Screw type food processing device

A food processing, screw-type technology, applied in kitchen utensils, household utensils, applications, etc., can solve problems such as inconvenient use, high device cost, and waste of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, a specific embodiment of the present invention will be described in detail below.

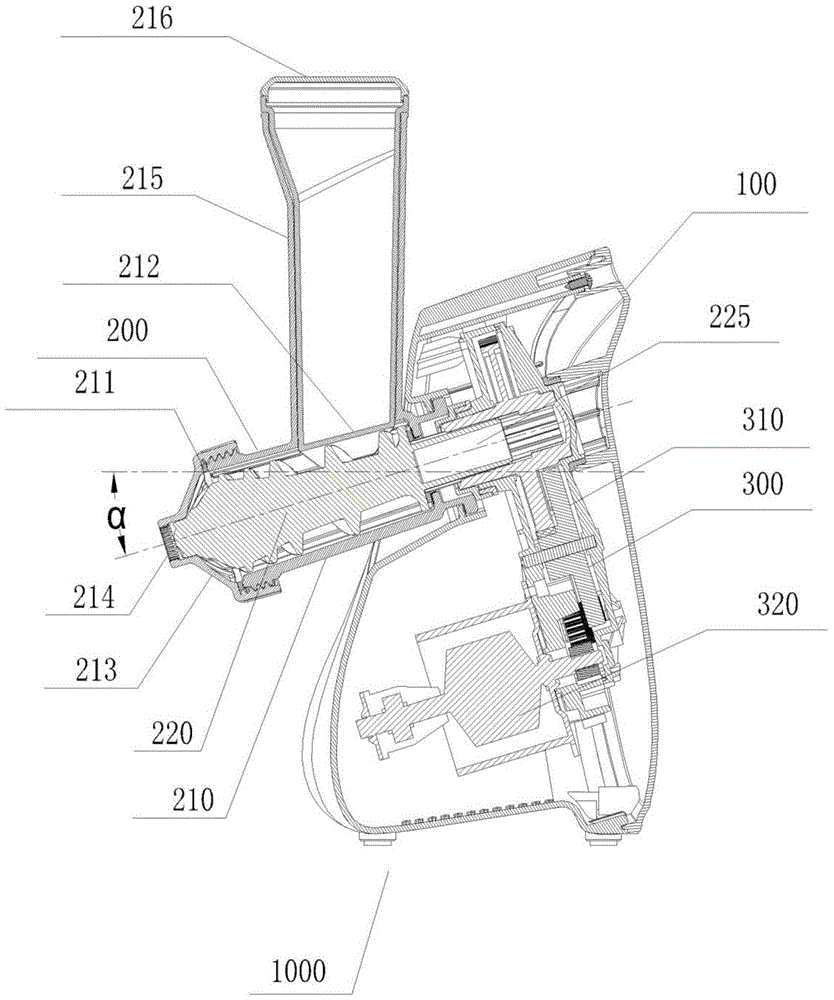

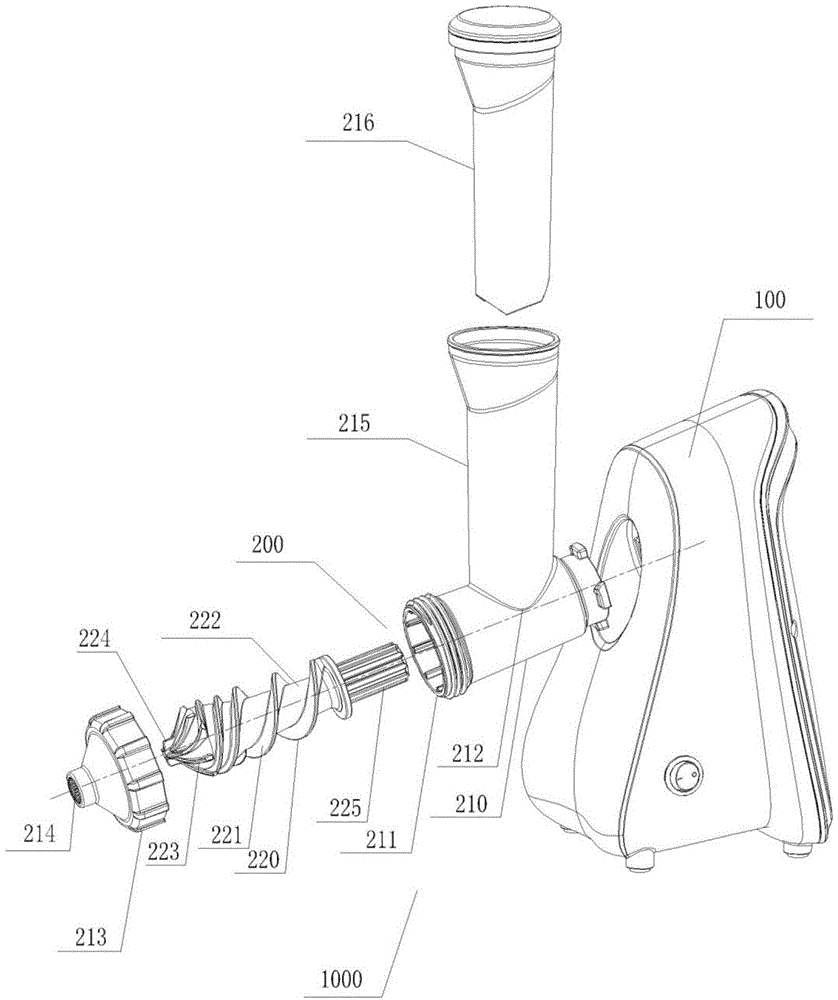

[0022] figure 1 Schematically shows the structure of a screw type food processing device of an embodiment. As shown in the figure, the screw type food processing device 1000 includes a casing 100 , a screw extrusion assembly 200 and a driving mechanism 300 . The casing 100 supports the screw extrusion assembly 200 and the driving mechanism 300 , and provides a protective casing for the driving mechanism 300 .

[0023] The screw extrusion assembly 200 includes an extrusion tube 210 and a screw 220 . The extruded tube 210 is a barrel-shaped structure, the mouth of the barrel is the discharge port 211 , and the side wall near the bottom of the barrel has a hole as the feed port 212 . The feed port 212 is arranged to open upward. A feed pipe 215 extending vertically is connected to the feed port.

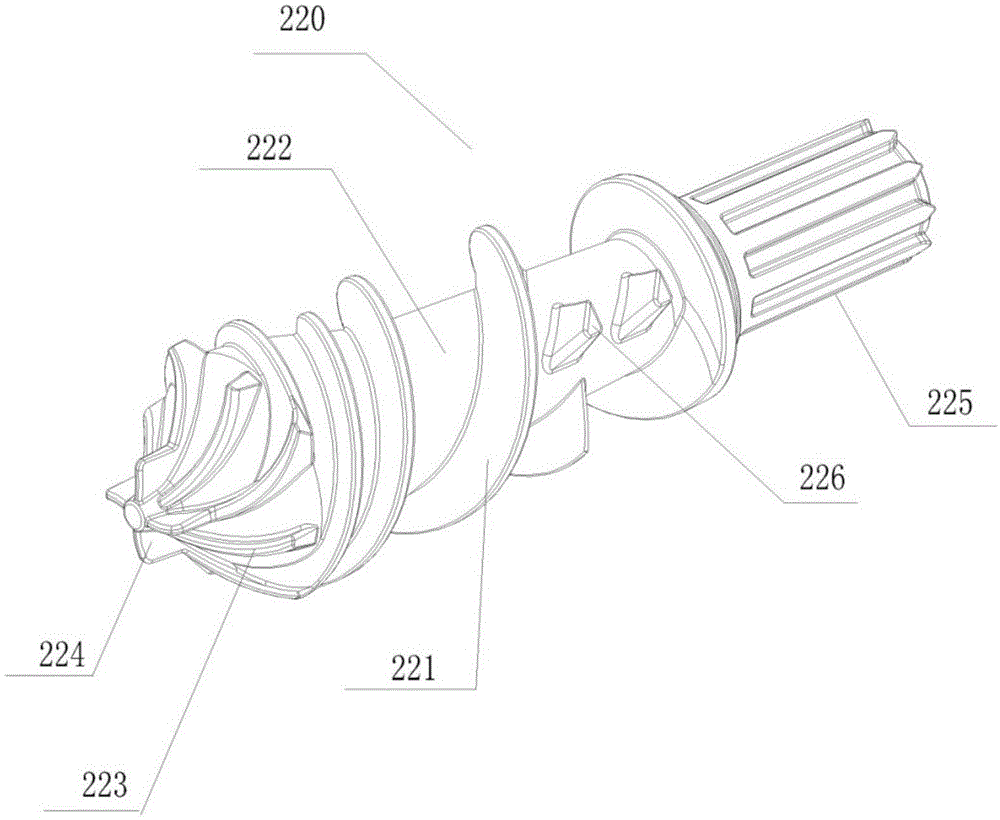

[0024] The screw 220 includes a colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com