Rice fine grinding and milling process

A technology of fine grinding and rice flour, applied in the fields of cocoa, grain processing, food science, etc., can solve the problems of difficult rice grinding, etc., and achieve the effects of convenient operation, extended grinding stroke and simple principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

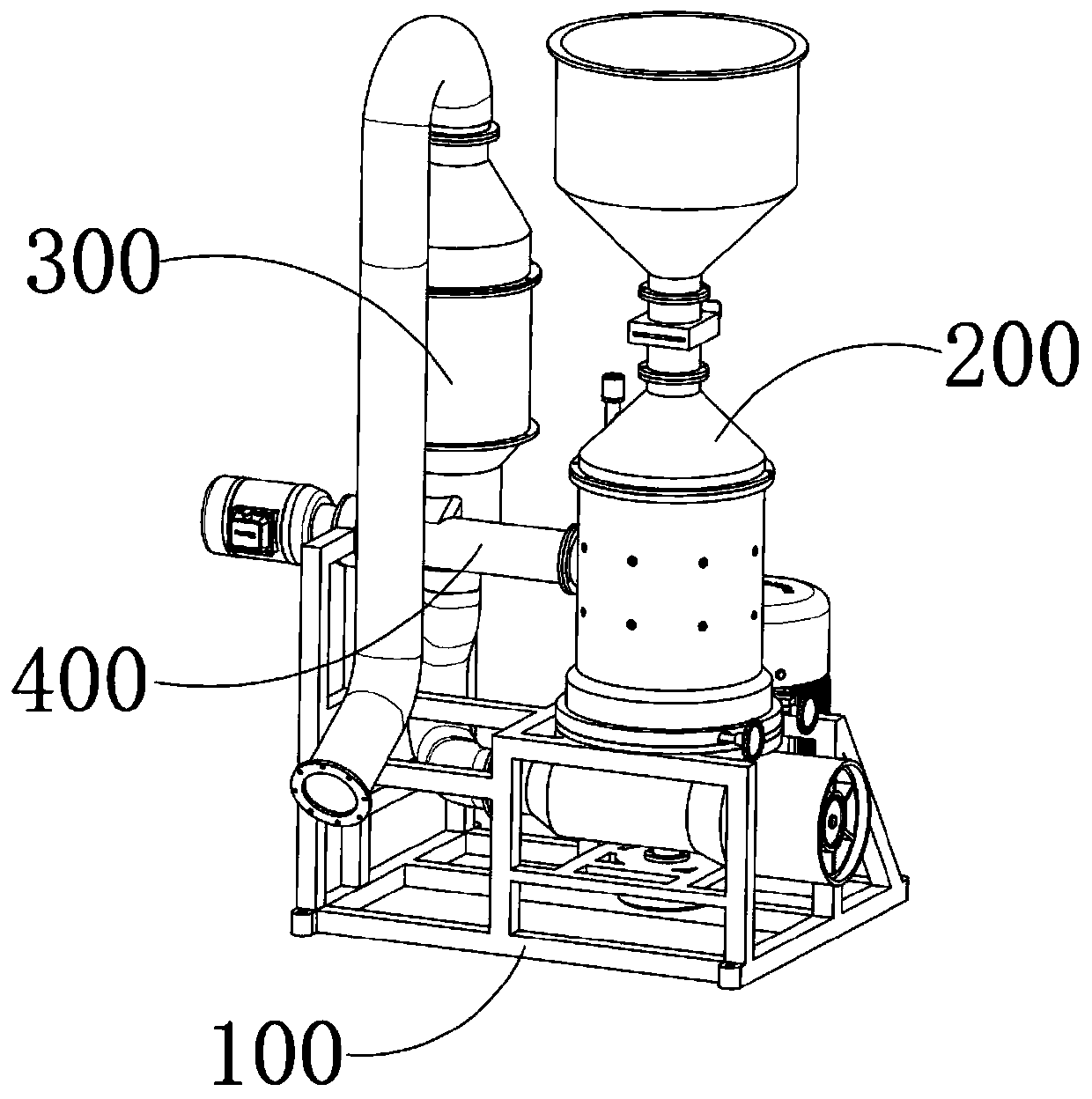

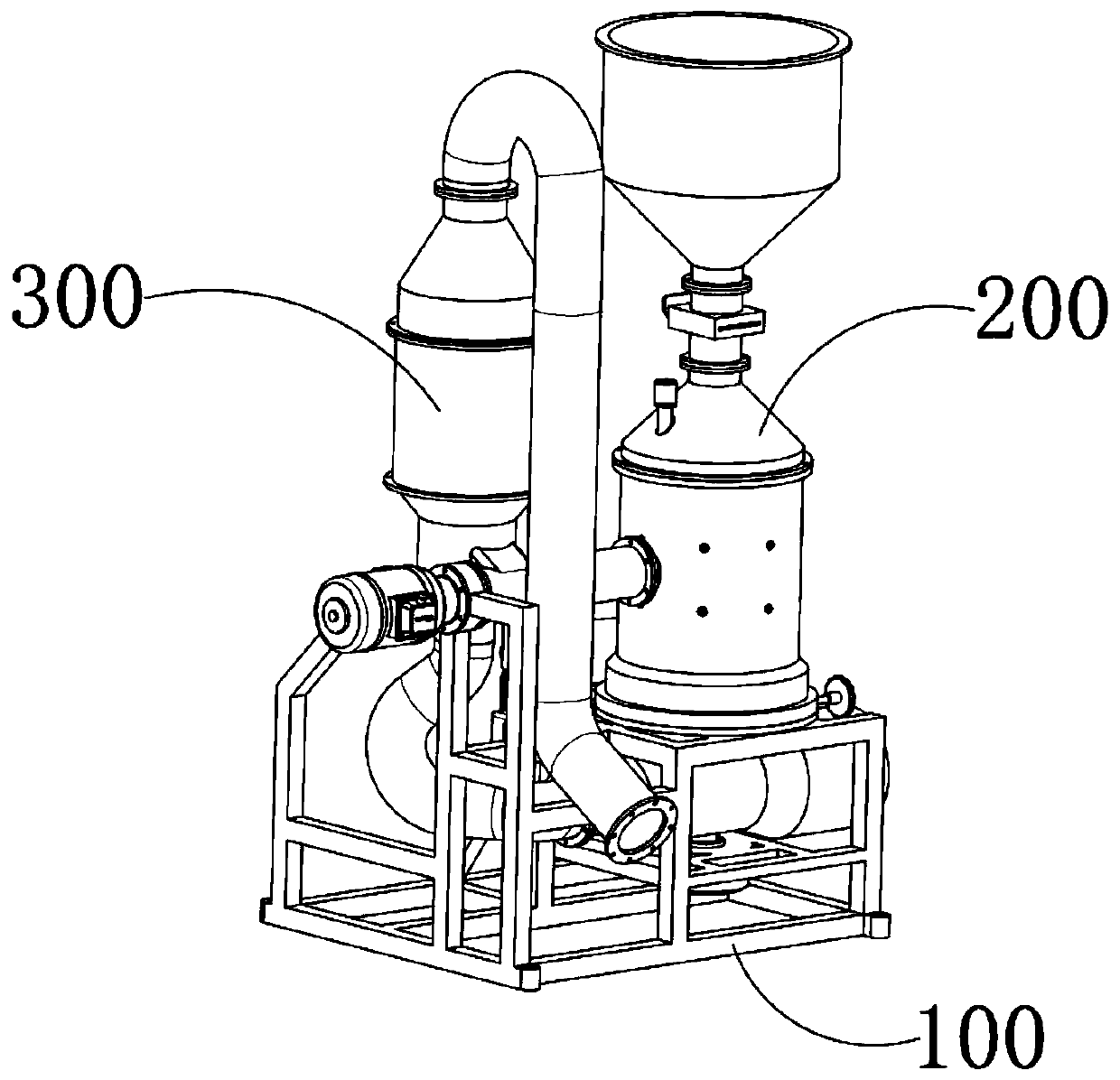

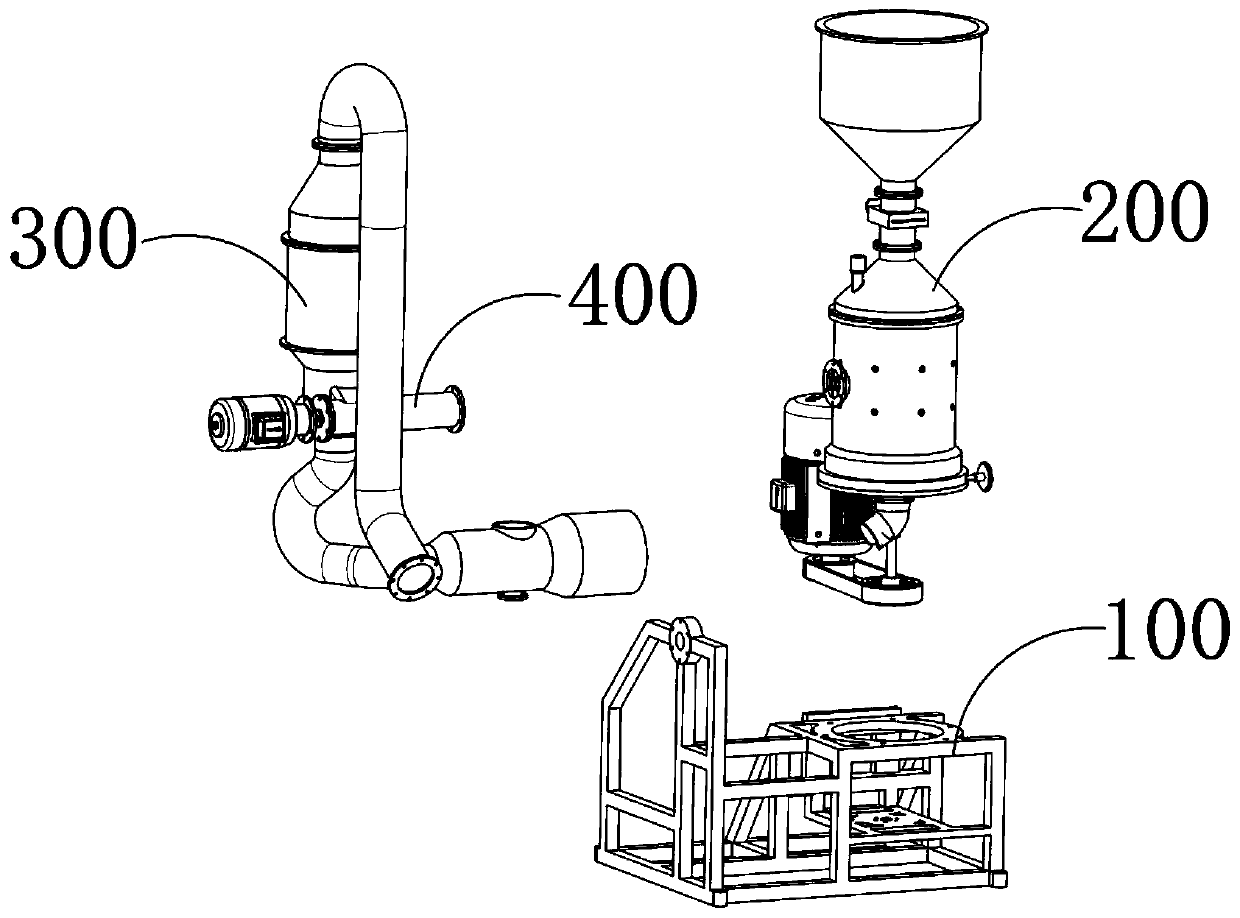

Image

Examples

Embodiment Construction

[0062] The refined milling process of rice comprises the steps of:

[0063] (1) Primary grinding stage;

[0064] S1: The drive mechanism 220 starts to run, the main shaft 206 will drive the upper grinding disc 207 and the crushing knife 208 to rotate at a high degree synchronously, and then, the feeding mechanism 230 will add the rice inside it from the top of the crushing tank 201 to the inside, and the side of the plate body 208b The rice is impacted and broken into broken rice, and evenly flows into the gap between the upper millstone 207 and the lower millstone 204 under the guidance of the guide plate 207b, and the high-speed rotating upper millstone 207 and the lower millstone 204 cooperate with each other to crush the broken rice. Grinding into rice flour and entering the inner cylinder 205b;

[0065] During processing, the driving mechanism 220 starts to run and drives the main shaft 206 to rotate at a high speed around its own axial direction. The main shaft 206 will...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com