Ultramicro grinding machine for sesame paste production and grinding method

A technology of sesame paste and grinding machine, which is applied in the fields of application, cocoa, and grain processing, etc., which can solve the problems of inability to grind high-quality sesame paste, and achieve the effect of novel structural design ideas, guaranteed quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

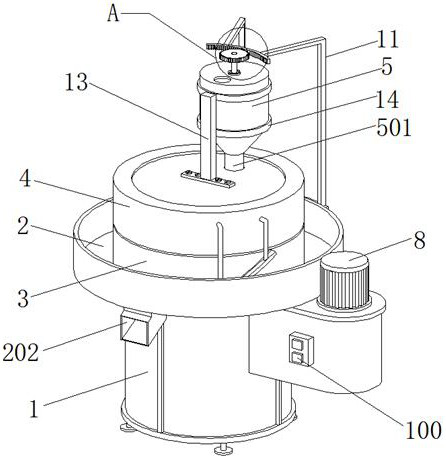

[0037] The present embodiment 1 discloses a kind of ultrafine grinder that is used for the production of sesame paste, and the structure of this grinder can refer to attached figure 1 And attached figure 2 , the main components mainly include a bottom machine base 1 , a receiving tank 2 , a lower grinding disc 3 , an upper grinding disc 4 , a storage bin 5 and a control panel 100 . The receiving tank 2 is installed on the upper end of the bottom frame 1, the lower grinding disc 3 is fixedly arranged in the receiving tank 2, the upper grinding disc 4 is arranged above the lower grinding disc 3, and the receiving tank 2, the lower grinding disc 3 Set coaxially with upper grinding disc 4.

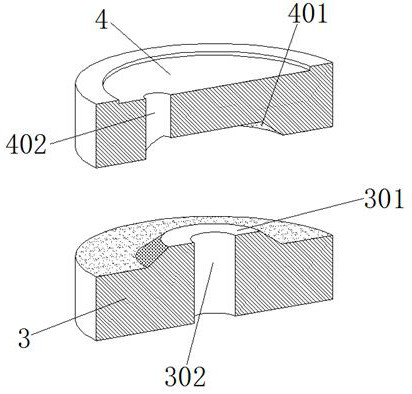

[0038] Reference attached image 3 , the lower surface of the upper grinding disc 4 is provided with a truncated conical groove 401 coaxially arranged with itself, the circumferential wall of the groove 401 is provided with rough grinding lines, and the lower surface of the upper grinding d...

Embodiment 2

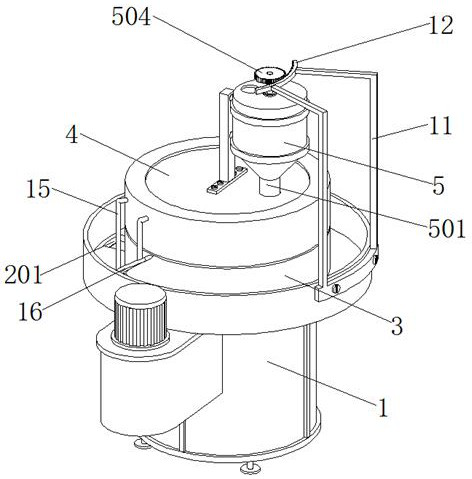

[0045] Embodiment 2 discloses an improved ultrafine grinder for sesame paste production based on Embodiment 1. Its similarities with Embodiment 1 will not be described again. For the differences, refer to the attached figure 2 And attached Figure 5 .

[0046] In this embodiment 2, two vertical downward connecting bars 15 are fixedly connected to the circumferential surface of the upper grinding disc 4, and the lower ends of the two connecting bars 15 are jointly connected with an arc-shaped scraper plate 16. The plate 16 is made of hard plastic or stainless steel, and the inner side of the scraper plate 16 is attached to the outer surface of the lower grinding disc 3 . The arrangement of the above-mentioned scraper 16 can scrape off the sesame paste left along the outer surface of the lower grinding disc 3 during the grinding process, and can ensure the cleanliness and tidiness of the entire grinding disc 3 at all times.

[0047] In addition, the present embodiment 2 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com