Preparation method for heat-conduction insulation silicone grease

A heat-conducting insulation and silicone grease technology, which is applied in the field of heat-conducting insulating silicone grease preparation, can solve the problems of time-consuming and labor-intensive grinding, insufficient grinding precision, and affecting the quality of insulating silicone grease, so as to avoid incomplete grinding and improve the effect and efficiency. , Improve the efficiency and speed of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

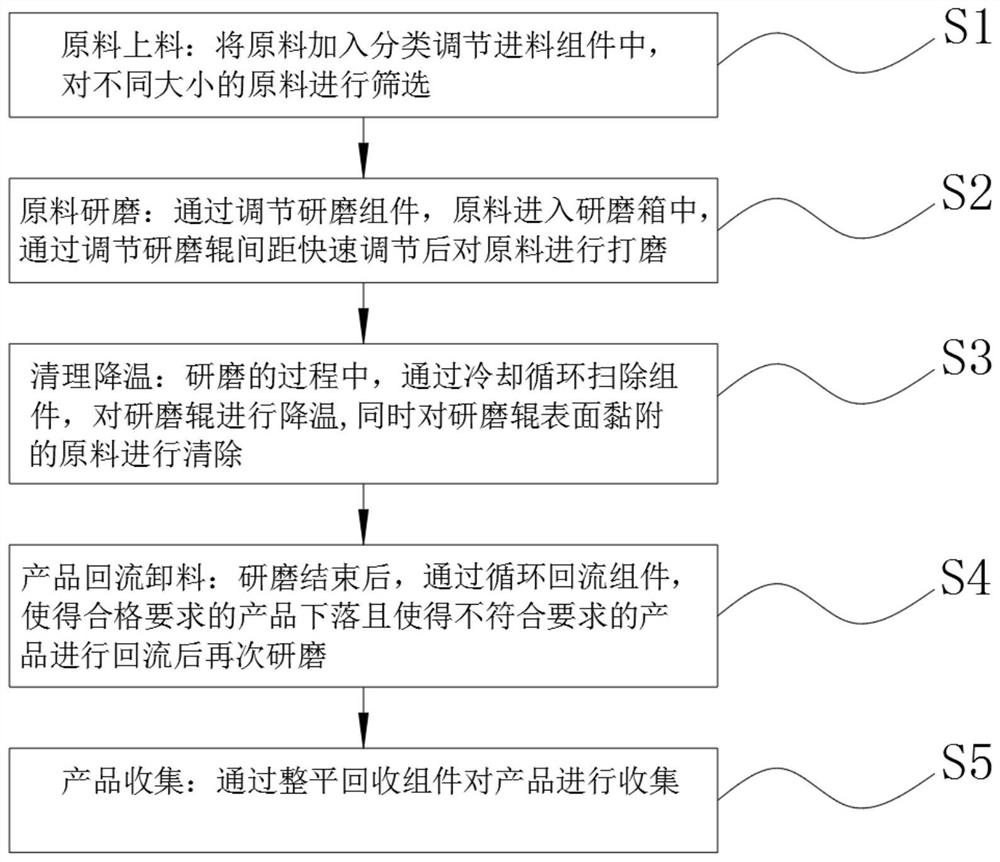

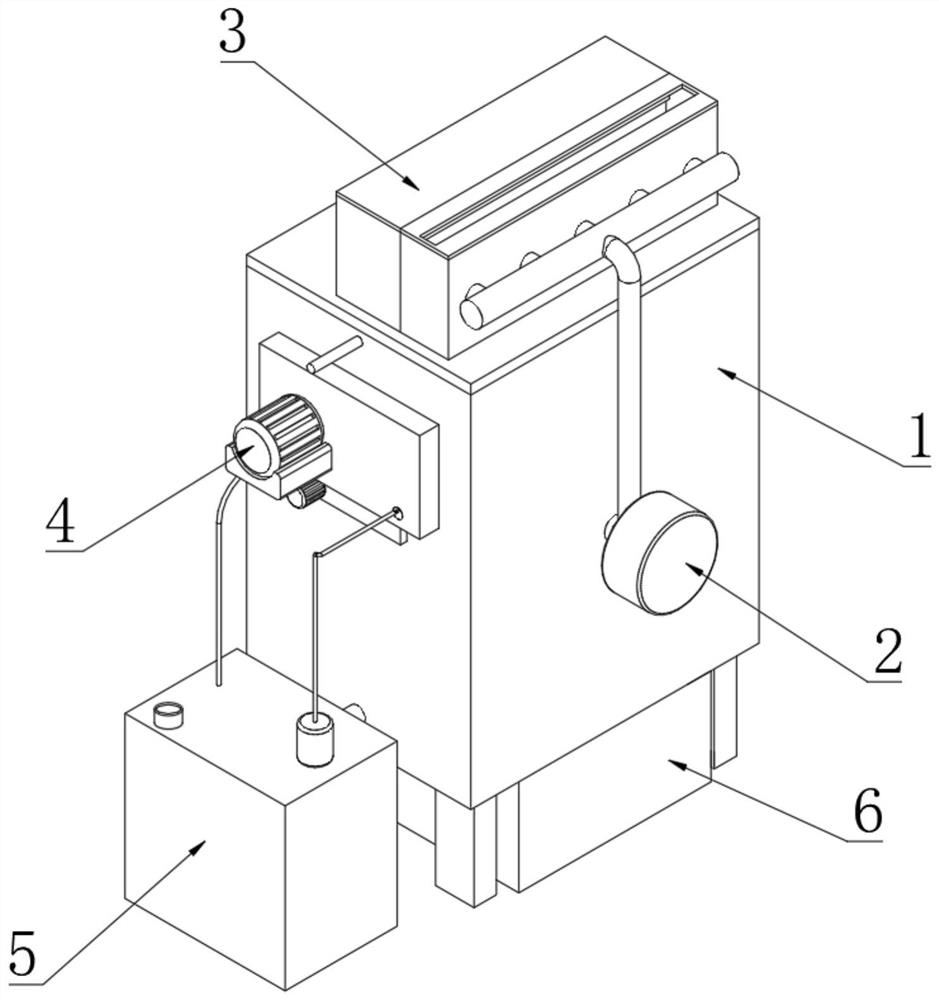

[0042] Example: such as figure 1 As shown, the present invention provides technical scheme, a kind of preparation method of heat conduction insulation silicone grease, comprises the following steps:

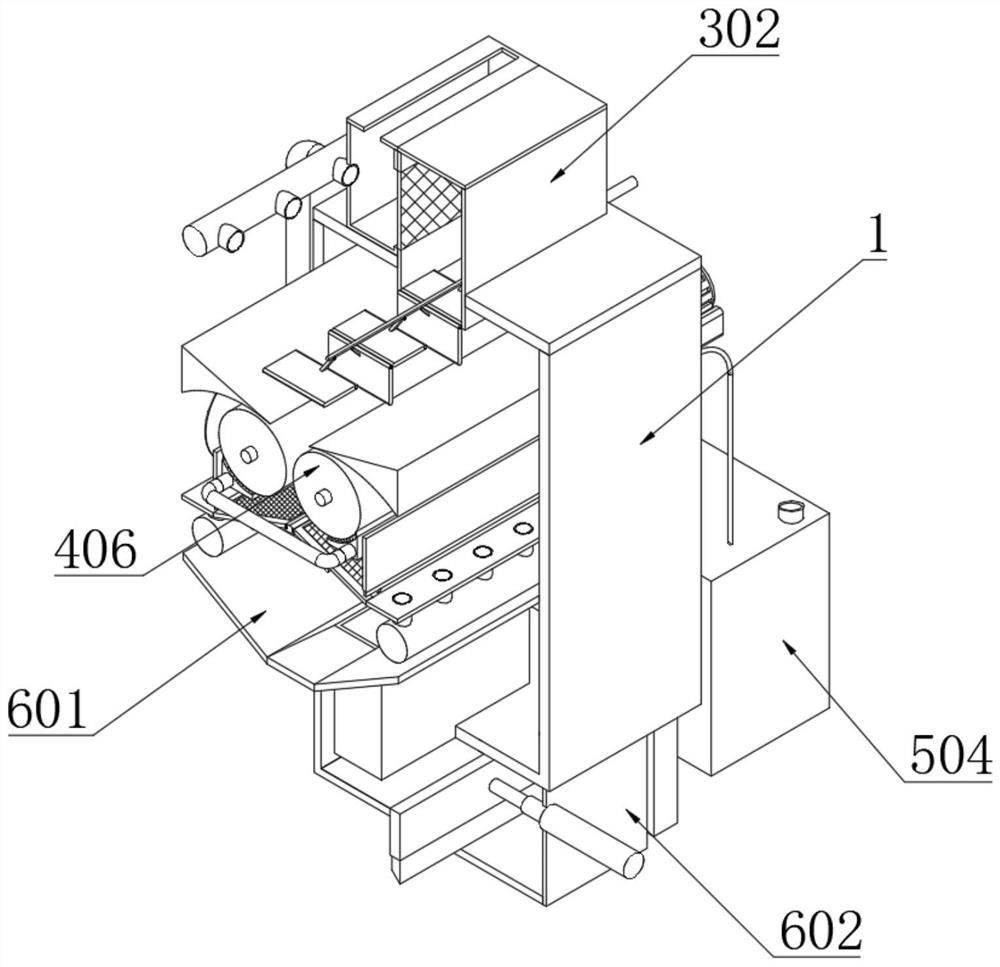

[0043] S1. Raw material feeding: add raw materials to the sorting and adjusting feeding component 3, and screen raw materials of different sizes.

[0044] S2. Raw material grinding: by adjusting the grinding assembly 4, the raw material enters the grinding box 1, and the raw material is ground after quickly adjusting the distance between the grinding rollers 406;

[0045] S3. Cleaning and lowering the temperature: during the grinding process, the assembly 5 is swept away through the cooling cycle, the temperature of the grinding roller 406 is lowered, and the raw materials adhered to the surface of the grinding roller 406 are removed at the same time.

[0046] S4. Product reflux unloading: after the grinding is finished, pass the reflux component 2 to make the qualified products...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com