Lead-free BiFeO3-based ferroelectric ceramic material with high energy storage density and high energy storage efficiency and preparation method thereof

A technology of ceramic materials and ferroelectric ceramics, applied in circuits, capacitors, electrical components, etc., can solve problems such as environmental protection and adverse human health, and achieve the effects of reducing residual polarization, reducing loss, and high polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Lead-free BiFeO 3 The composition of the base energy storage ceramic material is: 0.62BiFeO 3 -0.34BaTiO 3 -0.04Ba(Zn 1 / 3 Ta 2 / 3 )O 3 +0.15wt%.MnCO 3 , The steps of its preparation method include:

[0039] (1) Calculate the composition of each component Bi in the powder raw material according to the above chemical formula 2 O 3 , BaCO 3 , TiO 2 , Ta 2 O 5 , ZnO, MnCO 3 , Fe 2 O 3 The mass is prepared according to the composition ratio, mixed by wet ball milling, dried and compressed, and then calcined to obtain ceramic powder. Mix for 24 hours according to the mass ratio of raw material: ball: alcohol = 1:2:1 to make each component well mixed. After drying, pass through a 40-mesh sieve, briquette, heat up to 800°C at a heating rate lower than 5°C / min in an air atmosphere, and keep the temperature for 5 hours to synthesize ceramic powder;

[0040] (2) Grind the ceramic powder obtained in step (1) and pass through a 40-mesh sieve. Then according to the mass ratio of raw mater...

Embodiment 2

[0045] Lead-free BiFeO 3 The composition of the base energy storage ceramic material is: 0.60BiFeO 3 -0.34BaTiO 3 -0.06Ba(Zn 1 / 3 Ta 2 / 3 )O 3 +0.15wt%.MnCO 3 ;

[0046] Repeat the preparation method of Example 1 according to the above formula to obtain the lead-free BiFeO 3 Based energy storage ceramic materials.

[0047] The sintered lead-free BiFeO 3 The base energy storage ceramic material is thinned, cleaned, dried, screen-printed with silver paste, then dried, heated to 750°C at a heating rate of 2°C / min, and kept for 30 minutes to obtain ceramic components.

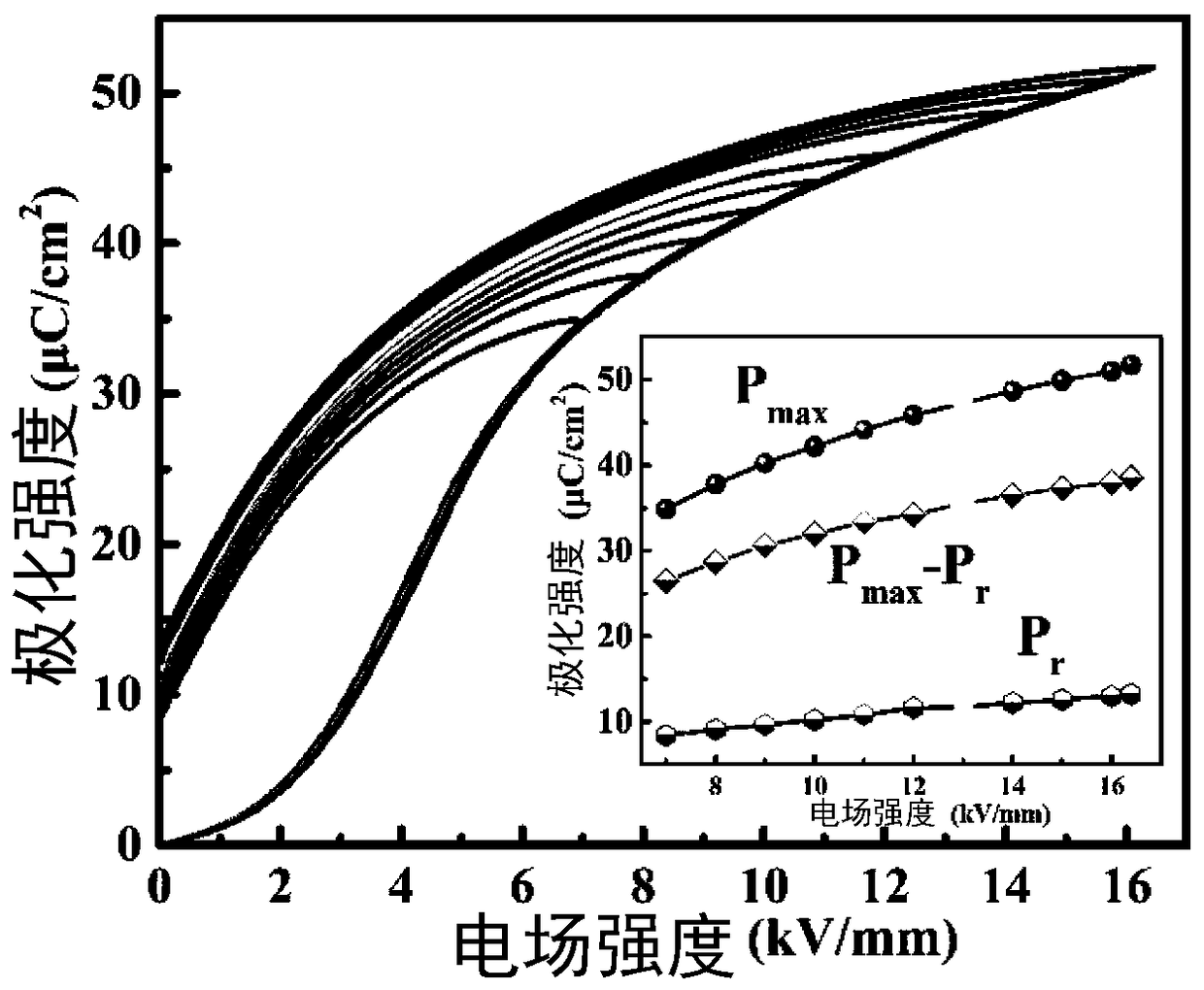

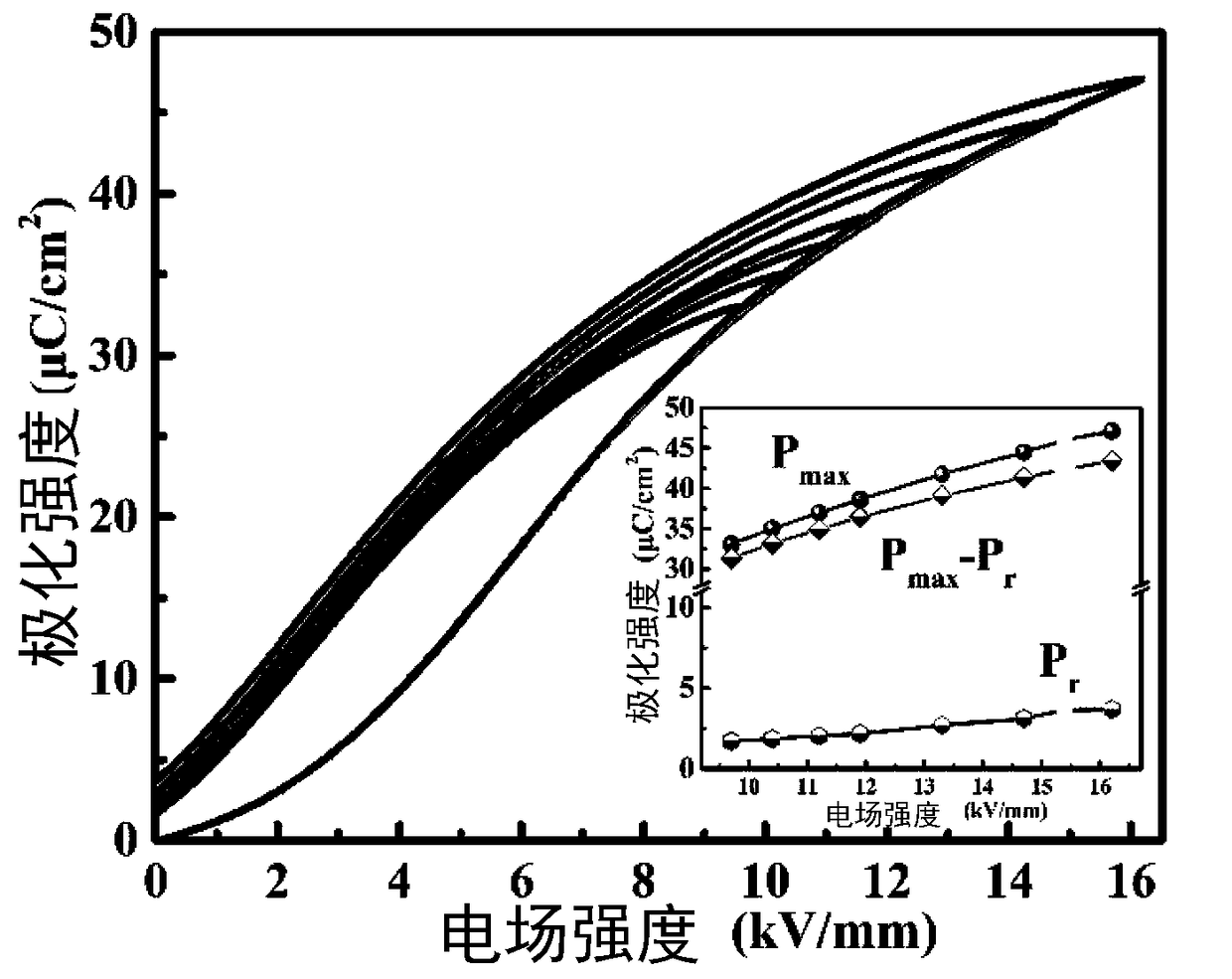

[0048] The ceramic element prepared in Example 2 was subjected to unipolar hysteresis loops under different electric fields at room temperature. The results are shown in figure 2 , The maximum polarization intensity (P max ), the residual polarization (P r ) And the amount of change in polarization (P max -Pr) as the electric field changes, see figure 2 The illustration and the calculation of the maximum reversible energ...

Embodiment 3

[0050] Lead-free BiFeO 3 The composition of the base energy storage ceramic material is: 0.56BiFeO 3 -0.34BaTiO 3 -0.10Ba(Zn 1 / 3 Ta 2 / 3 )O 3 +0.15wt%.MnCO 3 ;

[0051] Repeat the preparation method of Example 1 according to the above formula to obtain the lead-free BiFeO 3 Based energy storage ceramic materials.

[0052] The sintered lead-free BiFeO 3 The base energy storage ceramic material is thinned, cleaned, dried, screen-printed with silver paste, then dried, heated to 750°C at a heating rate of 2°C / min, and kept for 30 minutes to obtain ceramic components.

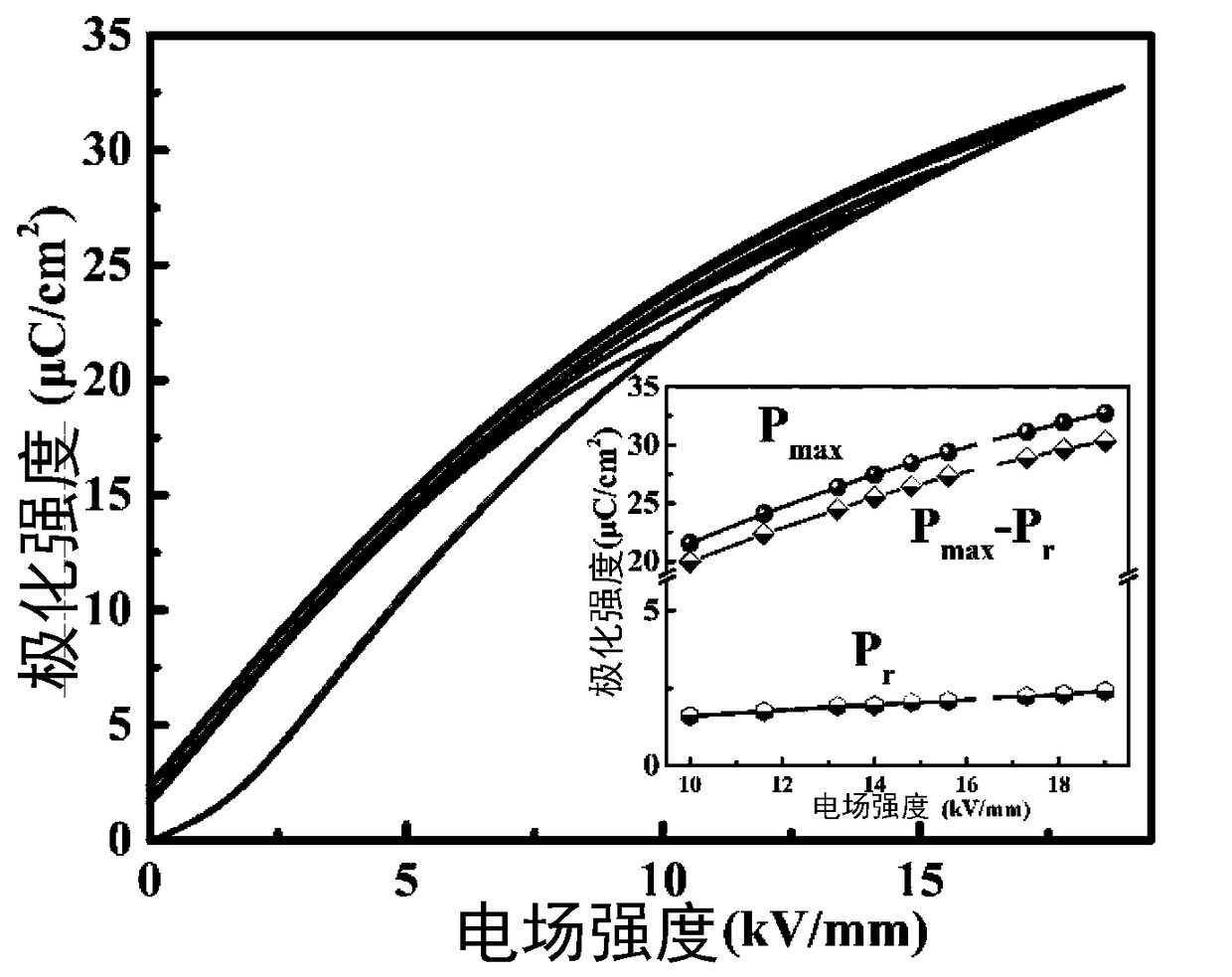

[0053] The ceramic element prepared in Example 3 was subjected to unipolar hysteresis loops under different electric fields at room temperature. The results are shown in image 3 , The maximum polarization intensity (P max ), the residual polarization (P r ) And the amount of change in polarization (P max -P r ) As the electric field changes, see image 3 The middle inset and the calculation of the maximum reversible energ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com