Integrated crushing and grinding equipment for cement raw material

A technology for crushing and grinding cement raw materials, which is applied in cement mixing devices, solid separation, clay preparation devices, etc. It can solve the problems of not meeting the production standards of cement grinding and non-uniform cement particle size, and achieves easy dosing and stable structure , good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

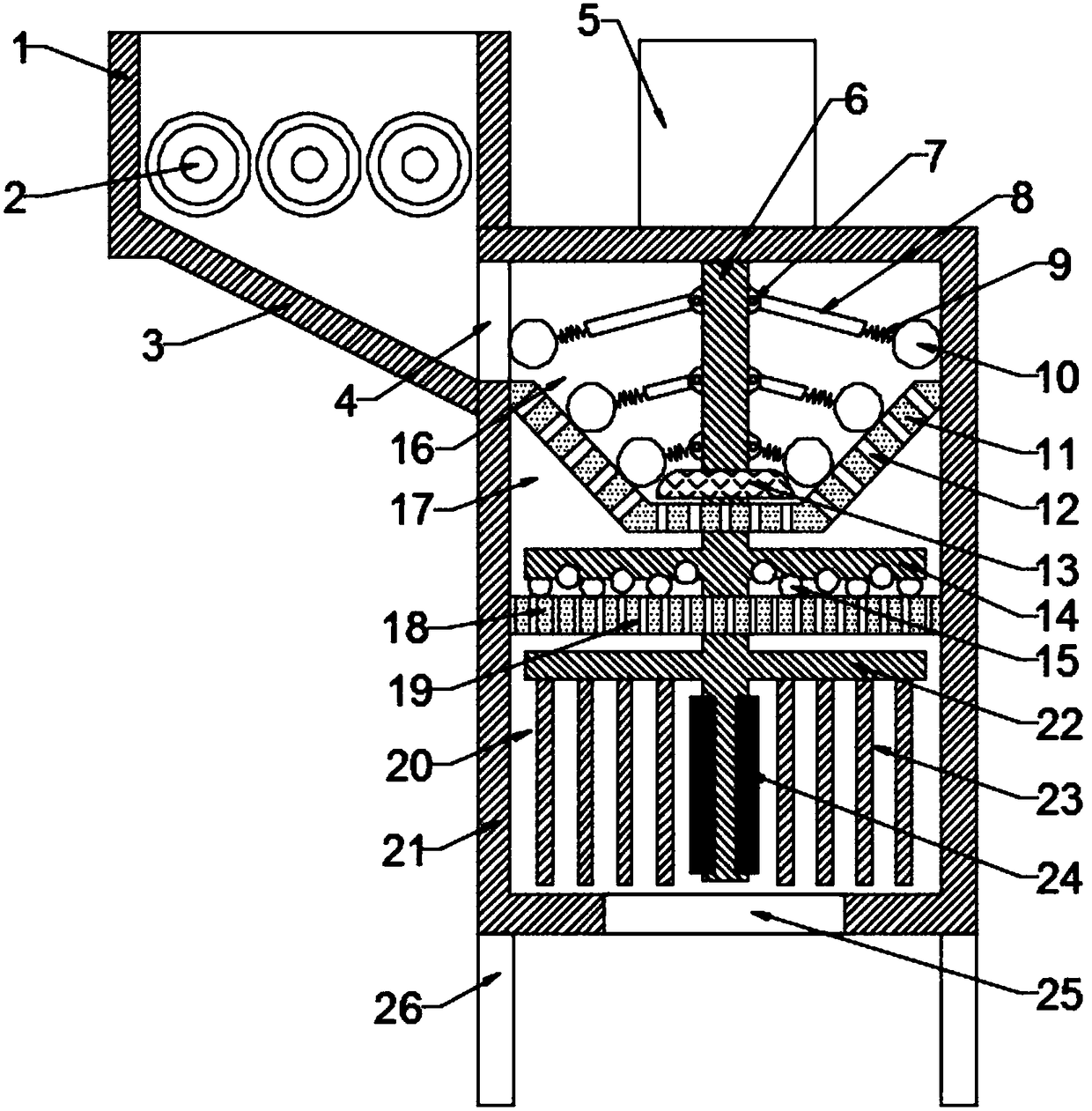

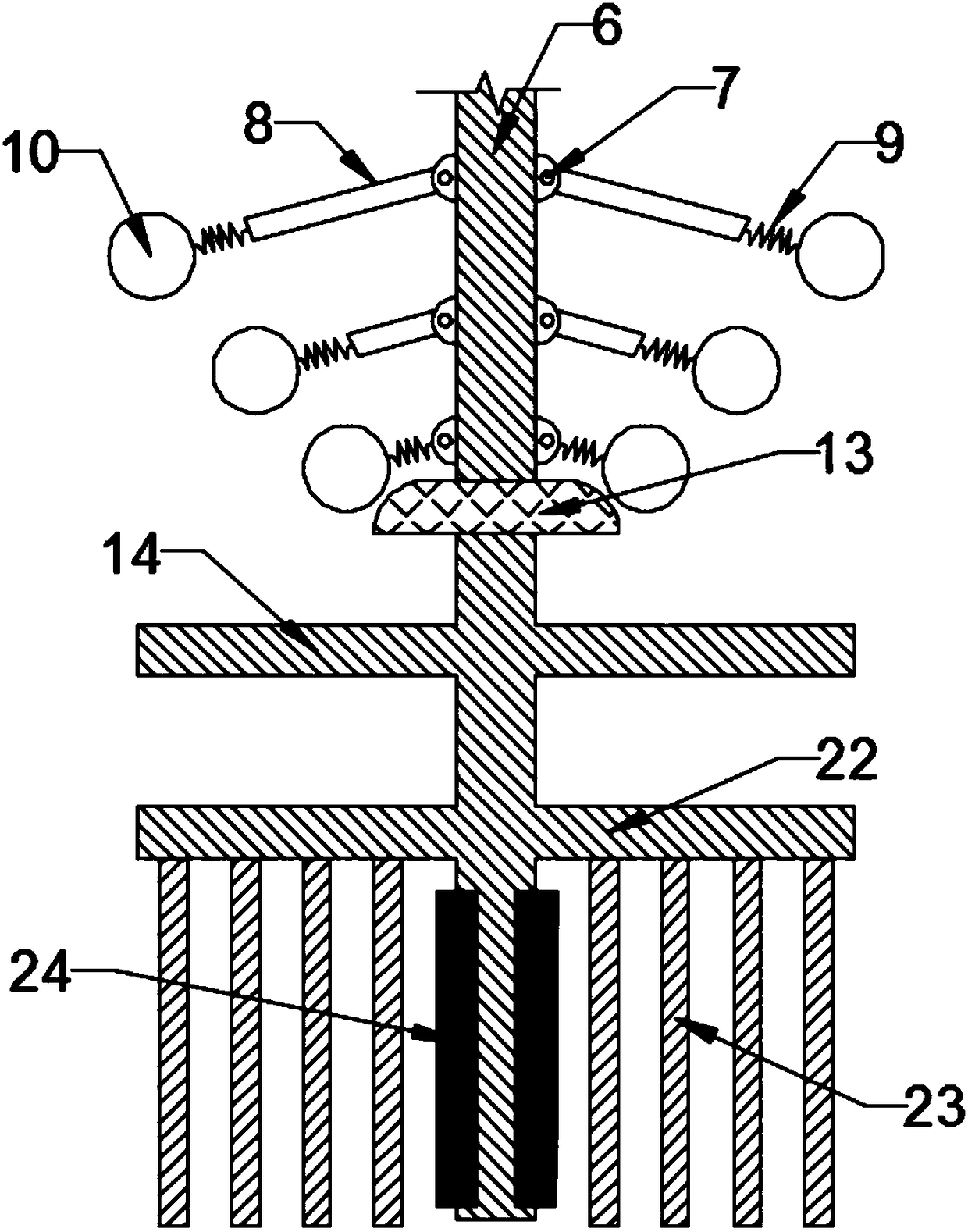

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

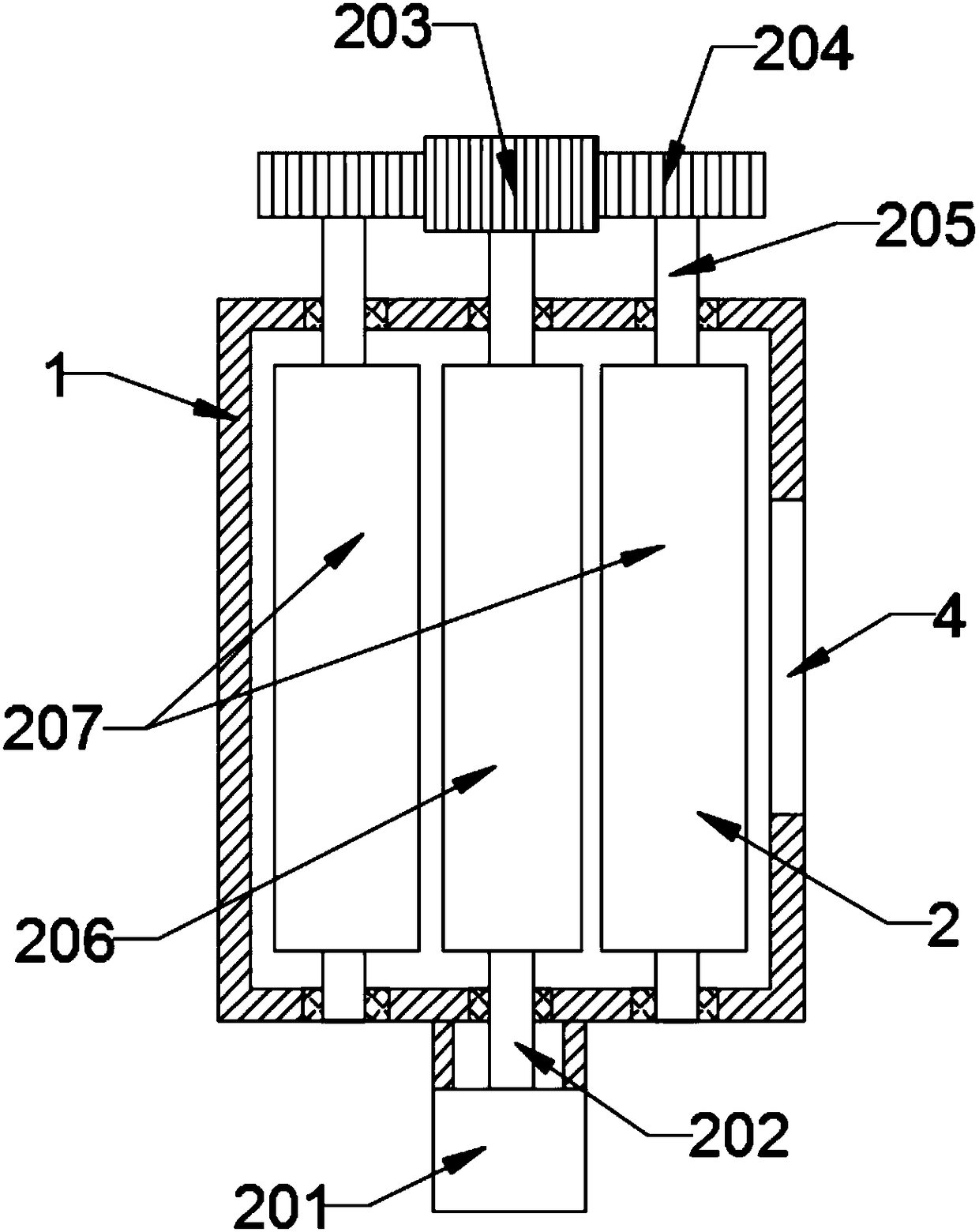

[0021] see Figure 1~4 , in an embodiment of the present invention, an integrated crushing and grinding equipment for cement raw materials, including a feeding hopper 1, a crushing mechanism 2, a rotating shaft 6, a grinding ball 10, a grinding hopper 11, a grinding disc 13, grinding pellets 15 and a tank body 21 , the bottom of the tank body 21 is welded on the bracket 26, the inside of the tank body 21 is connected to the grinding hopper 11 and the filter plate 18, and the grinding hopper 11 and the filter plate 18 divide the inside of the tank body 21 from top to bottom into the first grinding chamber 16 , the second grinding chamber 17 and the mixing chamber 20, the upper side of the tank body 21 is provided with a feeding port 4, the feeding port 4 communicates with the first grinding chamber 16, and a feeding ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com