SrTiO<3>-based lead-free high-energy-density ceramic material and preparation method thereof

A high energy storage density, ceramic material technology, applied in the direction of fixed capacitor dielectrics, fixed capacitor components, etc., can solve the problems of low improvement rate and non-compliance with market requirements, and achieve polarization strength improvement, low cost, and material cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] SrTiO of this example 3 Based lead-free high energy storage density ceramic material, its formula is (1-x)SrTiO 3 -xNa 0.5 Bi 0.5 TiO 3 , Where x=10mol%.

[0037] Step 1: prepare pure phase SrTiO 3 And pure phase Na 0.5 Bi 0.5 TiO 3 spare. Weigh SrCO according to the molar ratio of 1:1 3 And TiO 2 Mix to form mixture A; weigh Bi according to the molar ratio of 1:1:4 2 O 3 , Na 2 CO 3 And TiO 2 Mix to form Mixture B. SrCO 3 , Bi 2 O 3 , Na 2 CO 3 And TiO 2 The purity is 99.0% or more.

[0038] Step 2: Take the mixtures A and B, respectively, with zircon balls and deionized water, and mix them according to the mass ratio of 1:2:1.5, then use a planetary ball mill to ball mill for 7 hours, then dry at 85°C for 14 hours, and after briquetting, Placed in a box furnace at 1180°C for 3 hours and 850°C for 4 hours to form pre-composites of mixtures A and B for use;

[0039] Step 3: Take the mixture A pre-synthetic material and the mixture B pre-synthetic material, weigh 10 mol% of t...

Embodiment 2

[0045] SrTiO of this example 3 Based lead-free high energy storage density ceramic material, its formula is (1-x)SrTiO 3 -xNa 0.5 Bi 0.5 TiO 3 , Where x=20mol%. Other conditions are the same as in Example 1.

Embodiment 3

[0047] SrTiO of this example 3 Based lead-free high energy storage density ceramic material, its formula is (1-x)SrTiO 3 -xNa 0.5 Bi 0.5 TiO 3 , Where x=30mol%, and other conditions are the same as in Example 1.

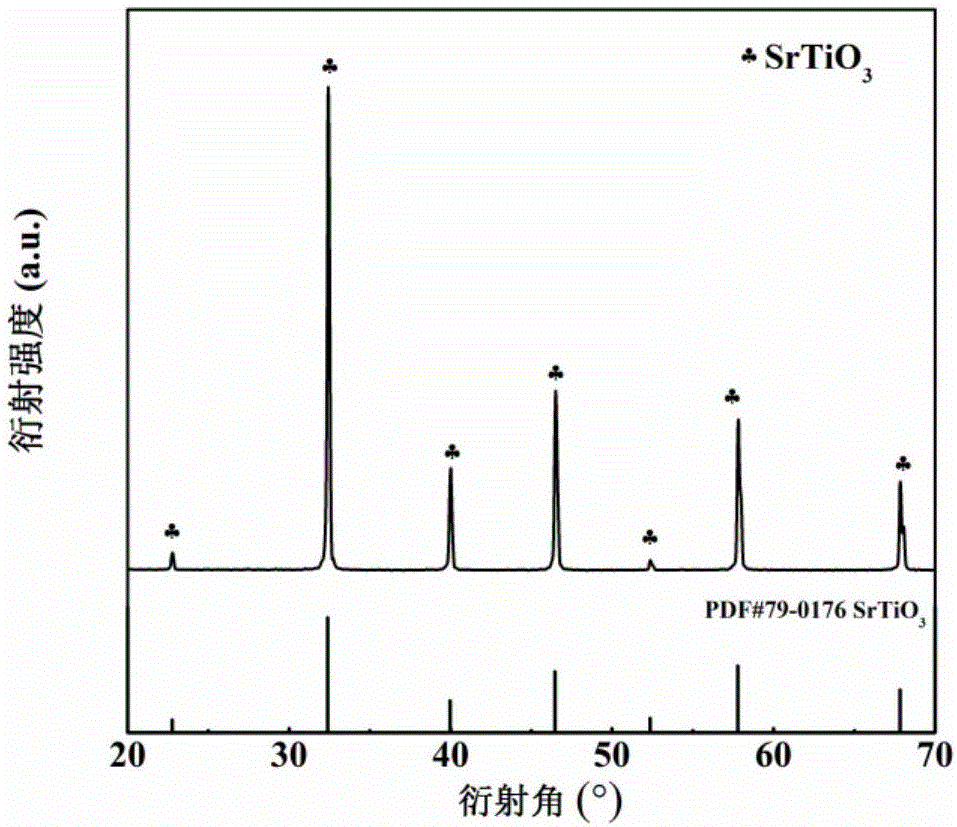

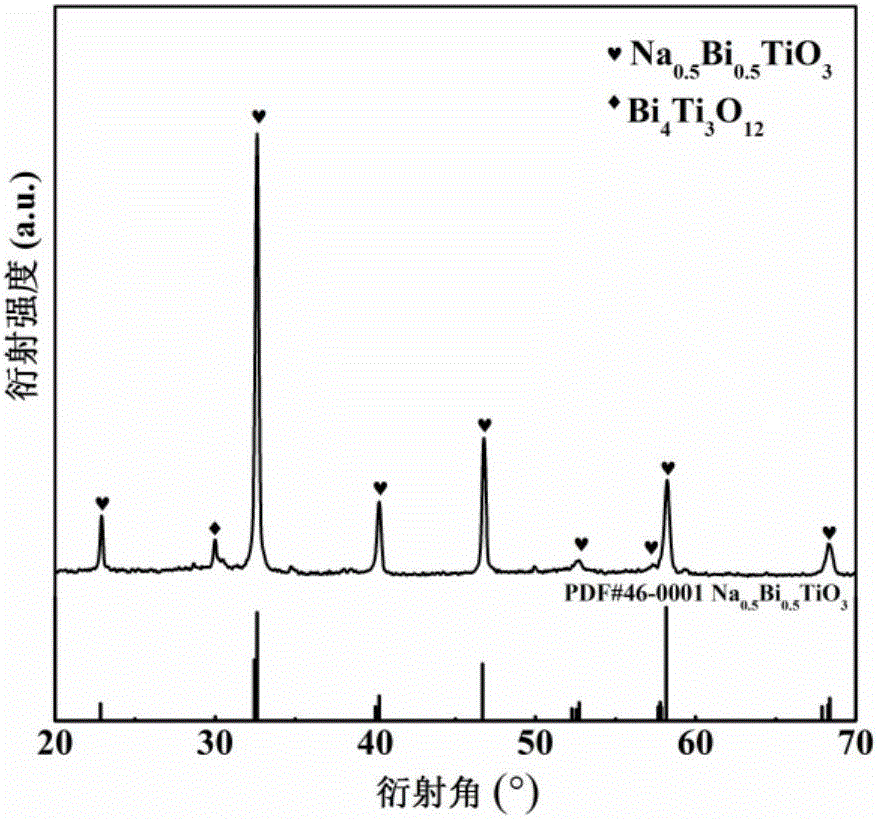

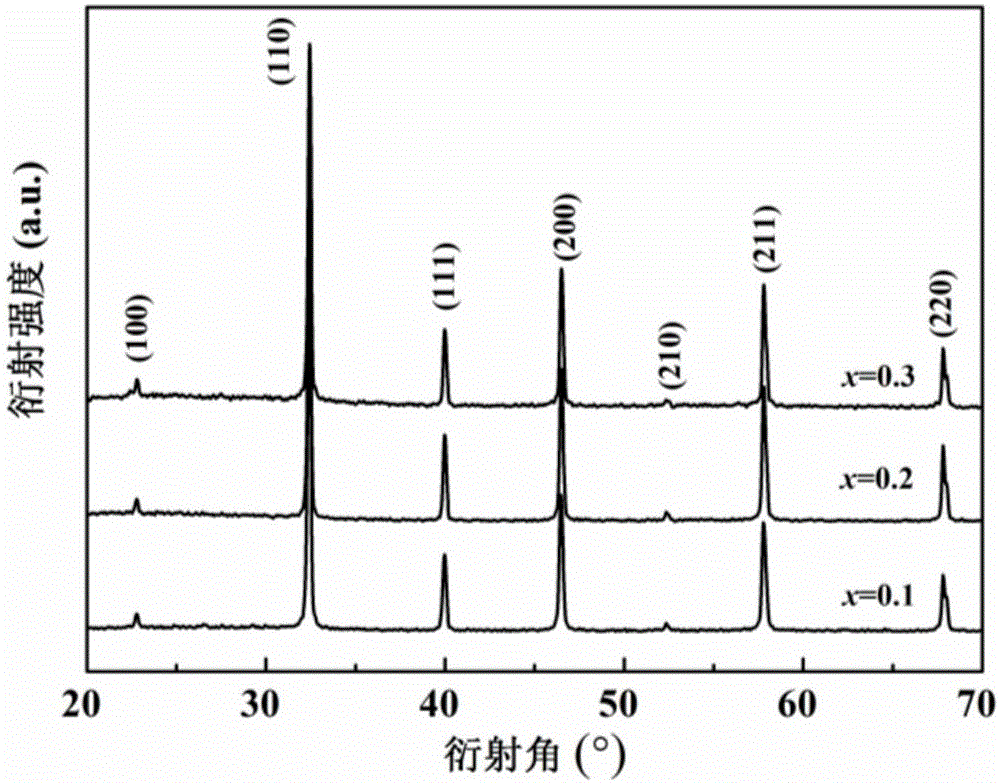

[0048] For testing the products of Examples 1-3, please refer to Figure 1-3 As shown, the prepared SrTiO 3 It can be seen from the XRD pattern that a pure phase of SrTiO is prepared 3 Powder. Prepared Na 0.5 Bi 0.5 TiO 3 It can be seen from the XRD pattern that the preparation contains Bi 4 Ti 3 O 12 Na of the second phase 0.5 Bi 0.5 TiO 3 Powder. At the same time, from image 3 It can be seen that (1-x)SrTiO 3 -xNa 0.5 Bi 0.5 TiO 3 (x=10mol%, 20mol%, 30mol%) The ceramic powder forms a pure phase perovskite structure, and there is no second phase. Na 0.5 Bi 0.5 TiO 3 Fully into SrTiO 3 The crystal lattice forms a solid solution and has a cubic structure. Figure 4(a) to Figure 4(c) The shaded part represents the energy storage density (J d ), see Table 1 for specific p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com