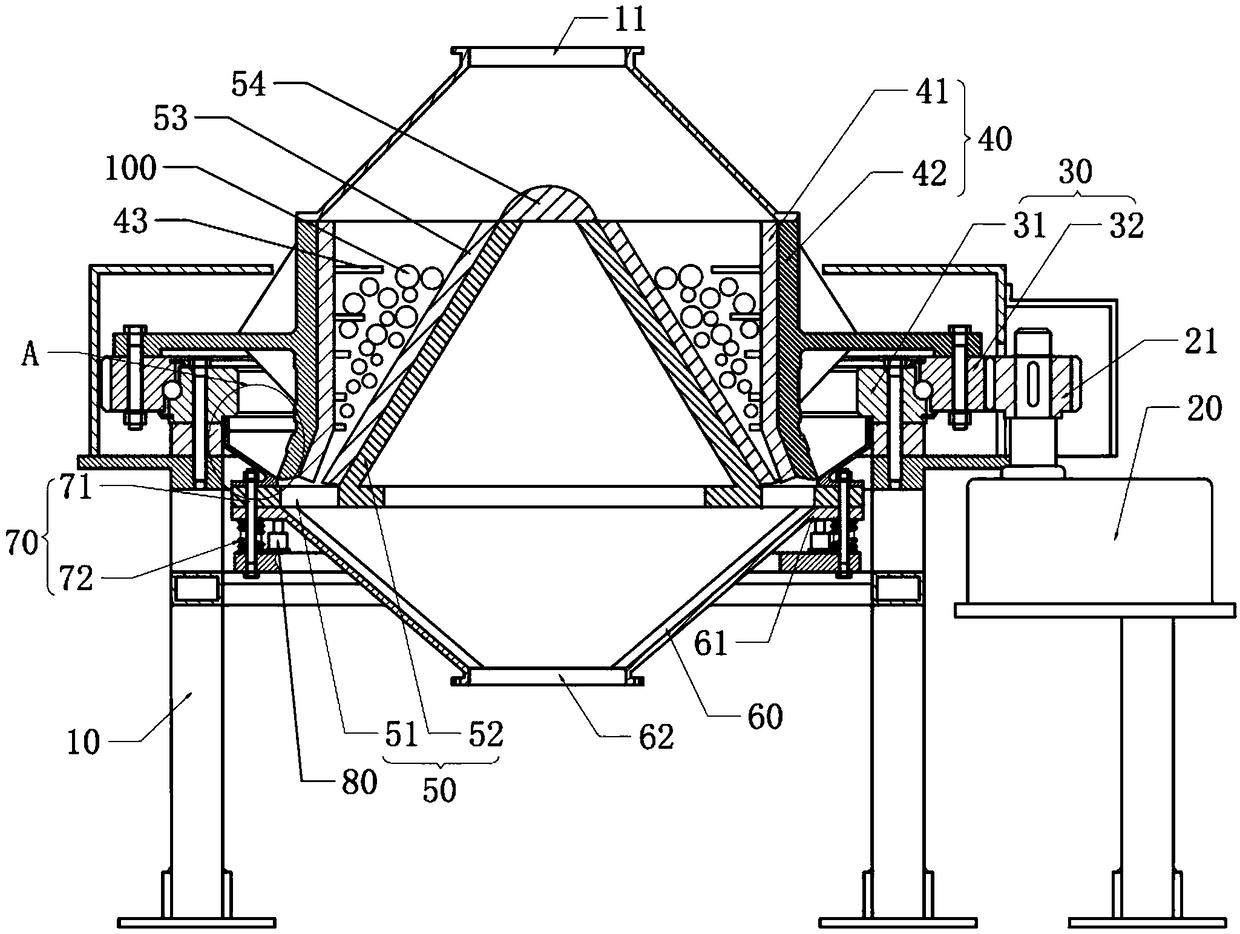

Spiral cone stirring ball grinding mill

PendingCN108499650AImprove stabilityImprove carrying capacityGrain treatmentsEngineeringSlewing bearing

The invention discloses a spiral cone stirring ball grinding mill. The spiral cone stirring ball grinding mill comprises a mill body, a driving device, a slewing bearing, a movable cone device, a fixed cone device and multiple grinding balls, wherein the slewing bearing, the movable cone device, the fixed cone device and the multiple grinding balls are arranged on the mill body. The driving mechanism can drive the movable cone device to rotate around the axis of the fixed cone device through the slewing bearing, and the grinding balls are placed in a cavity defined by the movable cone device and the fixed cone device jointly so as to carry out stirring and powder grinding on materials jointly. By means of the cooperation of the slewing bearing and the grinding balls, materials can be subjected to sufficient powder grinding, the effective work duration of the spiral cone stirring ball grinding mill is prolonged, the maintenance frequency can be reduced, and therefore the working efficiency and the powder grinding effect of the spiral cone stirring ball grinding mill can be greatly improved.

Owner:CHANGSHA UNIVERSITY

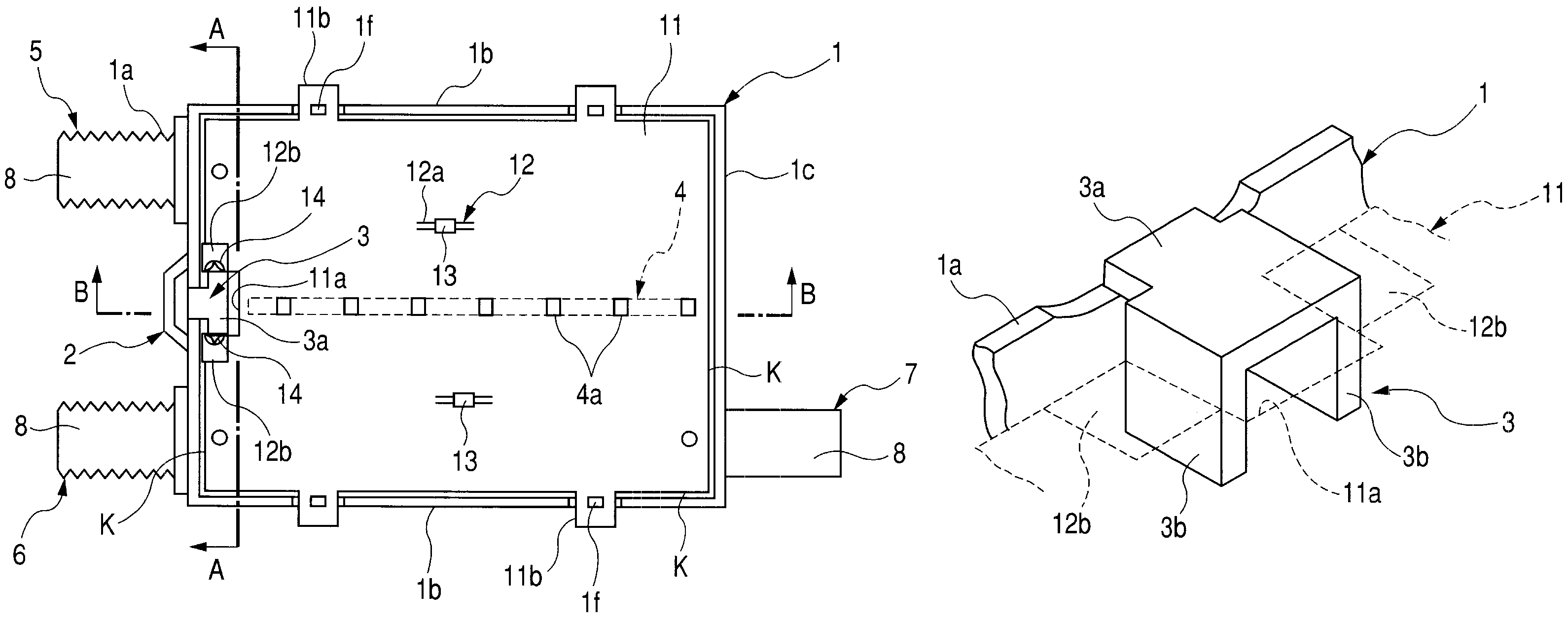

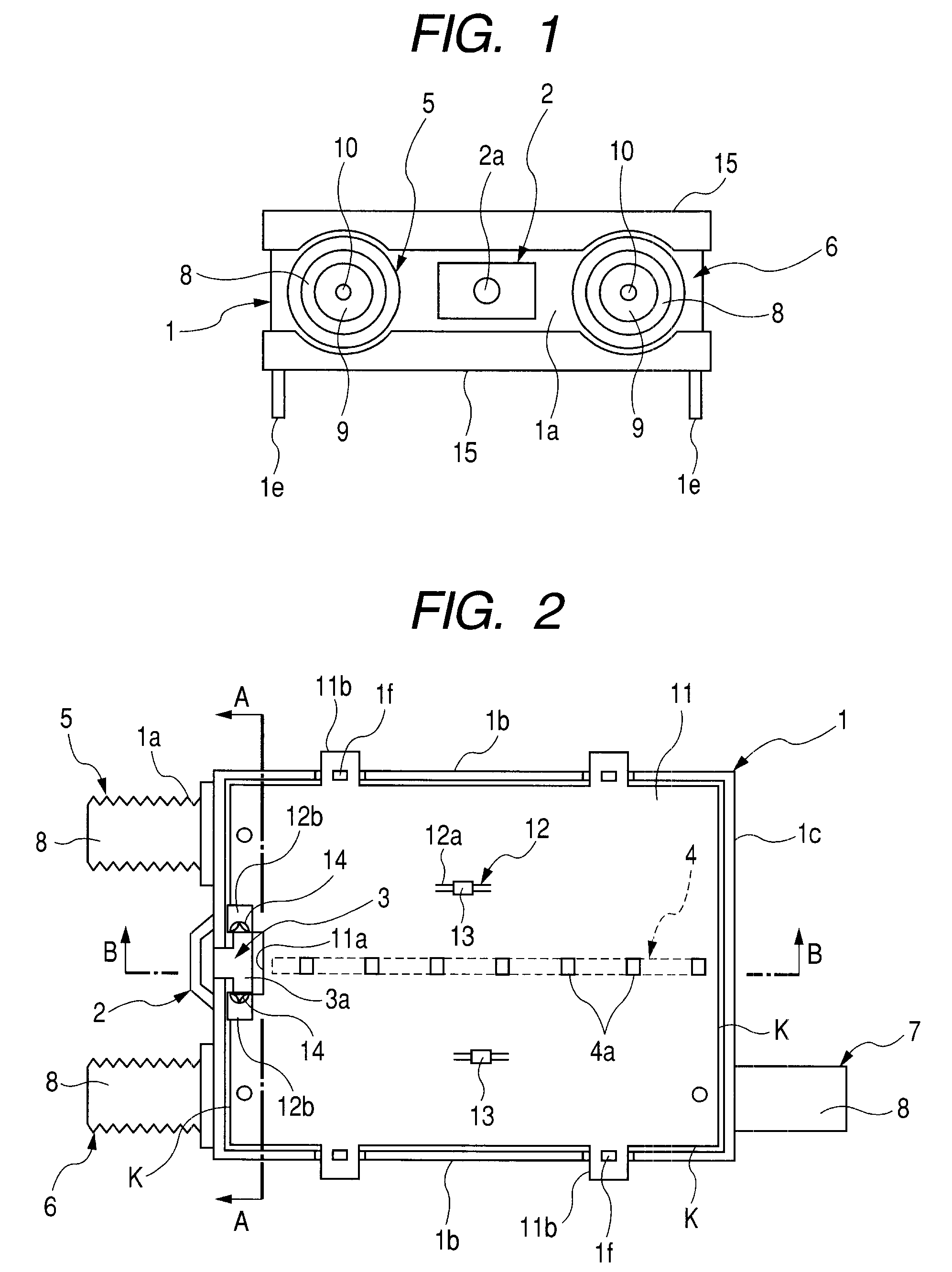

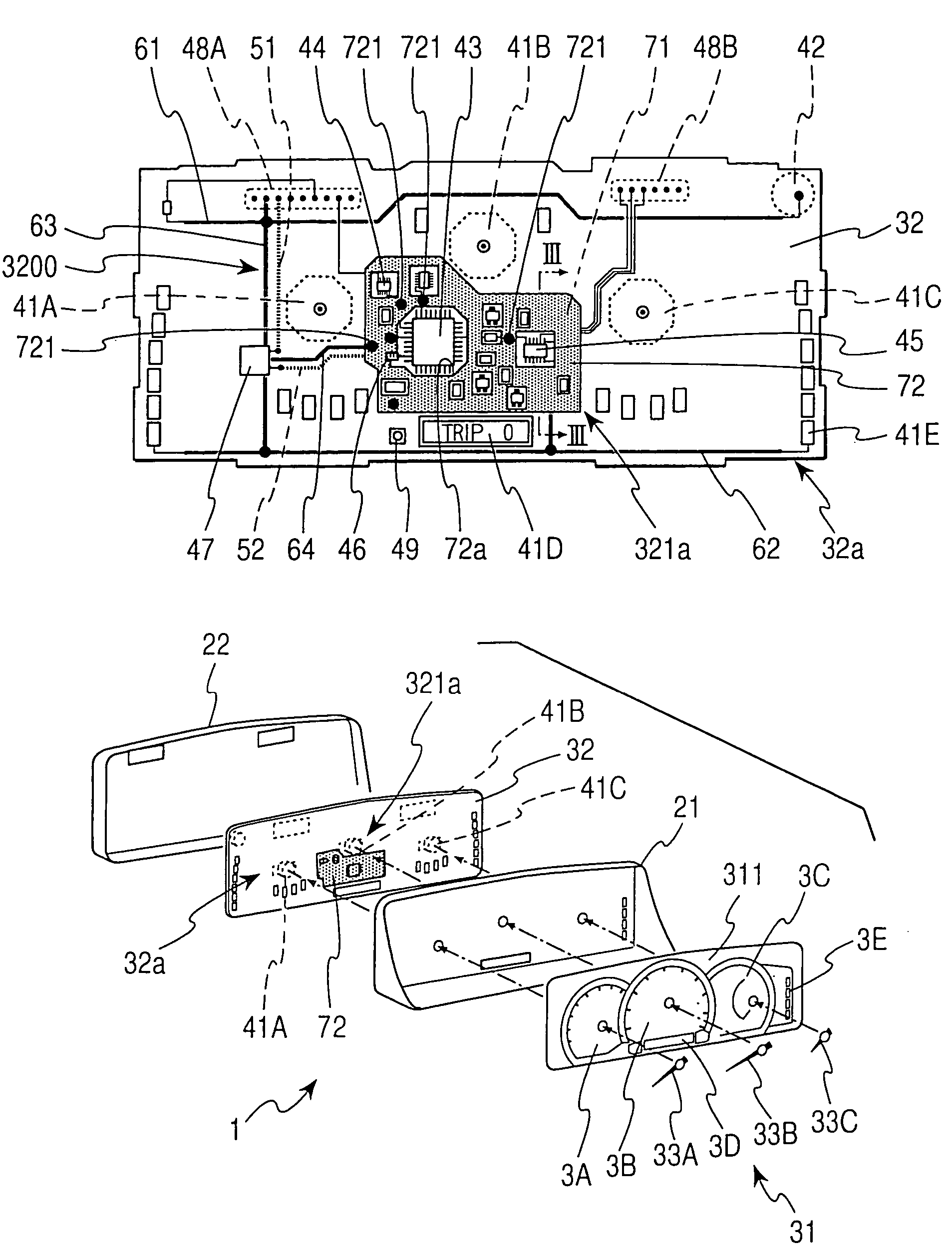

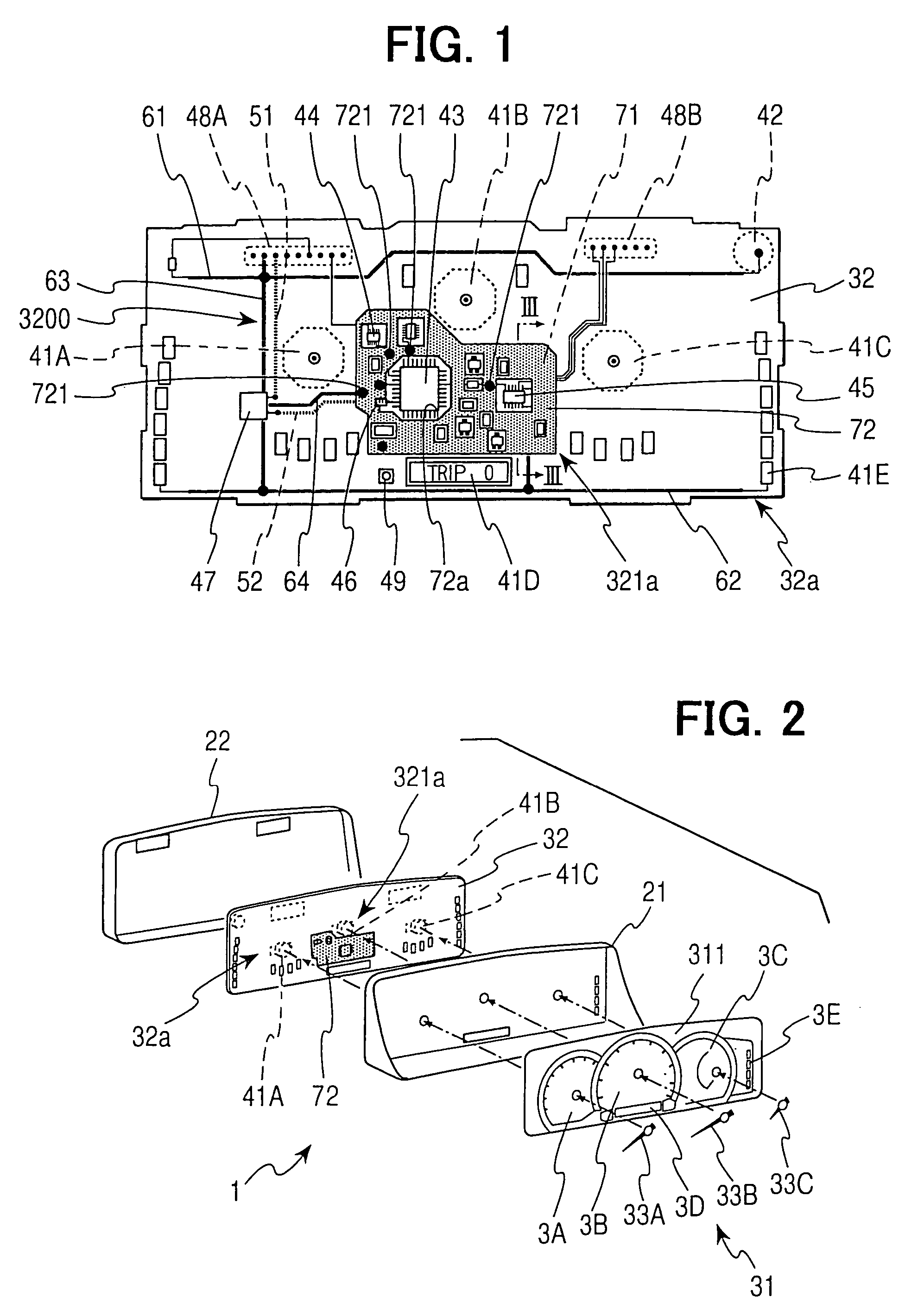

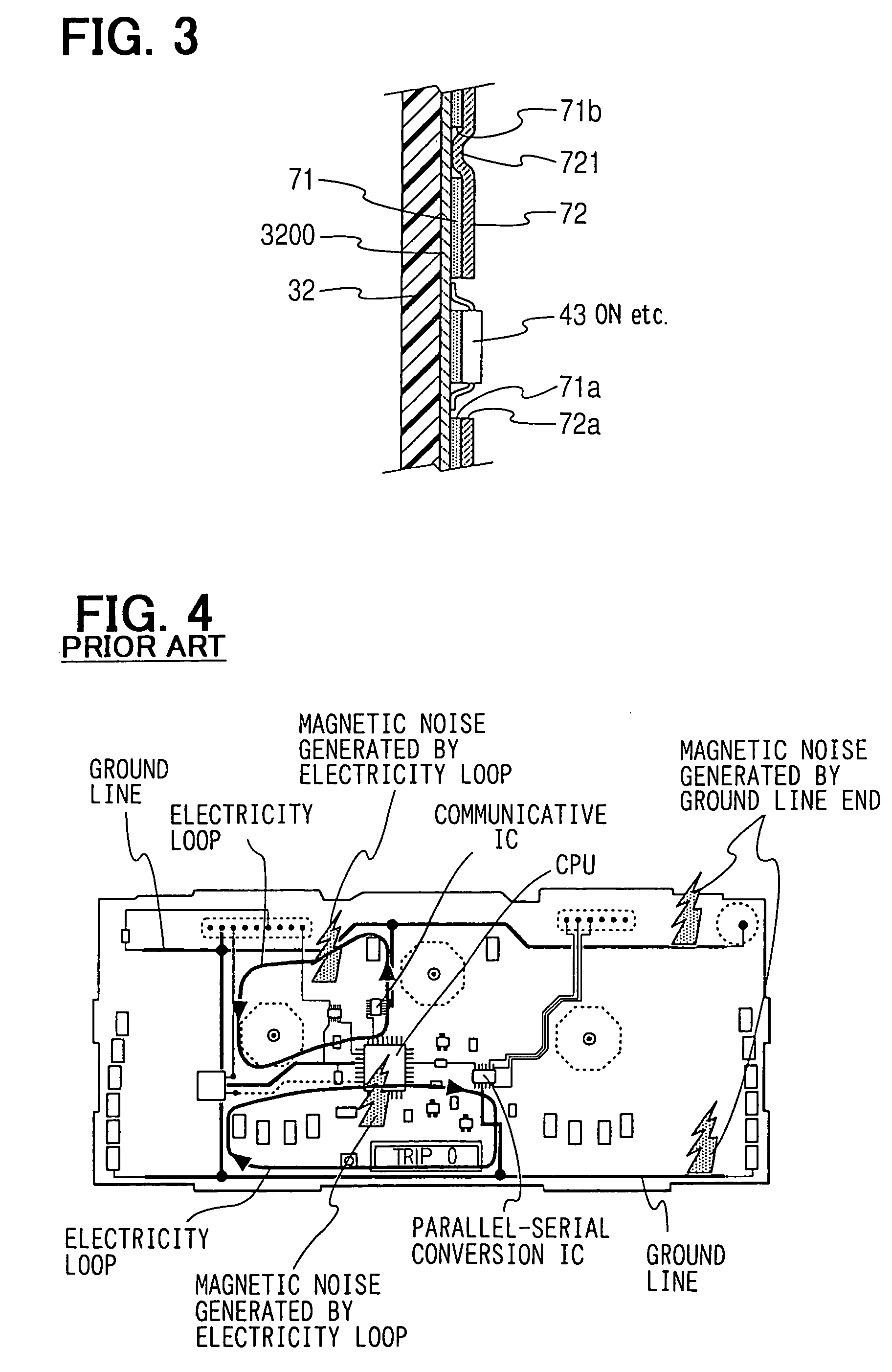

Printed board and meter unit provided therewith

InactiveUS7173827B2Reduce noiseAvoid noiseMagnetic/electric field screeningDigital data processing detailsElectricityEngineering

A printed board has a board, an electrically insulative membrane, formed on the board, and an electrically conductive membrane, formed on the electrically insulative membrane, in its area where a control circuit, including a CPU and etc., is installed. The electrically conductive membrane is electrically connected with ground patterns of a wiring pattern. Accordingly, ground connections at the control circuit are sufficiently performed. Therefore, even though ground connections in an area other than the control circuit are not sufficiently performed, a magnetic noise is prevented from being generated in a loop-shaped electricity supply line passing through a CPU and etc. Consequently, noises in printed board can be effectively reduced.

Owner:NIPPON SOKEN +1

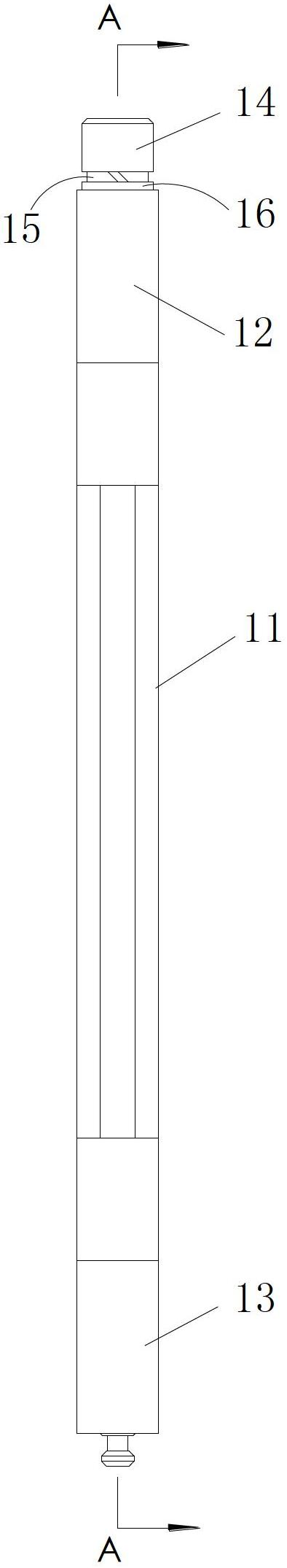

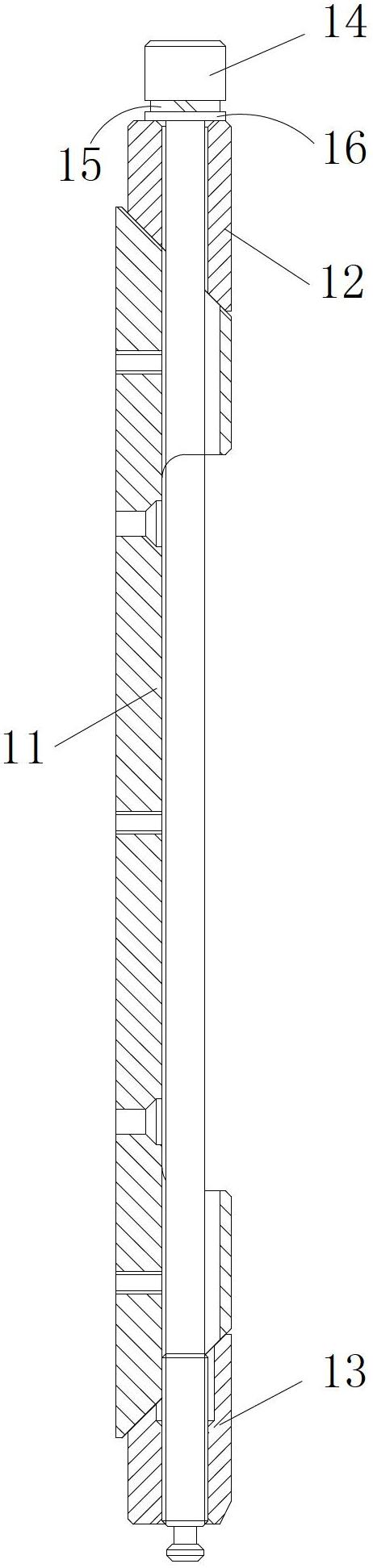

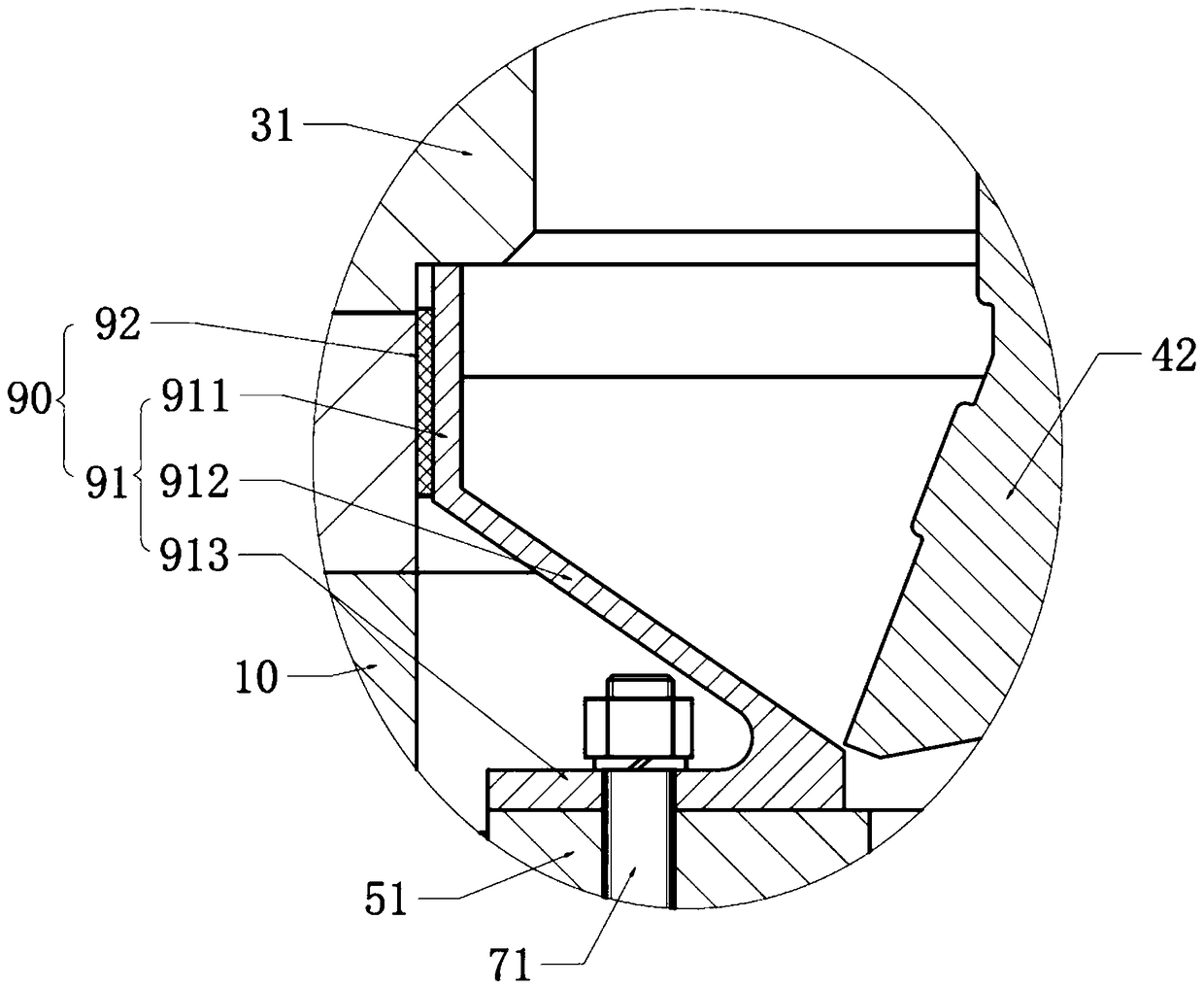

Multipoint floating locking device for printed circuit board

InactiveCN102695395AFully groundedSimple structural designSecuring devicesResilient/clamping meansPrinted circuit boardEngineering

The invention discloses a multipoint floating locking device for a printed circuit board. The multipoint floating locking device comprises a base, an outer locking sliding block, an inner locking sliding block and a bolt, wherein the outer locking sliding block, the base and the inner locking sliding block are connected to form a cuboid, and the bolt sequentially passes through a through hole of the outer locking sliding block and a through hole of the base and then is in threaded connection with the inner locking sliding block. The bottom surface of the base is fixedly connected with a printed circuit board, and the bolt is driven to rotate by inserting a tool into an internal hex hole at the head of the bolt, so that the bolt moves along the radial direction of the through hole of the base, thereby driving the outer locking sliding block and the inner locking sliding block to synchronously move outwards along the inclined end surface of the base and to be closely connected with a printed circuit board partition block fixedly arranged on a box body; and therefore, a new technical scheme is provided for the installation and fixing of the printed circuit board.

Owner:上海美多通信设备有限公司

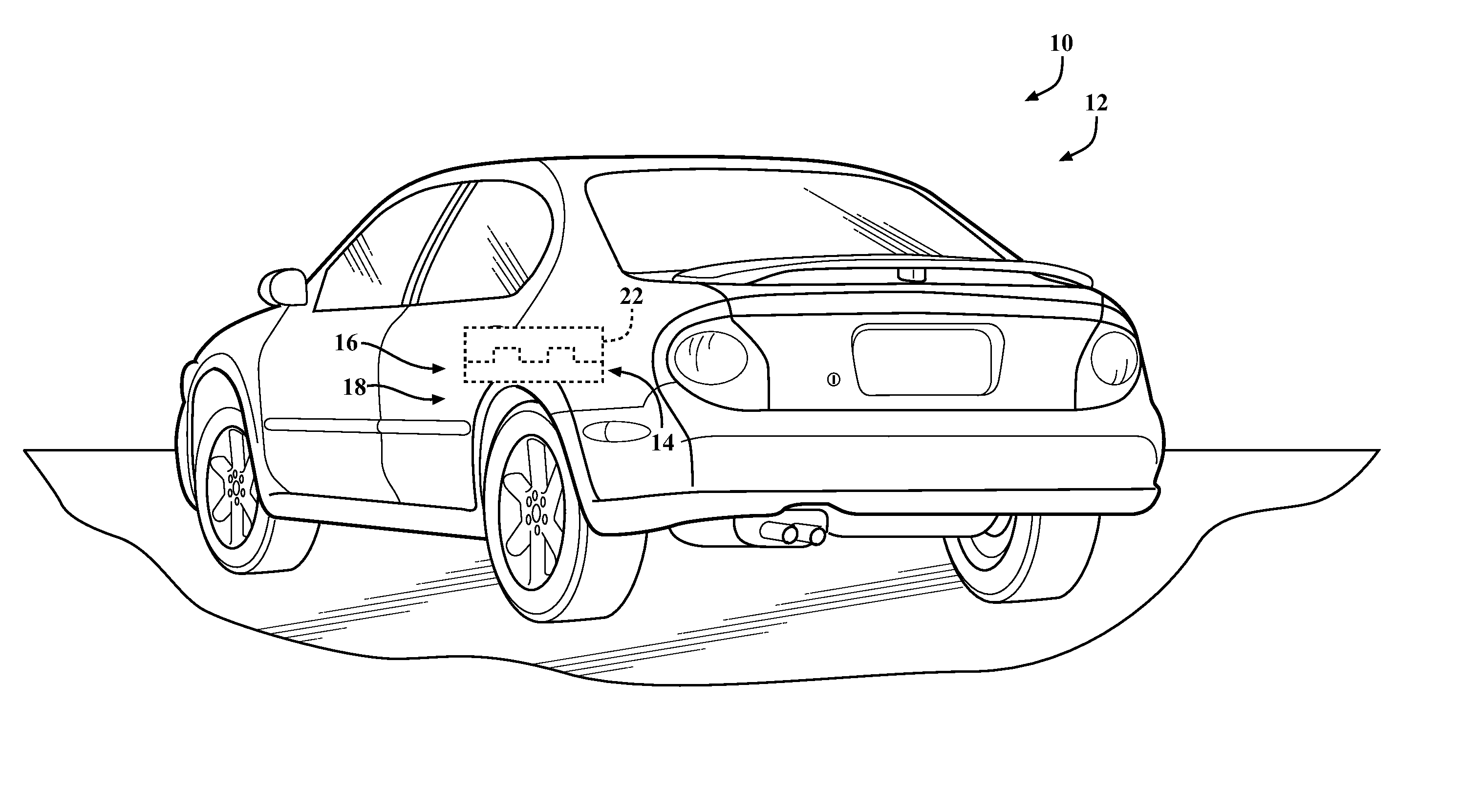

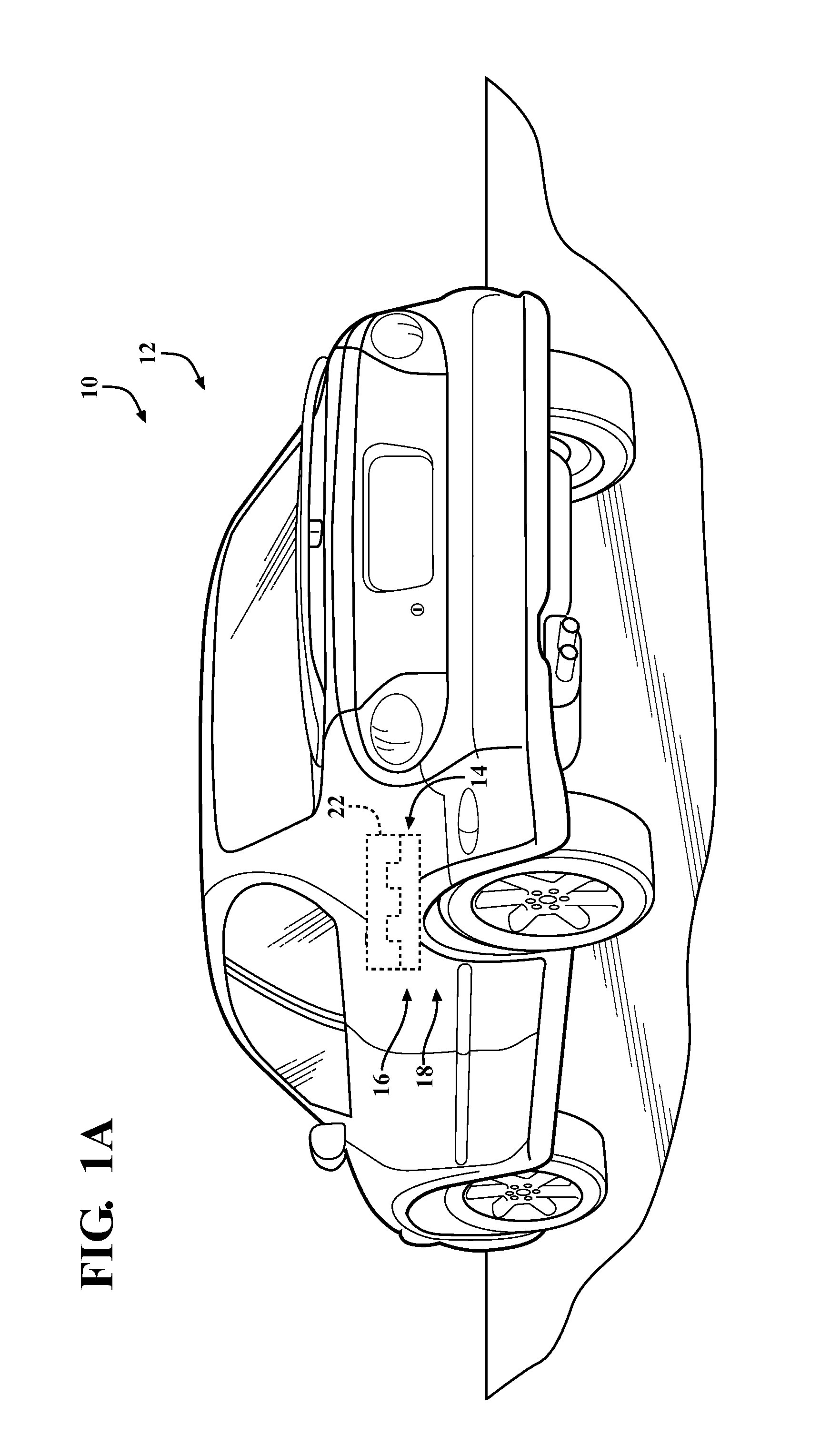

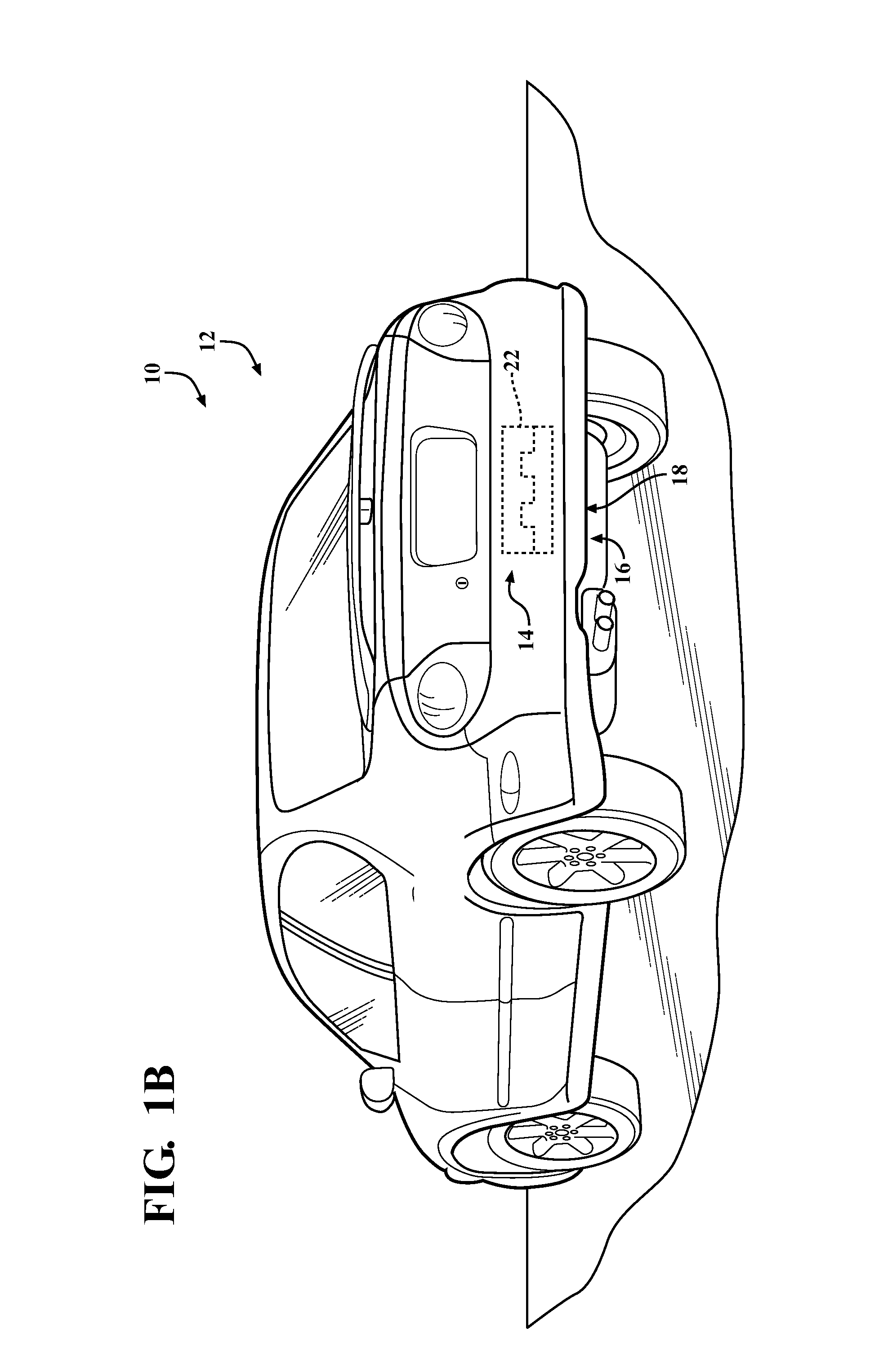

Antenna Assembly

InactiveUS20140191911A1Improve performanceIncrease flexibility of installationAntenna adaptation in movable bodiesRadiating elements structural formsMetallic materialsElectrical connection

A vehicle component having a housing made of non-metallic material and having at least one surface made of metallic material is provided, and an antenna assembly is disposed in the vehicle component. The antenna assembly includes a high-gain film-type antenna element having an input for receiving a wireless signal, an output, and a ground portion is disposed on said non-metallic portion of the housing of said vehicle component. The antenna assembly also includes a low noise amplifier (LNA) and a feeding structure including a coaxial cable and a ground wire. The coaxial cable establishes electrical communication between the antenna element and the LNA, and the ground wire establishes an electrical connection between the ground portion of the antenna element and the metallic surface of the vehicle component.

Owner:HARADA IND OF AMERICA

Ultramicro grinding machine for sesame paste production and grinding method

PendingCN113413964AGuaranteed qualityNovel structure design ideasCocoaGrain treatmentsEngineeringTooth surface

The invention relates to the technical field of sesame paste production, and particularly discloses an ultramicro grinding machine for sesame paste production and a grinding method. The ultramicro grinding machine includes an upper grinding disc, a lower grinding disc, a material receiving groove and a material bin; the lower grinding disc is arranged in the material receiving groove; the upper grinding disc is arranged on the upper surface of the lower grinding disc; a discharging hole is formed in the upper grinding disc; the material bin is arranged over the discharging hole, and the lower end of the material bin is connected with a discharging pipe inserted to the discharging hole; a rotating rod extending out of the upper surface of the material bin is arranged in the discharging pipe; the lower end of the rotating rod is connected with a spiral blade, and the top end of the rotating rod is connected with a gear; and an arc-shaped strip with the inner side surface provided with a tooth surface is fixedly arranged above the upper grinding disc, and the tooth surface on the arc-shaped strip is partially overlapped with the outer end of a circular path when the gear rotates along with the upper grinding disc. A quantitative discharging mechanism in the grinding machine disclosed by the invention is novel in structural design thought and simple in structure, the problem that quantitative discharging of sesame cannot be effectively controlled by an existing millstone type grinding machine is effectively solved, and the quality of sesame paste prepared by grinding is effectively guaranteed.

Owner:HEFEI UNIV OF TECH

Menthol extraction method

ActiveCN108002982AImprove decomposition effectImprove decomposition abilityOrganic compound preparationHydroxy compound separation/purificationMentholFreeze-drying

The invention discloses a menthol extraction method. The menthol extraction method comprises the following steps: adding a grinding fluid into mint leaves for grinding; then adding a decomposition liquor for decomposition; performing ultrasonic concussion; after that, filtering mint syrup by means of filtration under a reduced pressure; directly concentrating the filtrate; extracting filter residues by means of a Soxhlet extractor; concentrating the extract; after finish of concentration, merging the concentrated solutions; performing freeze drying on the merged concentrated solutions under avacuum condition; crushing the dry product; placing the crushed dry product into a supercritical extractor for supercritical extraction; after finish of extraction, performing fractional distillationon a crude product; and collecting fractions at 160-280 DEG C to obtain menthol. By adoption of the menthol extraction method, the technical problems of low purity, poor quality and low extraction ration of a menthol extraction product can be effectively solved, the menthol extraction ratio can reach 1.65% or above, and the product purity exceeds 92%.

Owner:SICHUAN JINSUIFANG PHARMA

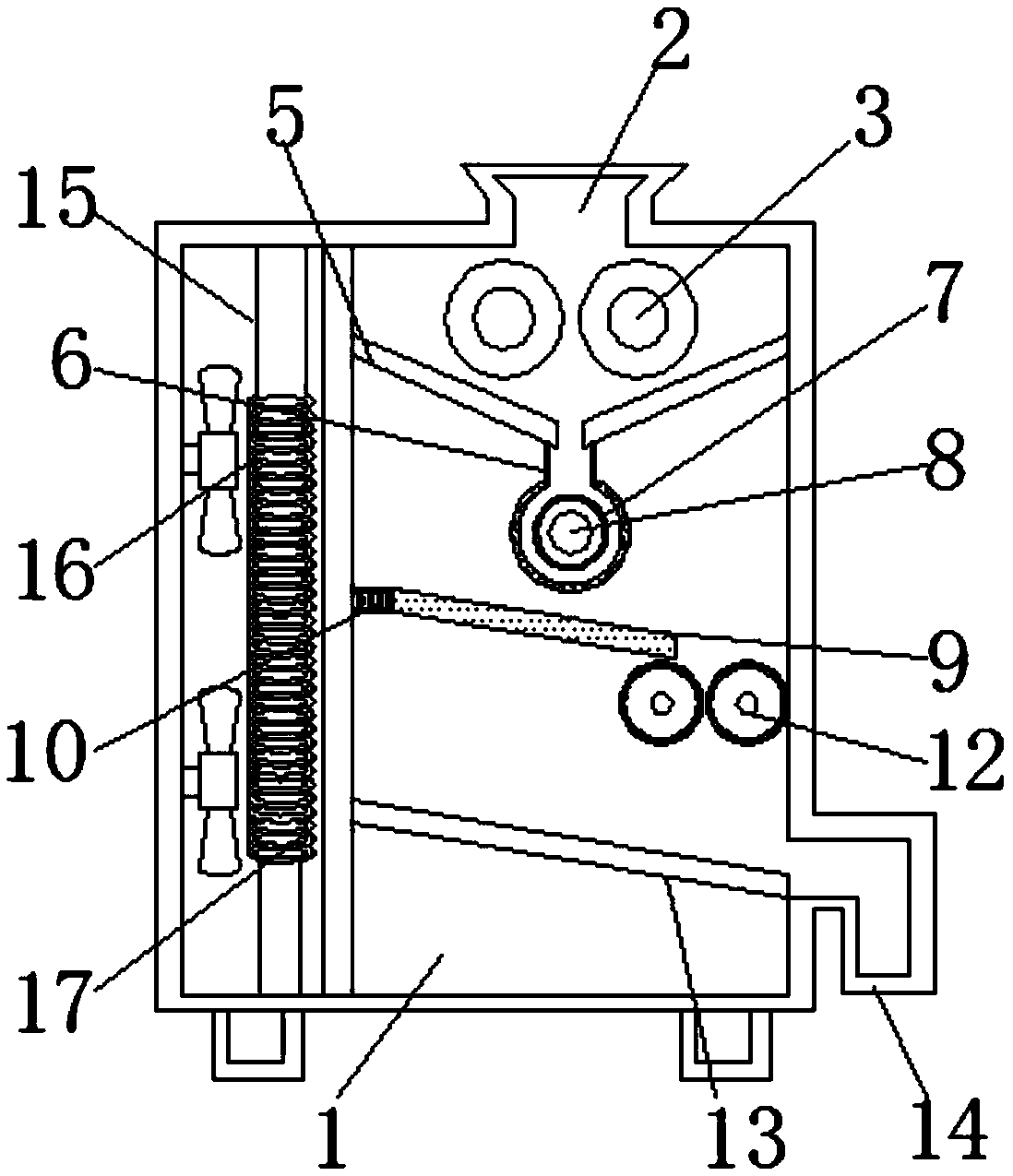

Grinding device for phosphate processing

InactiveCN110385186AGrind thoroughlyFully groundedDrying gas arrangementsGrain treatmentsPhosphatePulp and paper industry

The invention discloses a grinding device for phosphate processing. The grinding device comprises a box body, a baffle, a filter net, a spring and a third grinding roller, a feed port is formed in thetop of the box body, the baffle is located below a first grinding roller, a screen is fixedly arranged at the bottom of the baffle, a grinding cylinder is arranged on the inner side of the box and isconnected to the baffle through the screen, the filter net is fixed in the box body, a micro vibration motor is connected to one end of the filter net, a discharge plate is fixedly arranged at the bottom of the inner side of the box body, the third grinding roller is located between the filter net and the discharge plate, and an air bellow is arranged on one side of the box body. According to thegrinding device for phosphate processing, three grinding rollers of different specifications are arranged from top to bottom, crystals are ground into powder through the baffle, the filter net and the discharge plate in the box body, and a fan and a resistive heater are arranged at the positions, on one side of the box body, in the air bellow, so that the ground crystals are aired and dried.

Owner:JIANGSU XIAOCHUN NEW MATERIAL CO LTD

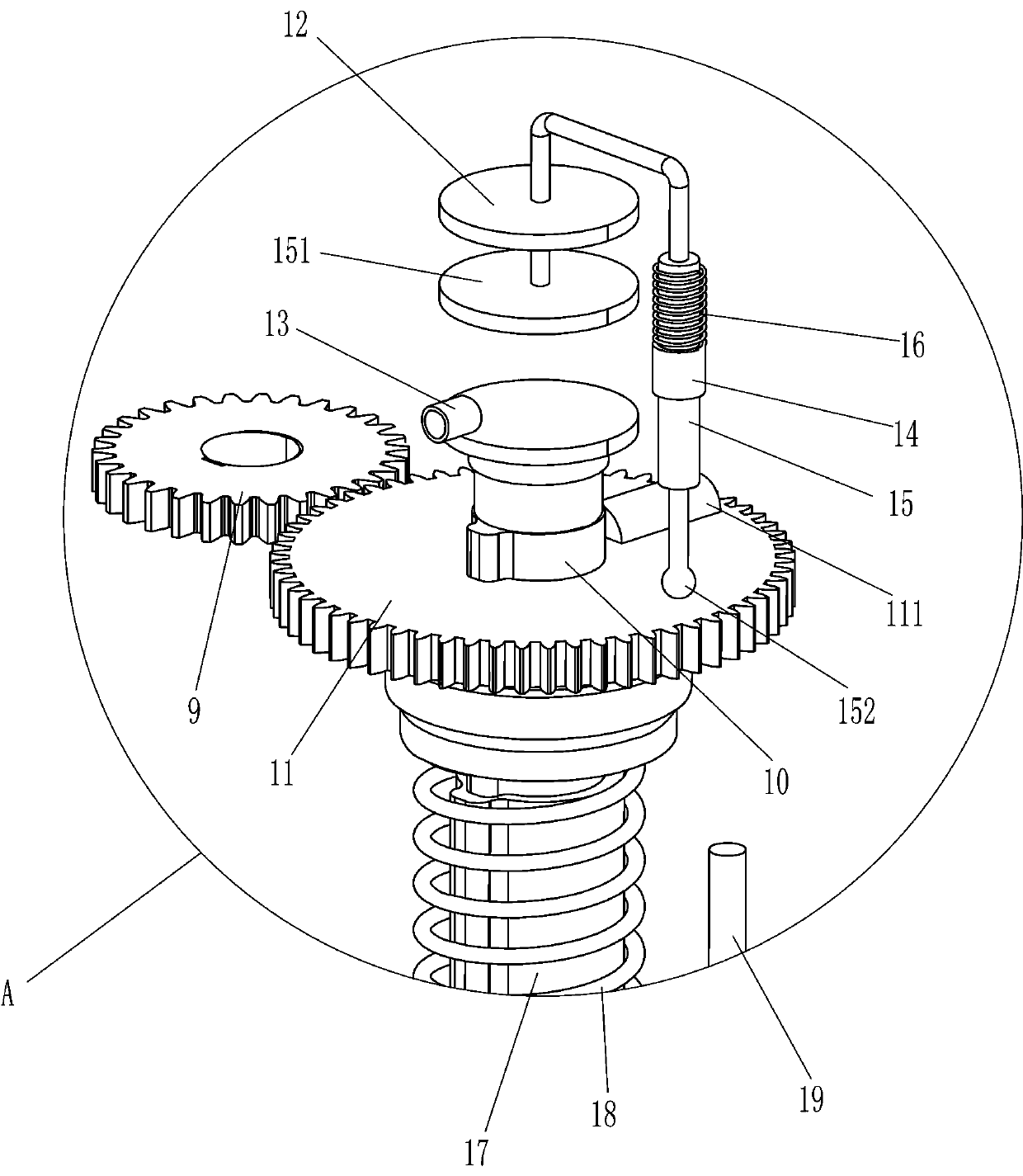

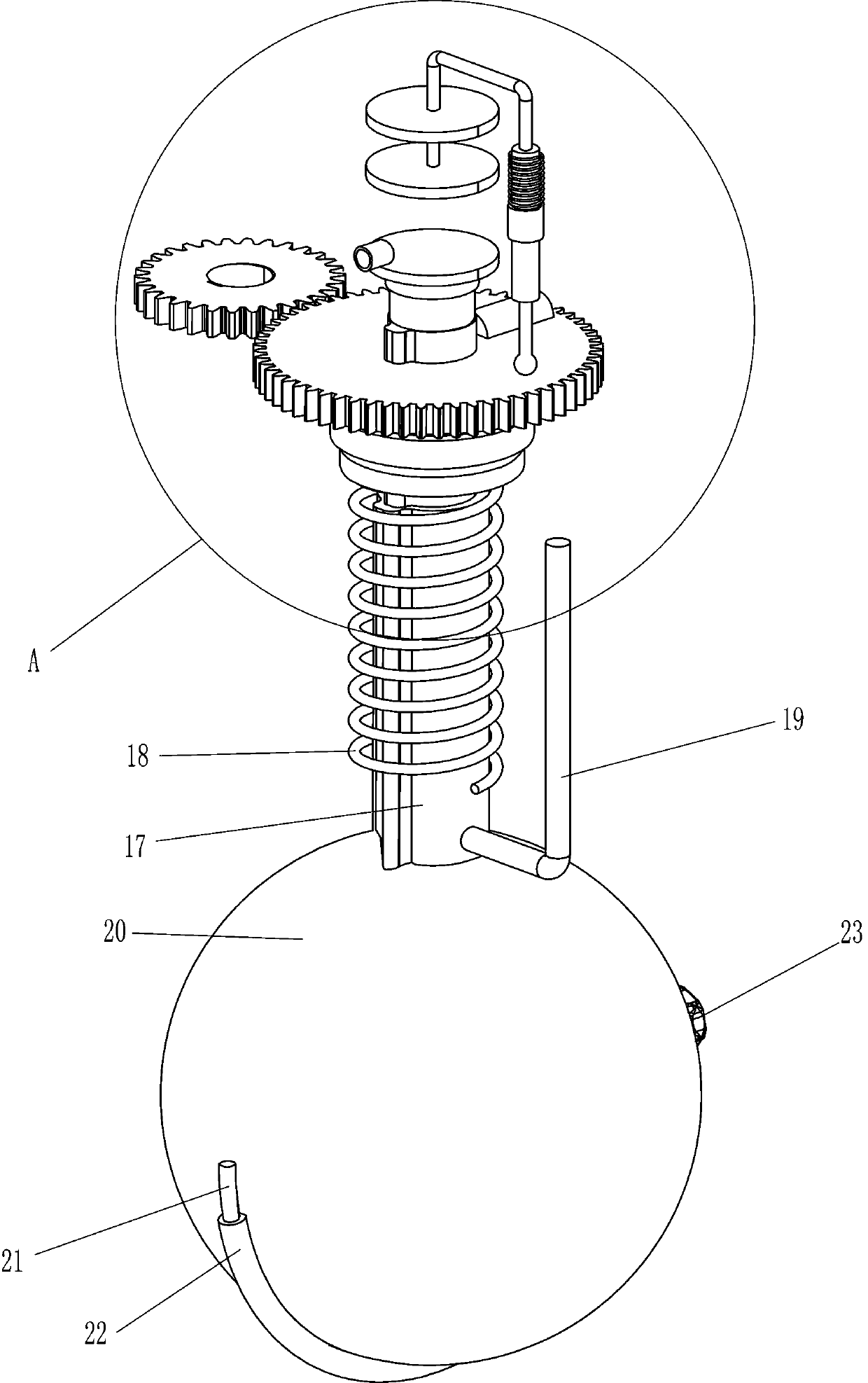

Comprehensive medicine grinding device for pediatric department

InactiveCN111530593AFully groundedQuality improvementCleaning using toolsGrain treatmentsElectric machineryBiomedical engineering

The invention relates a grinding device, in particular to a comprehensive medicine grinding device for the pediatric department. The technical problem to be solved is how to provide the comprehensivemedicine grinding device for the pediatric department capable of providing a standard for medical grinding and ensuring the grinding quality. The comprehensive medicine grinding device for the pediatric department comprises a machine frame which is used for installing the whole device, a storing assembly which is installed on the machine frame and used for placing medicines, a power assembly whichis installed on the machine frame and provides power for rotation through a motor, an air inlet assembly which is installed on the machine frame and the power assembly and inputs air in a lifting mode, and a lifting grinding assembly which is installed on the air inlet assembly and rises or falls through air. Ground qualified medicines can be screened out through a semicircular screen, unqualified medicines can be left in the semicircular screen to continue to be ground, the medicine grinding quality is improved, and grinding balls move down over rotating, so that the medicines can be more comprehensively ground.

Owner:欧阳深

Pure-cotton fabric dyeing system saving materials

InactiveCN107805905AImprove finenessIncrease profitTextile treatment machine arrangementsGrain treatmentsPrimary screeningEngineering

The invention relates to a material-saving dyeing system for pure cotton fabrics, which includes a dye barrel, a feeding pipe is arranged above the dye barrel, and a screening part, which includes a screening mechanism and a device for driving the screening set on one side of the dye barrel. The mechanism rotates the power mechanism. The sieving mechanism is used to sieve the primary dye in the dye barrel and output the sieved fine dye to the outside, and the coarse particle dye remains in the dye barrel; the grinding part includes the Grinding mechanism on one side and agitating mechanism on the other side, a grinding area is formed on the side of the dye barrel close to the grinding mechanism, and a sedimentation area is formed on the other side, the grinding mechanism is used to grind the coarse particle dye, and the agitating mechanism is used to deposit The coarse particle dye at the bottom of the dye barrel is transferred to the grinding mechanism; the invention overcomes the insufficient fineness of the dye in the dyeing process of pure cotton fabric, which leads to poor dyeing effect and the coarse particle dye in the dye cannot be processed, resulting in a waste of dye Large, low utilization issues.

Owner:CHANGXING YONG XIN TEXTILE PRINTING DYEING

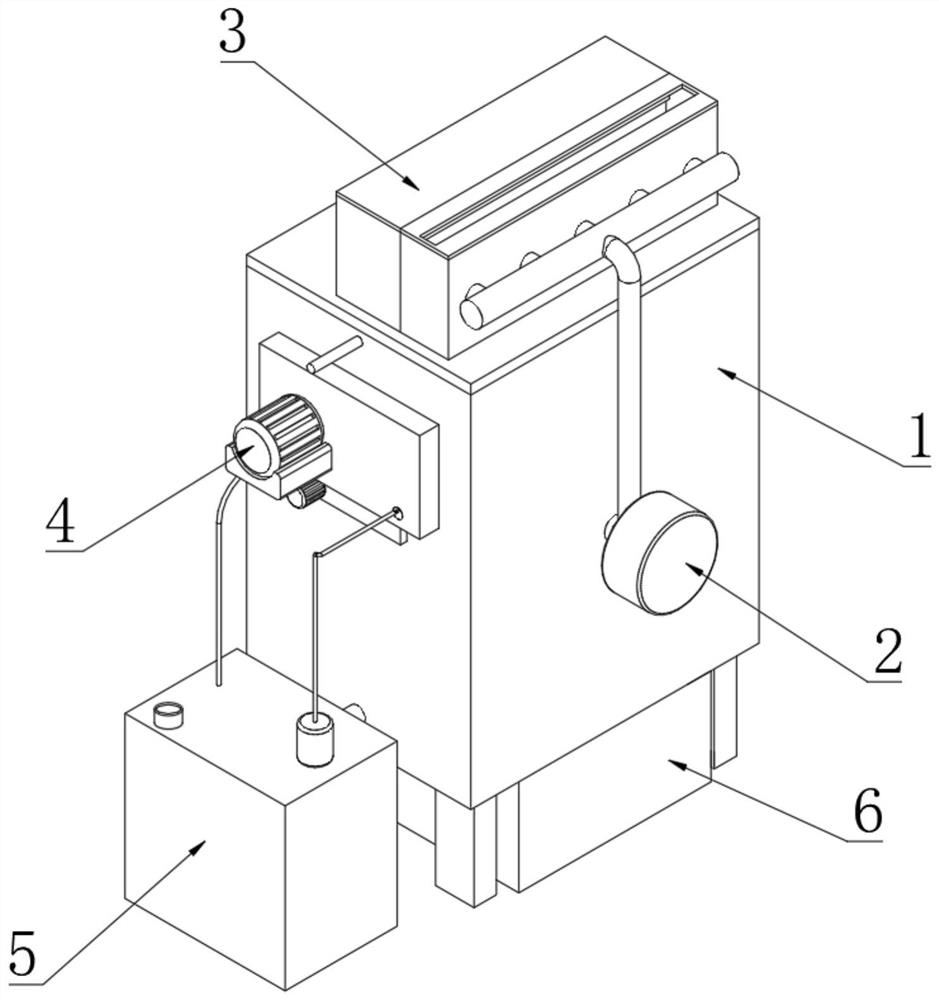

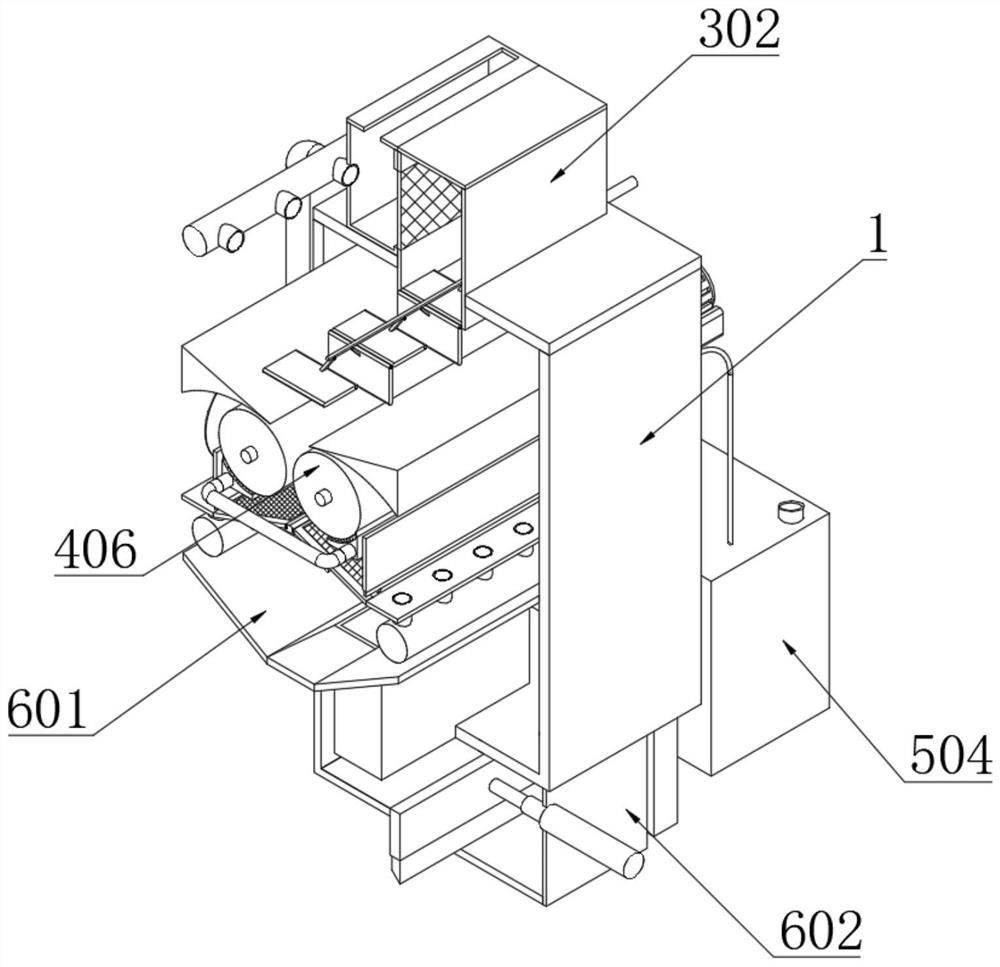

Preparation method for heat-conduction insulation silicone grease

ActiveCN111841719AScientific and reasonable structureSafe to useGrain treatmentsThermal insulationGrinding

The invention discloses a preparation method for heat-conduction insulation silicone grease. The preparation method comprises a grinding box, wherein an installation rod is installed between the innerwalls of the grinding box through bolts; two ends of the installation rod are independently provided with a T-shaped groove; a T-shaped block is independently in sliding connection in each T-shaped groove; a shaking plate is in sliding connection in a shaking groove; the middle of the outer side of a rotary shaft is fixedly sheathed with a convex rod; two ends of the top surface of a filtering net are independently welded with a convex block; one end of the grinding box is provided with a fan; and positions, which are positioned on the bottom end positions of two bearing plates, of one end ofthe fan are independently connected with an air blowing pipe. Compared with the prior art, the preparation method is characterized in that a grinded product carries out inclined circular-arc movement, so that the product is even in dispersion to achieve a purpose of even blanking. A bottom end blocking problem of the grinding box enables raw materials which are not completely grinded to form circular arc shaped reflux, through the circular arc shaped reflux, the raw materials which are not completely grinded can enter between two grinding rollers along a raw material falling tangent direction, grinding quality and efficiency can be improved, and the problem of incomplete grinding is avoided.

Owner:苏州晶之电科技有限公司

Novel stirring ball mill

ActiveCN108993650AImprove stabilityImprove carrying capacityGrain treatmentsEngineeringSlewing bearing

The invention discloses a novel stirring ball mill. The novel stirring ball mill comprises a body, a driving mechanism as well as a slewing bearing, a movable cone device, a fixed cone device, a buffer device, an ejection device and multiple milling balls which are arranged on the body, wherein the driving mechanism can drive the movable cone device to rotate around the axis of the fixed cone device through the slewing bearing, and the fixed cone device is arranged on the body through the buffer device; a base of the ejection device is fixedly mounted on the body, the top end of the ejection device can make contact with the fixed cone device, and the ejection device is used for supporting the fixed cone device; the milling balls are placed between the movable cone device and the fixed conedevice and used for milling materials. By means of the scheme, the materials can be sufficiently milled, the effective work time of the novel stirring ball mill can be prolonged, the maintenance times can be reduced, and the working efficiency and the milling effect of the novel stirring ball mill can be substantially improved.

Owner:CHANGSHA UNIVERSITY

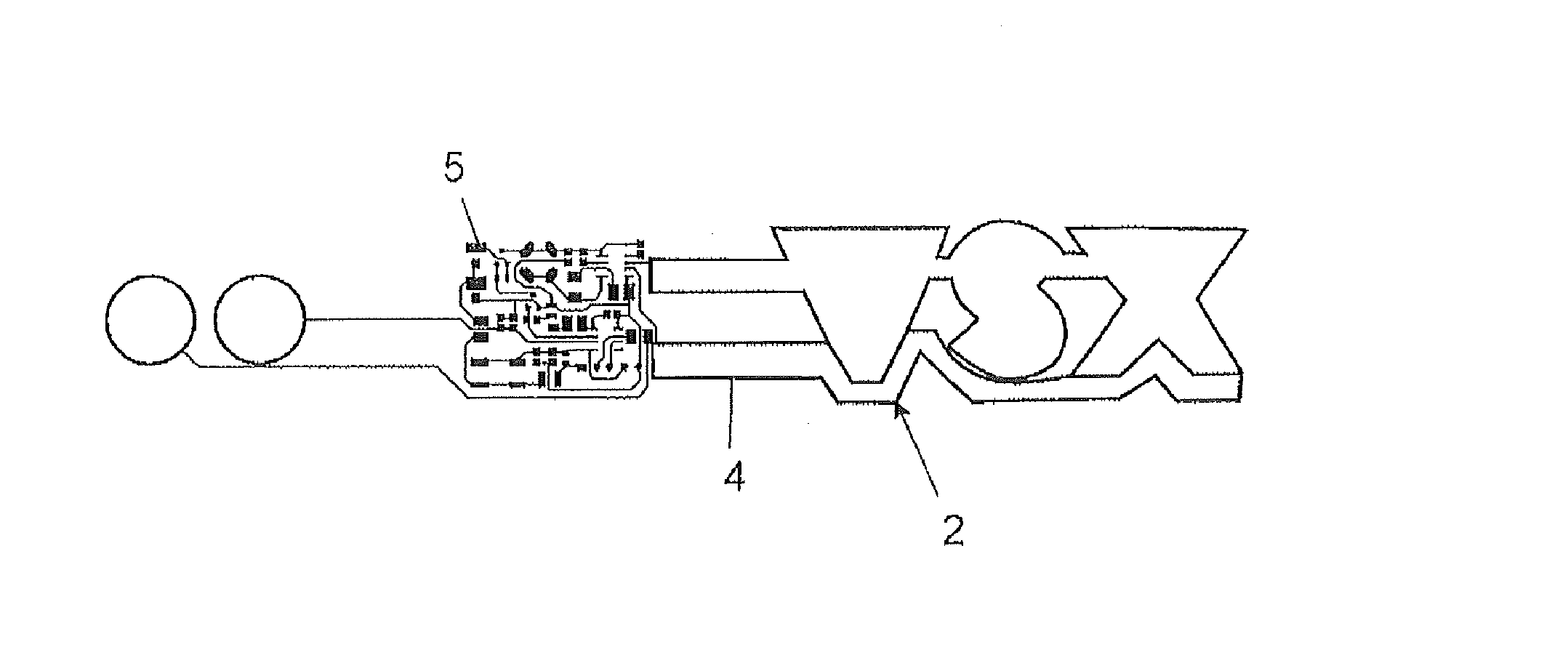

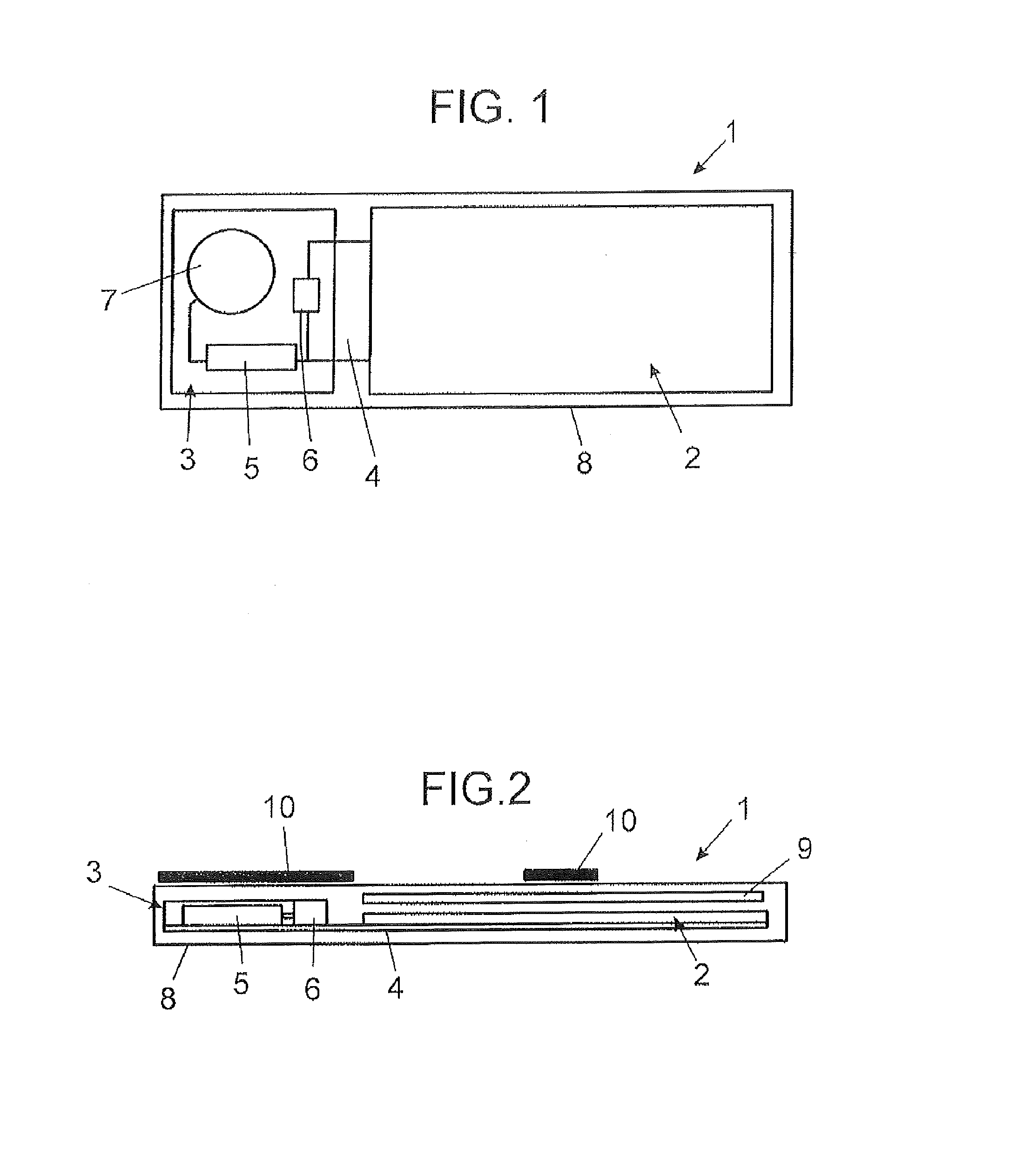

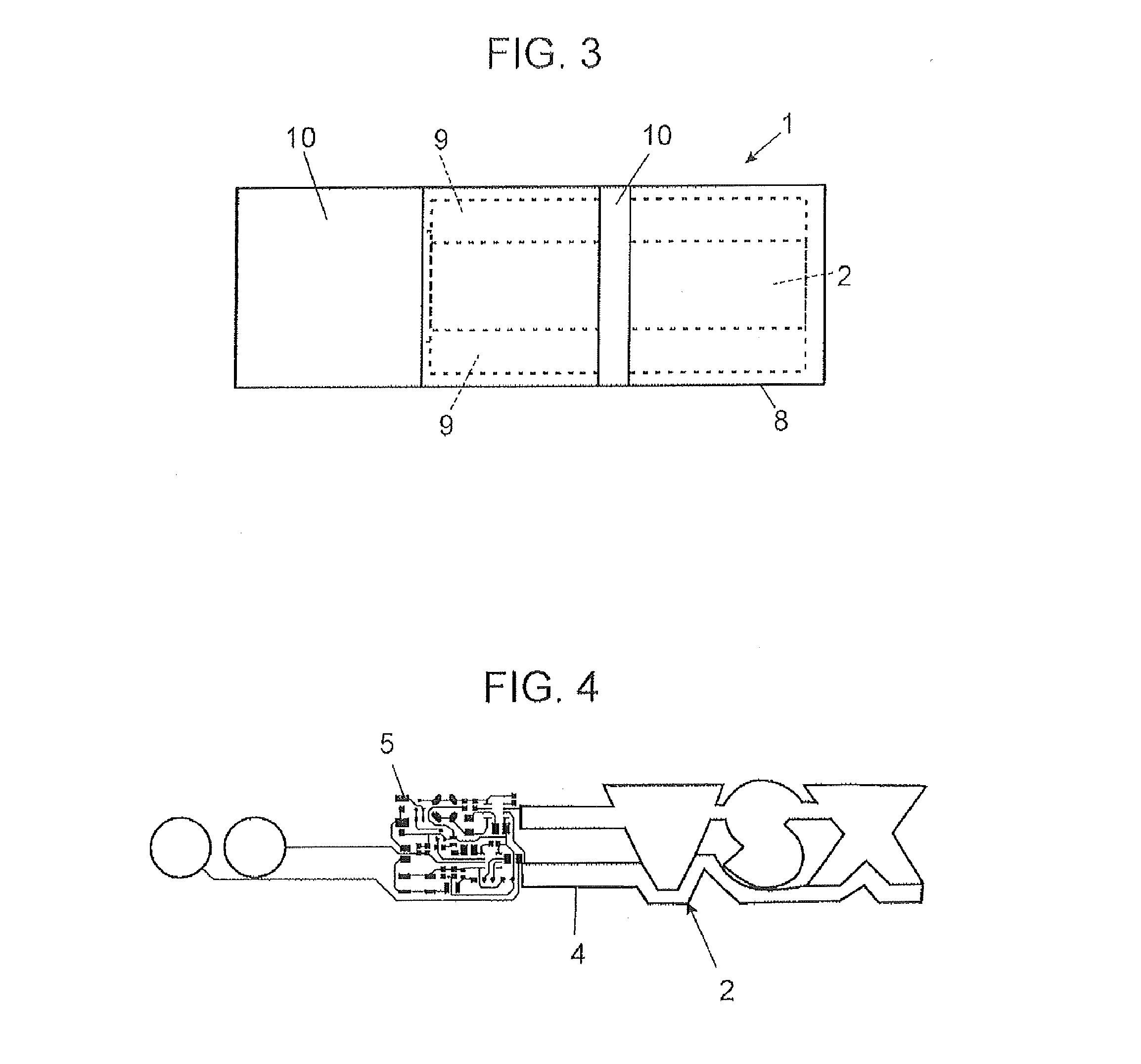

Electroluminescent compact laminar element

ActiveUS20170027249A1Fully groundedPlanar light sourcesDischarge tube luminescnet screensPlastic materialsEngineering

The invention relates to a compact electroluminescent laminar element comprising a flexible electroluminescent lamp (2) and an electronic module (3) which is connected in the same layer as the lower electrode (4) to said lamp (2) and comprises at least an electronic control component (5), an electronic component (6) for activating the lamp (2), and a battery (7), where said lamp (2) and said electronic module (3) are housed together in an encapsulating substrate (8) consisting of a textile or plastic material, forming a closed and compact element that can be water-impermeable. The activation component (6) is a push-button, a temperature sensor, or a movement sensor. It also comprises a reflective layer (9).

Owner:LIGHT FLEX TECH SL

Technology for leaching cobalt-copper white alloy

InactiveCN101818246AFully groundedSimple processProcess efficiency improvementSlagHydrogen-Ion Concentrations

The invention relates to technology for leaching a cobalt-copper white alloy, which is characterized by comprising the following steps of: a, grinding the cobalt-copper white alloy by adopting crushing equipment, and sieving with a sieve with 80 to 100 meshes for later use; b, mixing in a molar ratio of Cu2+ in soluble copper salt to Fe in the sieved cobalt-copper white alloy of (1-3):1, adopting stirring equipment for stirring, and obtaining solution after reaction; c, adding strong acid into the solution after reaction, controlling hydrogen ion concentration in the aqueous solution to between 2 and 5 mol / L, controlling the stirring speed to between 300 and 1,000 revolutions per minute, and heating a reactor to control the temperature of the solution to between 70 and 100 DEG C; and d, when the leaching reaction time is 4 to 24 hours until the cobalt percentage in slag is 0.1 to 0.5 percent, adopting solid-liquid separation equipment for solid-liquid filtering separation, obtaining a filter cake and filter liquor after separation, using the filter cake as an auxiliary copper product, directly shifting the filter liquor to the next process, and finishing the leaching technology. The technology for leaching the cobalt-copper white alloy has the advantages of high leaching rate and high metal recovery, and is suitable for scale production.

Owner:南通新玮镍钴科技发展有限公司

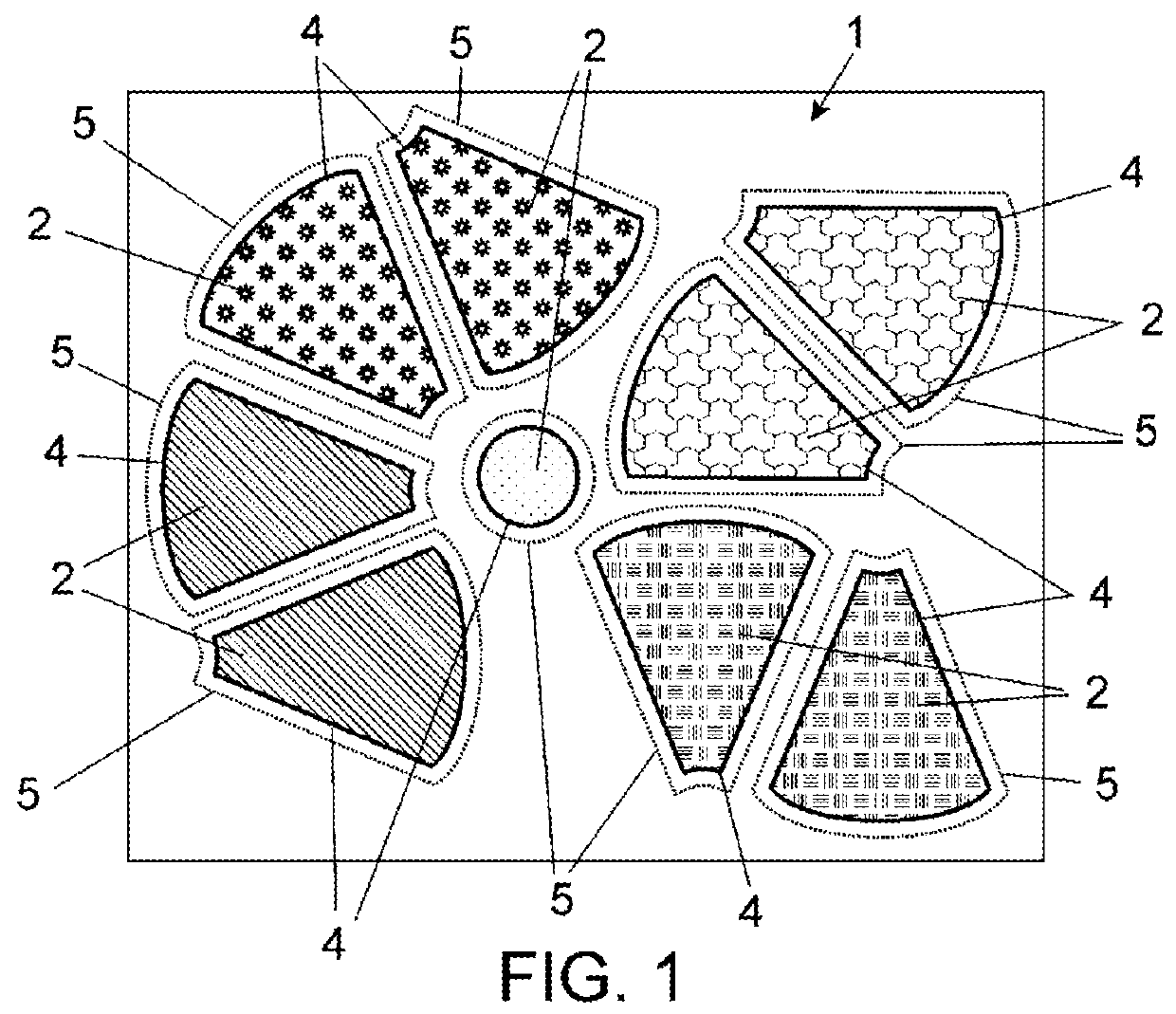

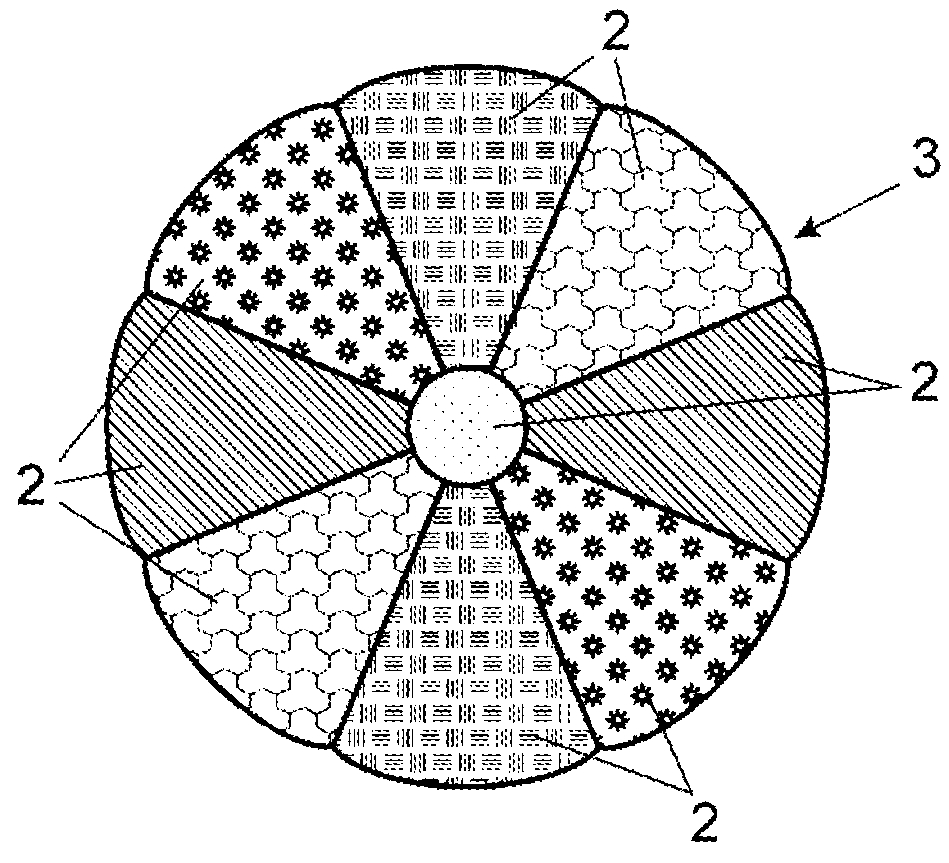

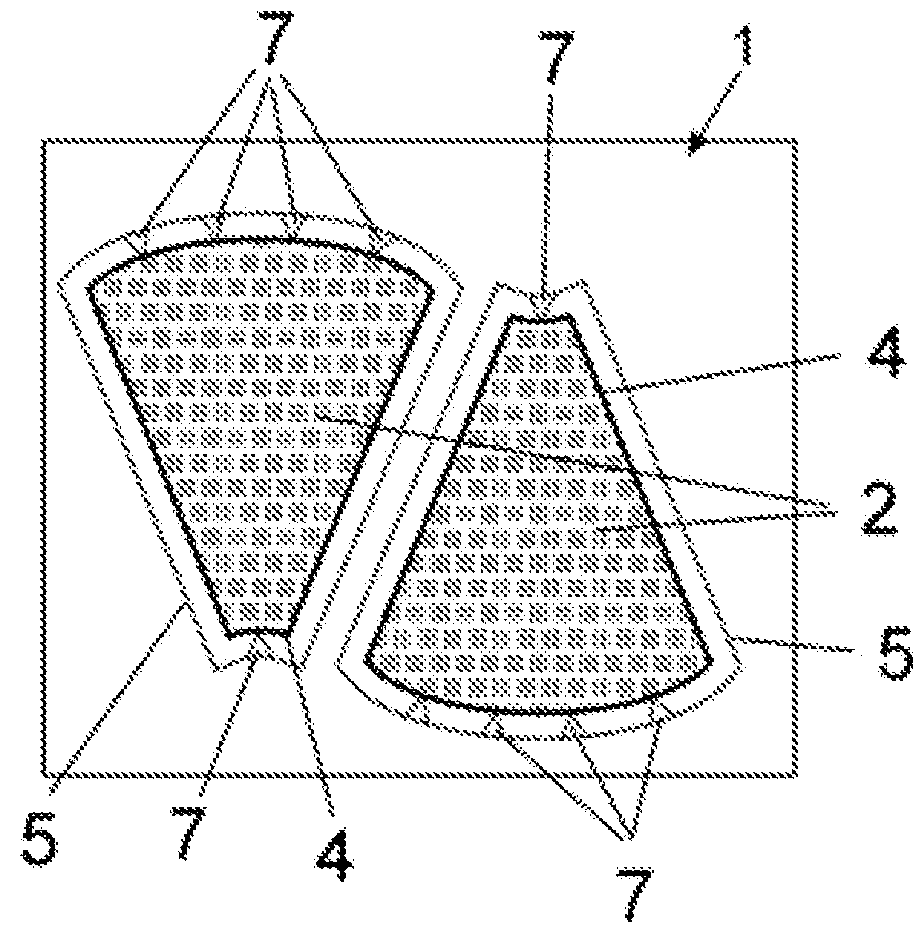

Piece of fabric for hand-sewn works and method for making said works with said fabrics

ActiveUS20180177256A1Method of creating the project is notably reducedPrecise and accurate mannerHand sewingLayered productsEngineeringHand sewn

A piece of fabric for manual sewing projects and method of creating said projects with said fabric, consisting of a piece (1) of cloth that incorporates, with identical or different colors, prints and / or textures, the figures (2) for creating a certain patchwork design (3), each figure (2) being marked with a seam line (4) that defines the outline thereof and a cutting line (5) that defines a perimeter border that is optionally pre-perforated. The method only comprises obtaining said piece (1), cutting the figures (2) along the cutting line (5) and sewing them together. Optionally, the patchwork design (3) is selected and the piece (1) is ordered with the desired figures (2) and colors, prints and / or textures.

Owner:DAMA INT 1991 SA

Cement production method by adding lignosulfonate

The invention discloses a cement production method by adding lignosulfonate, which includes the following steps of breaking raw materials for cement production to form coarse materials; grinding the coarse materials into fine powder through a grinding machine by a powder concentrator, and then collecting the powder by utilizing a dust collector to be used as raw material powder; after further mixing the raw material powder uniformly, conveying the raw material powder to a cement kiln to generate clinker after being preheated to decompose. Cement grinding aid is added during the grinding by the grinding machine; the cement grinding aid includes the following components in parts by weight: 15 parts of triethanolamine, 60 parts of diethylene glycol, 20 parts of sodium tripolyphosphate, 104 parts of xylitol, 18 parts of sodium thiosulfate, 11 parts of lignosulfonate, 45 parts of water. The advantage of abundant grinding of cement raw materials is realized.

Owner:张芳

Cement production method by adding naphthalene sulfonate water reducer

The invention discloses a cement production method by adding naphthalene sulfonate water reducer, which includes the following steps of breaking raw materials for cement production to form coarse materials; grinding the coarse materials into fine powder through a grinding machine by a powder concentrator, and then collecting the powder by utilizing a dust collector to be used as raw material powder; after further mixing the raw material powder uniformly, conveying the raw material powder to a cement kiln to generate clinker after being preheated to decompose. Cement grinding aid is added during the grinding by the grinding machine; the cement grinding aid includes the following components in parts by weight: 12 parts of triethanolamine, 52 parts of diethylene glycol, 12 parts of sodium tripolyphosphate, 106 parts of xylitol, 11 parts of sodium thiosulfate, 6 parts of naphthalene sulfonate water reducer, 65 parts of water. The advantage of abundant grinding of cement raw materials is realized.

Owner:张芳

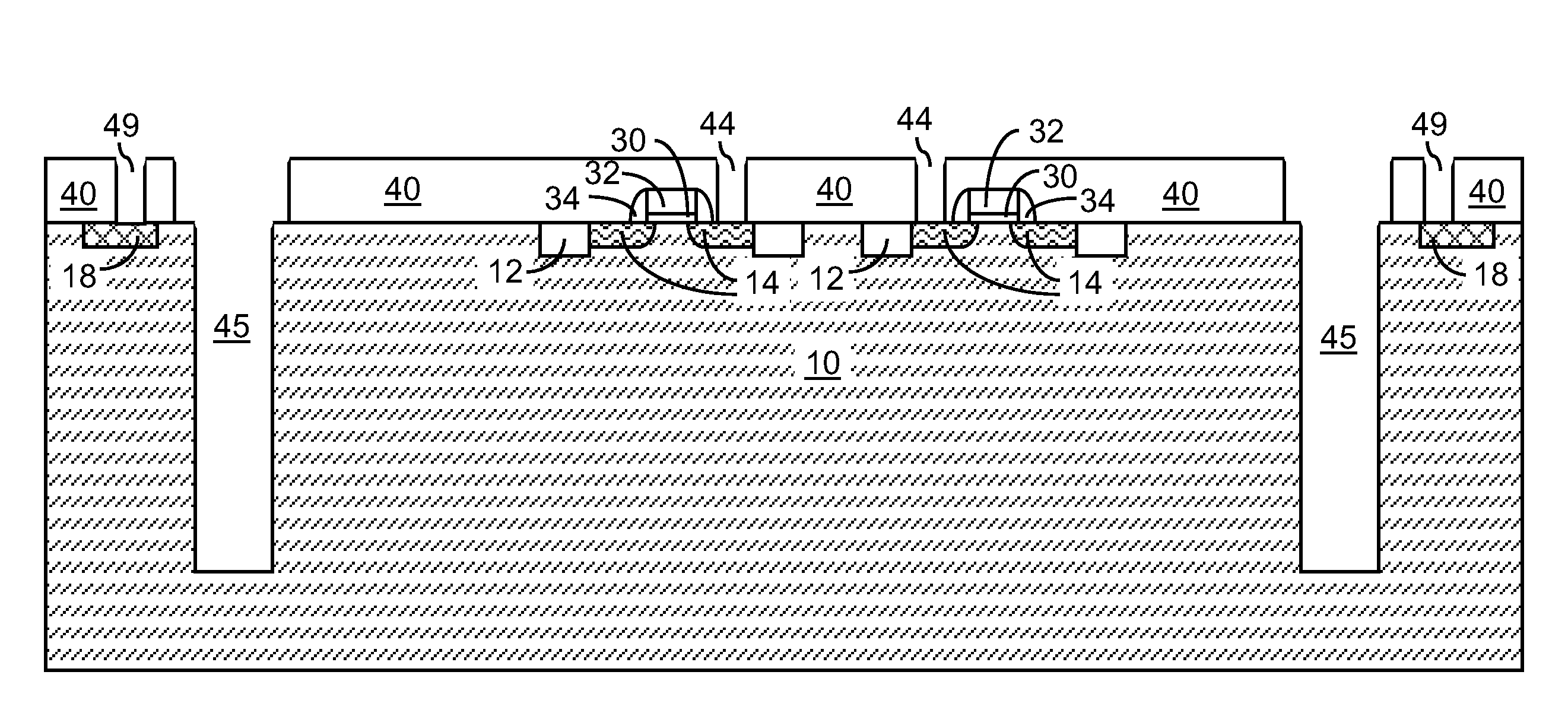

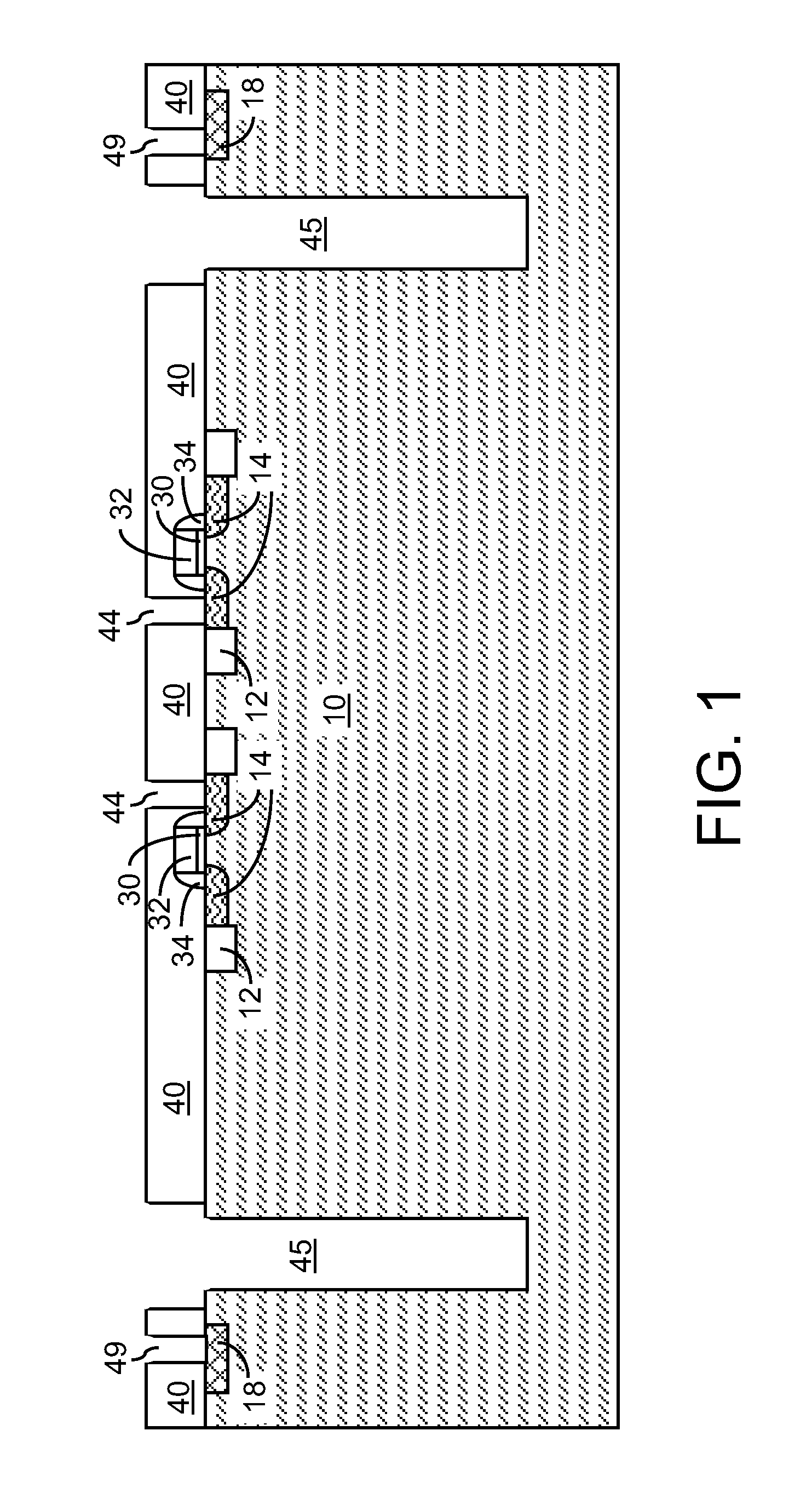

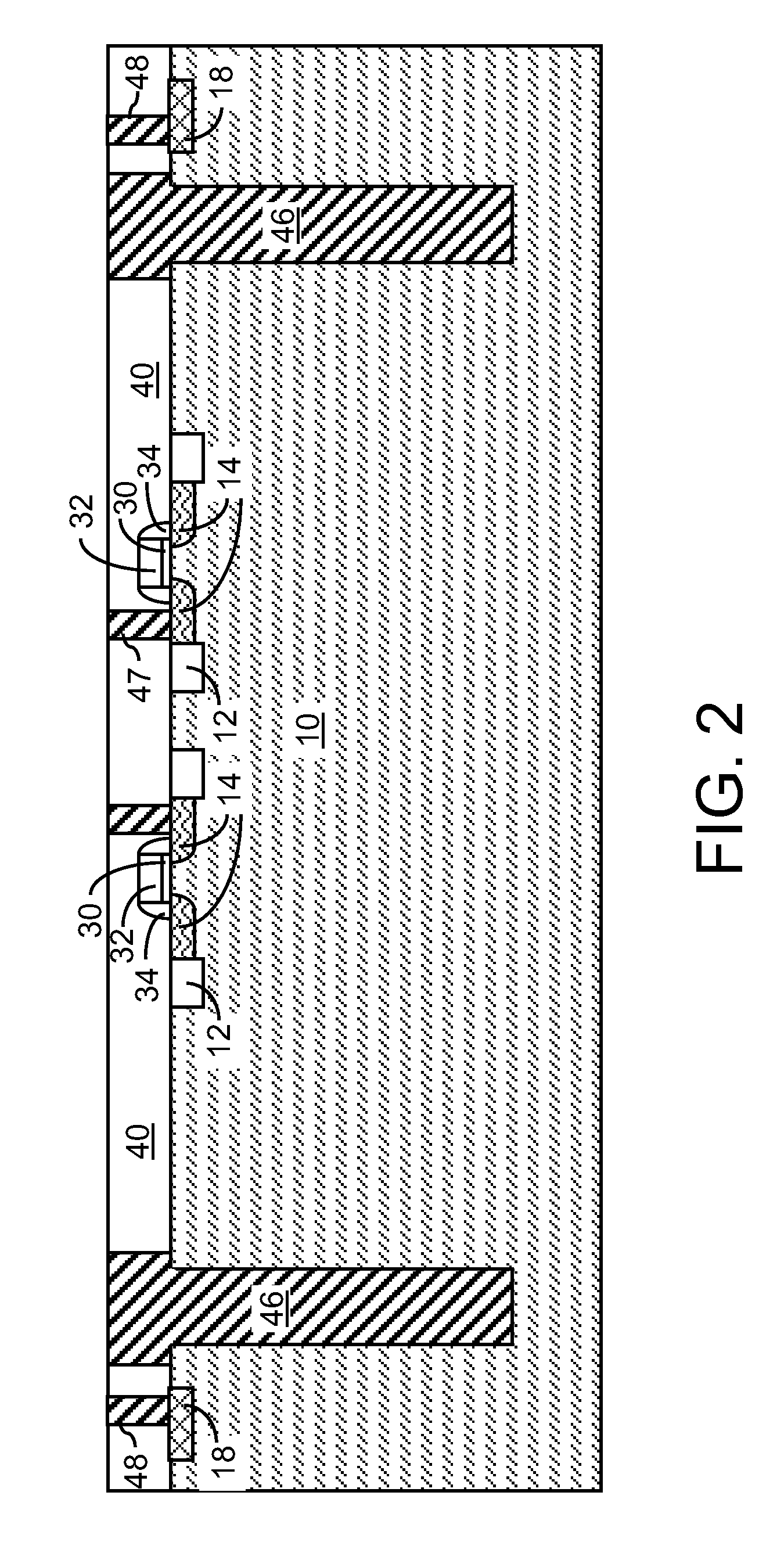

Chip guard ring including a through-substrate via

ActiveUS8169055B2Fully groundedArea minimizationSemiconductor/solid-state device detailsSolid-state devicesStructure functionSemiconductor chip

Owner:TESSERA INC

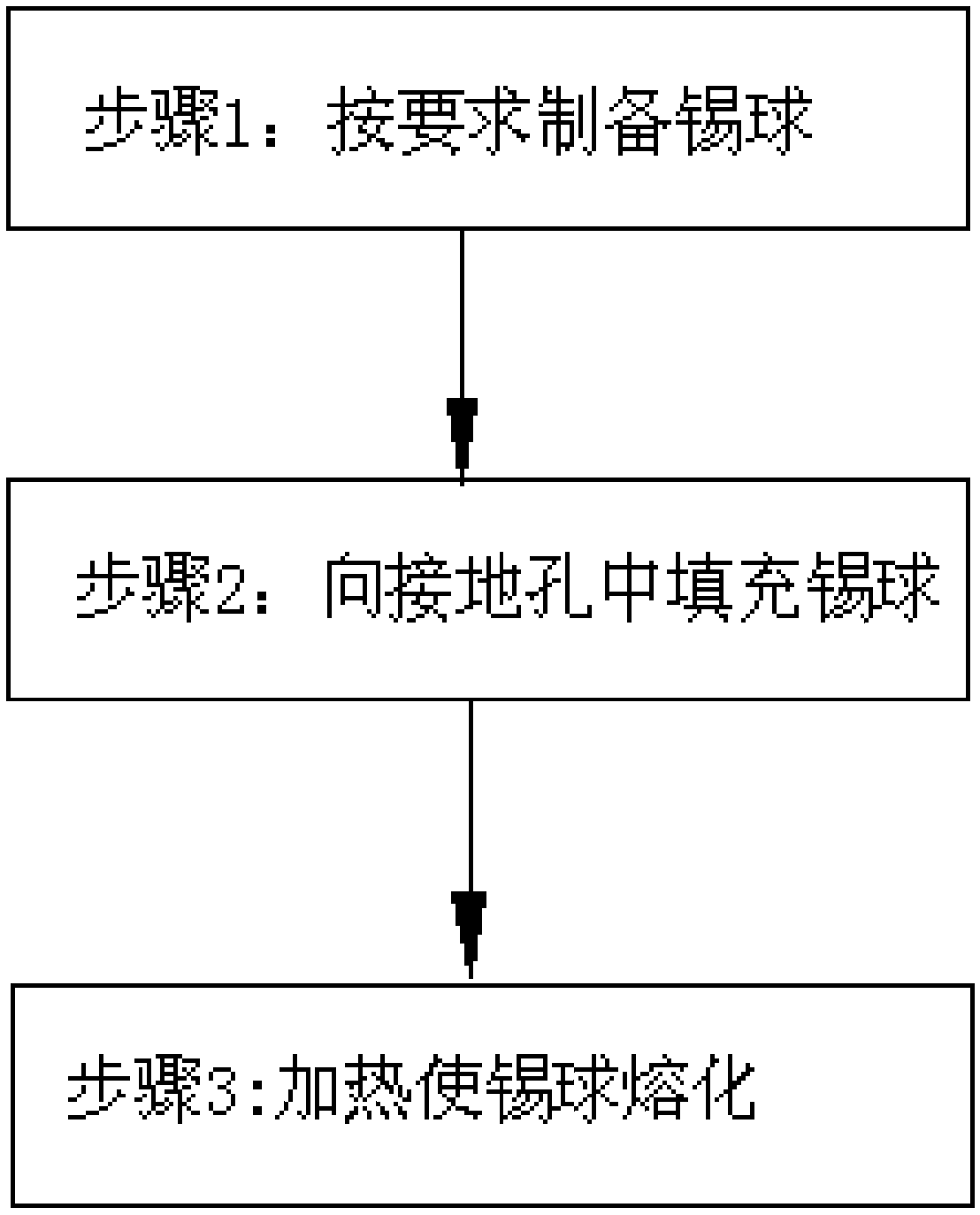

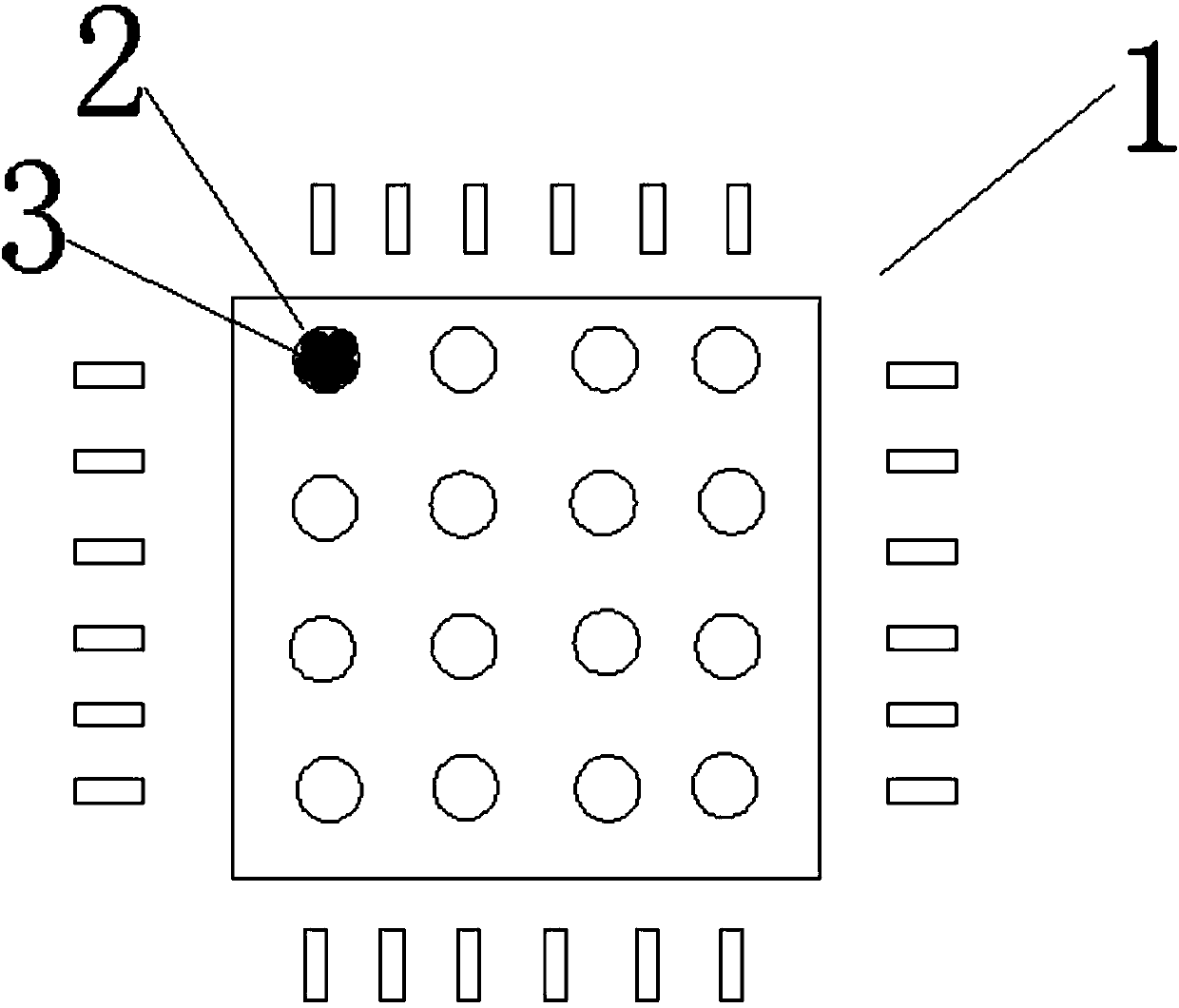

Welding method for improving sufficient ground connection and heat dissipation of chip

InactiveCN107708328AAdequate heat dissipationImprove welding qualityPrinted circuit assemblingMetallurgical bondingSolder ballEngineering

The invention discloses a welding method for improving sufficient ground connection and heat dissipation of a chip. The welding method is characterized by comprising the following steps: step SS1, preparing solder balls; step SS2, filling the solder balls in the step SS1 into bonding pad ground connection holes in a chip bonding pad on a circuit board; and step SS3, heating so that the solder balls in the bonding pad ground connection holes in the step SS2 are melted. Compared with the prior art, the working procedures of filling the solder balls into the bonding pad ground connection holes one by one and then putting the solder balls on a heating platform to be heated so that the solder balls in the bonding pad ground connection holes are melted are added, so that the bonding pad ground connection holes are filled with soldering tin to realize sufficient ground connection with the ground of the chip, sufficient heat dissipation of the chip is guaranteed, and the welding quality of thechip is improved.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com