Patents

Literature

78results about How to "Ensure sufficient separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

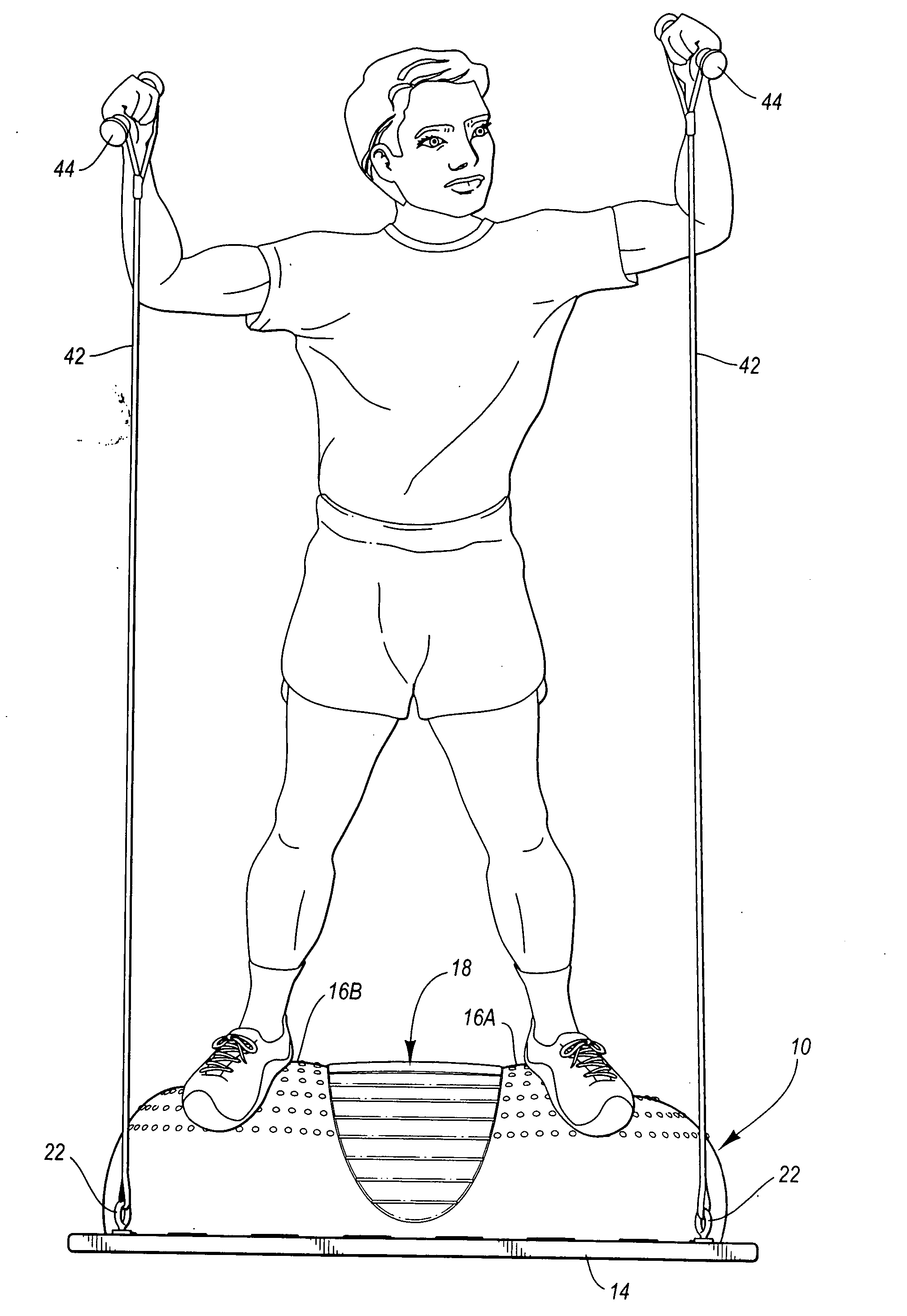

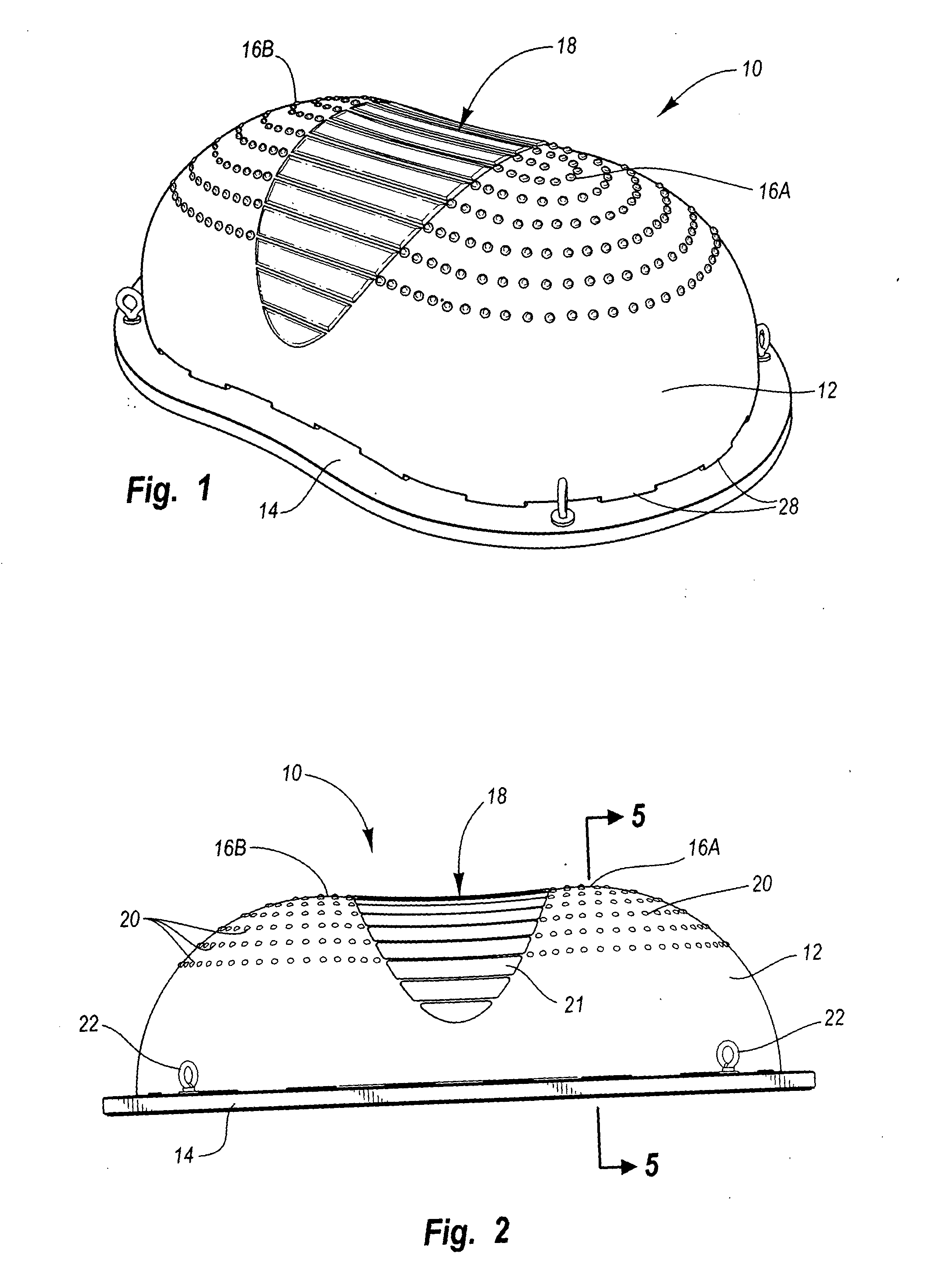

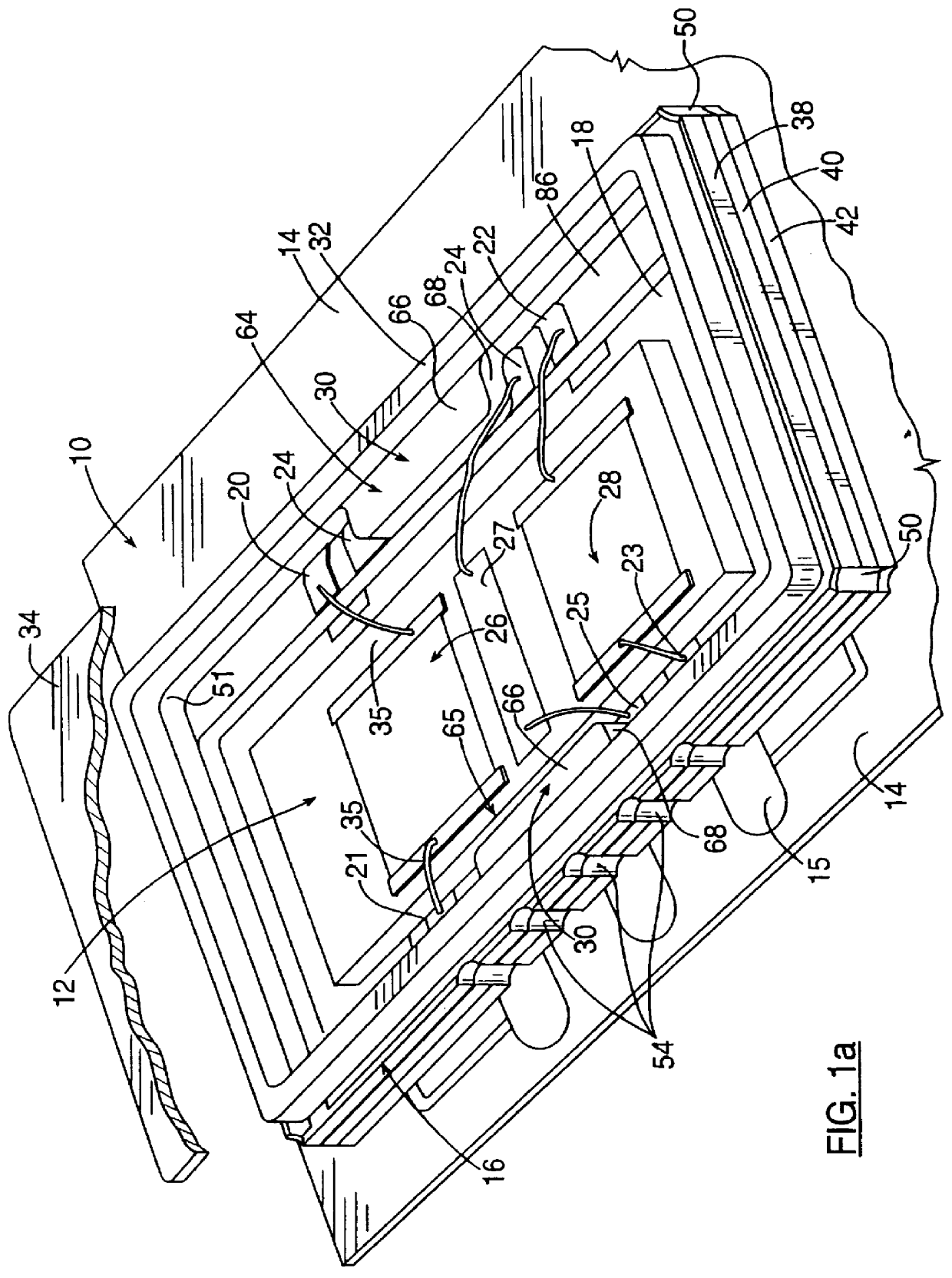

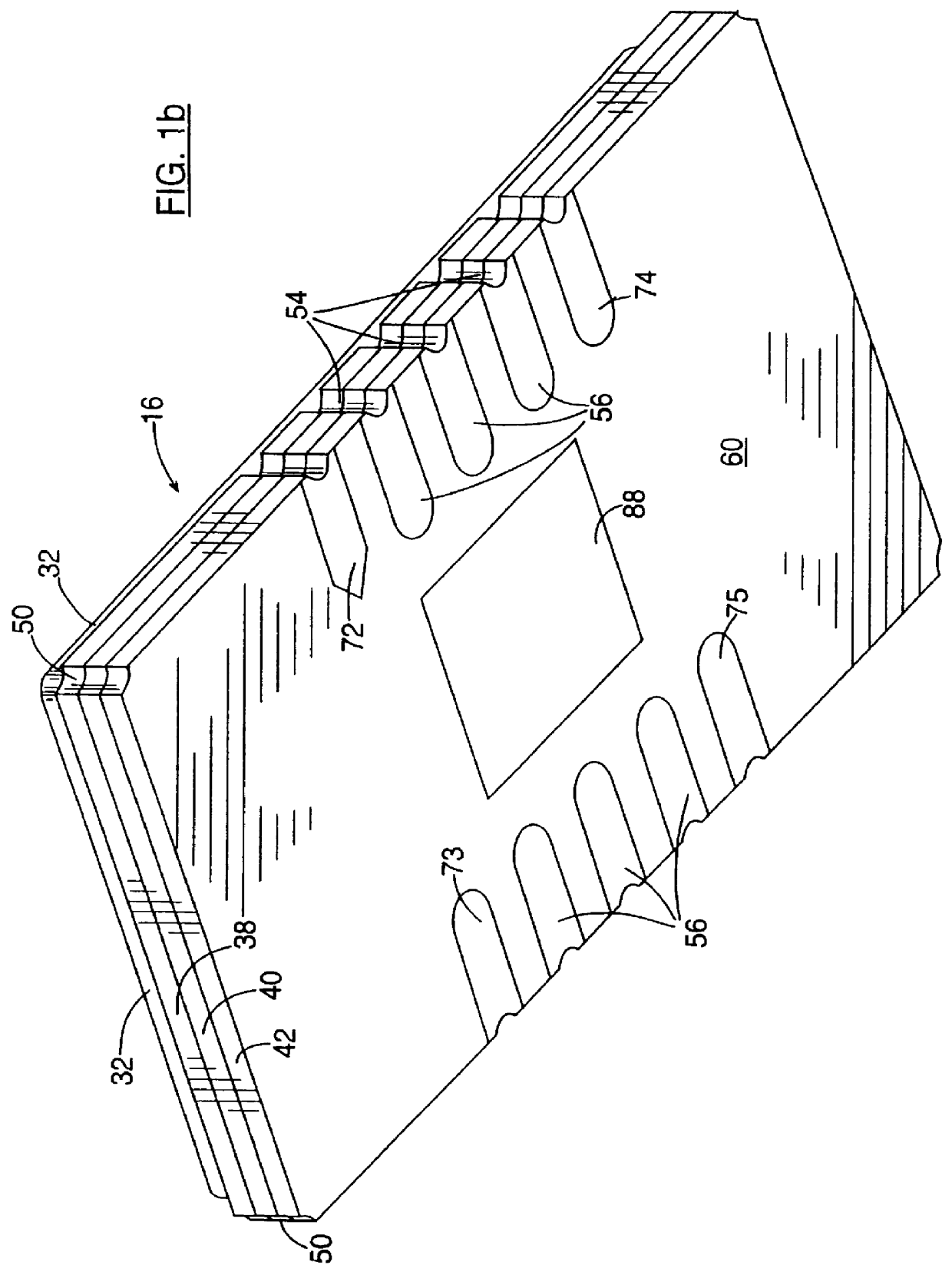

Exercise device with elongate flexible member

InactiveUS20050049123A1Ensure sufficient separationReduce instabilityStiltsMuscle exercising devicesEngineeringExercise balance

The present invention is directed to an exercise device that enhances a body workout by requiring a user to maintain balance while exercising. The exercise device has an elongate flexible member connected to a base. The flexible member has an upper surface and a lower surface. The upper surface has a pair of foot placement portions configured and arranged such that a user positioned thereon must exercise balance. The foot placement portions are separated along the longitudinal axis such that a user standing thereon assumes an athletic stance.

Owner:ICON IP

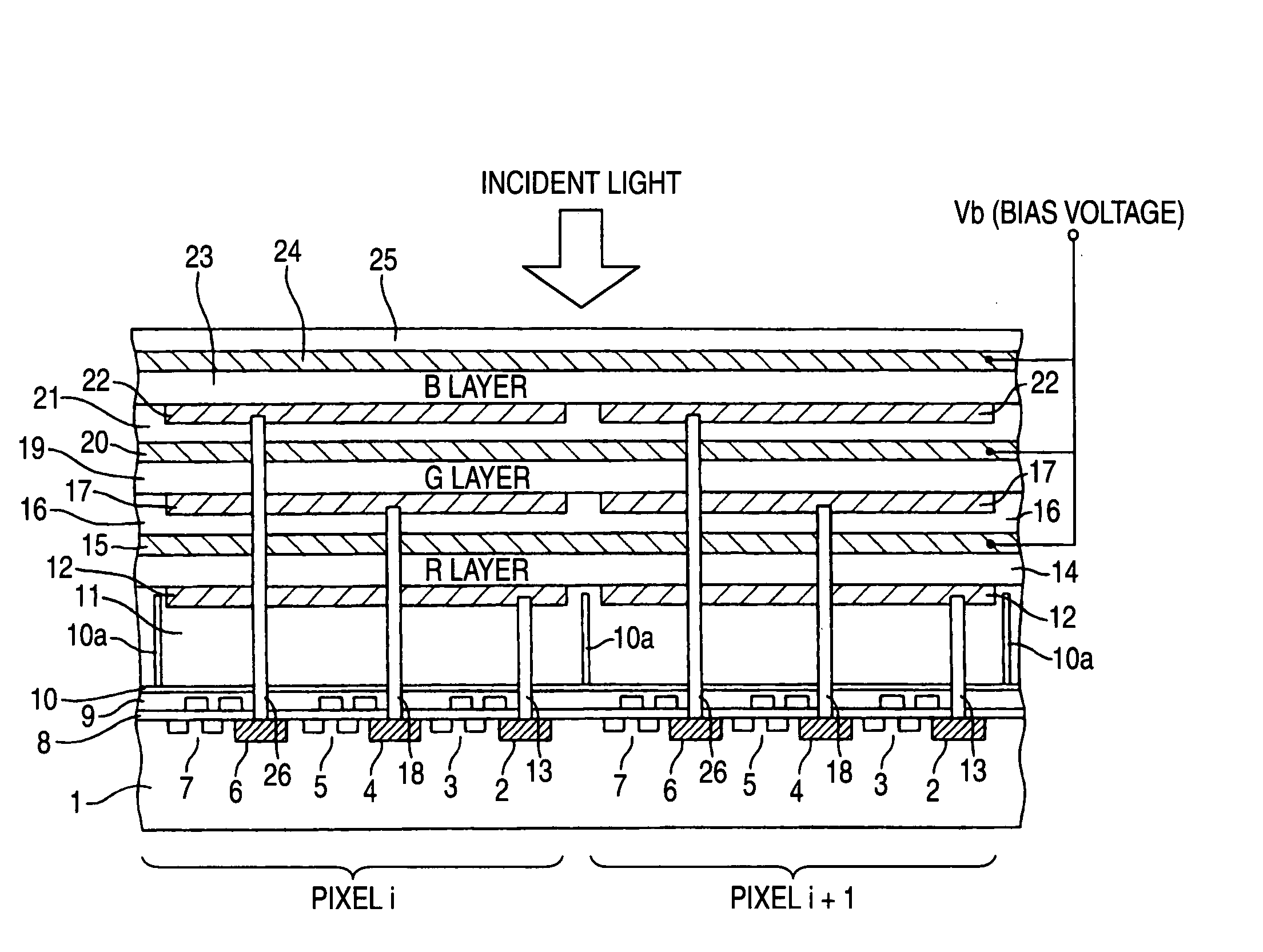

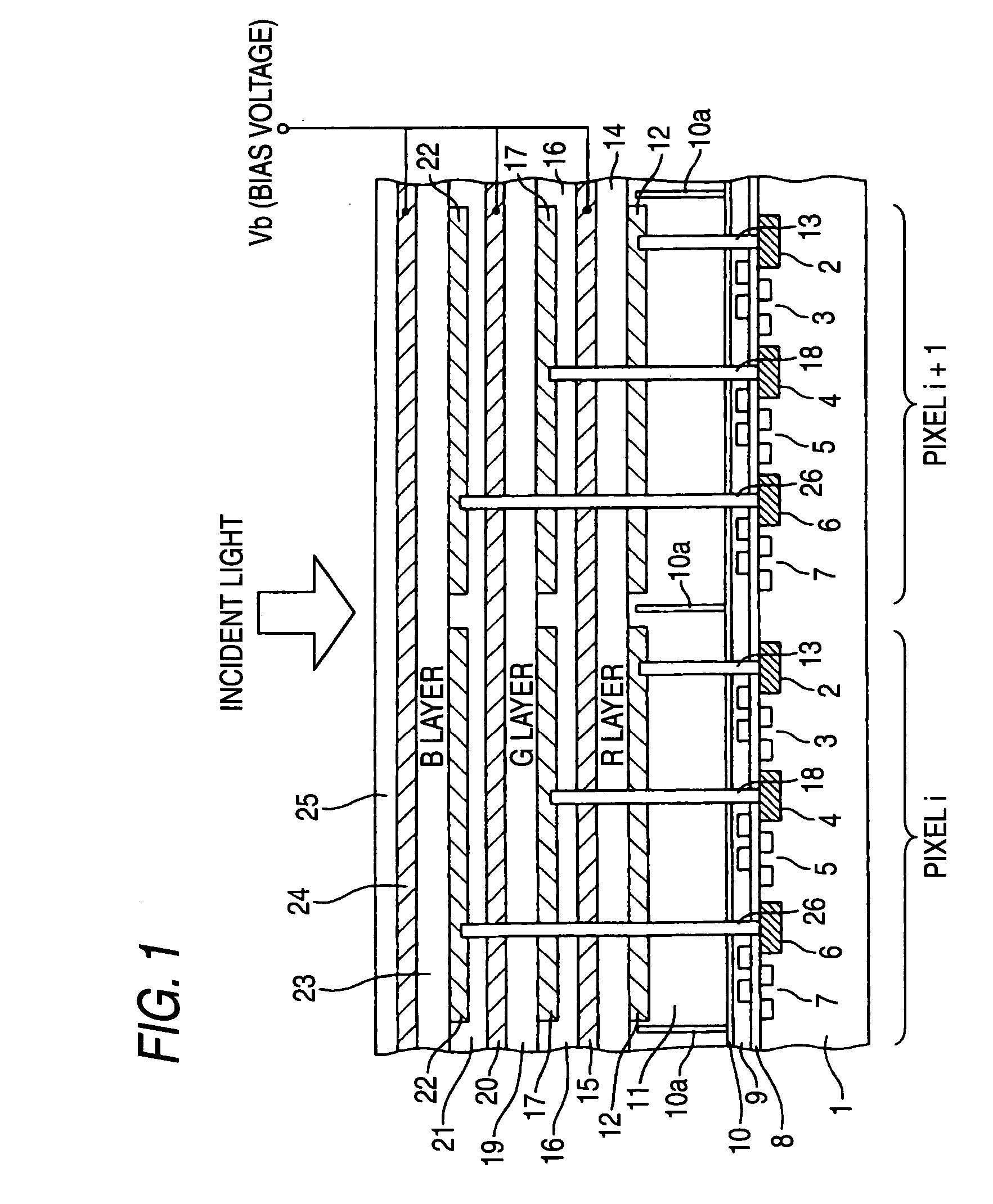

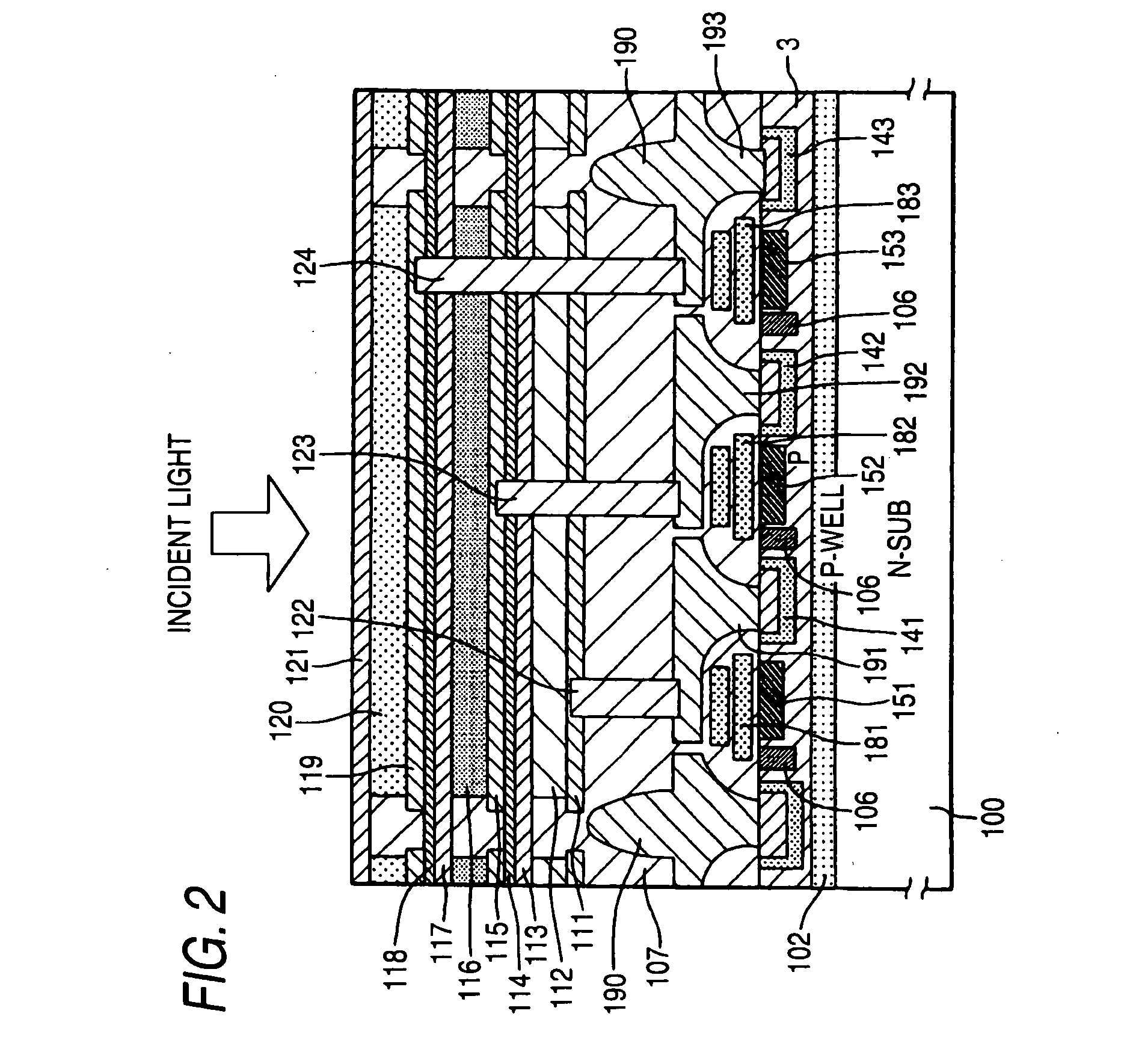

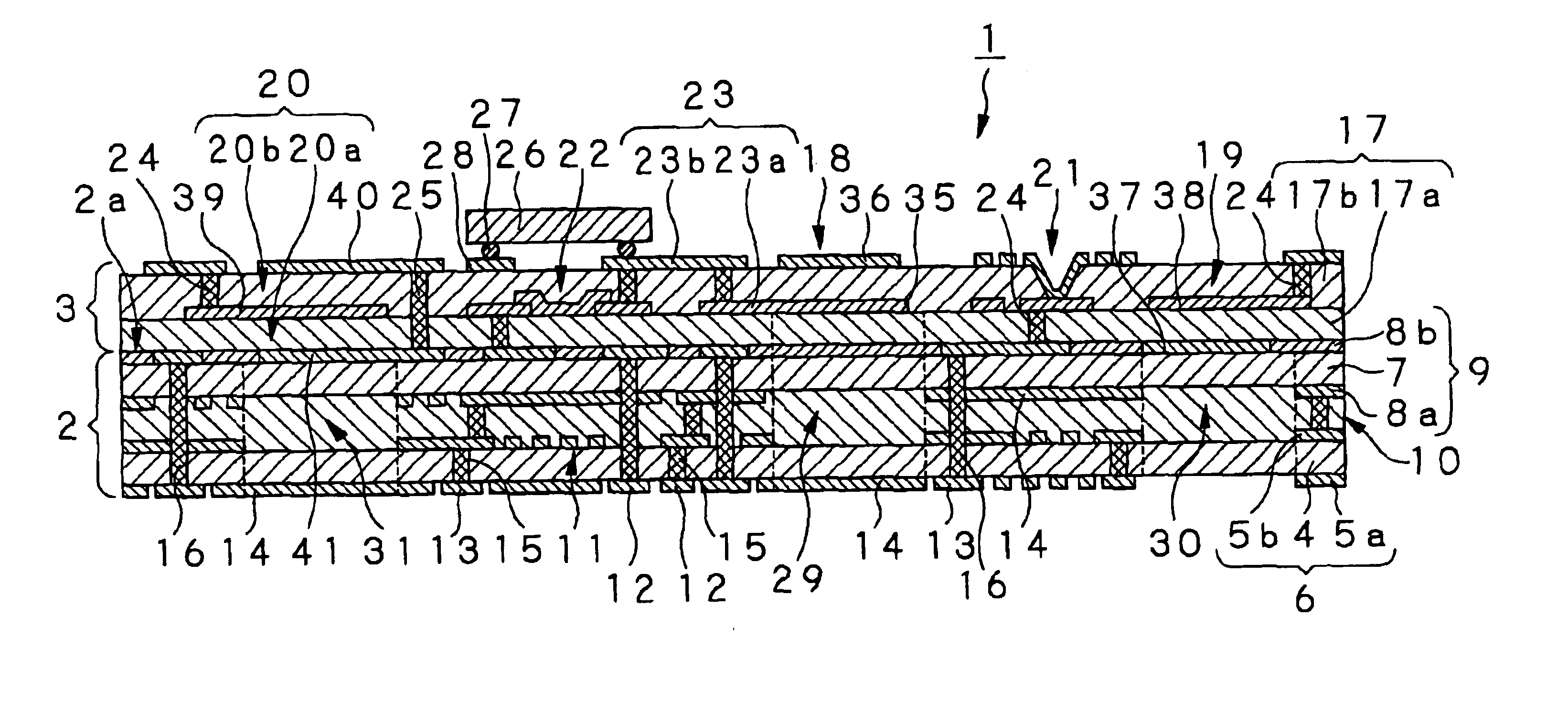

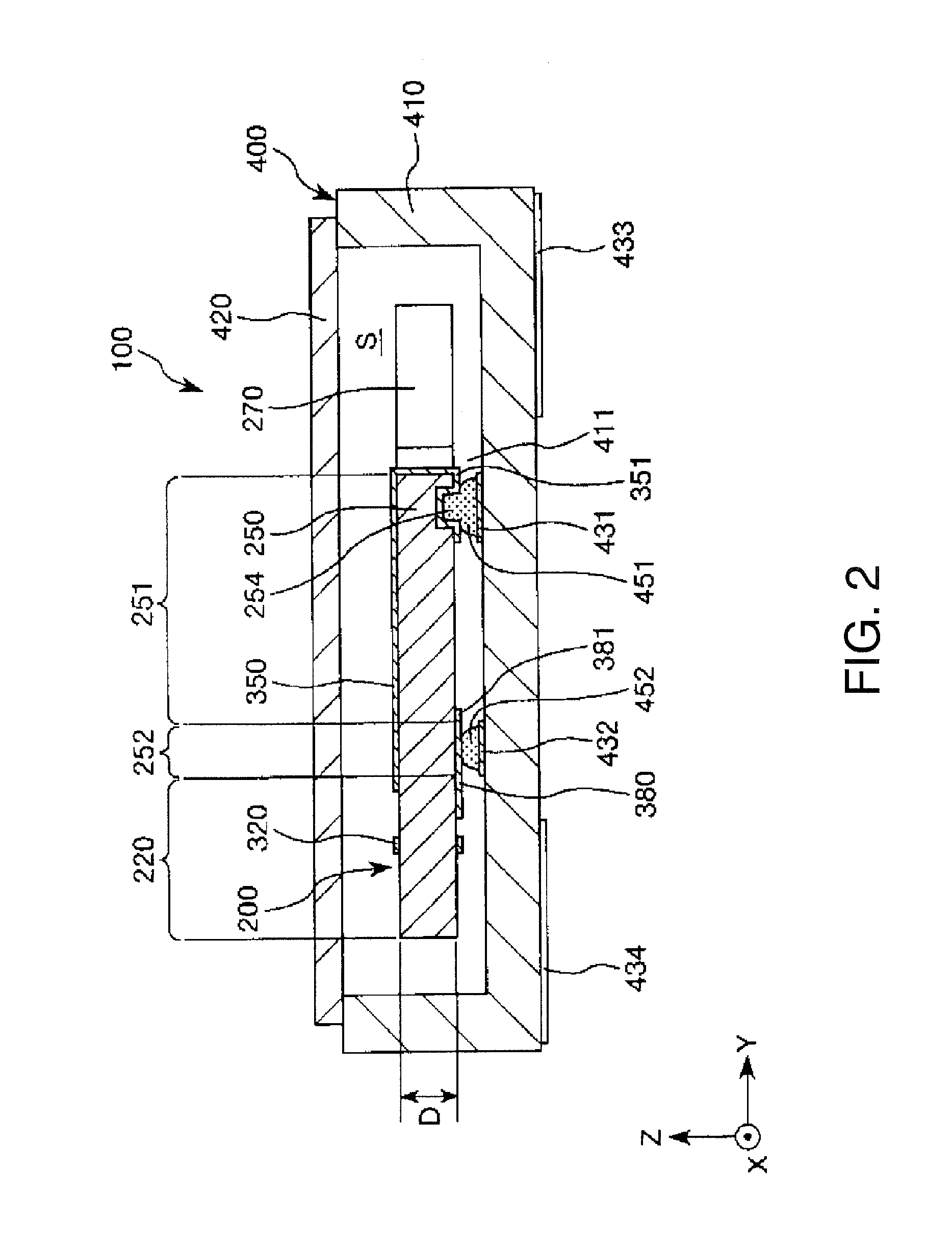

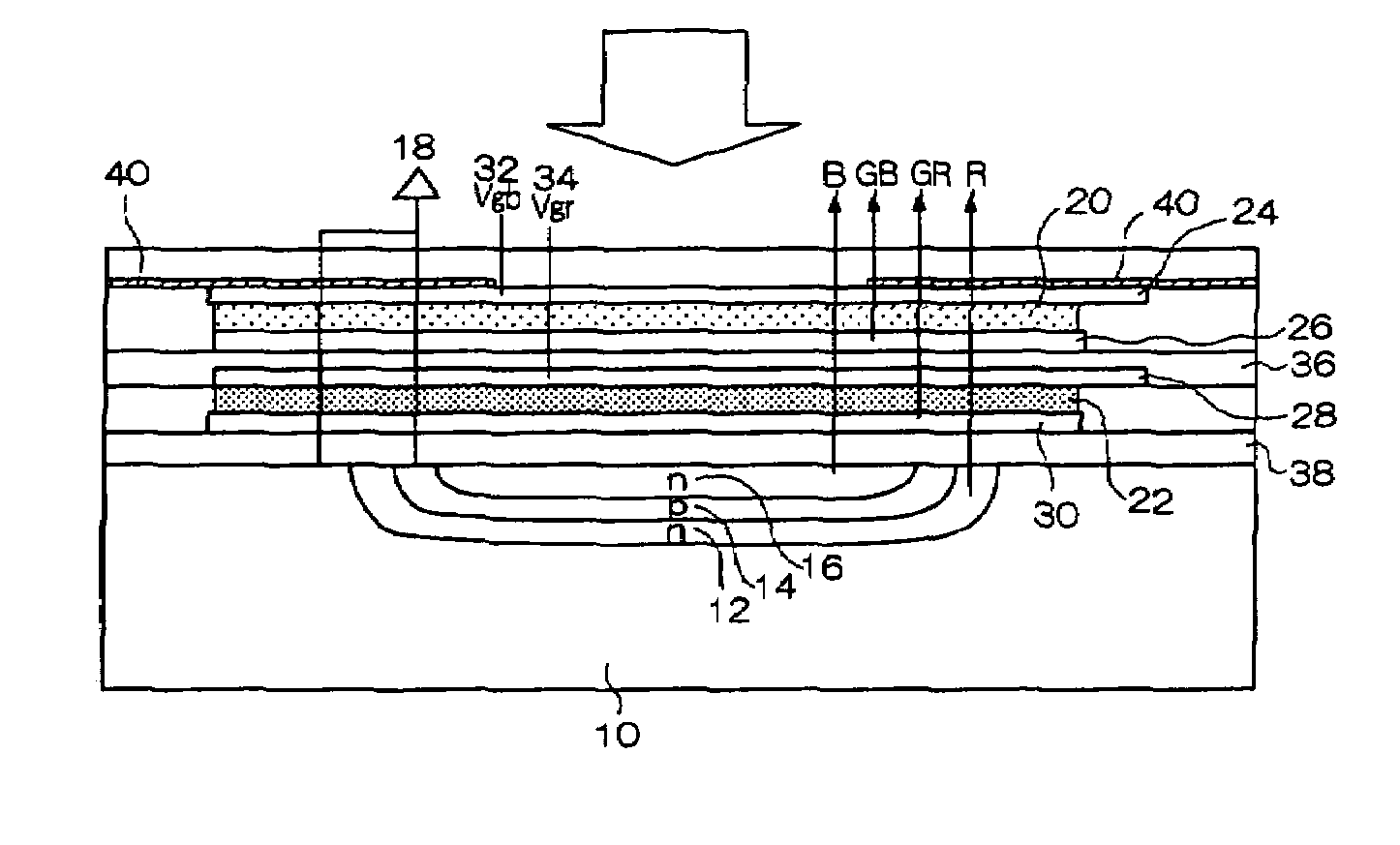

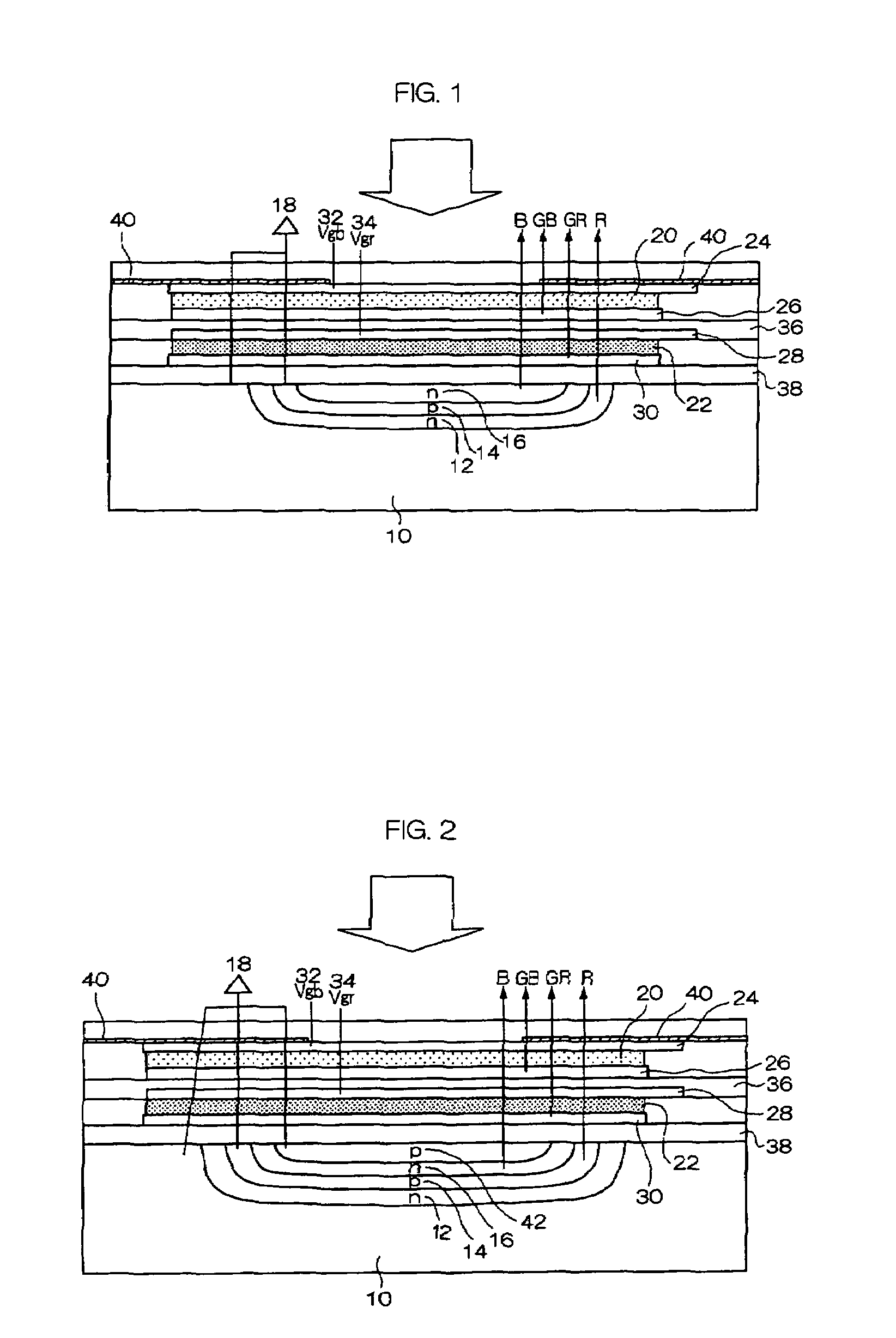

Photoelectric conversion layer-stacked solid-state imaging element

InactiveUS20060181629A1High-quality color imageEnsure sufficient separationTelevision system detailsTelevision system scanning detailsPhotoelectric conversionSemiconductor

A photoelectric conversion layer-stacked solid-state imaging element comprises: a semiconductor substrate having a signal reading circuit formed thereon; at least one layer of photoelectric conversion layer each of which is provided interposed between a common electrode layer and a plurality of pixel electrode layers corresponding to pixels, said at least one layer of photoelectric conversion layer being stacked above the semiconductor substrate via a light shielding layer; and inhibiting structures each of which inhibits a reflected light produced by reflection of incident light on the light shielding layer, the incident light having passed through said at least one layer of photoelectric conversion layer and entered into a pixel, from entering in direction toward adjacent pixels.

Owner:FUJIFILM CORP

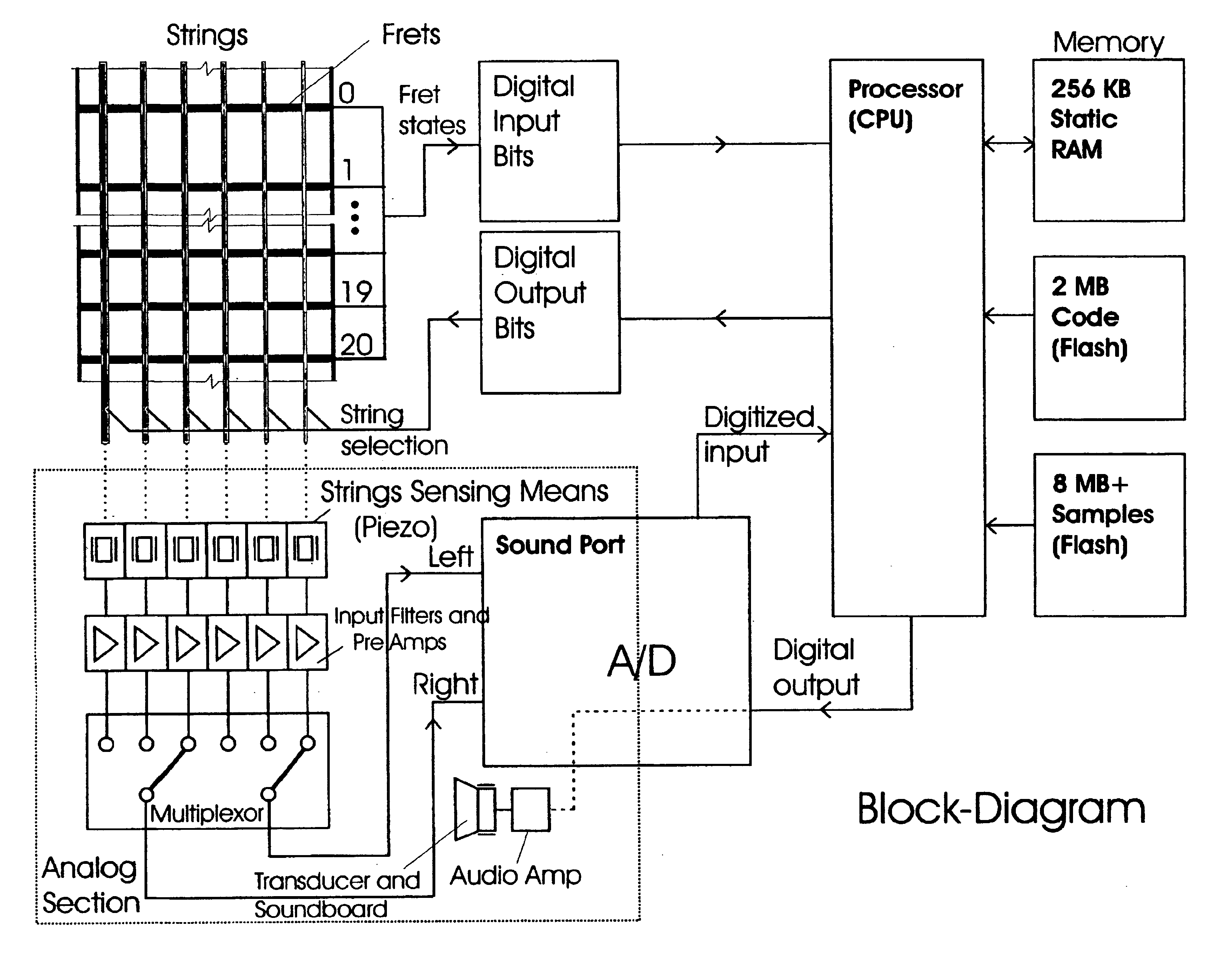

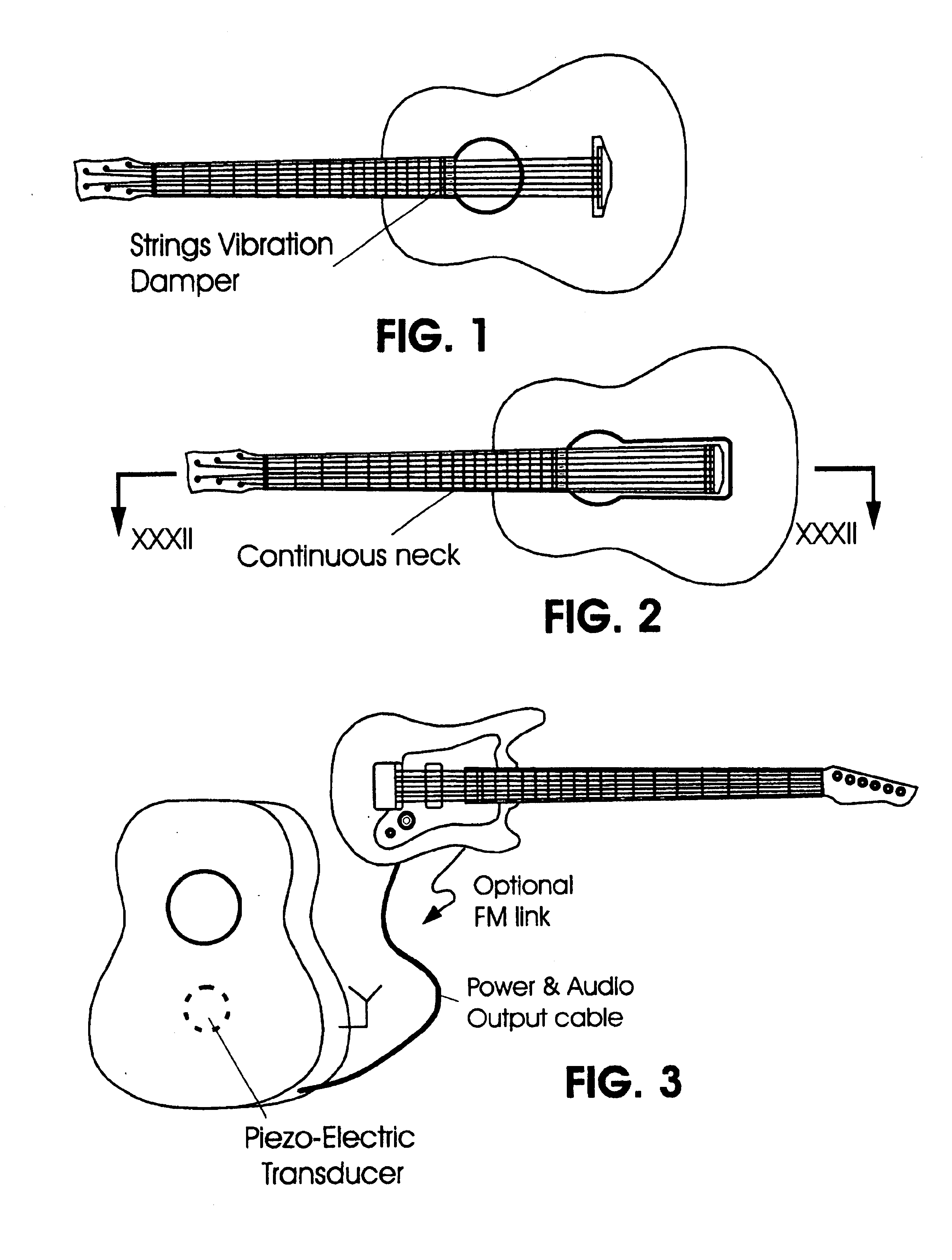

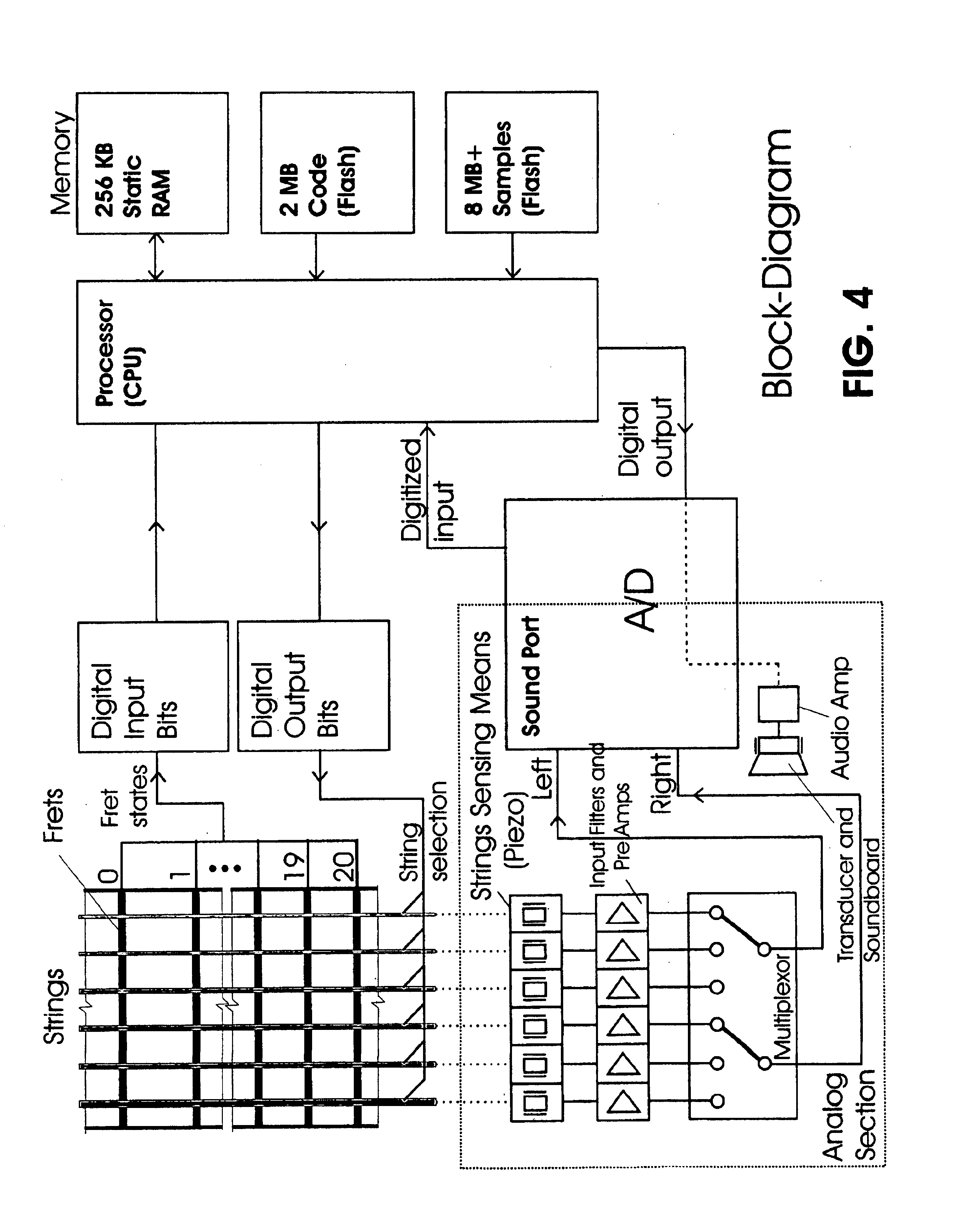

Electronic-acoustic guitar with enhanced sound, chord and melody creation system

InactiveUS6846980B2Overcome disadvantagesLow costVibration measurement in solidsElectrophonic musical instrumentsElectricityEngineering

An electronic battery operated and self contained acoustic guitar allowing playing back high quality prerecorded notes through its own soundboard electromechanically activated by a piezoelectric vibrating means. The guitar allows to play chords or melody with simplified fingering and provides trigger events (note ON, Off, velocity of the note played) with less than 15 ms delay. When the guitar is not powered it can be played as a normal high quality musical instrument.

Owner:IPR INNOVATIVE PROD RESOURCES

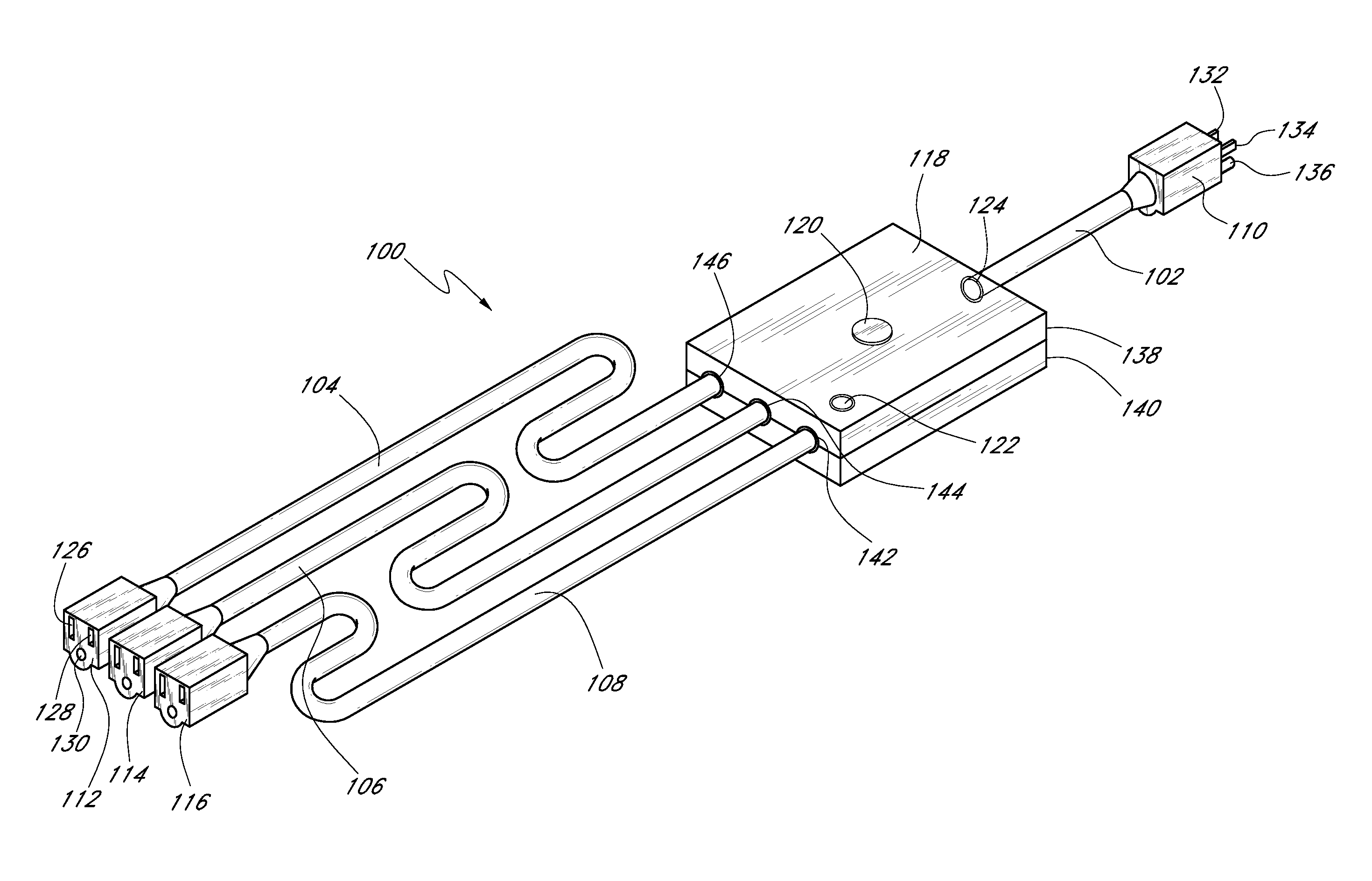

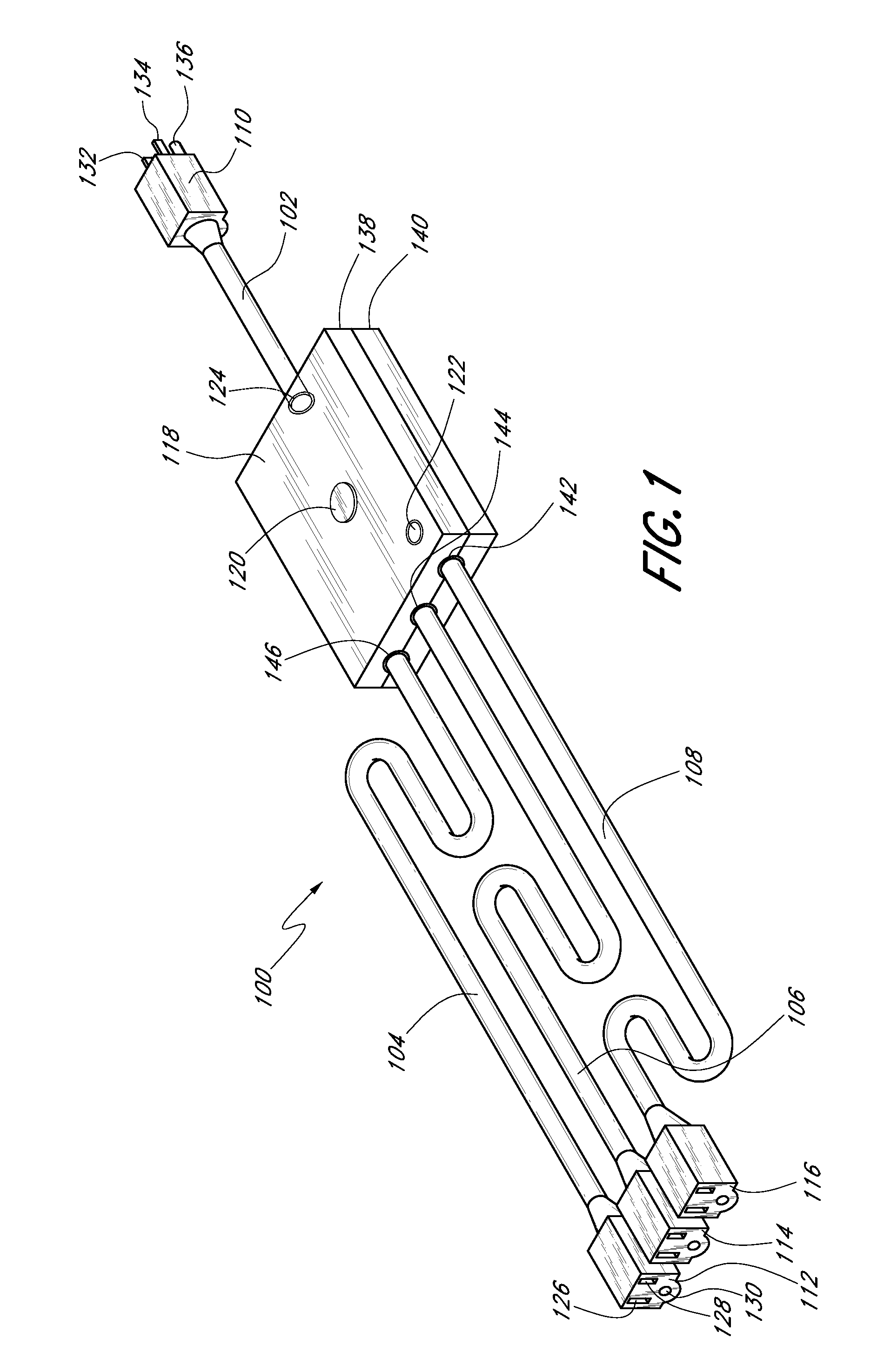

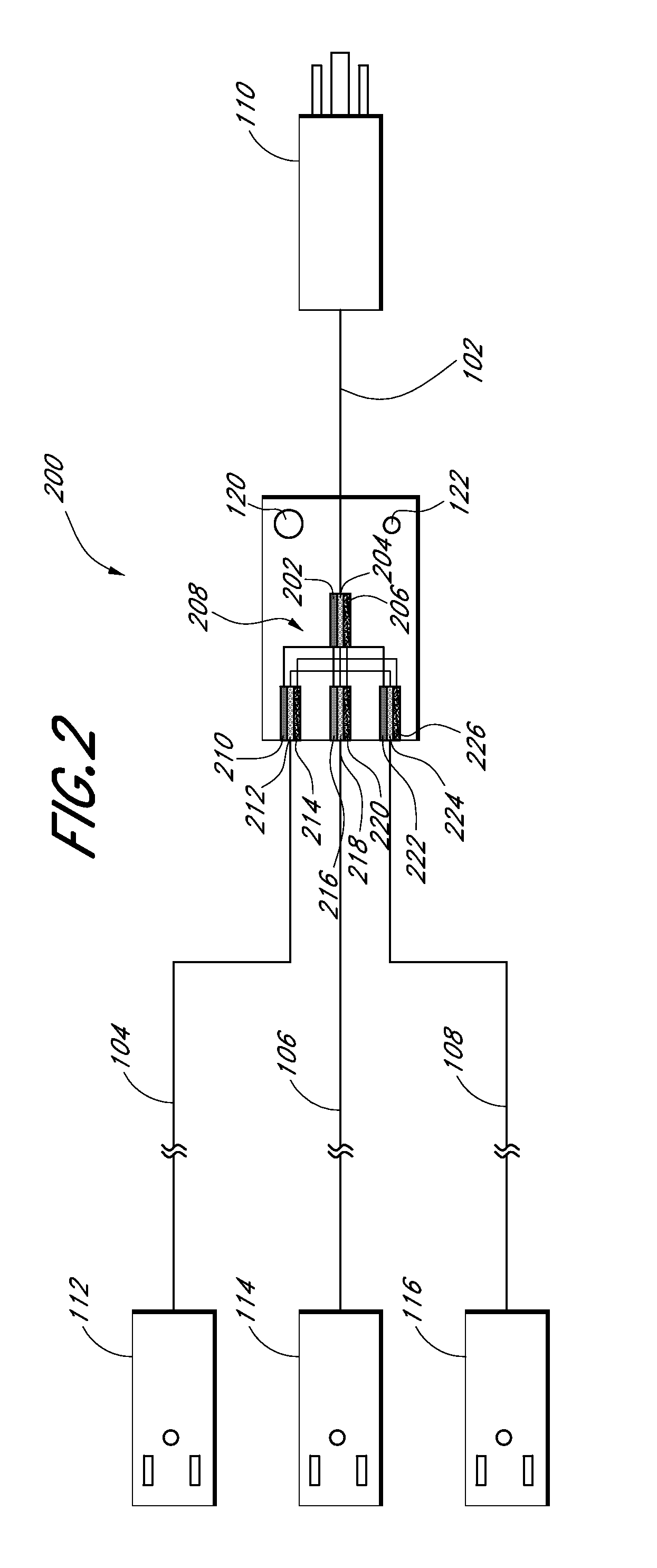

Electrical extension cord

InactiveUS20100090851A1Ensure sufficient separationIncreased durabilityCoupling device detailsElectric connection structural associationsElectricityCoupling

An electrical extension cord to conduct and provide electrical power to multiple locations on a job site includes a power supply portion having an electrical connector configured to be received in an electrical outlet that provides a source of electricity. The extension cord includes a power distribution portion having at least a first electrical cord and at least a second electrical cord with each cord having an electrical connector configured to receive a mating connector of an electrically powered device and the extension cord further includes a junction that electrically couples the power supply portion and the power distribution portion with the coupling being enclosed by a housing. The first cord and the second electrical cord define a length of at least six feet measured from the housing.

Owner:HAUSER BRUCE

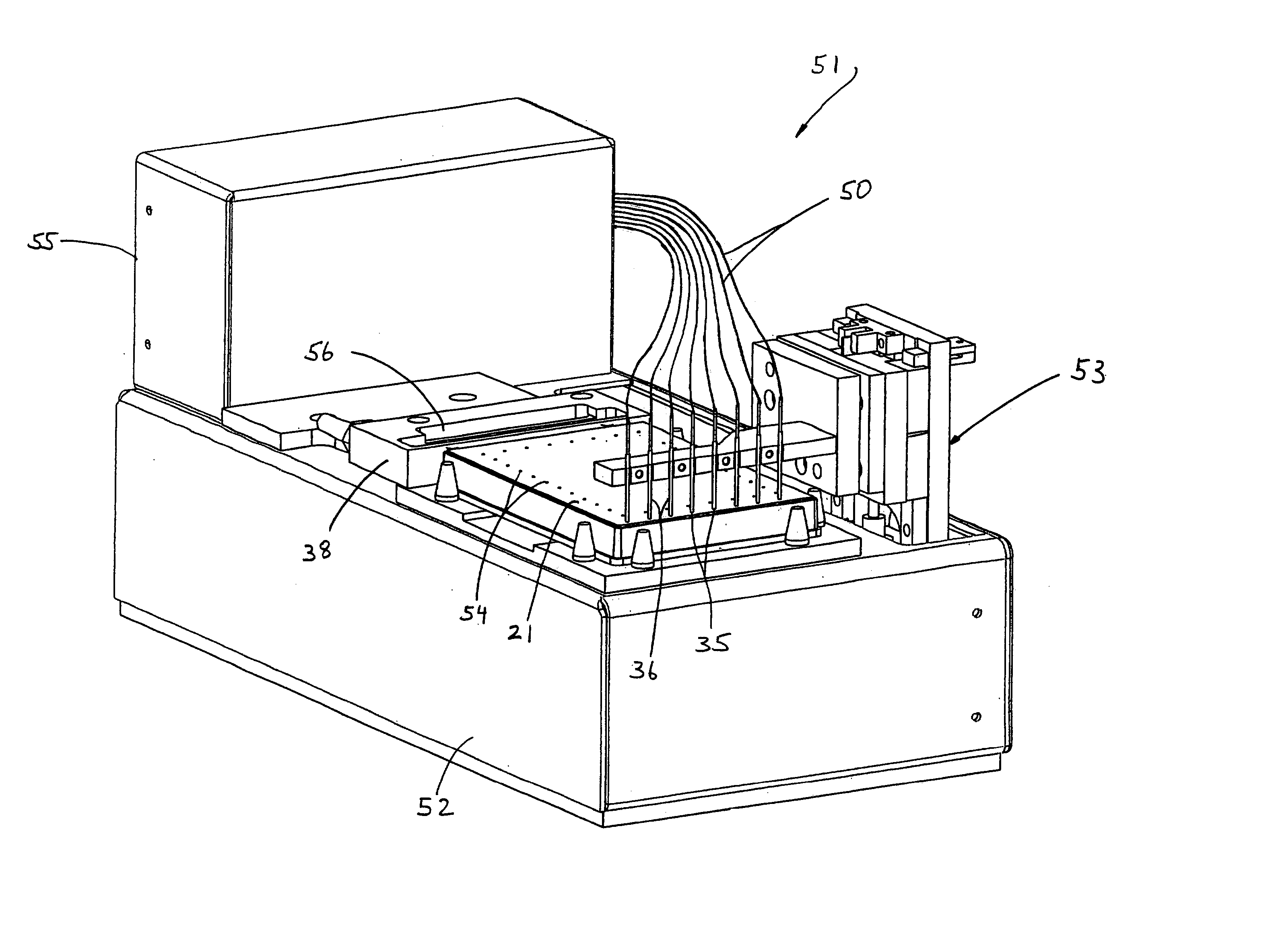

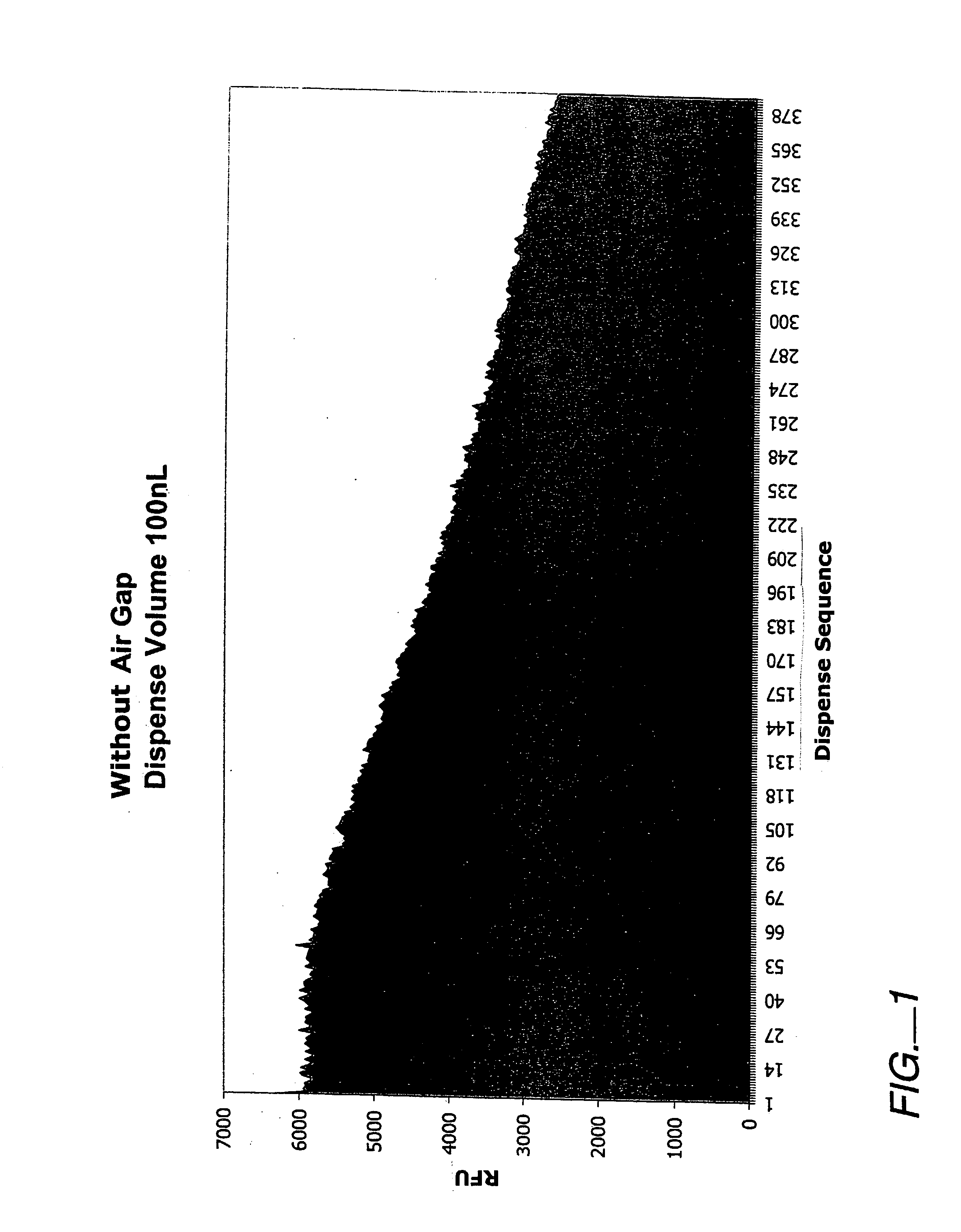

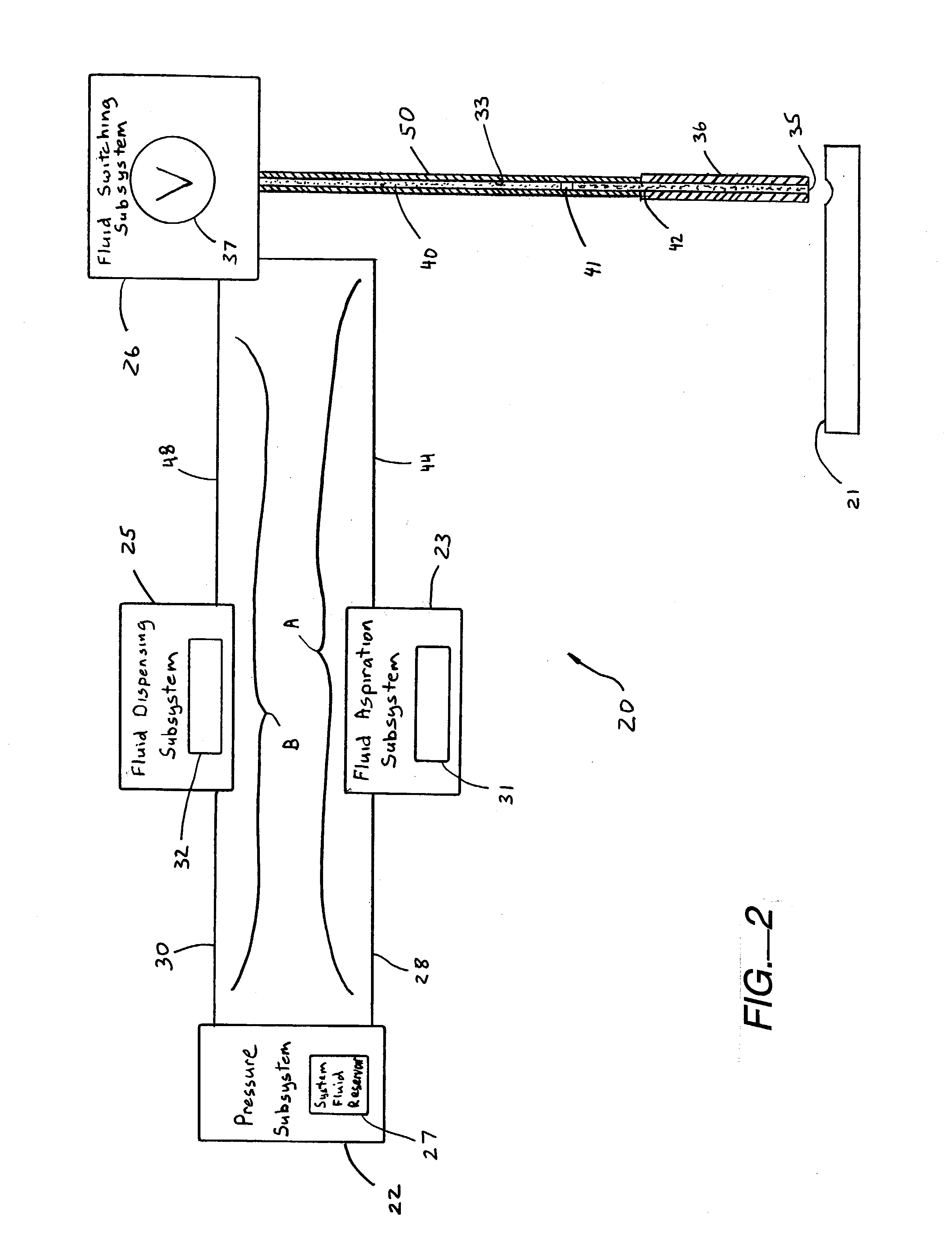

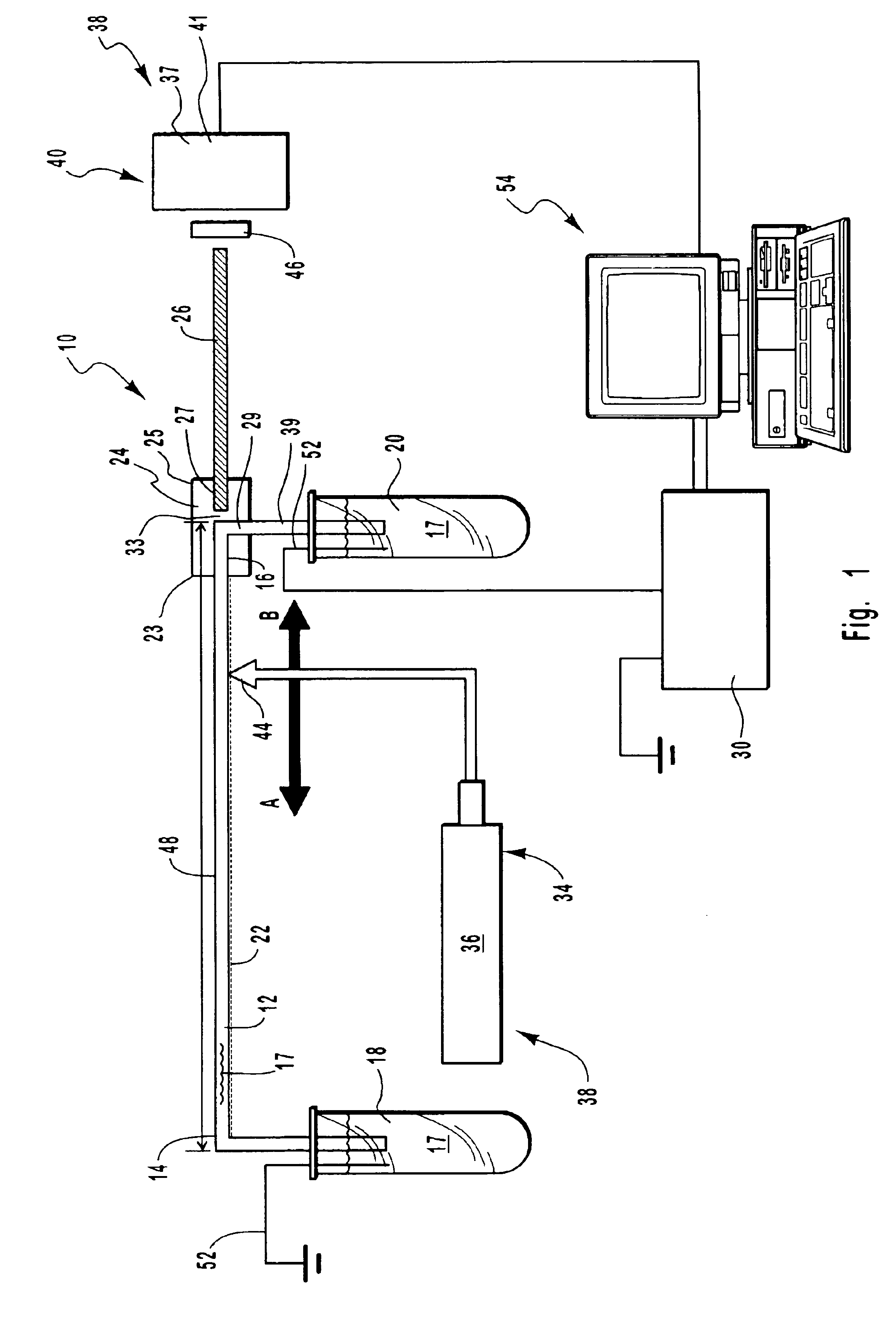

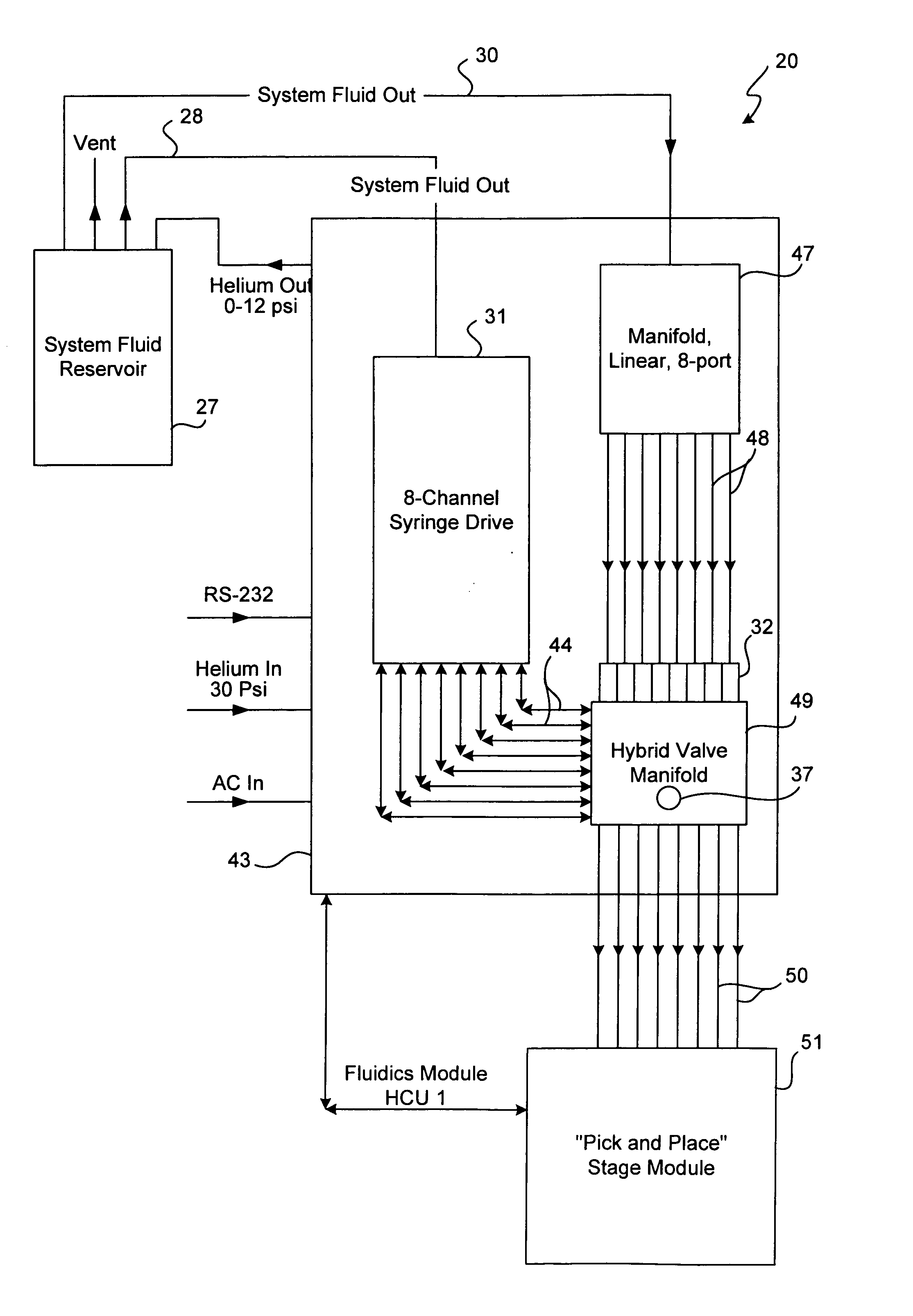

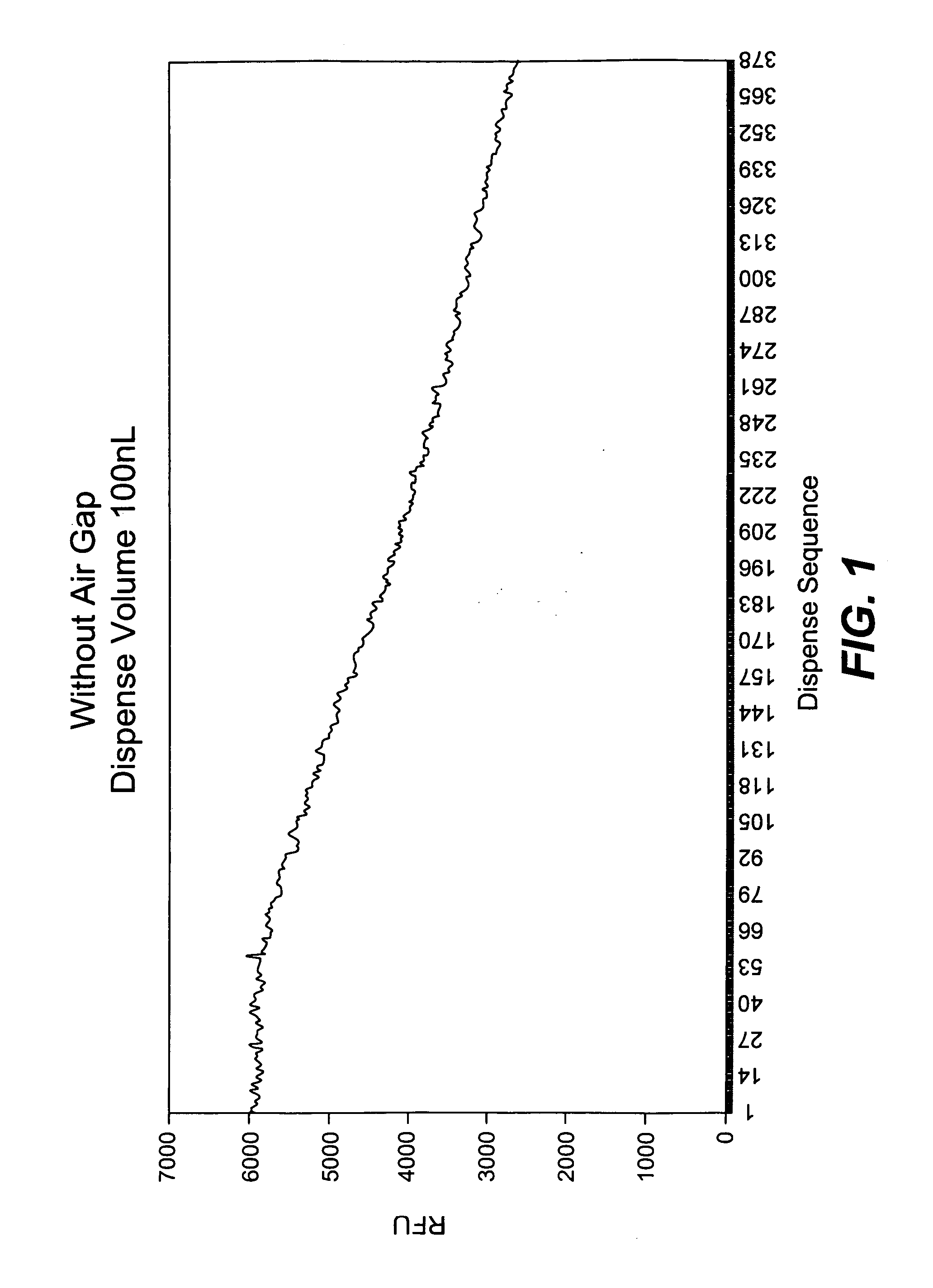

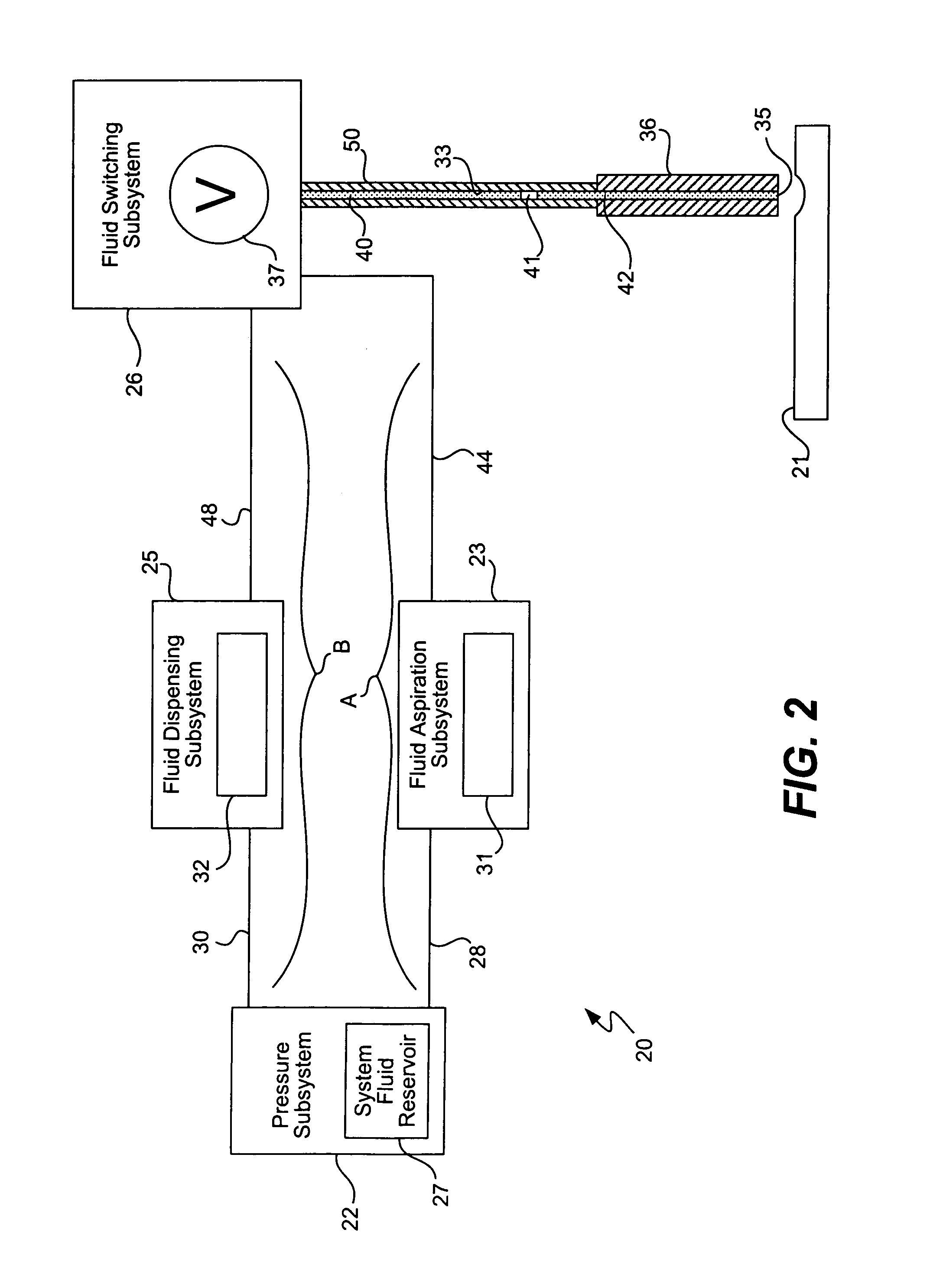

High performance, low volume, non-contact liquid dispensing apparatus and method

ActiveUS20030170903A1Ensure sufficient separationMinimize dispersion and dilutionLavatory sanitoryBurettes/pipettesEngineeringMechanical engineering

An apparatus and method for delivering repetitive, precision, low volume liquid dispensing from a dispensing orifice of a non-contact liquid dispensing apparatus. An elongated communication passageway of the dispensing apparatus is defined by interior walls having one end in fluid communication with a system fluid reservoir and an opposite end terminating at the dispensing orifice. A system fluid is placed in the communication passageway extending substantially continuously from the system fluid reservoir to the dispensing orifice. A relatively small volume of gaseous fluid is aspirated through the dispensing orifice, and into the communication passageway in a manner such that the gaseous fluid extends substantially continuously across the transverse cross-sectional dimension of the communication passageway. Subsequently, a dispensing liquid is aspirated through the dispensing orifice and into the communication passageway in a manner such that the relatively small volume of aspirated gaseous fluid forms a minute, unitary air gap fully enclosed between the interior walls of the communication passageway and a liquid interface between the system fluid and the dispensing liquid contained in the communication passageway. This minute air gap substantially prevents dispersion and dilution therebetween at the liquid interface. To effect dispensing, a rapid pressure pulse with a predetermined pulse width is applied to the system fluid upstream from the minute air gap, causing the pressure pulse to traverse the minute air gap to the dispensing liquid without substantial fluid compression of the minute air gap. This enables substantially accurate, relatively small volume, non-contact liquid dispensing of the dispensing liquid from the dispensing orifice.

Owner:BIONEX SOLUTIONS

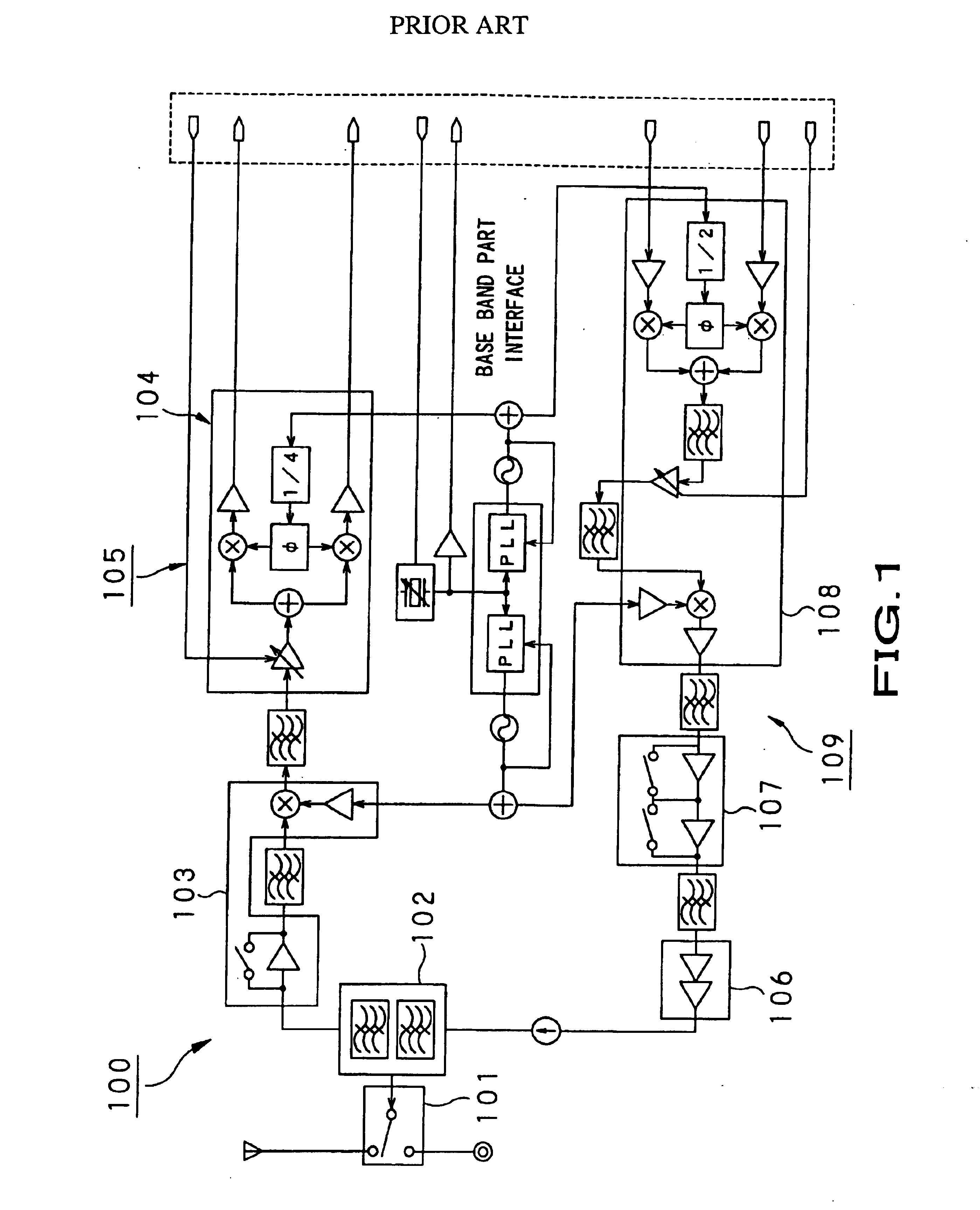

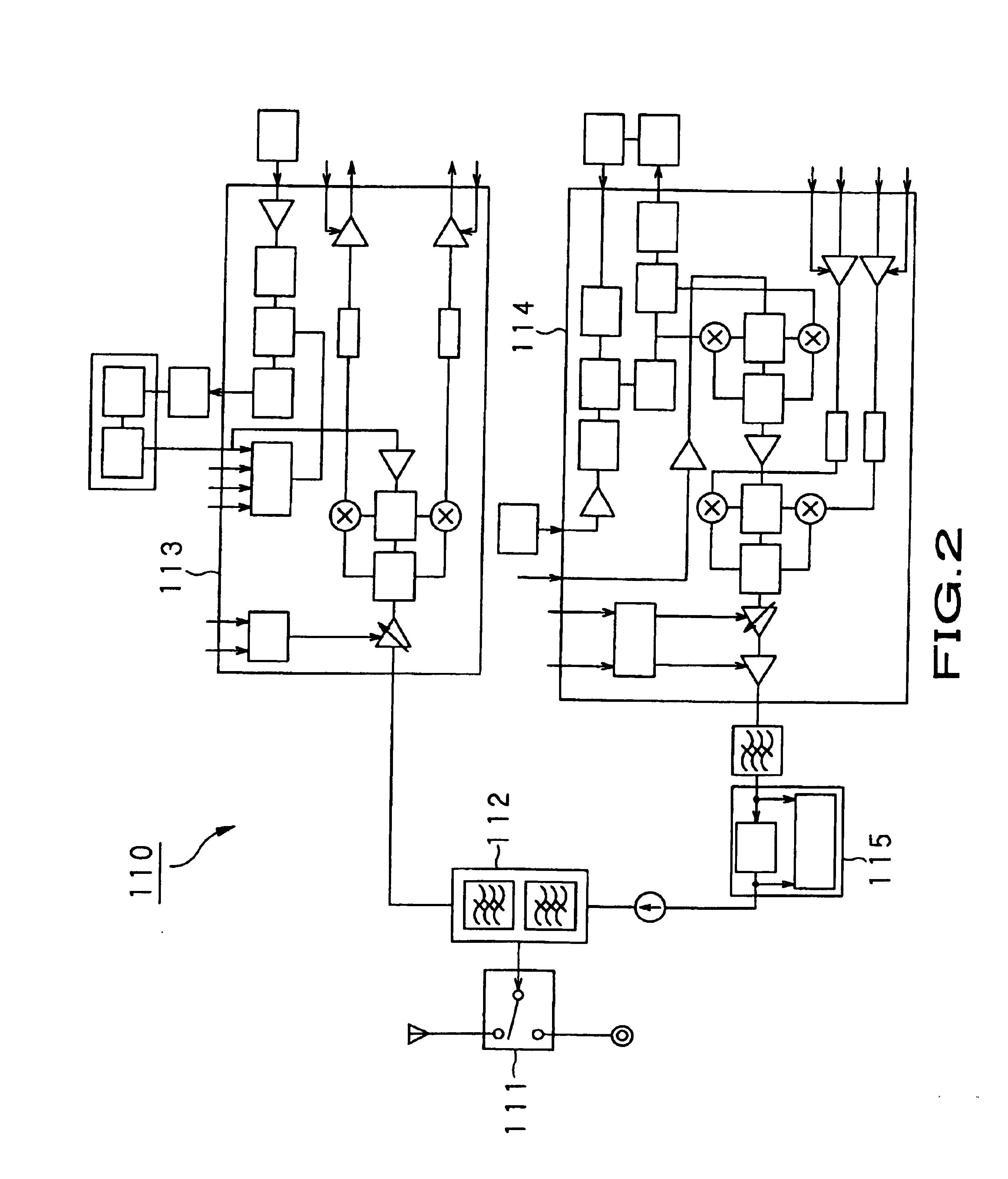

High frequency module board device

InactiveUS6889155B2Parasitic capacityGood capacitance characteristicsVehicle testingSemiconductor/solid-state device detailsParasitic capacitanceEngineering

The present invention relates to a high frequency module board device having a high frequency transmitting and receiving circuit for modulating and demodulating a high frequency signal. The high frequency module board device comprises a base board (2) whose main surface is formed as a build-up surface (2a) and a high frequency circuit part (3) formed on the build-up surface of the base board (2) and having passive elements formed. The base board (2) has an area (29) in which wiring is not formed in a lower layer from a fourth wiring layer (8b). The high frequency circuit part (3) has an upper electrode part (36) and a lower electrode part (35) in positions corresponding to the area (29) in which the wiring is not formed. Thus, since a capacitance (18) is provided just above the area (29) in which the wiring is not formed, a parasitic capacity that the capacitance (18) receives from ground patterns (14) is reduced. Accordingly, the characteristics of the capacitance (18) can be improved.

Owner:SONY CORP

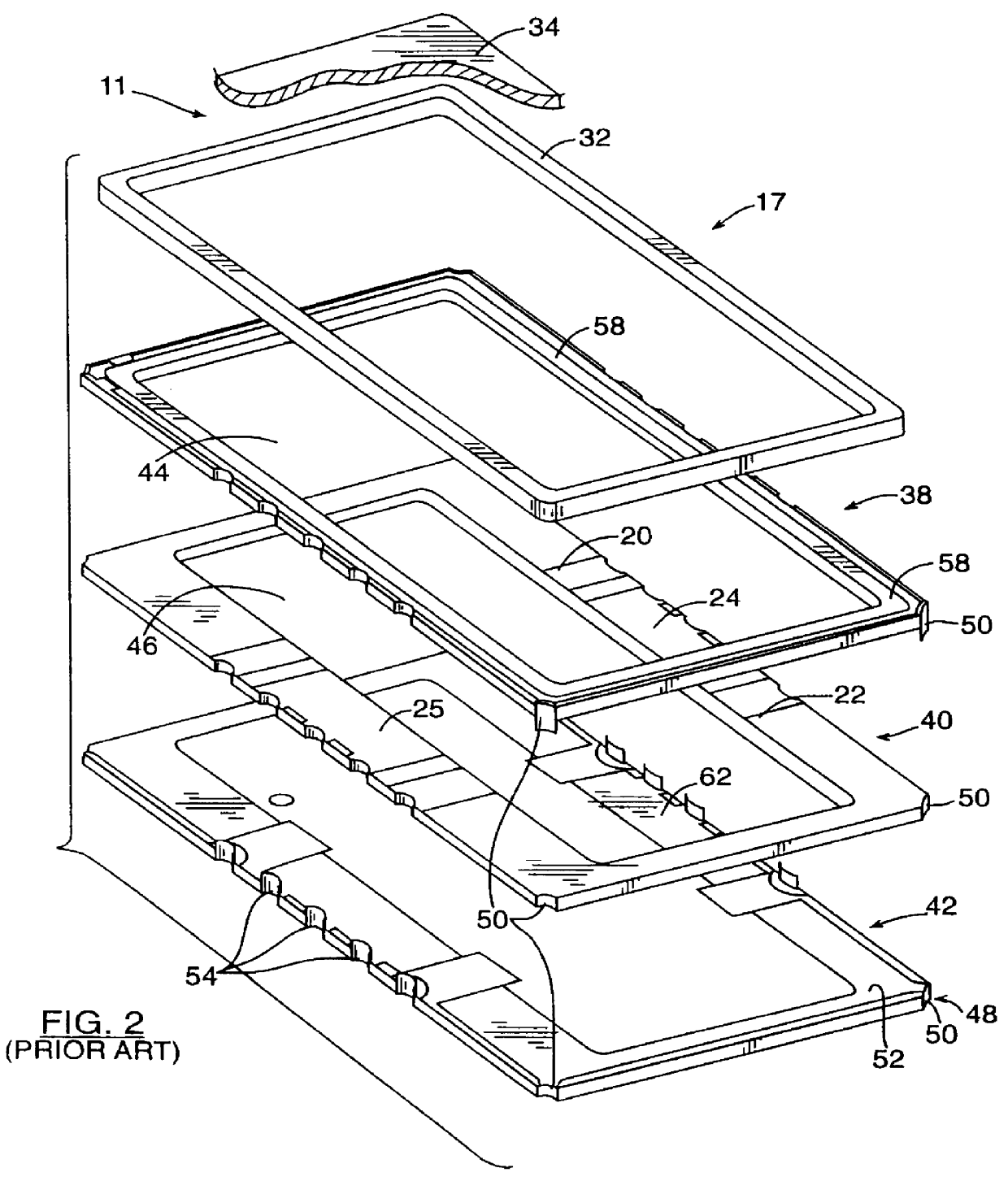

Leadless ceramic chip carrier crosstalk suppression method

InactiveUS6105226AReduce electromagnetic signal effectReduce crosstalkPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblySurface mountingElectrical connection

A leadless ceramic chip carrier useful in surface mounting of SAW devices includes electrically conductive vias and metalization between input and output bond pads for improved crosstalk suppression between input and output device connections. A protrusion extending from a top layer of a multilayer ceramic carrier provides additional electrical contact to a package seal brazed thereto. The vias are positioned between input and output bond pads and connect the metalized protrusion to package ground pads through contact with multiple metalized layers of the package for enhancing the electrical connection between the package Kovar seal ring and customer accessed ground pads. For further suppression of crosstalk, bond pads within the package for connection to the SAW device are spaced at a greater distance from each other than their corresponding pads on the package bottom surface thus maintaining an optimum spacing for package connection to printed circuit board pads for minimizing thermal mismatch effects.

Owner:TRIQUINT

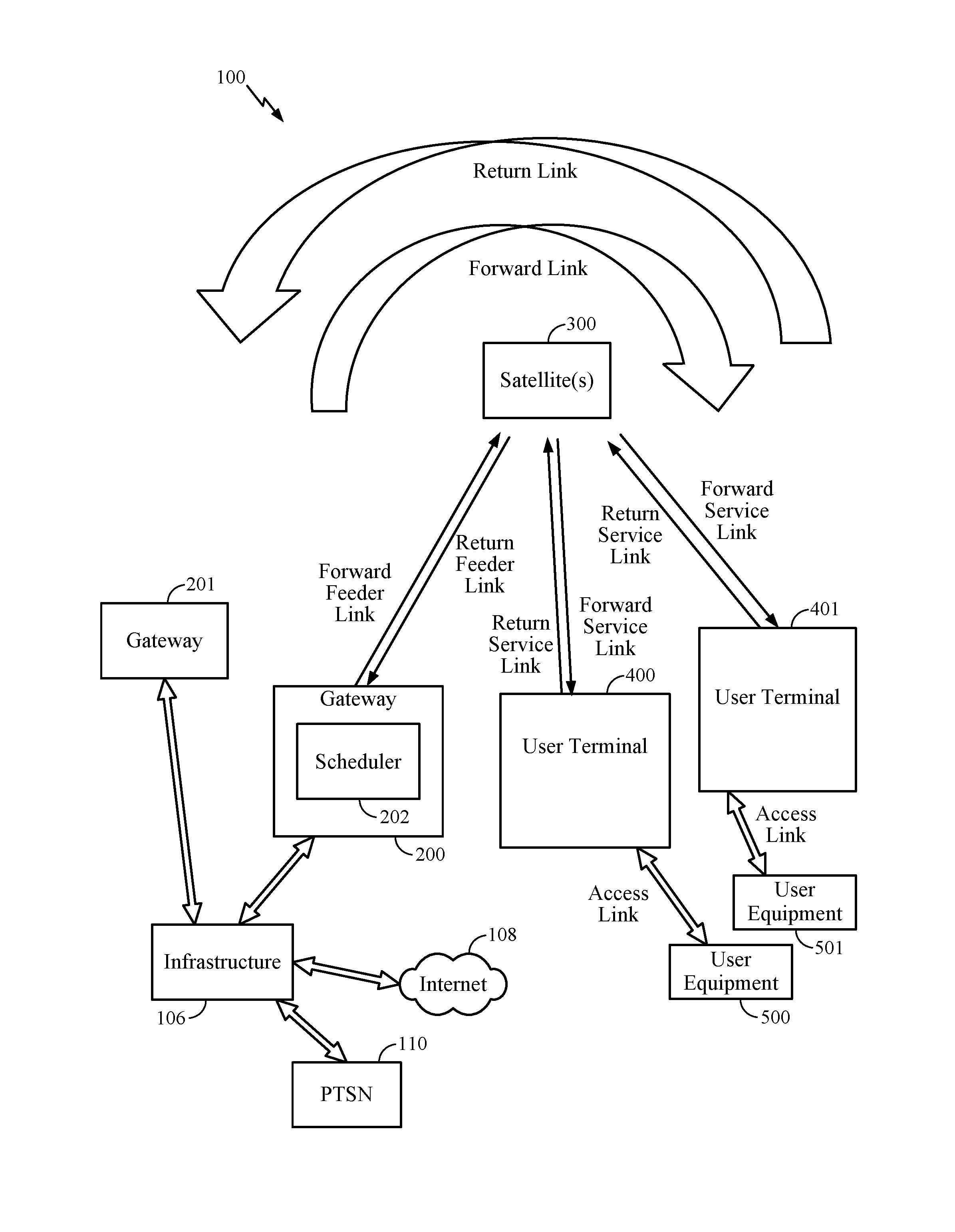

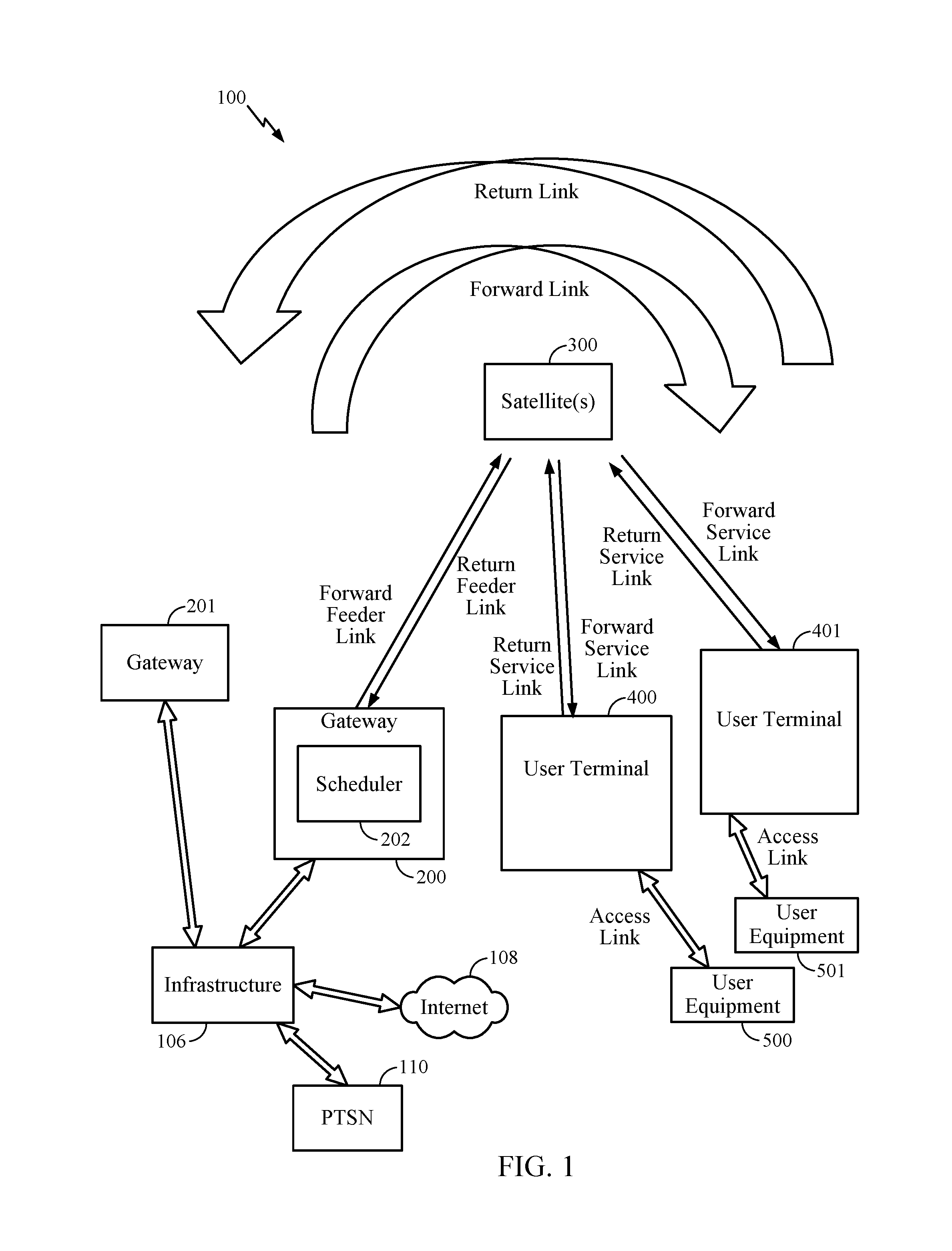

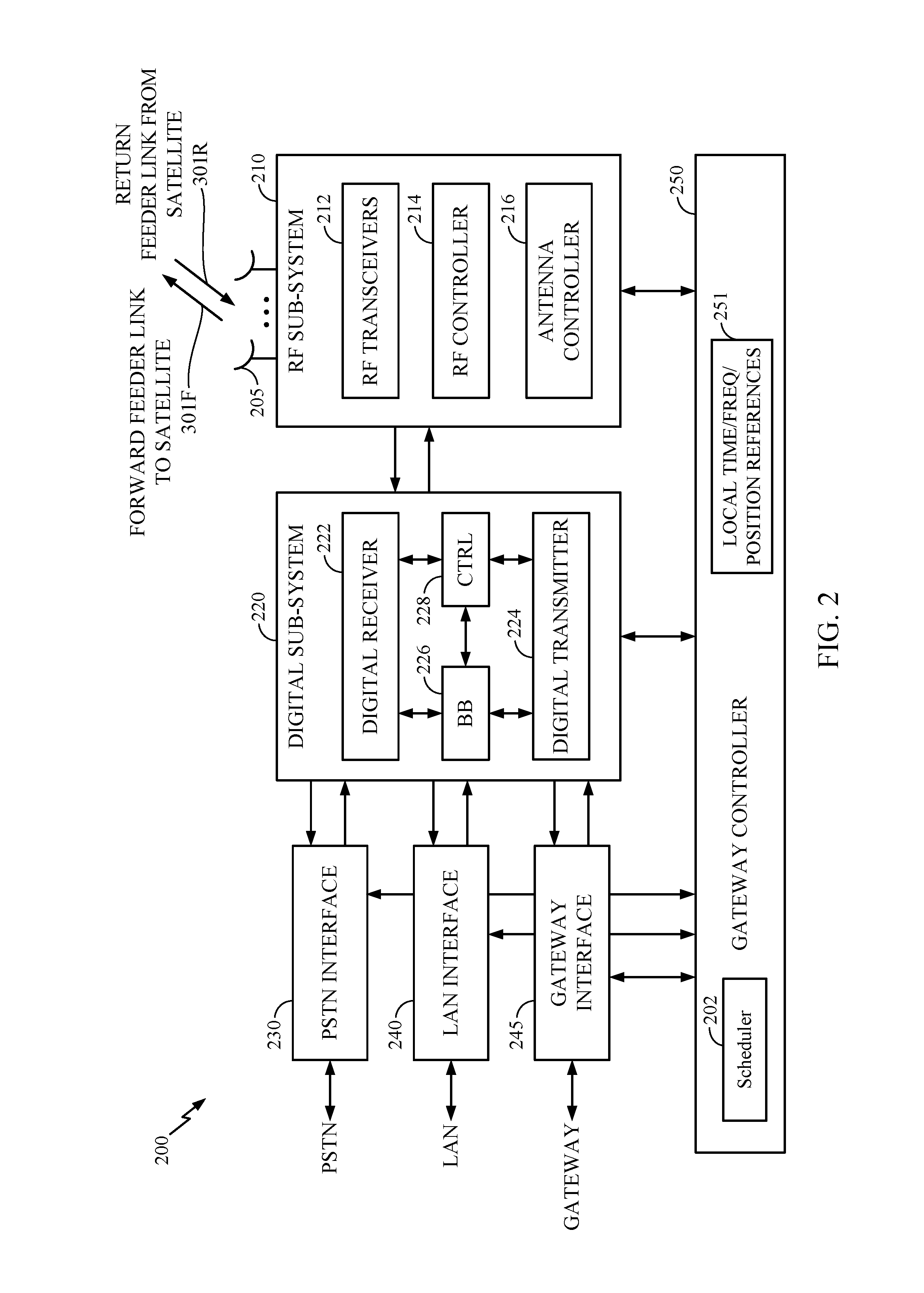

Method and apparatus for efficient data transmissions in half-duplex communication systems with large propagation delays

ActiveUS20170005741A1Efficient data transmissionEnsure sufficient separationRadio transmissionTransmission monitoringData transmissionTime lag

Methods and apparatus for efficient transmission of data by half-duplex transceivers in satellite communication systems are provided. Time reference for the return link is skewed or time-lagged relative to the time reference for the forward link to reduce the amount of guard time required to separate return link transmission from forward link reception by the half-duplex transceiver of a user terminal. The guard time is determined based on a maximum differential round-trip propagation delay and transition times of the half-duplexer transceiver to switch between transmit and receive modes. In a satellite communication system in which a large number of active user terminals are present in a beam coverage, random time offsets are applied to spread approximately equal traffic loads across the time offsets.

Owner:QUALCOMM INC

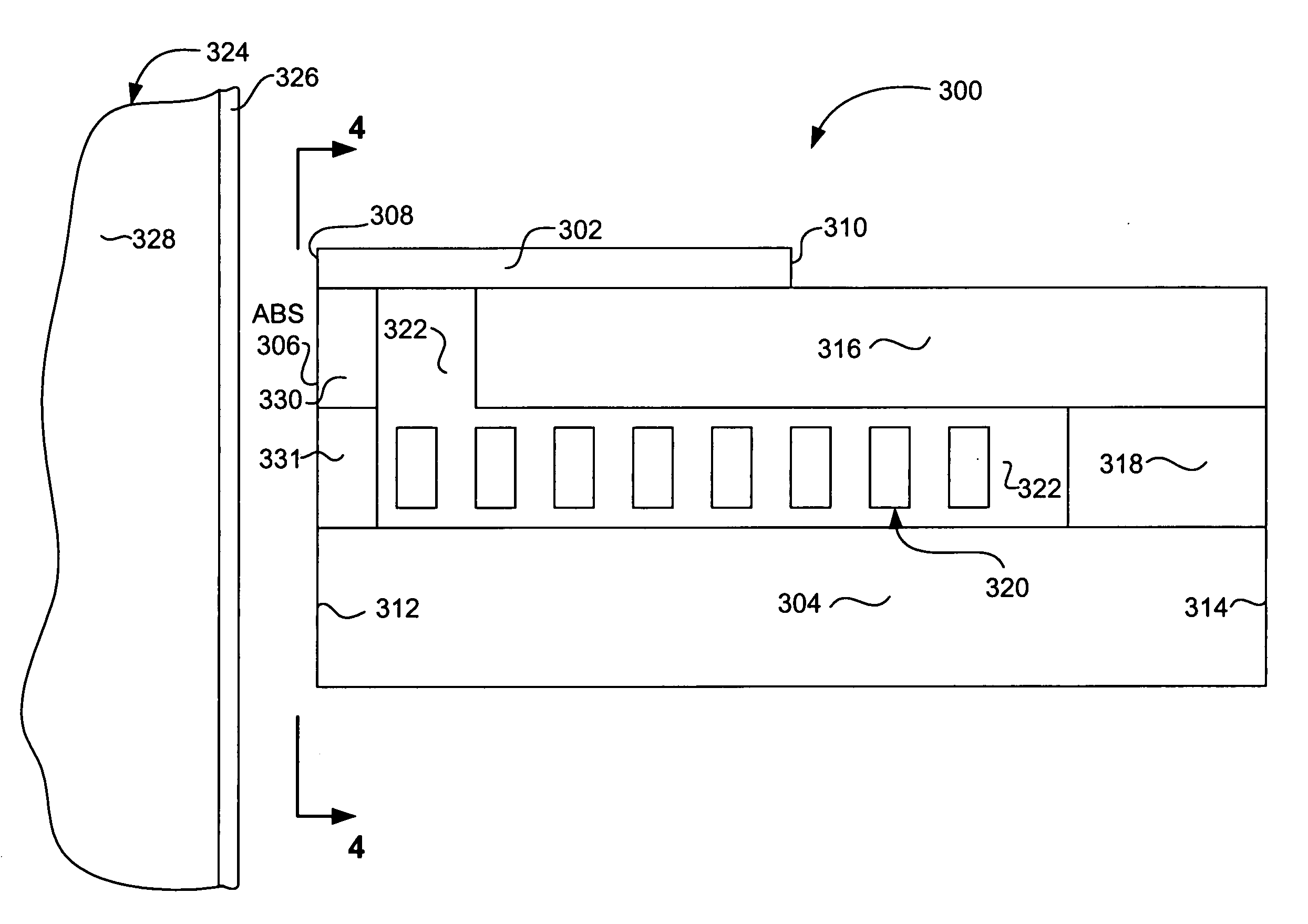

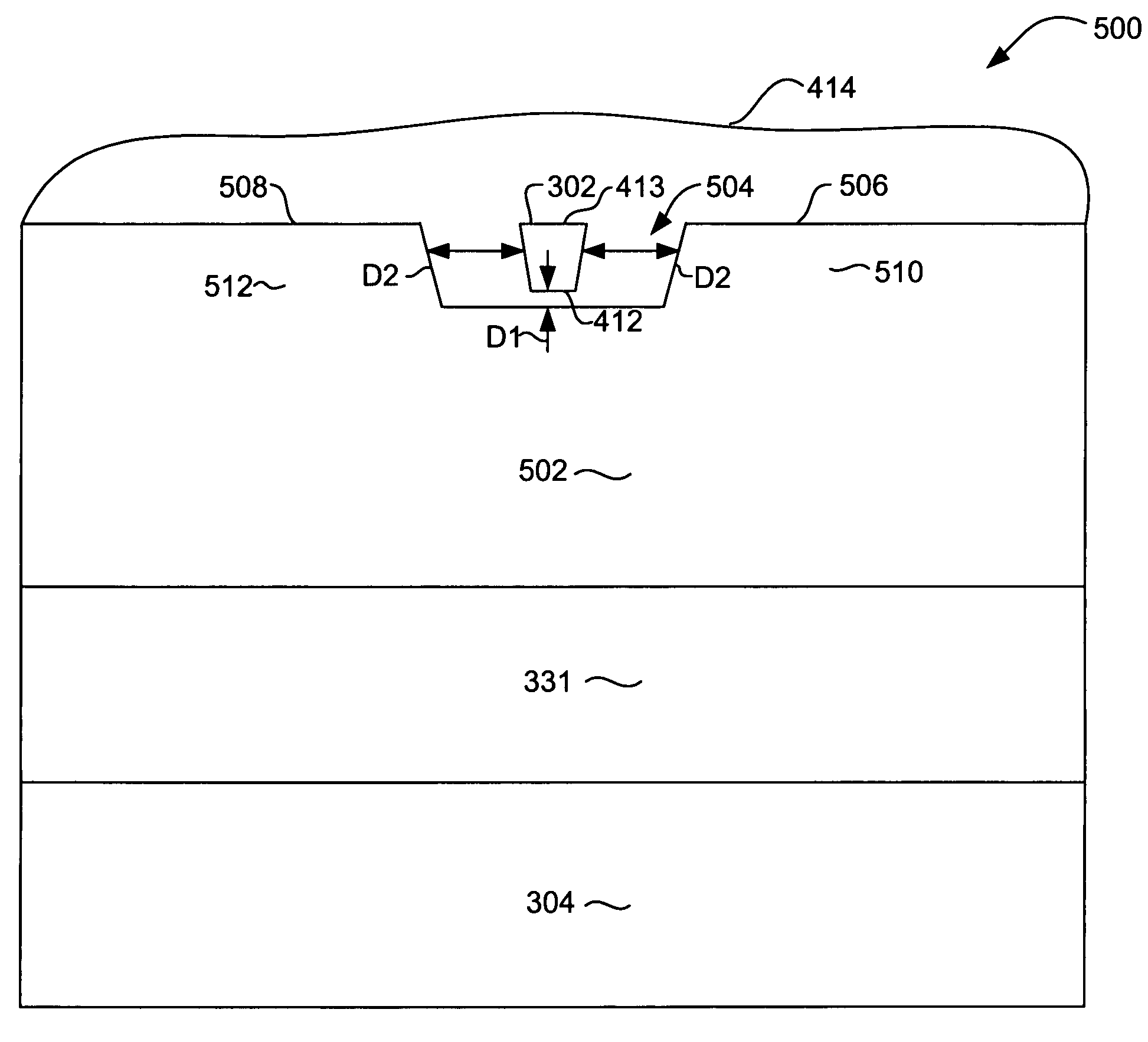

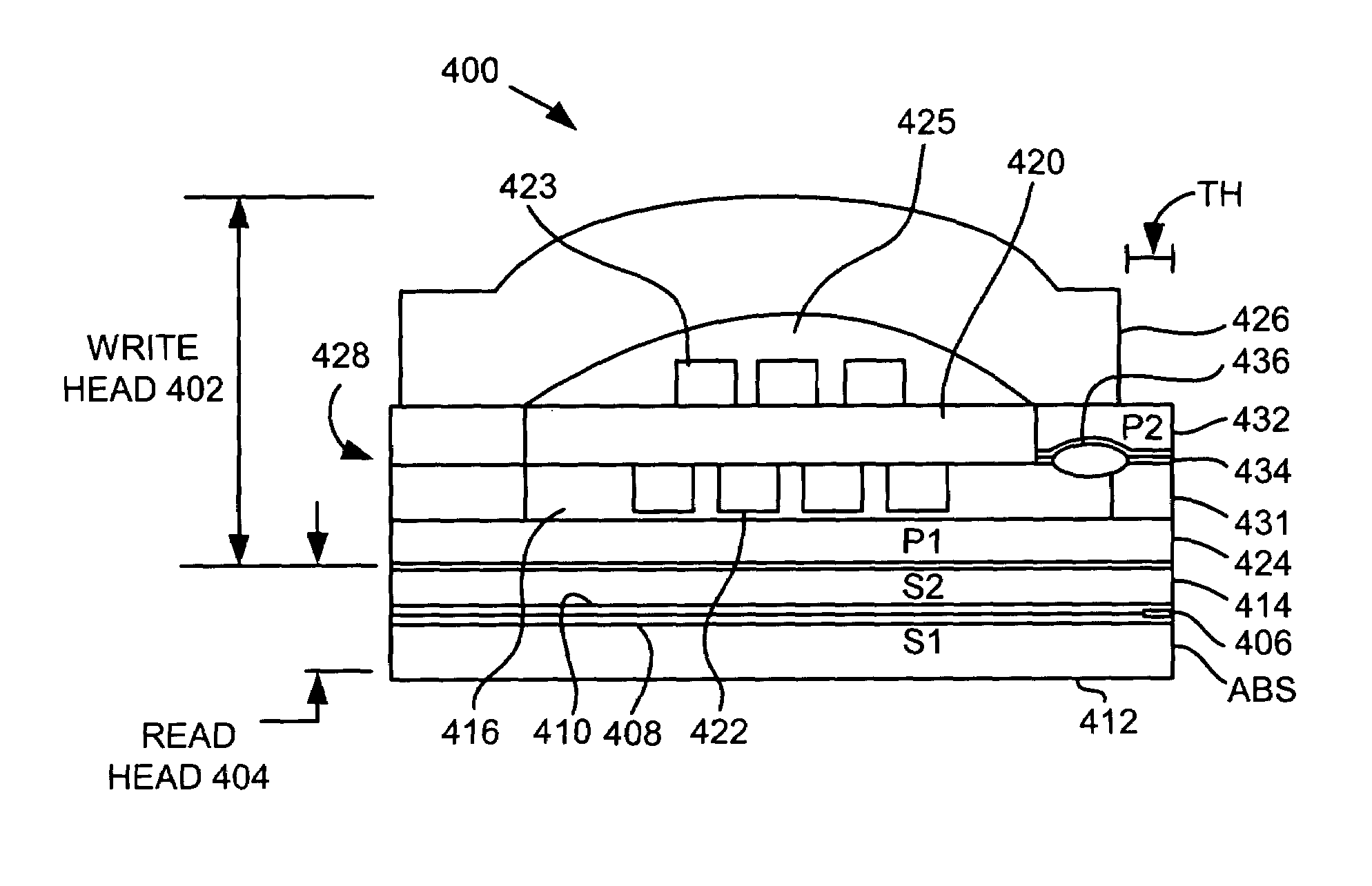

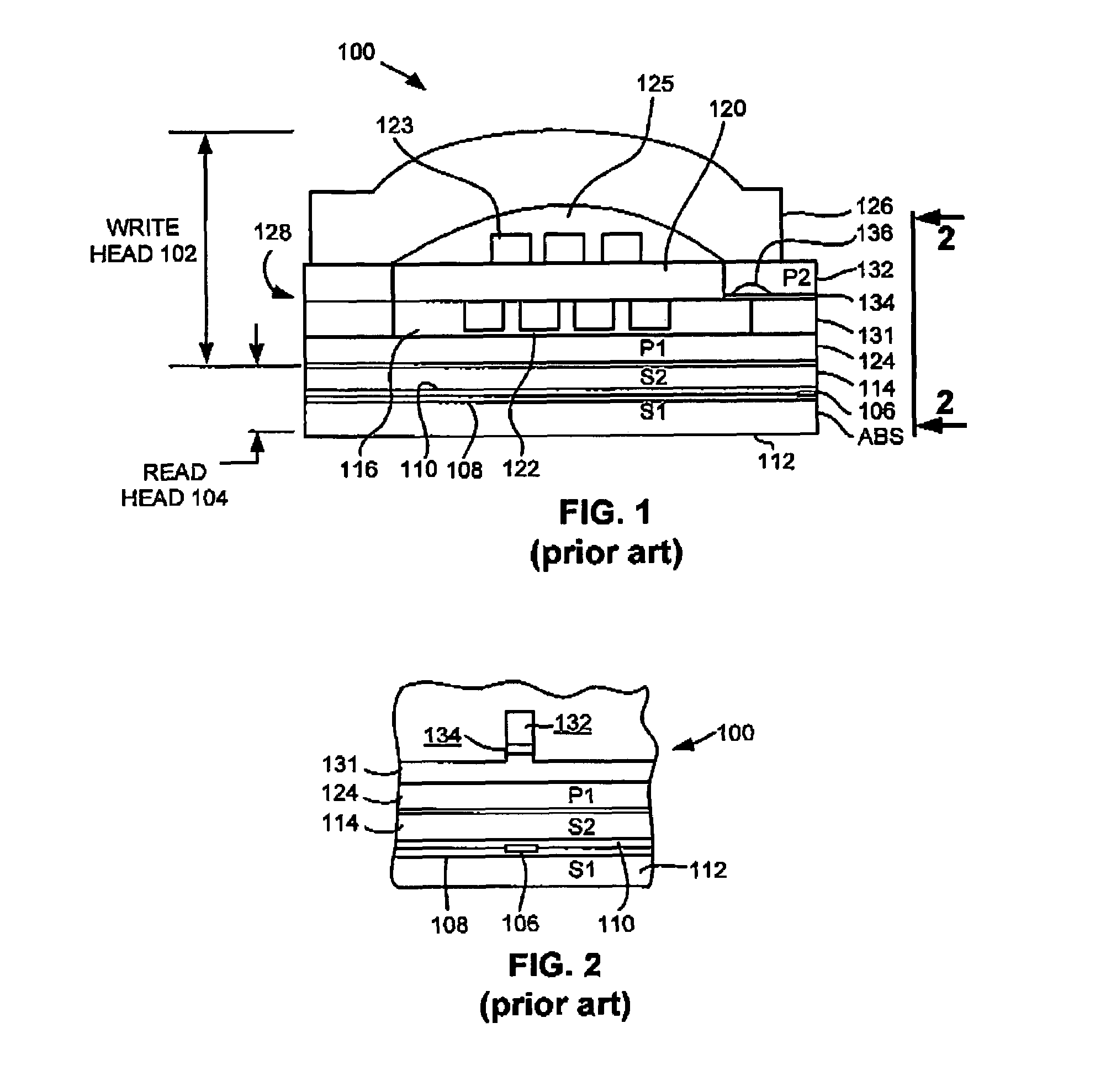

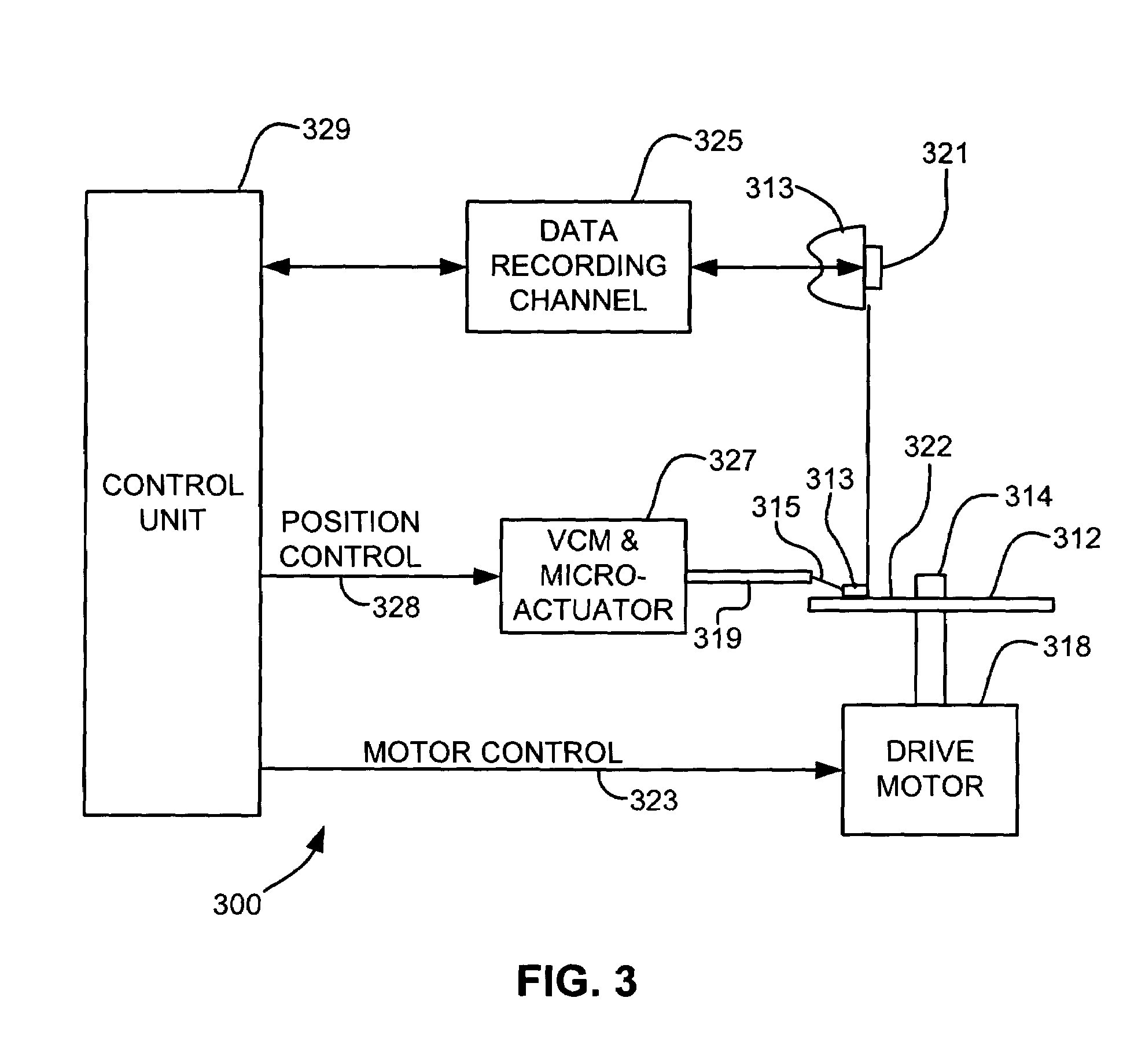

Flux shunt structure for reducing return pole corner fields in a perpendicular magnetic recording head

InactiveUS20060245108A1Improve protectionSufficient magnetic separationManufacture head surfaceHeads using thin filmsEngineeringMagnetic shield

A magnetic head for use in a perpendicular recording system having a novel shield structure that provides exceptional magnetic shielding from extraneous magnetic fields such as from a write coil, shaping layer or return pole of the write head. The magnetic head includes a write pole, a return pole and a magnetic shield that is magnetically connected with the return pole near the ABS and extends toward the write pole. The shield is formed with a notch at its edge closest to the write pole. The notch assures adequate physical, magnetic, and electrical separation between the write pole and the shield, while allowing un-notched portions of the shield to provide additional magnetic shielding.

Owner:WESTERN DIGITAL TECH INC

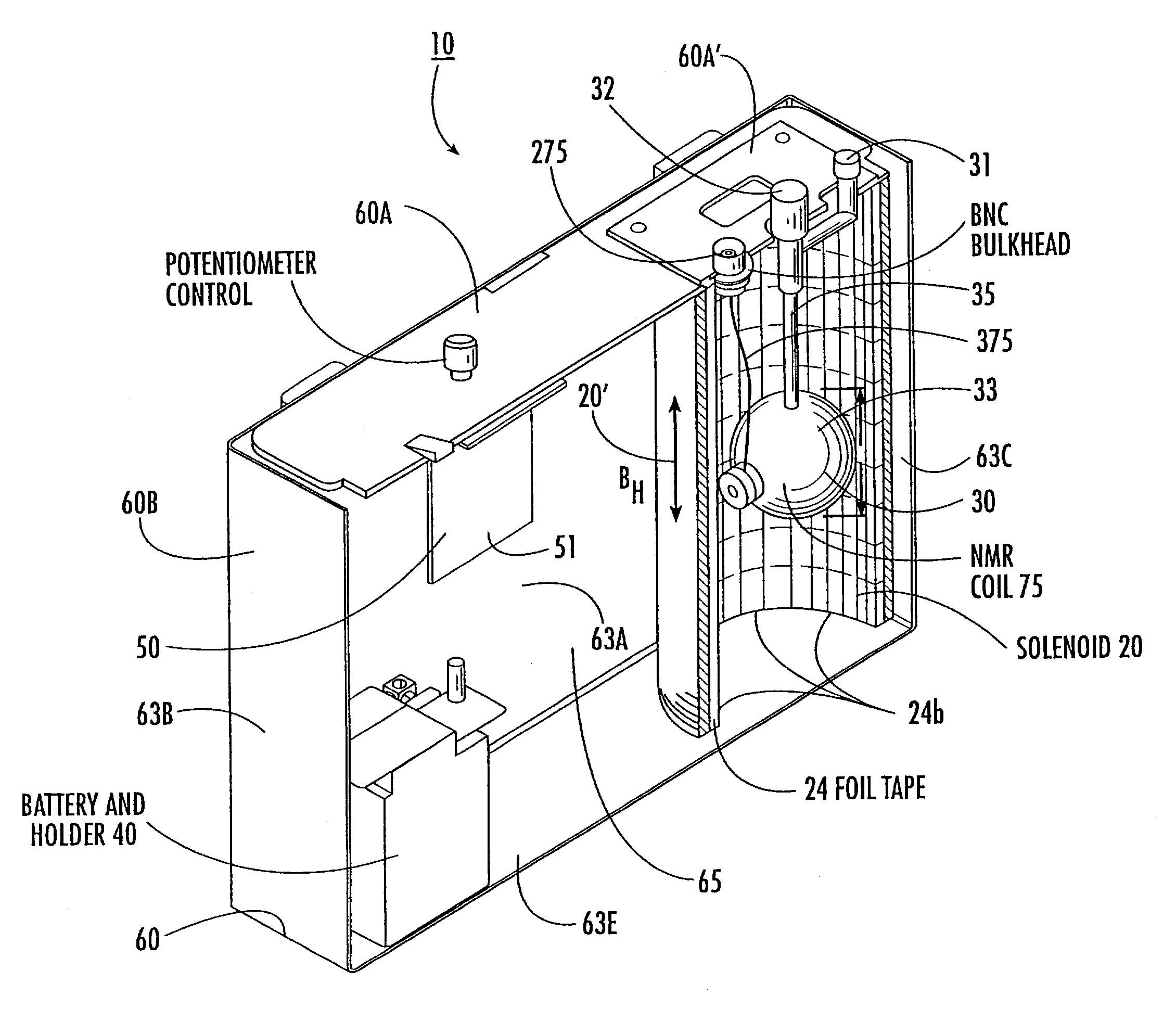

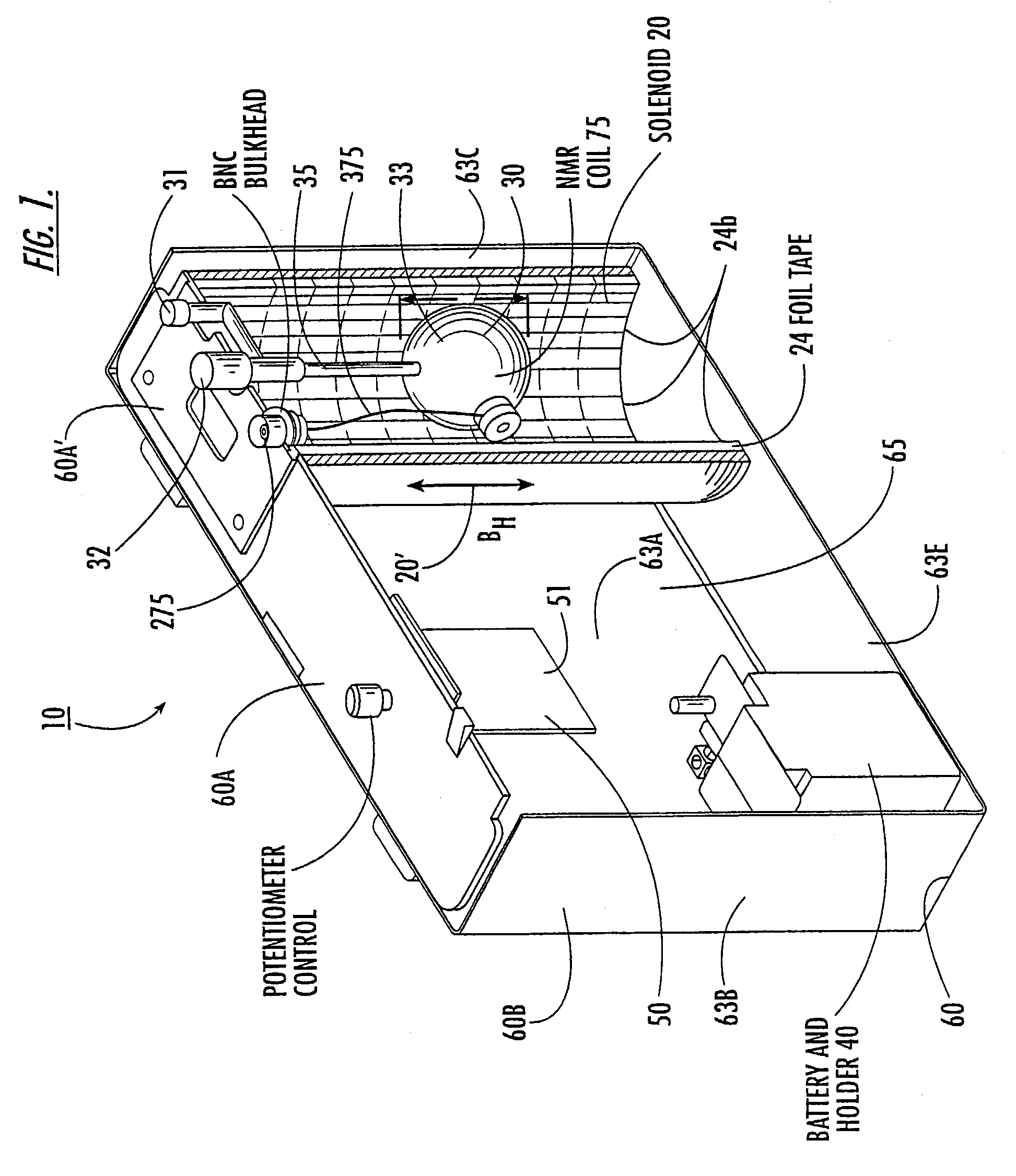

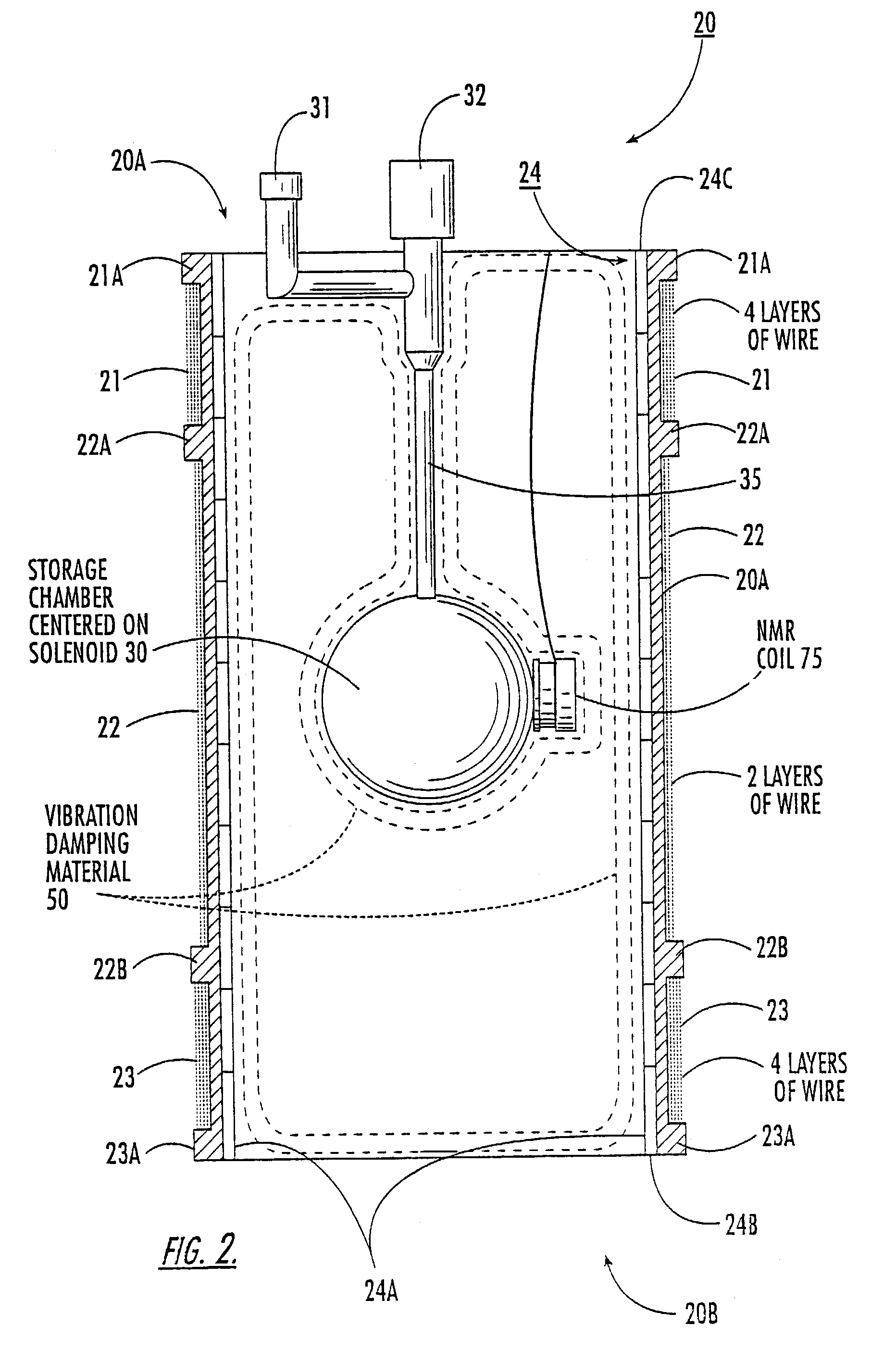

Hyperpolarized gas containers, solenoids, transport and storage devices and associated transport and storage methods

InactiveUS6995641B2Minimize impactEasy to transportLiquefactionDispersion deliveryNoble gasDistribution method

A compact portable transport unit for shipping hyperpolarized noble gases and shielding same from electromagnetic interference and / or external magnetic fields includes a means for shifting the resonance frequency of the hyperpolarized gas outside the bandwidth of typical frequencies associated with prevalent time-dependent fields produced by electrical sources. Preferably the transport unit includes a magnetic holding field which is generated from a solenoid in the transport unit. The solenoid includes a plurality of coil segments and is sized and configured to receive the gas chamber of a container. The gas container is configured with a valve, a spherical body, and an extending capillary stem between the valve and the body. The gas container or hyperpolarized product container can also be formed as a resilient bag. The distribution method includes positioning a multi-bolus container within the transport unit to shield it and transporting same to a second site remote from the first site and subsequently dispensing into smaller patient sized formulations which can be transported (shielded) in another transport unit to yet another site.

Owner:POLAREAN

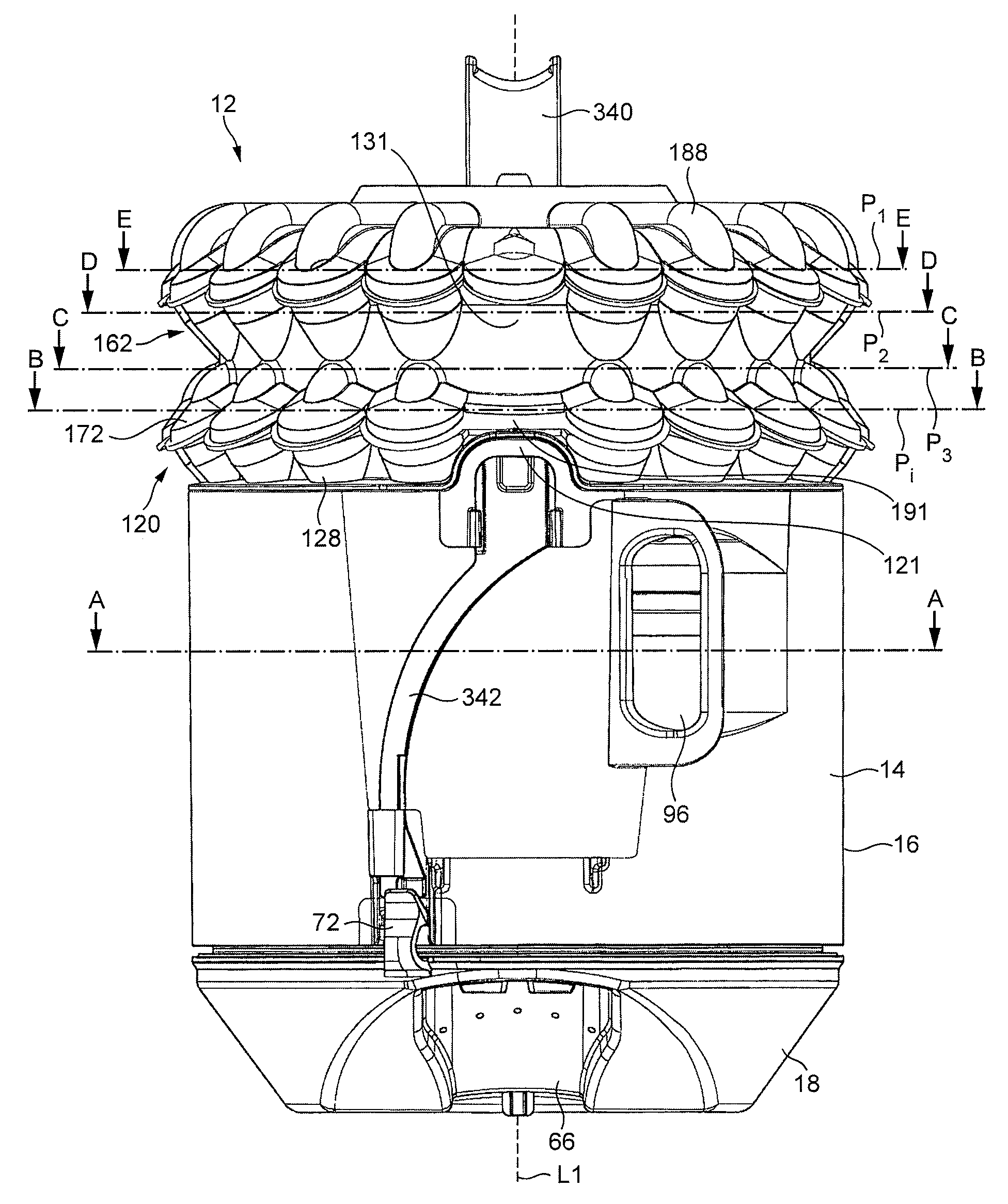

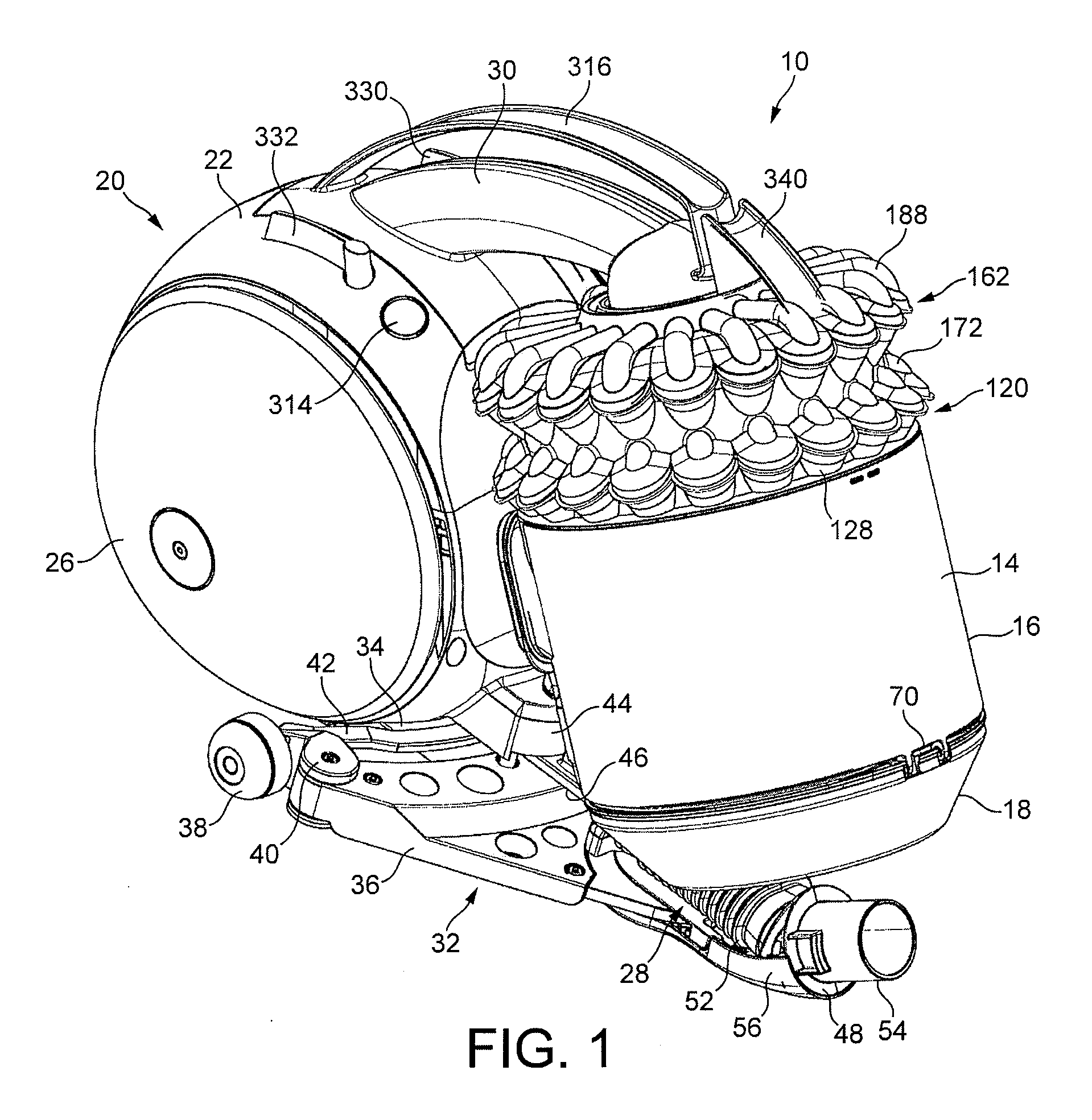

Surface treating appliance

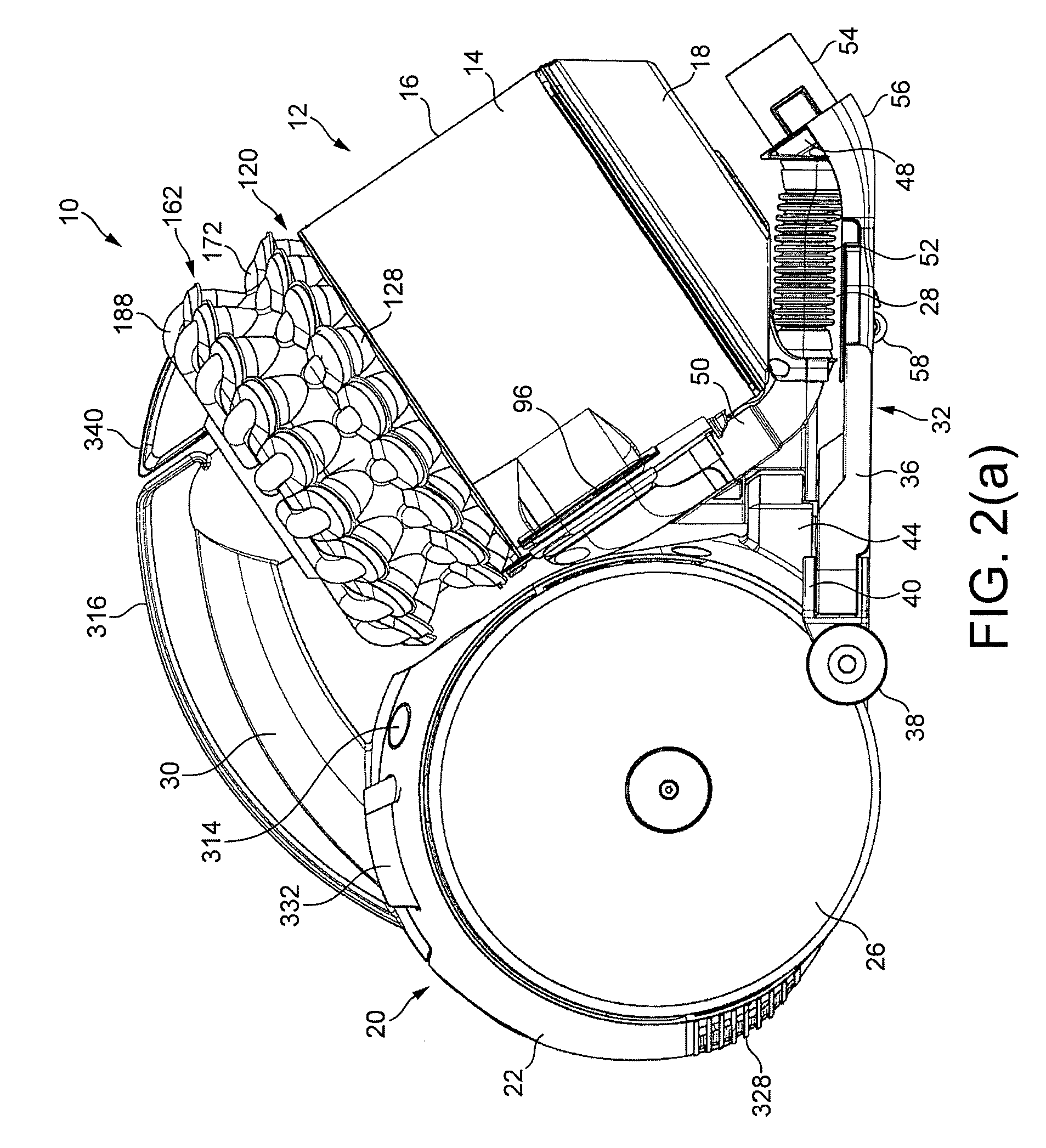

InactiveUS20120284960A1Ensure sufficient separationEfficient separationCleaning filter meansSuction filtersCycloneEngineering

A surface treating appliance includes a first cyclonic separating unit including at least one first cyclone, a second cyclonic separating unit including a plurality of second cyclones arranged in parallel about an axis, and a third cyclonic separating unit including a plurality of third cyclones arranged in parallel about the axis. Each of the second cyclones and the third cyclones has a tapering body with an outside wall. The plurality of third cyclones is divided into at least a first set of third cyclones and a second set of third cyclones, each of the plurality of second cyclones and the first set of third cyclones being arranged about the second set of third cyclones. At least a part of the outside wall of each of the plurality of second cyclones and each of the first set of third cyclones forms part of the external surface of the surface treating appliance.

Owner:DYSON TECH LTD

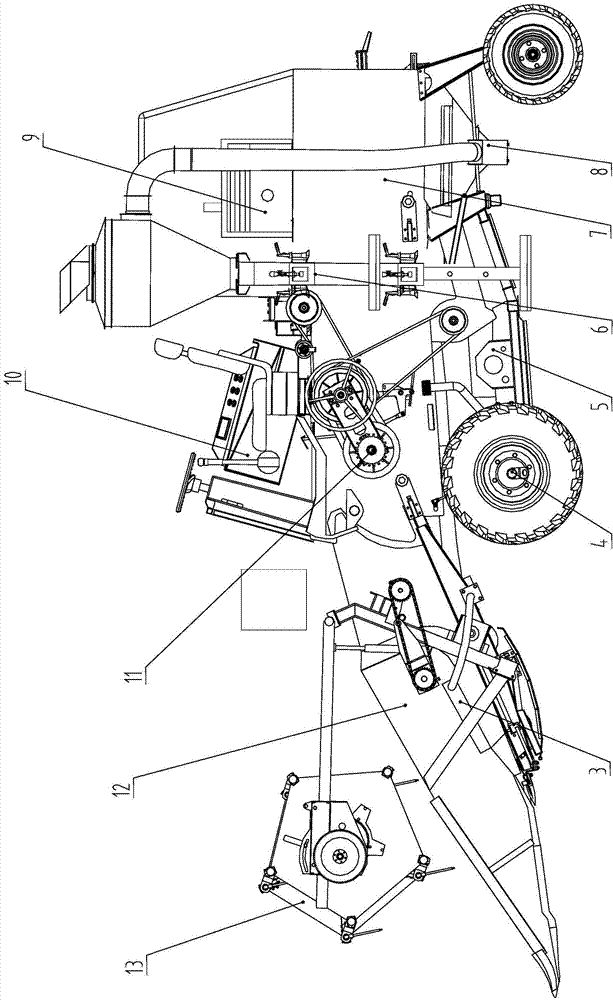

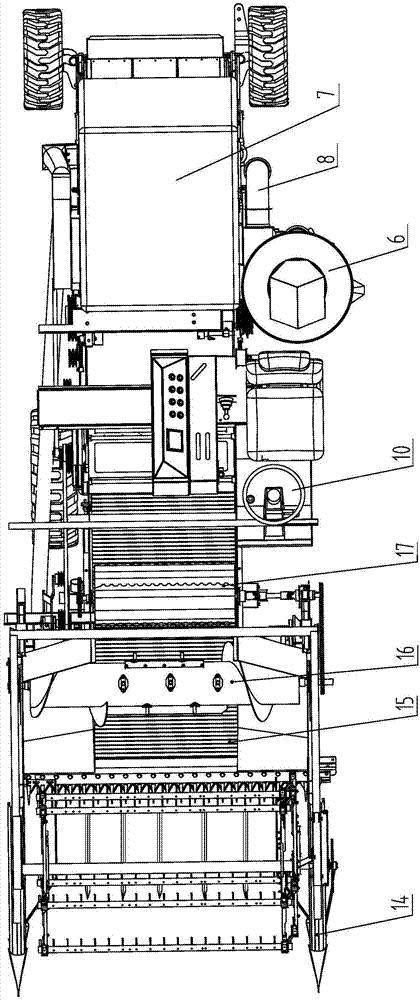

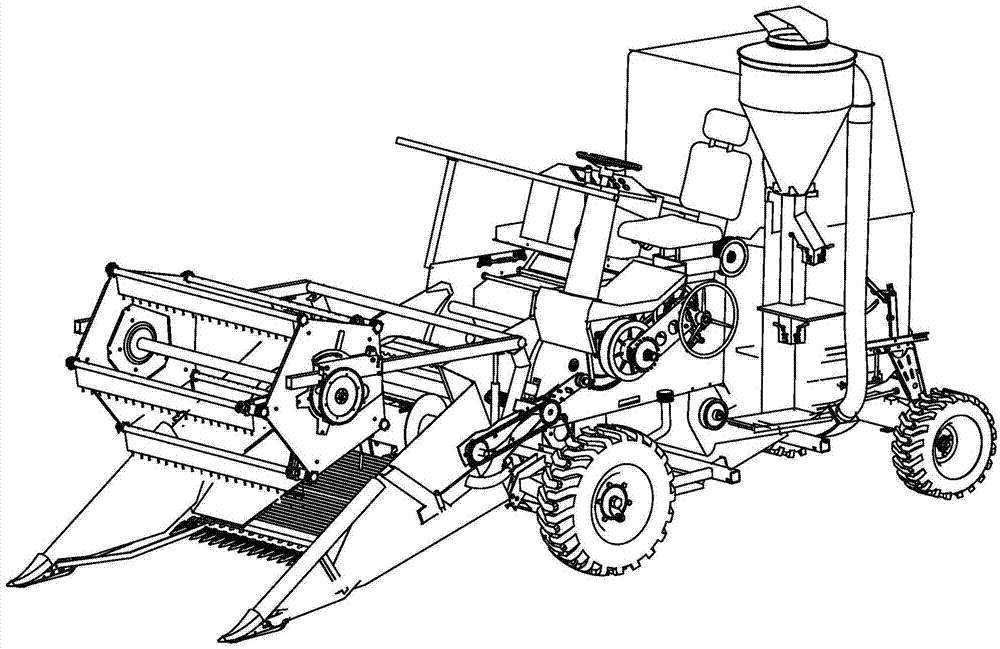

Area grain combine harvester

The invention provides an area grain combine harvester which comprises a walking device, a pneumatic assisting header device, a threshing device, a cleaning device, a pneumatic conveying device, a bagging device, a hydraulic integration device, a driving operation device and an engine device. The walking device is placed at the bottom end of a whole machine. The pneumatic assisting header device is placed at the front end of the whole machine. The threshing device and the cleaning device are arranged behind the pneumatic assisting header device in sequence. The pneumatic conveying device is communicated with an outlet of the cleaning device. The bagging device is placed at the back end of the whole machine and is communicated with the tail end of the pneumatic conveying device. Conveyed seeds are bagged according to area unit quantity. Each time harvesting in one area is over, a corresponding device is operated to carry out seed clearing under a moving-stopping state, and seed mixing between different areas is avoided. Working efficiency is high, the grain breaking rate and the loss rate are low, inner grains can be cleared easily, seed residues are avoided, and the problem that during harvesting, seed mixing is caused by inner residual seeds of machines between different areas is effectively solved.

Owner:QINGDAO AGRI UNIV +1

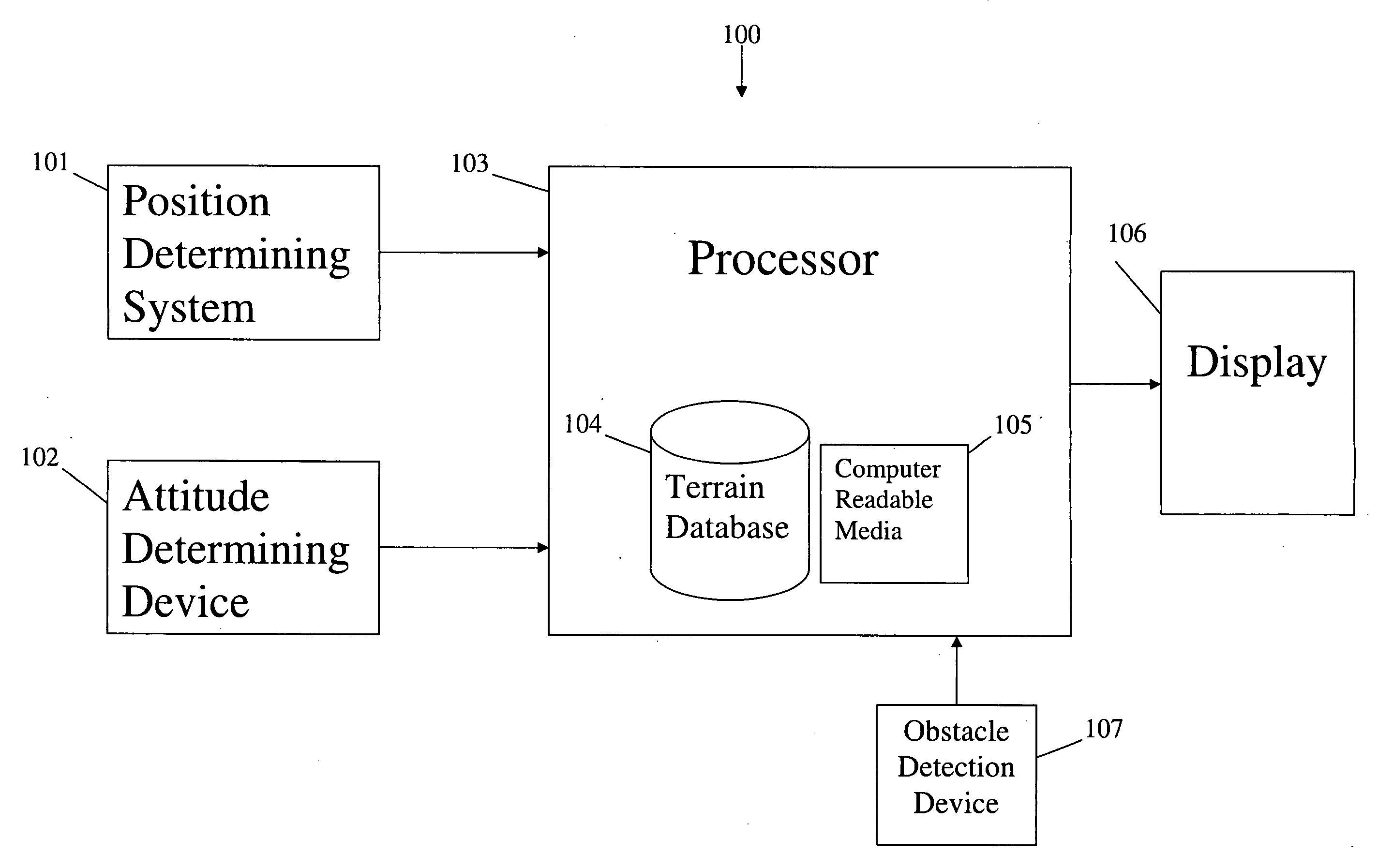

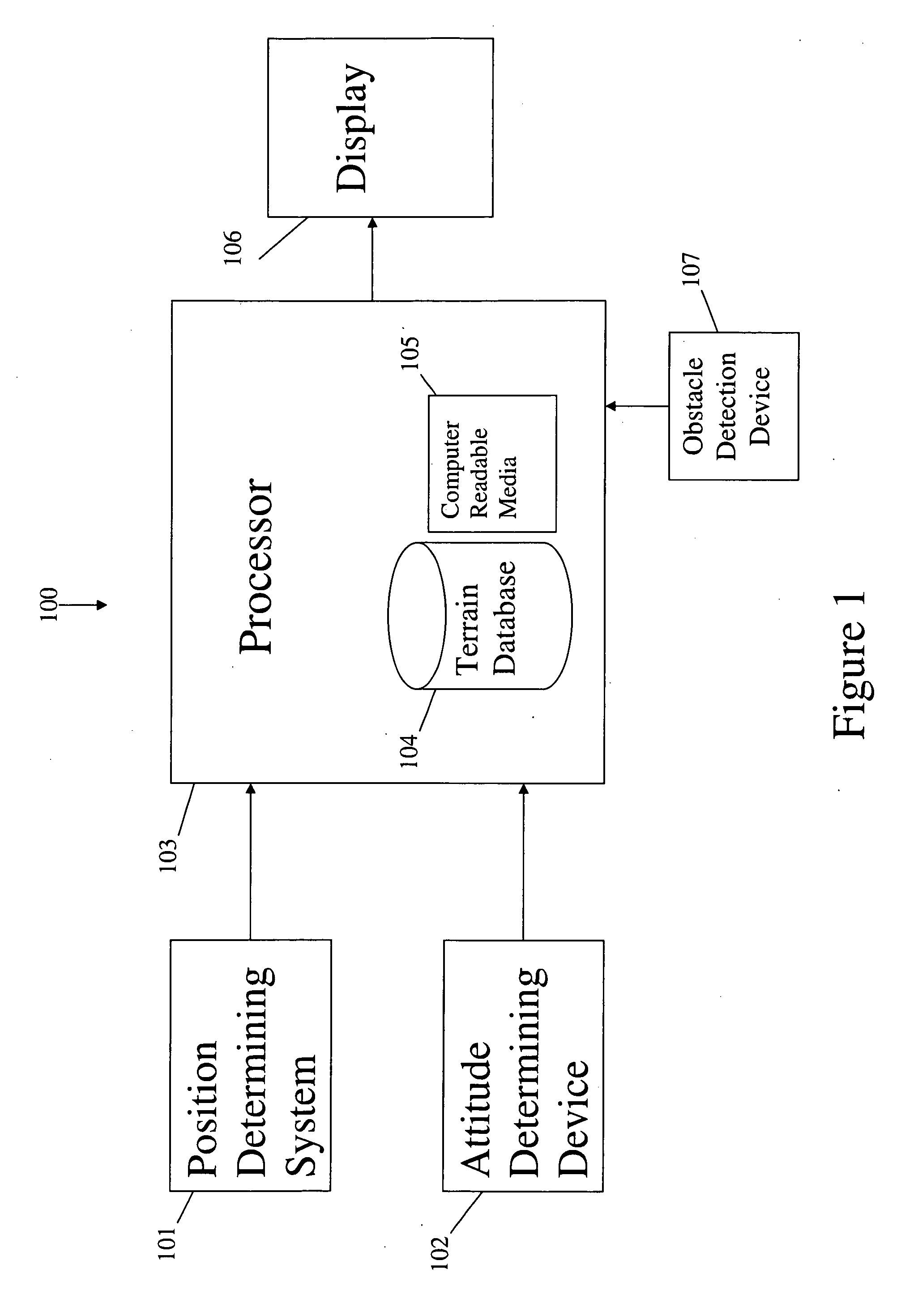

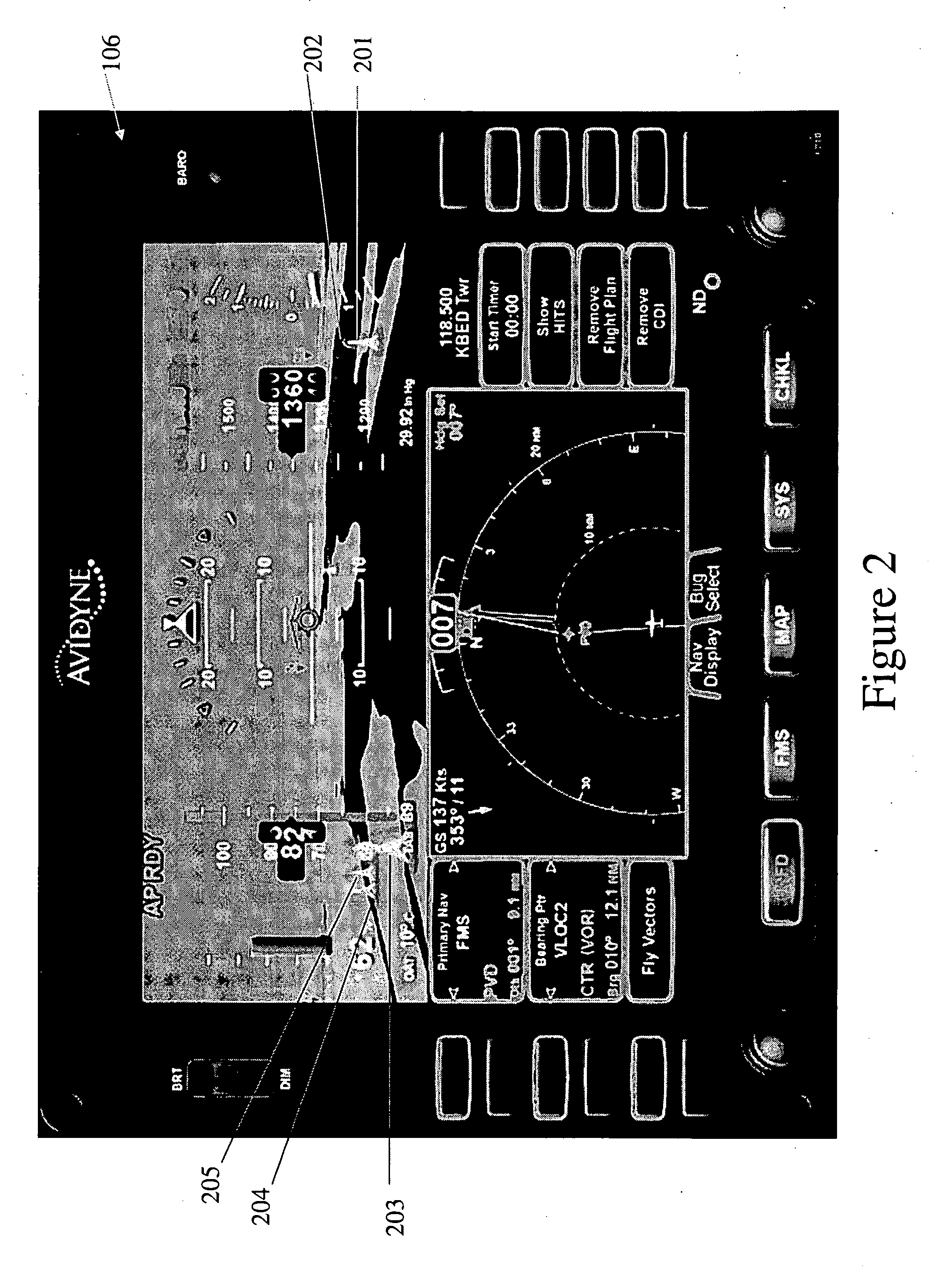

Symbology for a flight display

InactiveUS20090265088A1Ensure sufficient separationIncrease awarenessAnalogue computers for vehiclesAnalogue computers for trafficSymbolic SystemsHorizon

Flight display systems are provided that present a pilot with a three dimensional view of an area within a potential flight path of an aircraft. The three dimensional view may include representations of potential obstacles and avoidance zones surrounding the potential obstacles. The view may also include cardinal compass representation aligned with the visual horizon. Aircraft traffic obstacle symbols may be variable based on the type of aircraft represented.

Owner:AVIDYNE CORPORATION

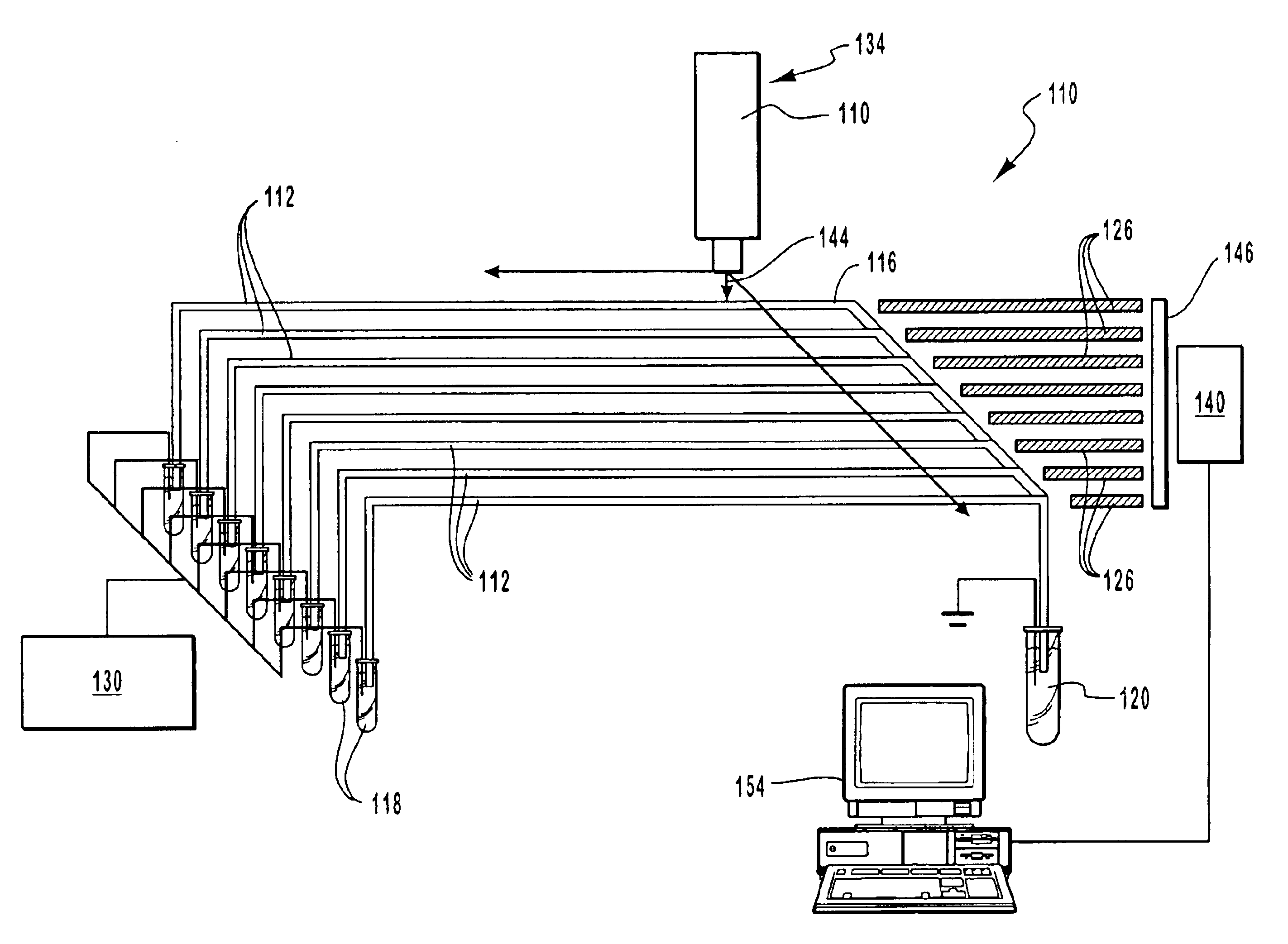

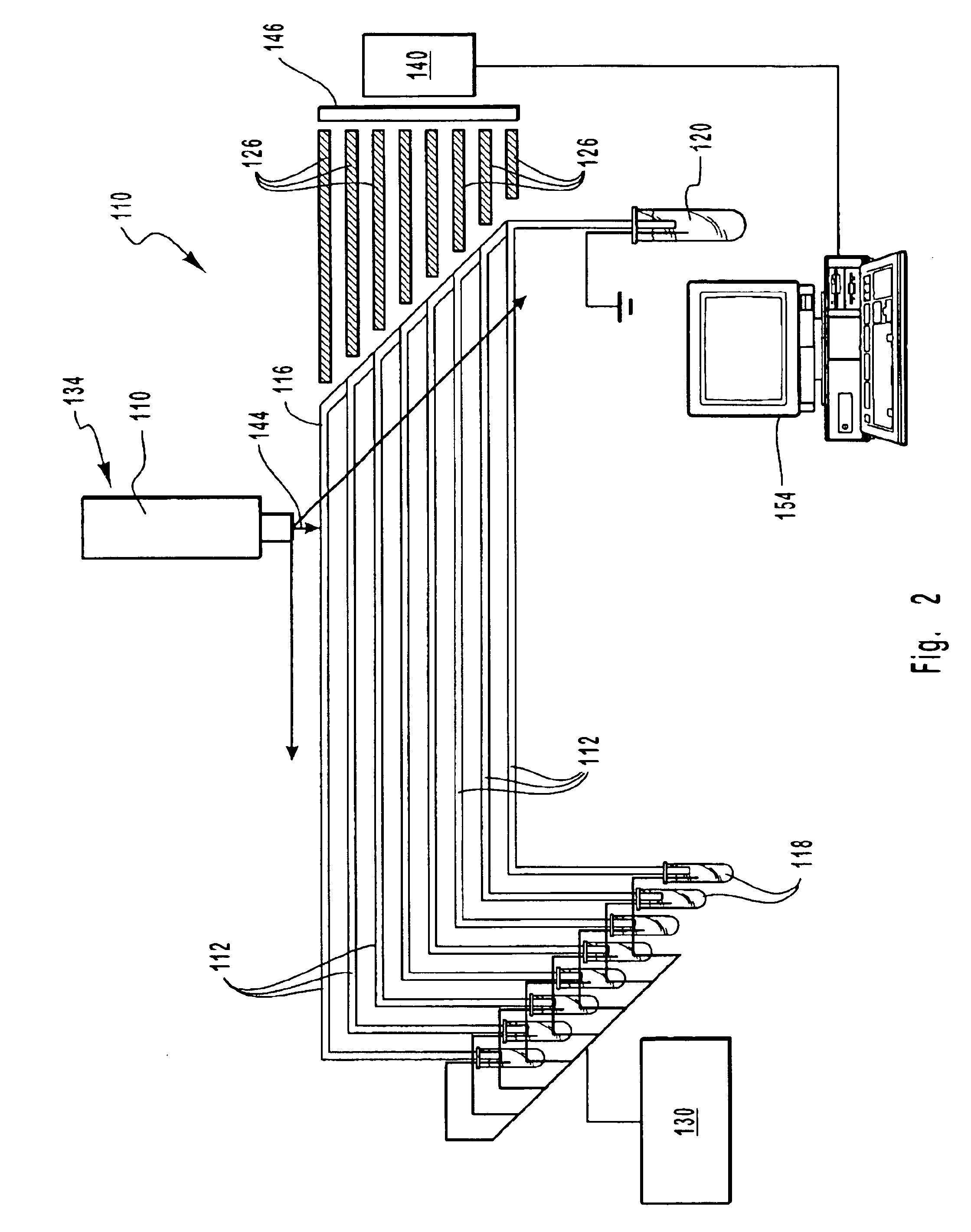

Particle sizer and DNA sequencer

InactiveUS6942773B1Ensure sufficient separationEasy to separateSludge treatmentVolume/mass flow measurementFluorescenceElectrophoresis

An electrophoretic device separates and detects particles such as DNA fragments, proteins, and the like. The device has a capillary which is coated with a coating with a low refractive index such as Teflon® AF. A sample of particles is fluorescently labeled and injected into the capillary. The capillary is filled with an electrolyte buffer solution. An electrical field is applied across the capillary causing the particles to migrate from a first end of the capillary to a second end of the capillary. A detector light beam is then scanned along the length of the capillary to detect the location of the separated particles. The device is amenable to a high throughput system by providing additional capillaries. The device can also be used to determine the actual size of the particles and for DNA sequencing.

Owner:LOS ALAMOS NATIONAL SECURITY

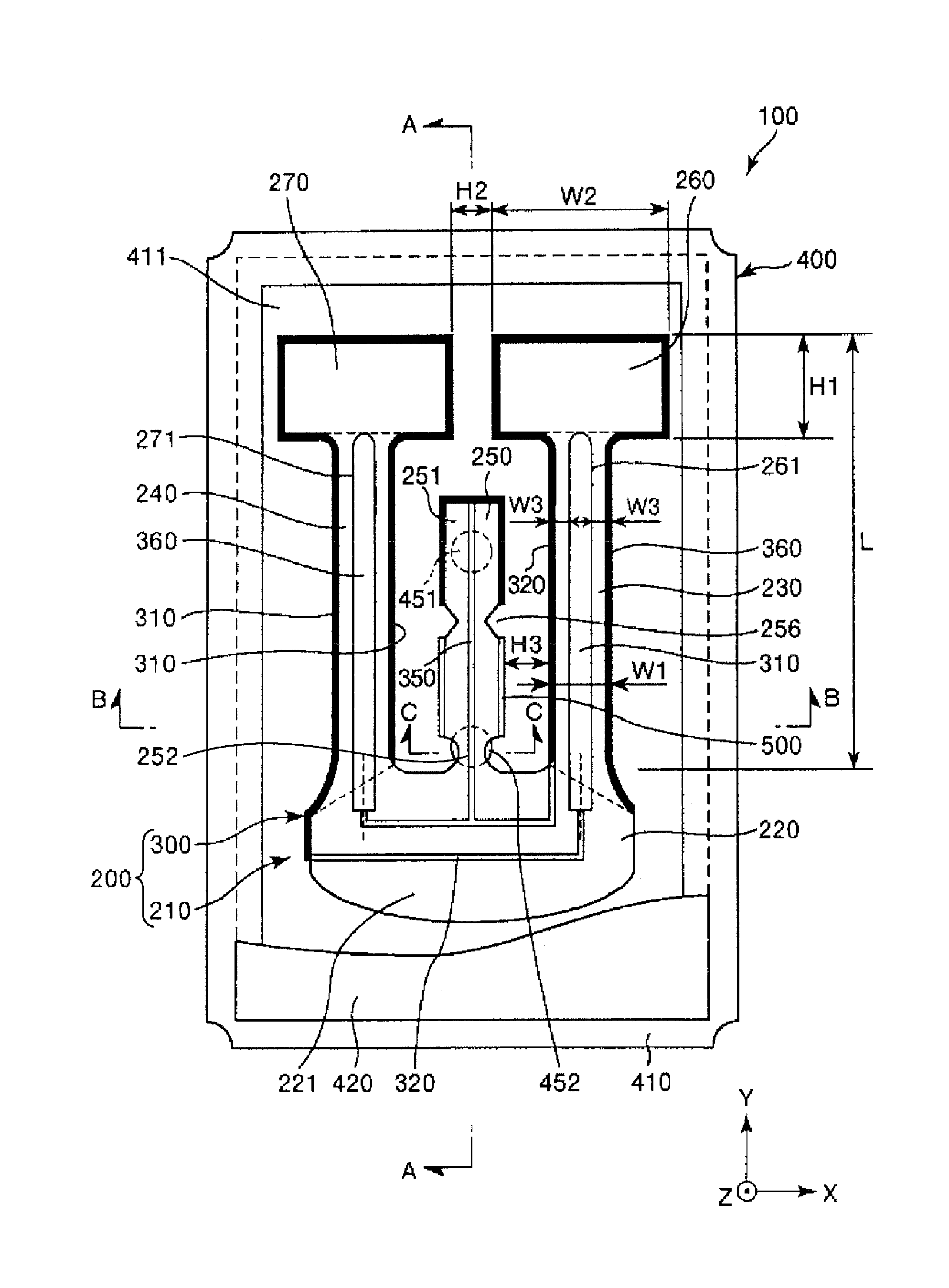

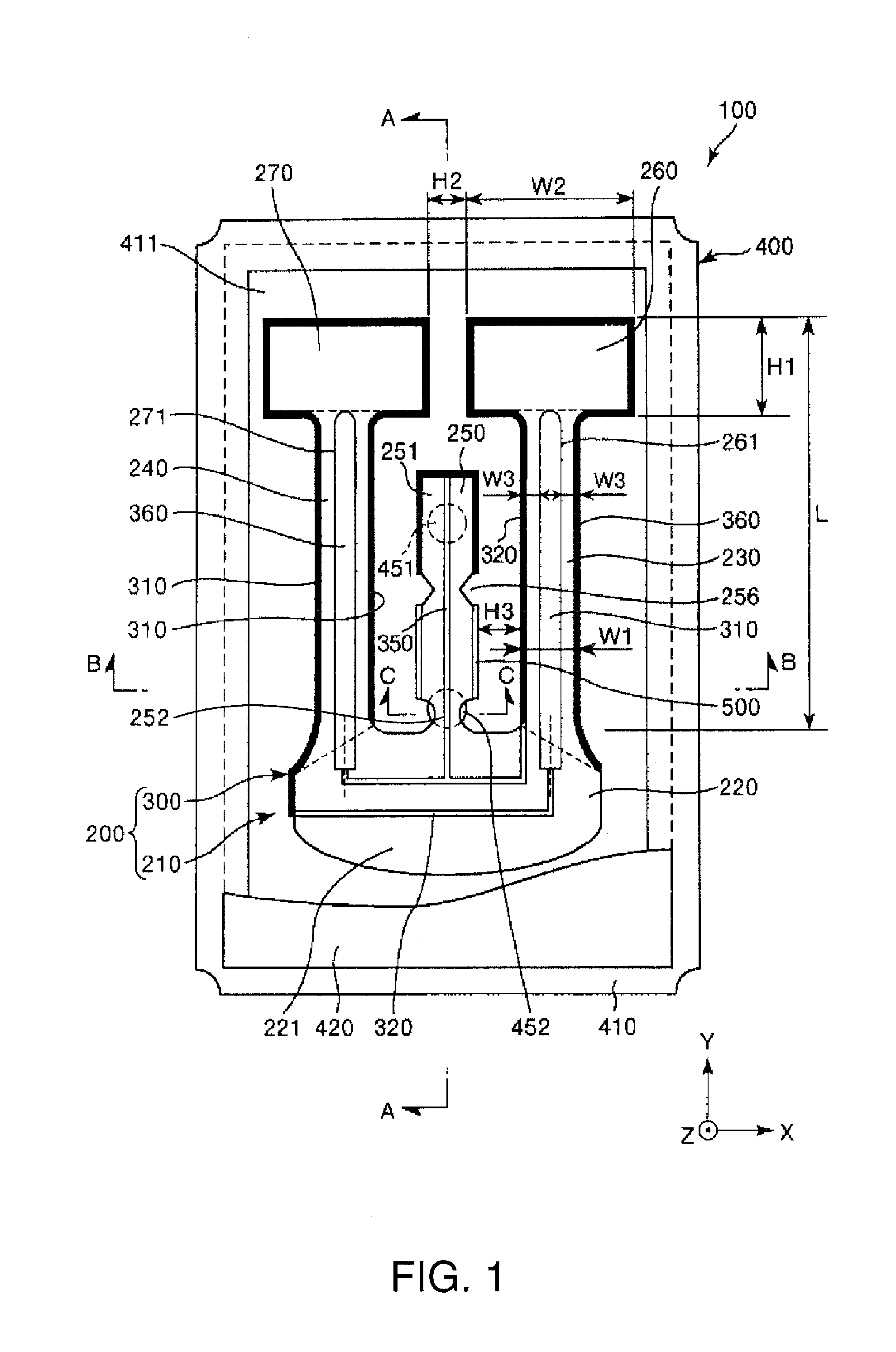

Resonator element, resonator, oscillator, electronic apparatus, and moving object

ActiveUS20140292435A1Ensure sufficient separationEasy to separateImpedence networksPiezoelectric/electrostriction/magnetostriction machinesElectronBiomedical engineering

A resonator includes a resonator element including a base section, vibrating arms extending from the base section, and a support arm disposed between the vibrating arms, a package adapted to support the resonator element, and electrically-conductive adhesives adapted to fix the support arm to the package, the support arm includes a tip portion and a width-decreasing portion having a width smaller than the width of the tip portion, and the electrically-conductive adhesive has contact with at least a part of the width-decreasing portion in a planar view.

Owner:SEIKO EPSON CORP

Surface treating appliance

ActiveUS20120284954A1Ensure sufficient separationEfficient separationCleaning filter meansSuction filtersEngineeringSurface processing

Owner:DYSON TECH LTD

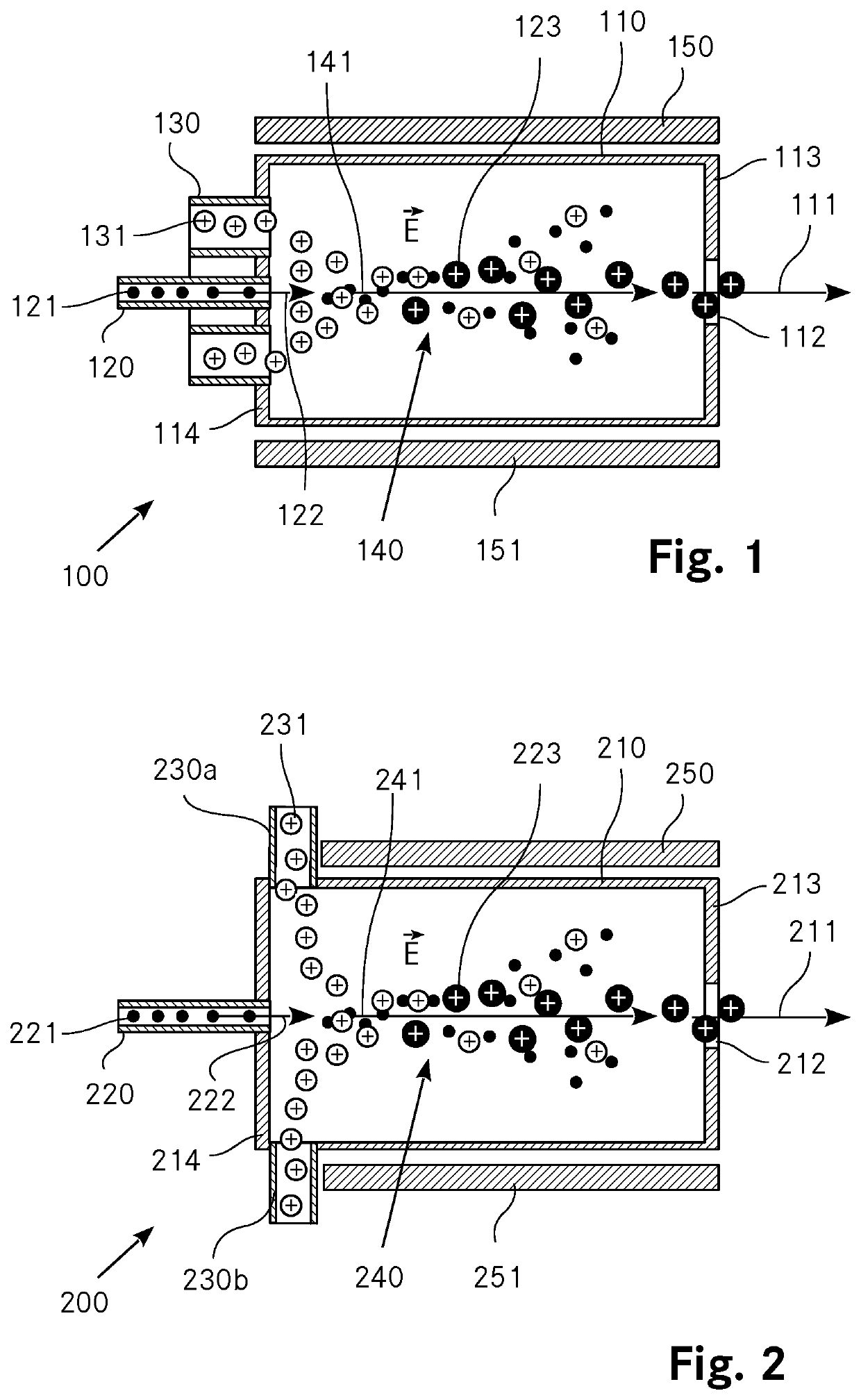

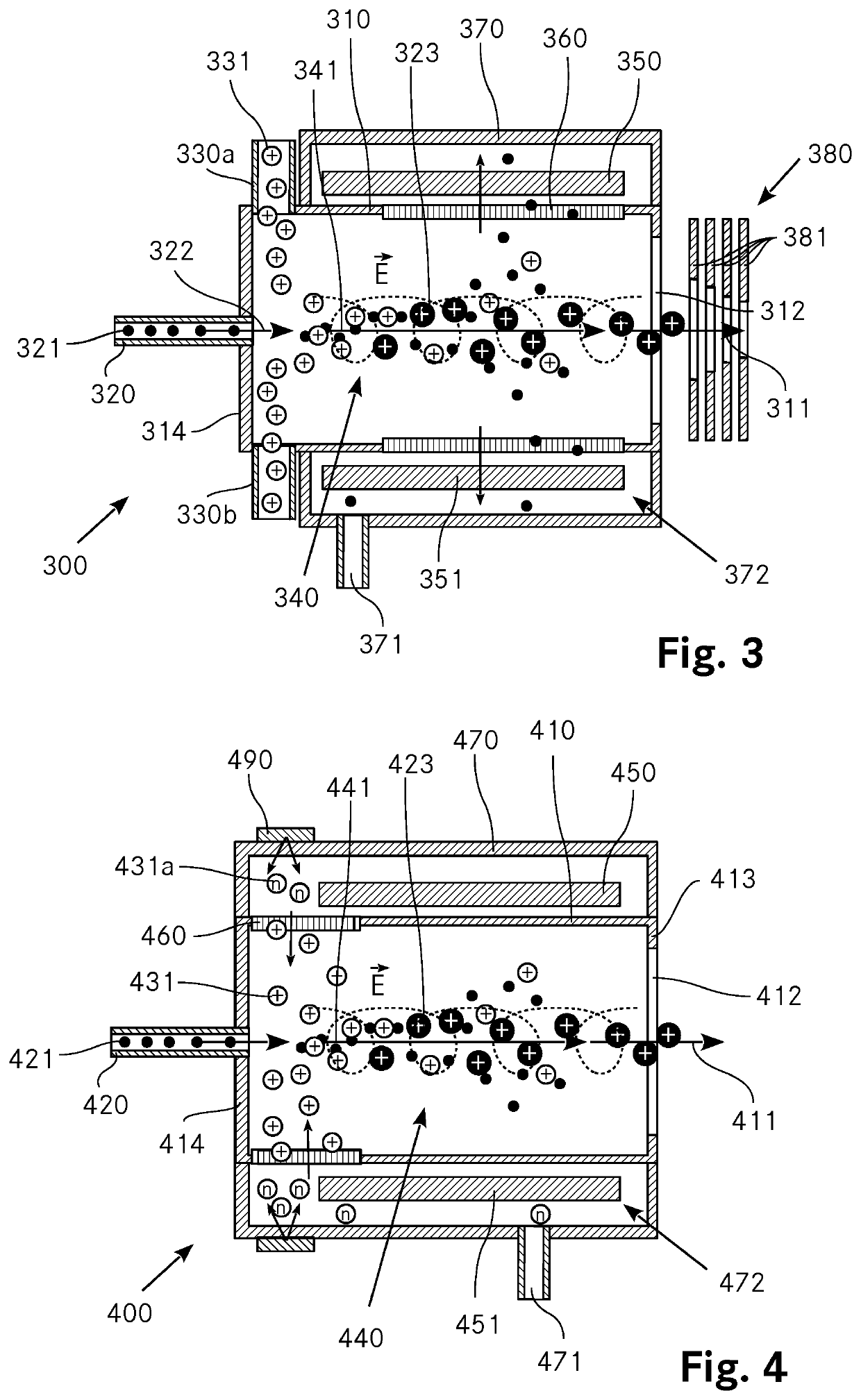

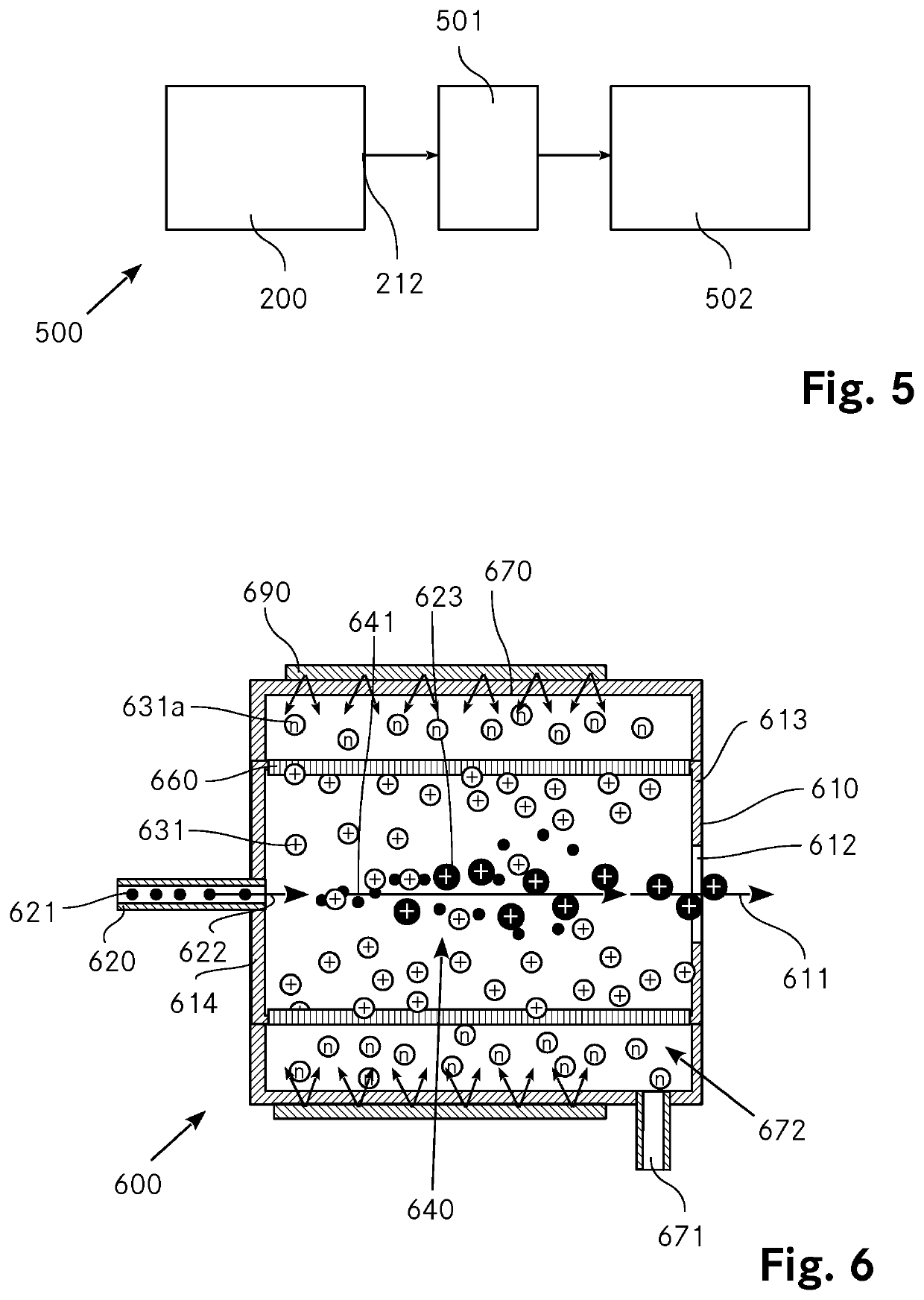

Ion molecule reactor and setup for analyzing complex mixtures

PendingUS20200243317A1High sensitivitySufficient specificitySamples introduction/extractionElectron/ion optical arrangementsChemical physicsAnalyte

An ion molecule reactor for generating analyte ions from analytes comprises: a) a reaction volume in which reagent ions can interact with the analytes in order to form analyte ions; b) at least one analyte inlet for introducing the analytes along an inlet path into the reaction volume whereby, preferably, the inlet path runs essentially along at least a first section of the predefined transit path in the reaction volume; c) at least one reagent ion source and / or at least one reagent ion inlet for providing reagent ions into the reaction volume; d) optionally, at least one ion guide comprising an electrode arrangement which is configured for producing an alternating electrical, magnetic and / or electromagnetic field, that allows for guiding the reagent ions and / or the analyte ions at least along a section of the predefined transit path, preferably along the whole transit path, through the reaction volume. There is also provided a sampler comprising one or more chambers, wherein each chamber is configured for receiving an individual sample and comprises an inlet and an outlet, such that a gaseous fluid flow can pass through each of the chambers.

Owner:TOFWERK

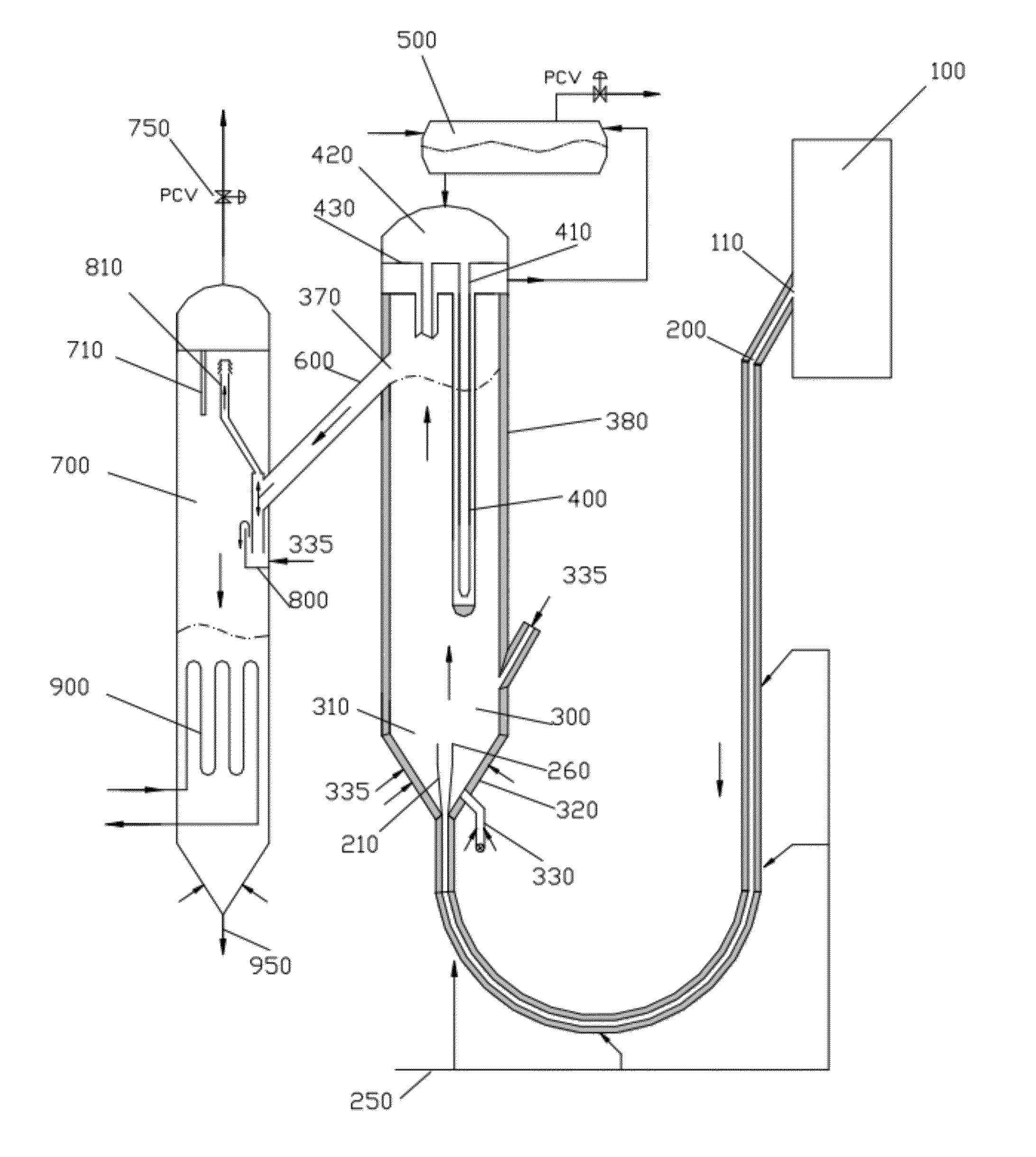

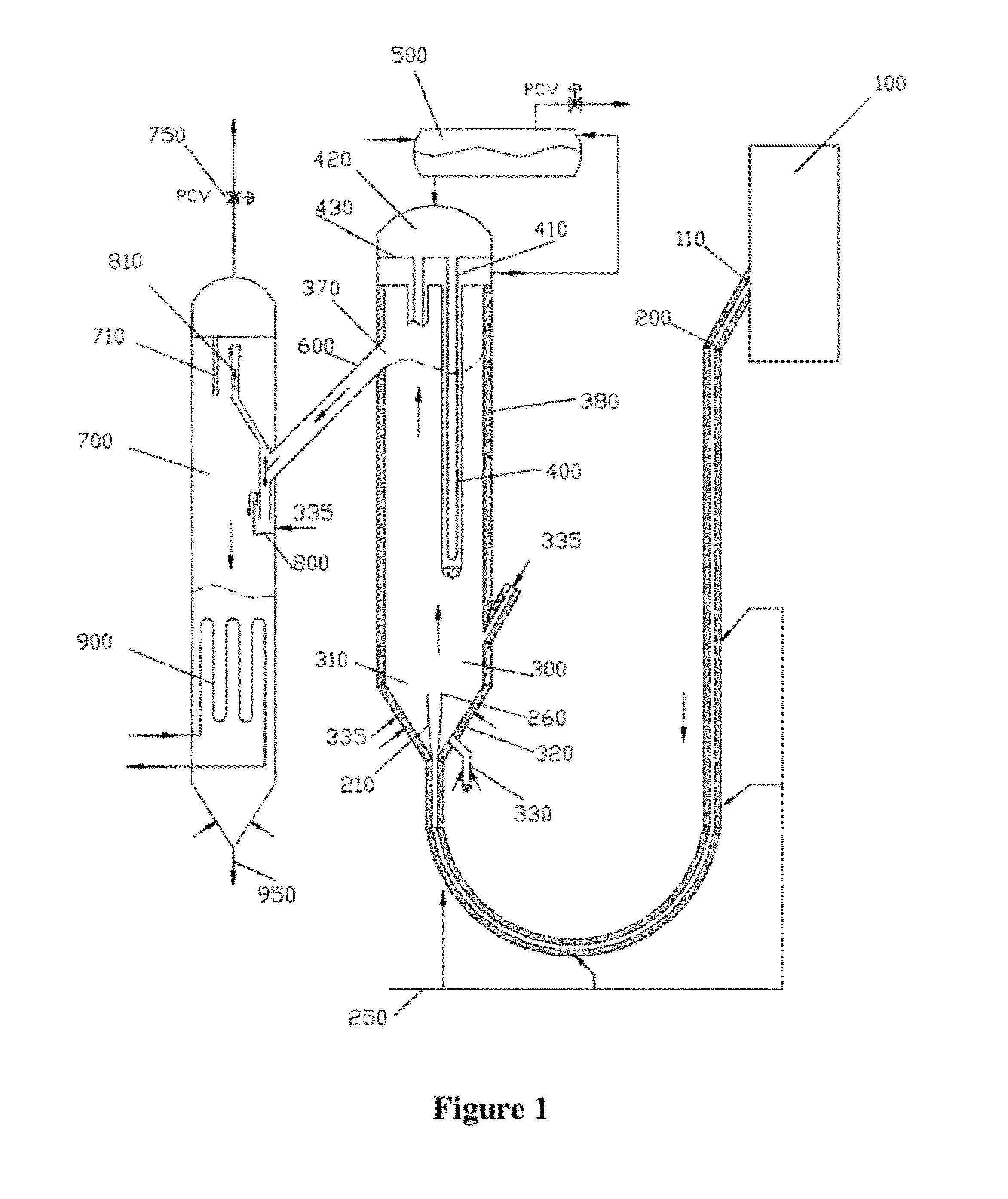

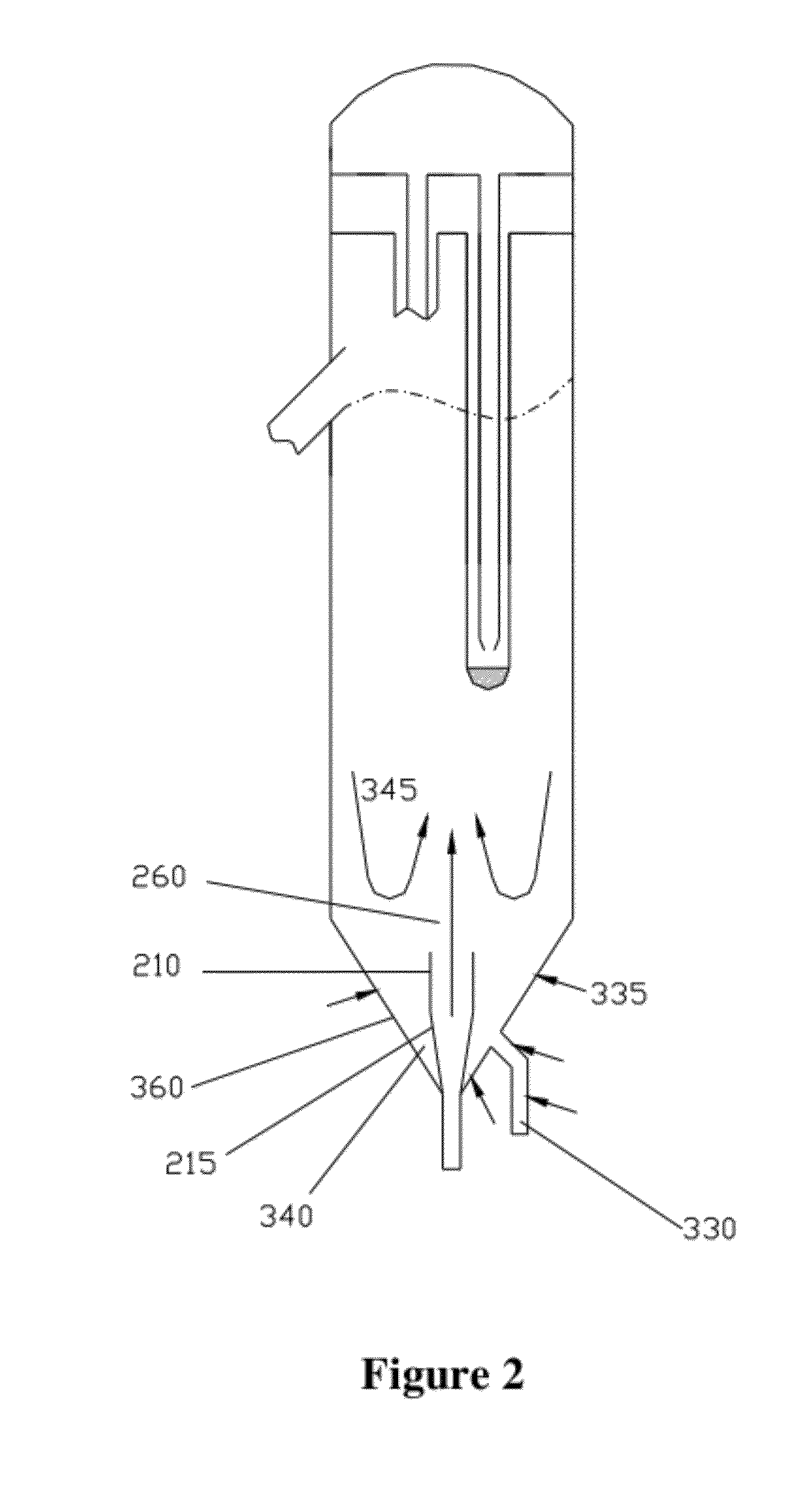

Ash And Solids Cooling In High Temperature And High Pressure Environment

ActiveUS20120031584A1Avoid interferenceEnsure sufficient separationFluidized bed combustionCorrosion preventionSolid particleHigh pressure

Disclosed are cooling and depressurization system equipment, arrangement and methods to cool solid particles from a coal gasifier operating at high temperature and pressure. Ash from the coal needs to be continuously withdrawn from a circulating fluidized bed gasifier to maintain the solids inventory in the gasifier. The system disclosed enables use of conventional materials of construction for heat transfer surfaces. The supports for the cooling surfaces are located on the lower temperature upper section of the primary cooler. The cooled solids along with the fluidizing gas exits the primary cooler to a secondary receiving vessel where the solids can be further cooled by conventional means. The fluidizing and entrained gas entering the secondary vessel is filtered and vented through a vent pressure control valve. The column of cooled solids in the secondary vessel is depressurized by a continuous depressurization system to low pressures which are sufficient for conveying the solids to silos for disposal. The system and methods proposed are equally applicable to many high temperature, high pressure processes that require cooling and depressurization of process solids.

Owner:THE SOUTHERN CO

Flux shunt structure for reducing return pole corner fields in a perpendicular magnetic recording head

InactiveUS7639450B2Improve protectionEnsure sufficient separationManufacture head surfaceHeads using thin filmsEngineeringMagnetic shield

A magnetic head for use in a perpendicular recording system having a novel shield structure that provides exceptional magnetic shielding from extraneous magnetic fields such as from a write coil, shaping layer or return pole of the write head. The magnetic head includes a write pole, a return pole and a magnetic shield that is magnetically connected with the return pole near the ABS and extends toward the write pole. The shield is formed with a notch at its edge closest to the write pole. The notch assures adequate physical, magnetic, and electrical separation between the write pole and the shield, while allowing un-notched portions of the shield to provide additional magnetic shielding.

Owner:WESTERN DIGITAL TECH INC

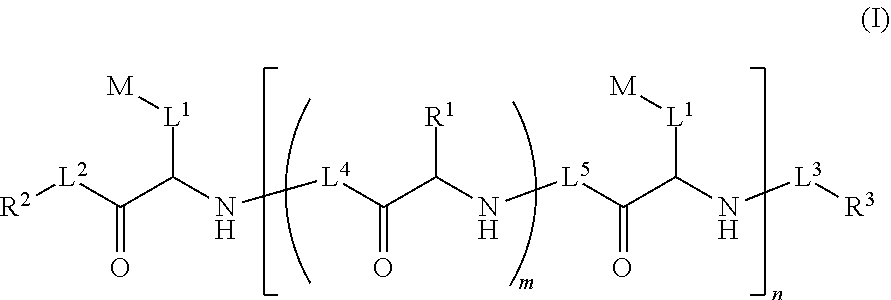

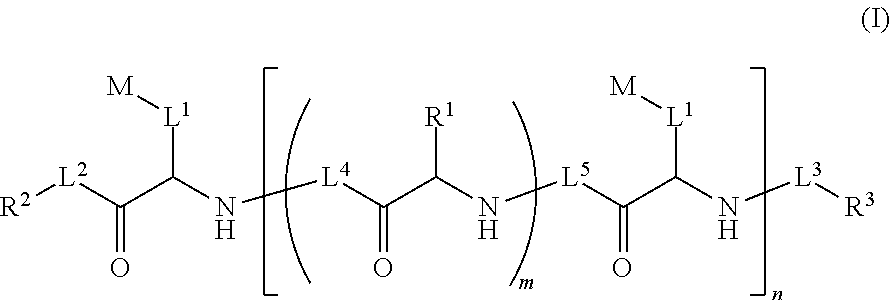

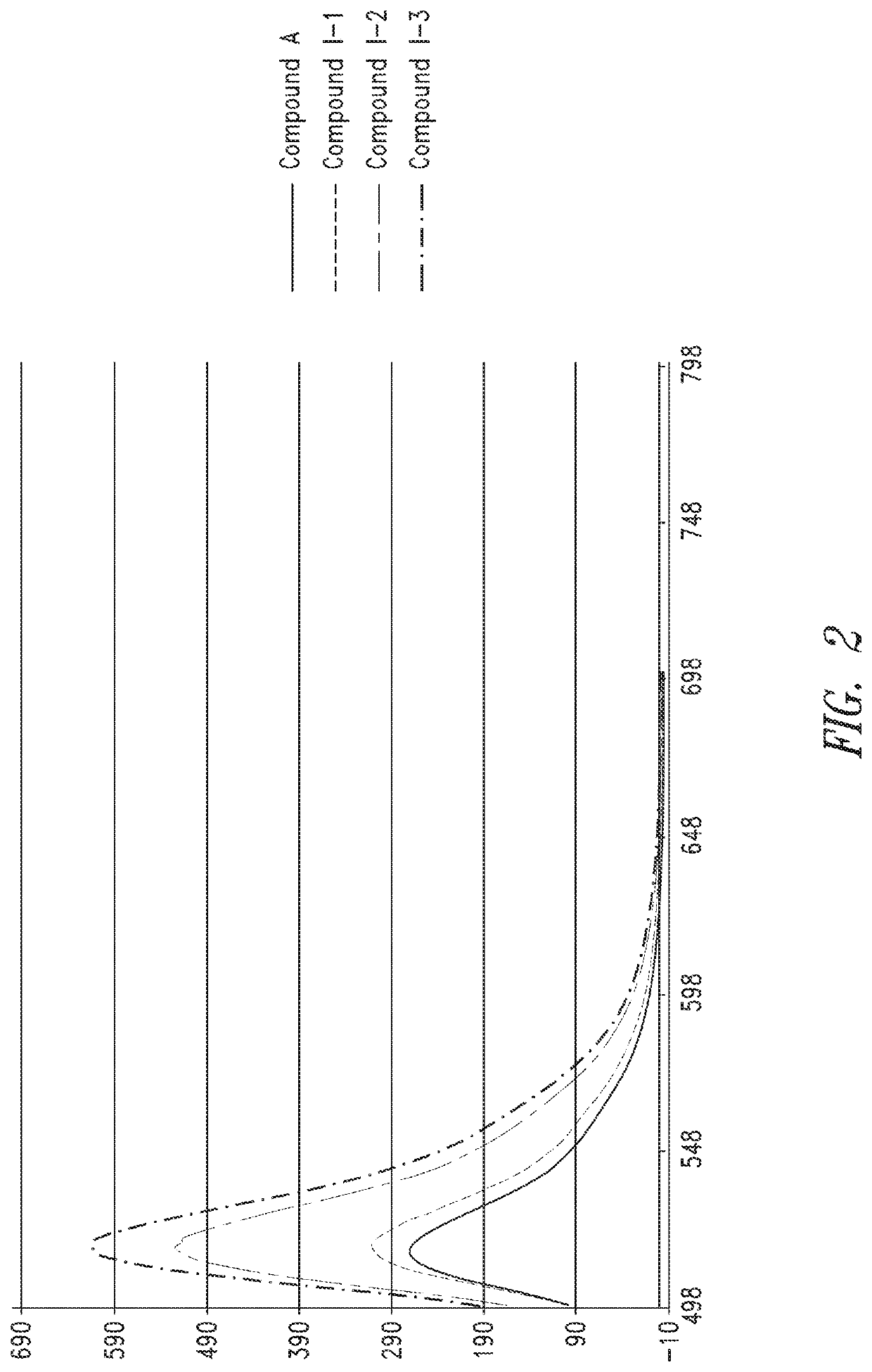

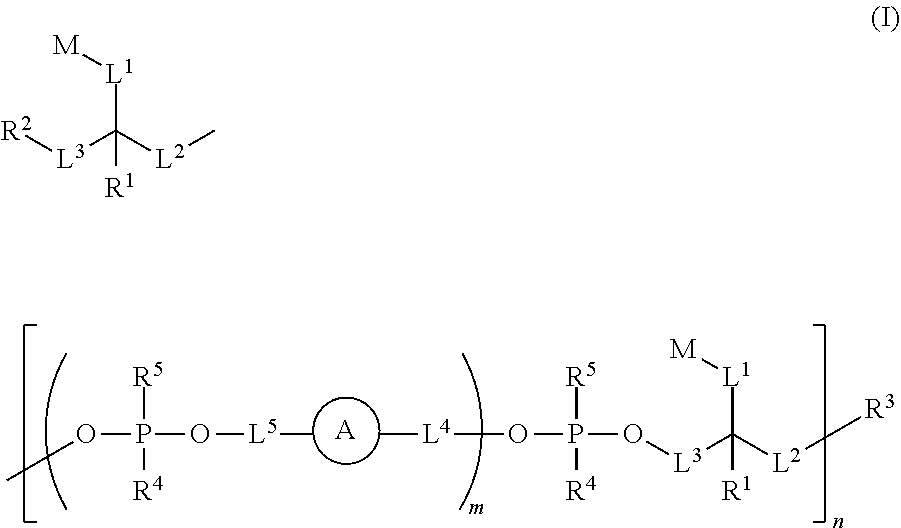

Ultra bright polymeric dyes with peptide backbones

ActiveUS20190153232A1Ensure sufficient separationEasy to mergeOrganic dyesCarrier-bound/immobilised peptidesFluorescenceStereoisomerism

Compounds useful as fluorescent or colored dyes are disclosed. The compounds have the following structure (I), including stereoisomers, salts and tautomers thereof, wherein R1, R2, R3, L1, L2, L3, L4, L5, M, m and n are as defined herein. Methods associated with preparation and use of such compounds are also provided.

Owner:SONY CORP

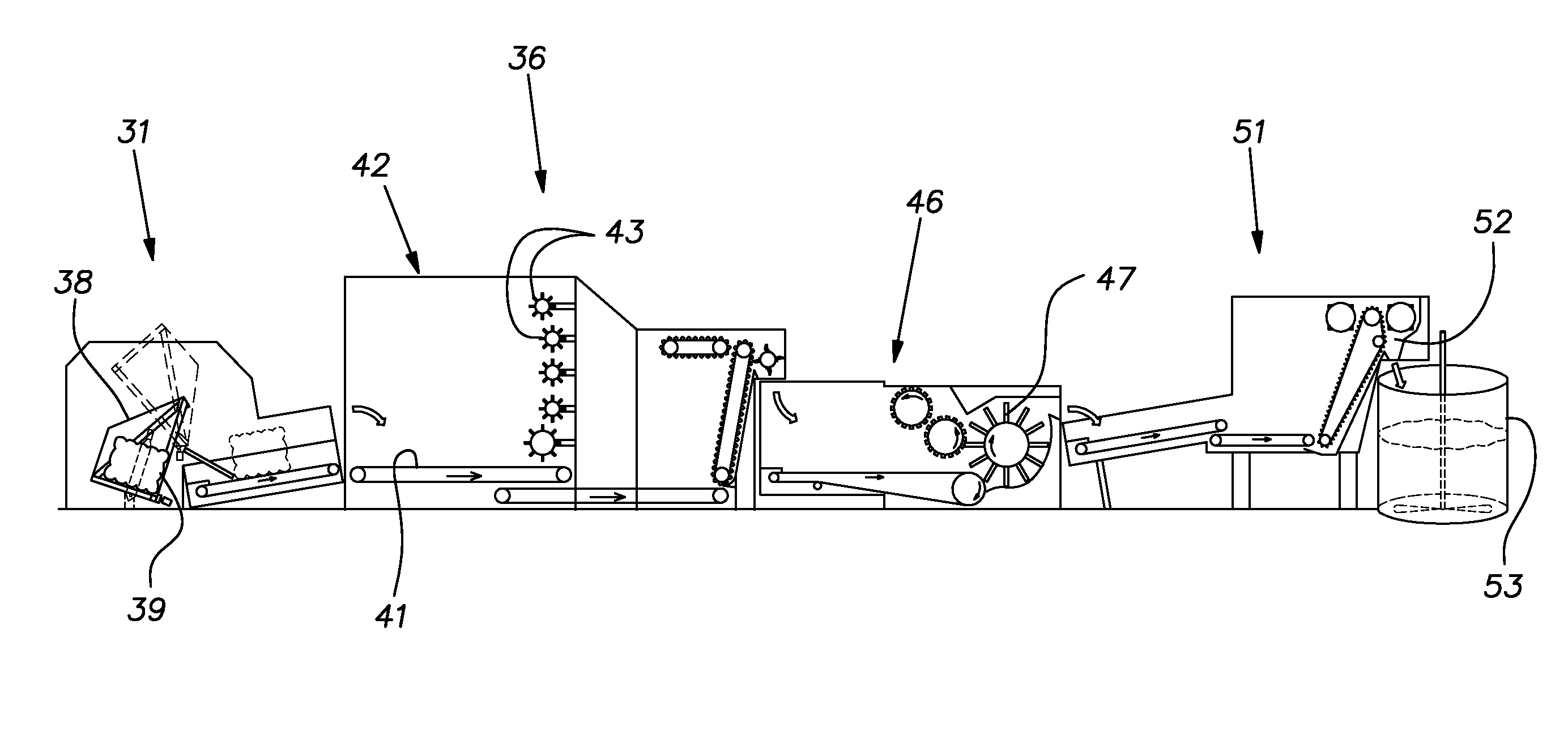

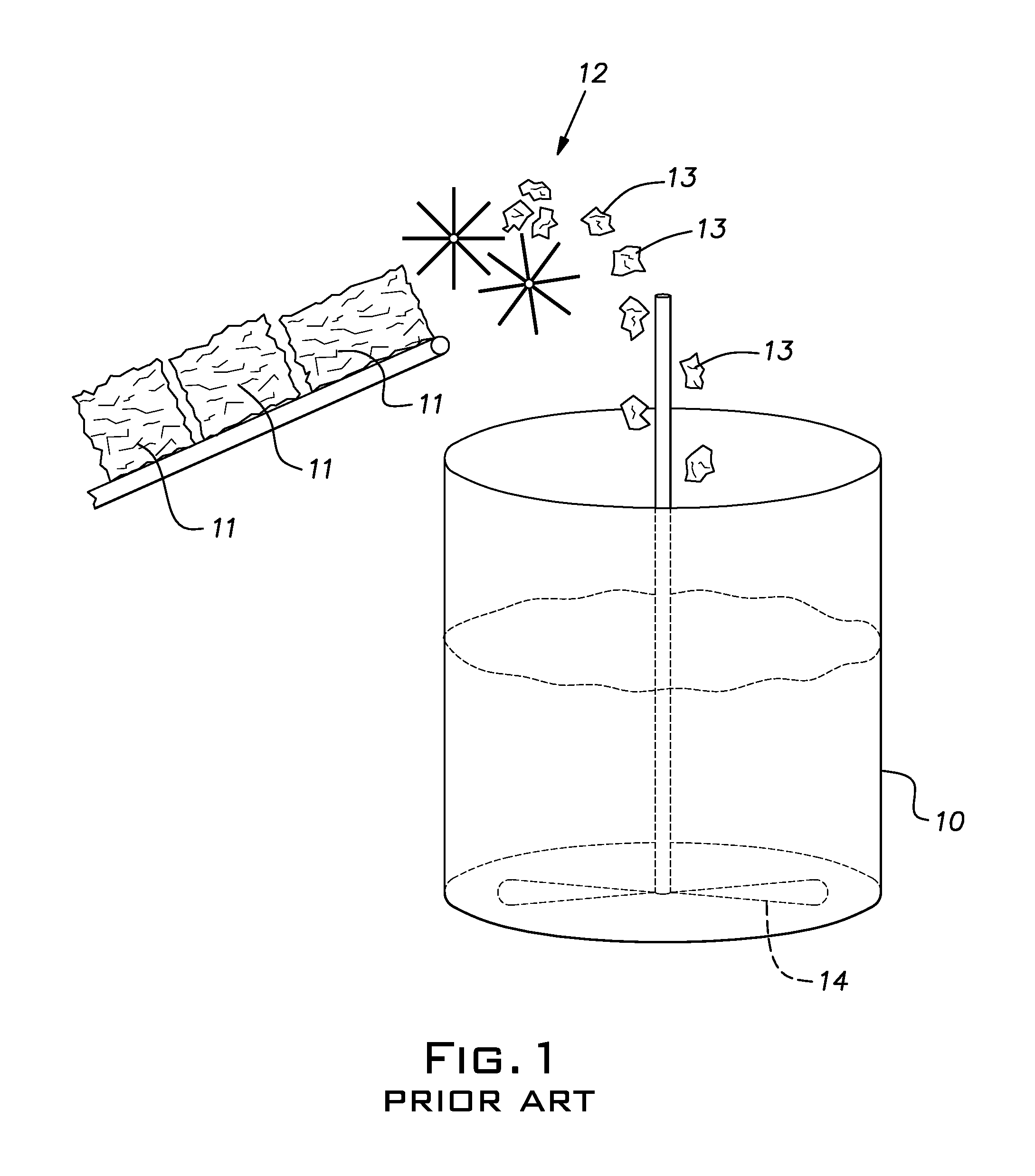

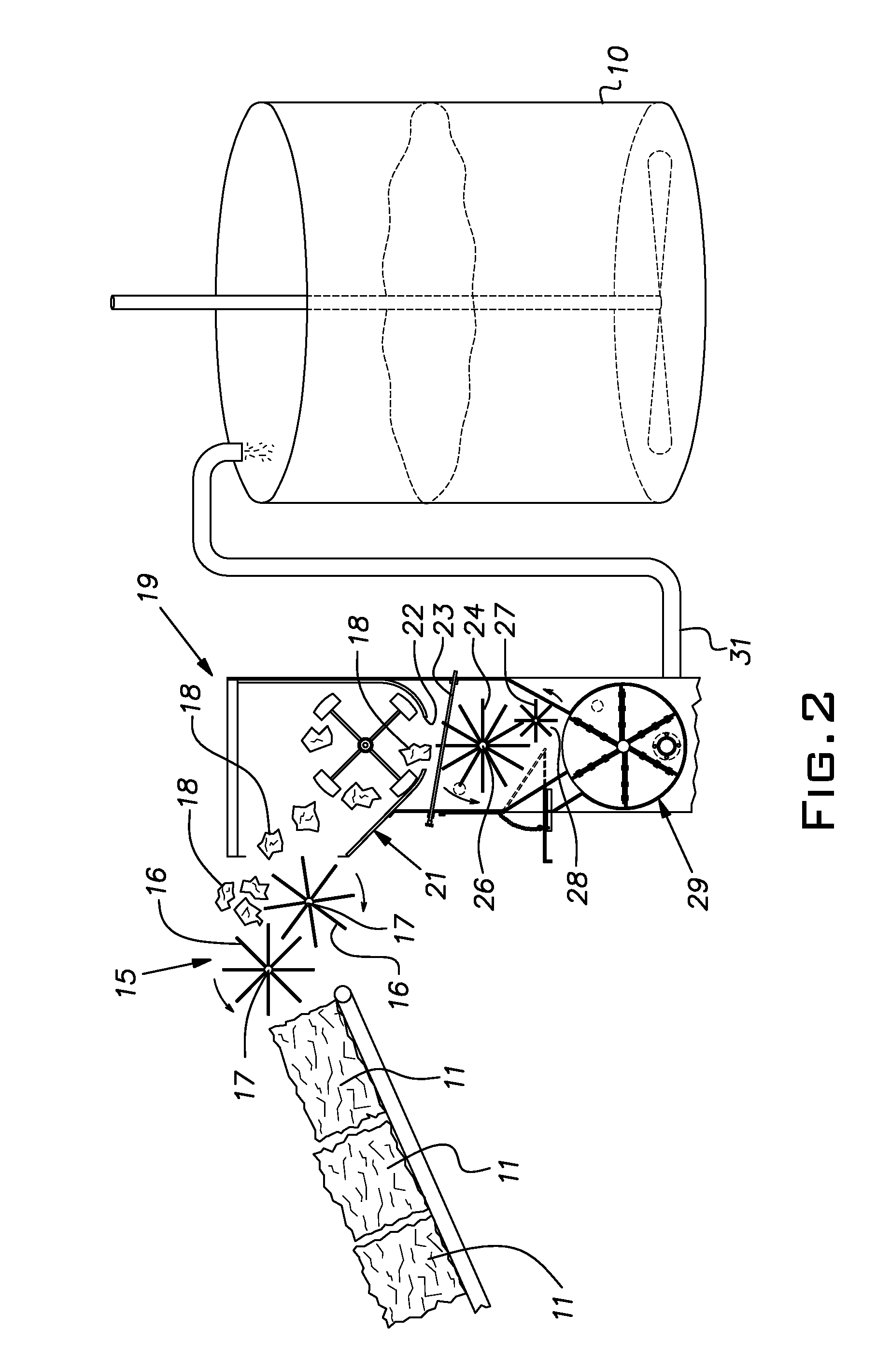

Air dispersion of mineral fibers in ceiling tile manufacture

InactiveUS8894811B1Improve performanceHigh NRC valueNon-fibrous pulp additionNatural cellulose pulp/paperFiberMaterials science

A method of forming a dilute water slurry for water felting a basemat for an acoustical ceiling tile comprising delivering a bale of compressed mineral wool with a density of at least 8 lbs. per cubic foot at an unbaling station, releasing a binding holding the bale in compression, mechanically separating the fibers of a mineral wool bale with mechanical instrumentalities arranged to disperse the fibers to a generally uniform density of less than 2 lbs. per cubic foot prior to passage of the fibers through the tank inlet, and causing the separated mineral fibers to pass into the mixing tank for contact with water suspended binder.

Owner:USG INTERIORS LLC

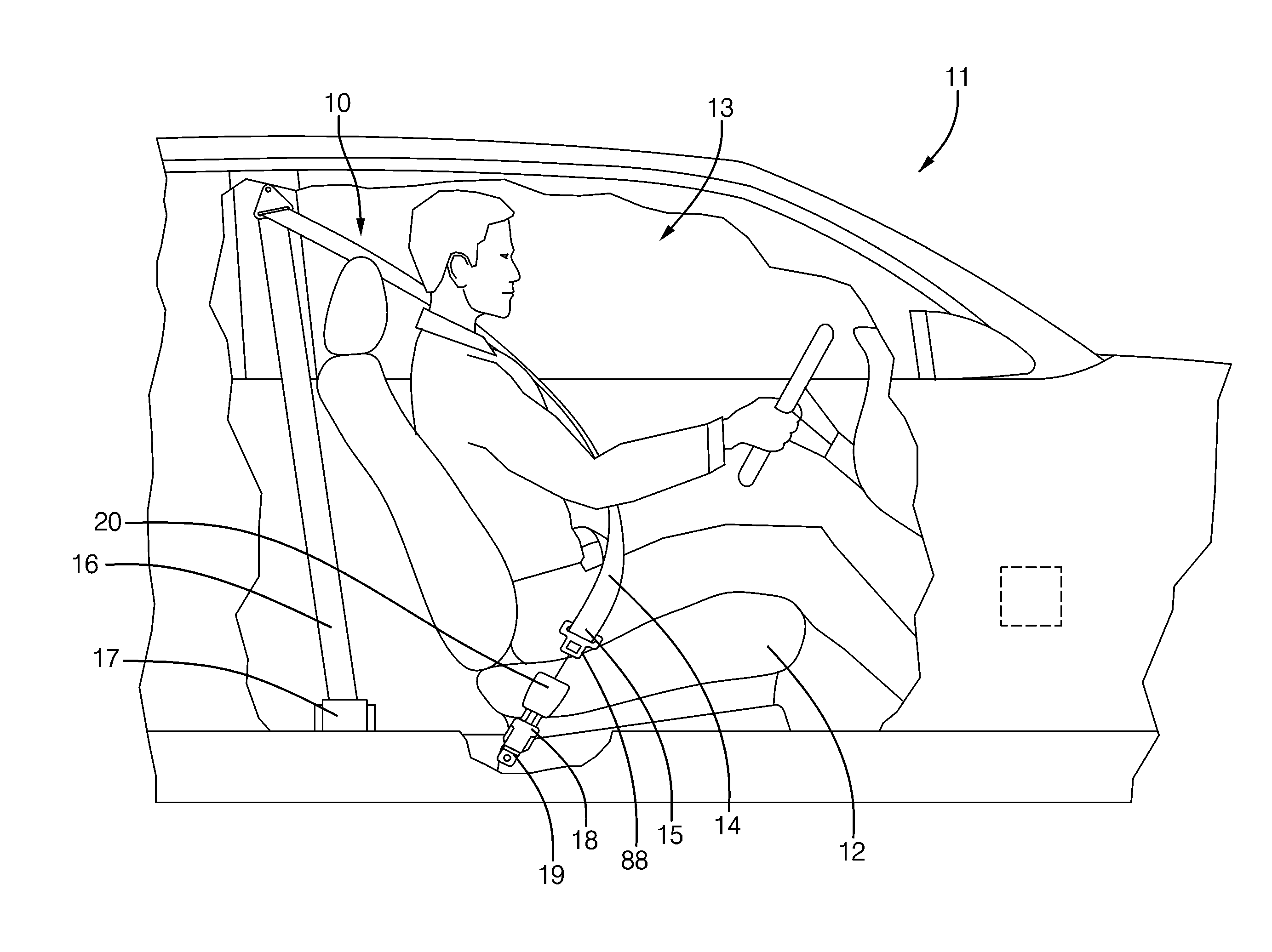

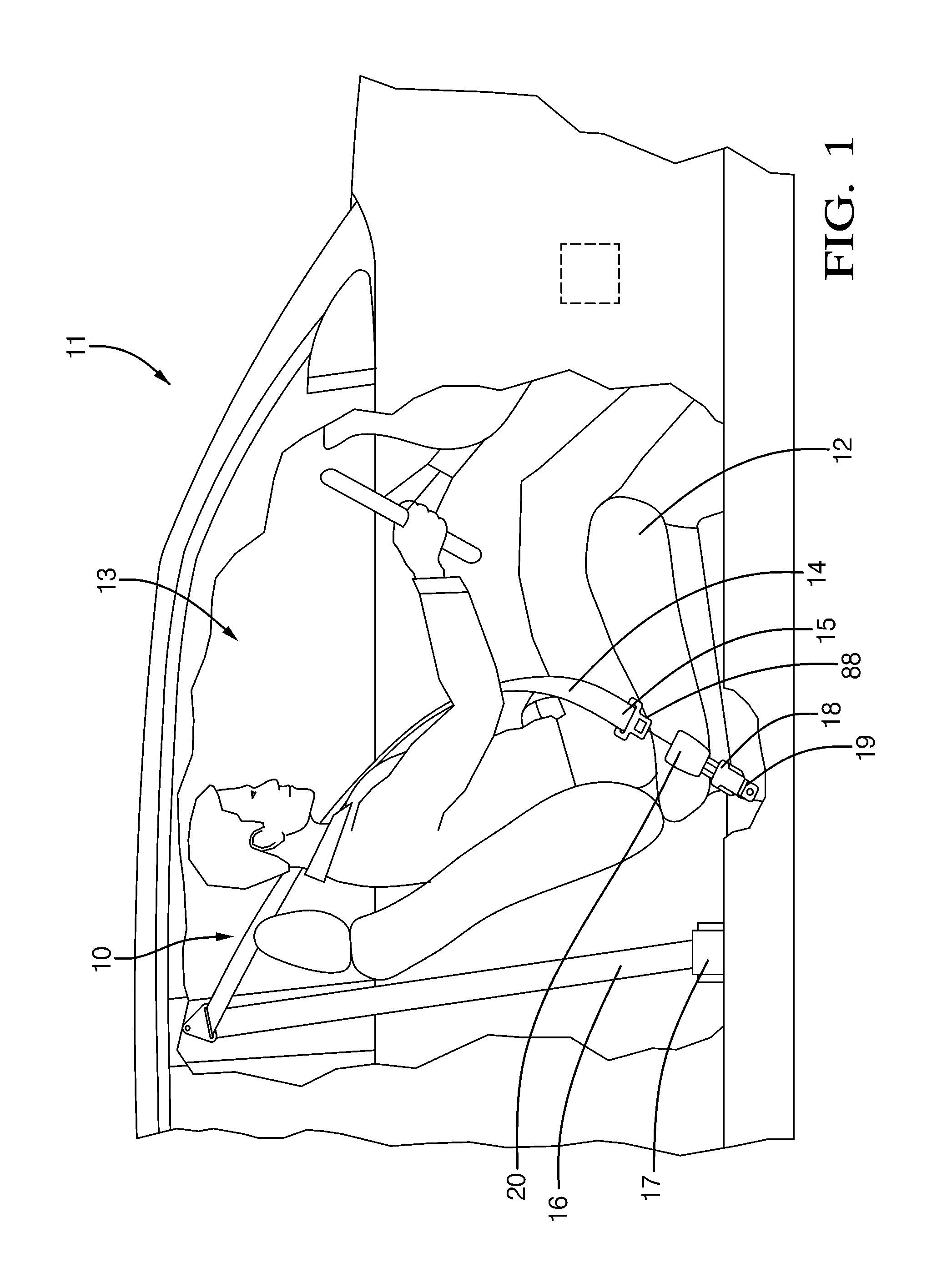

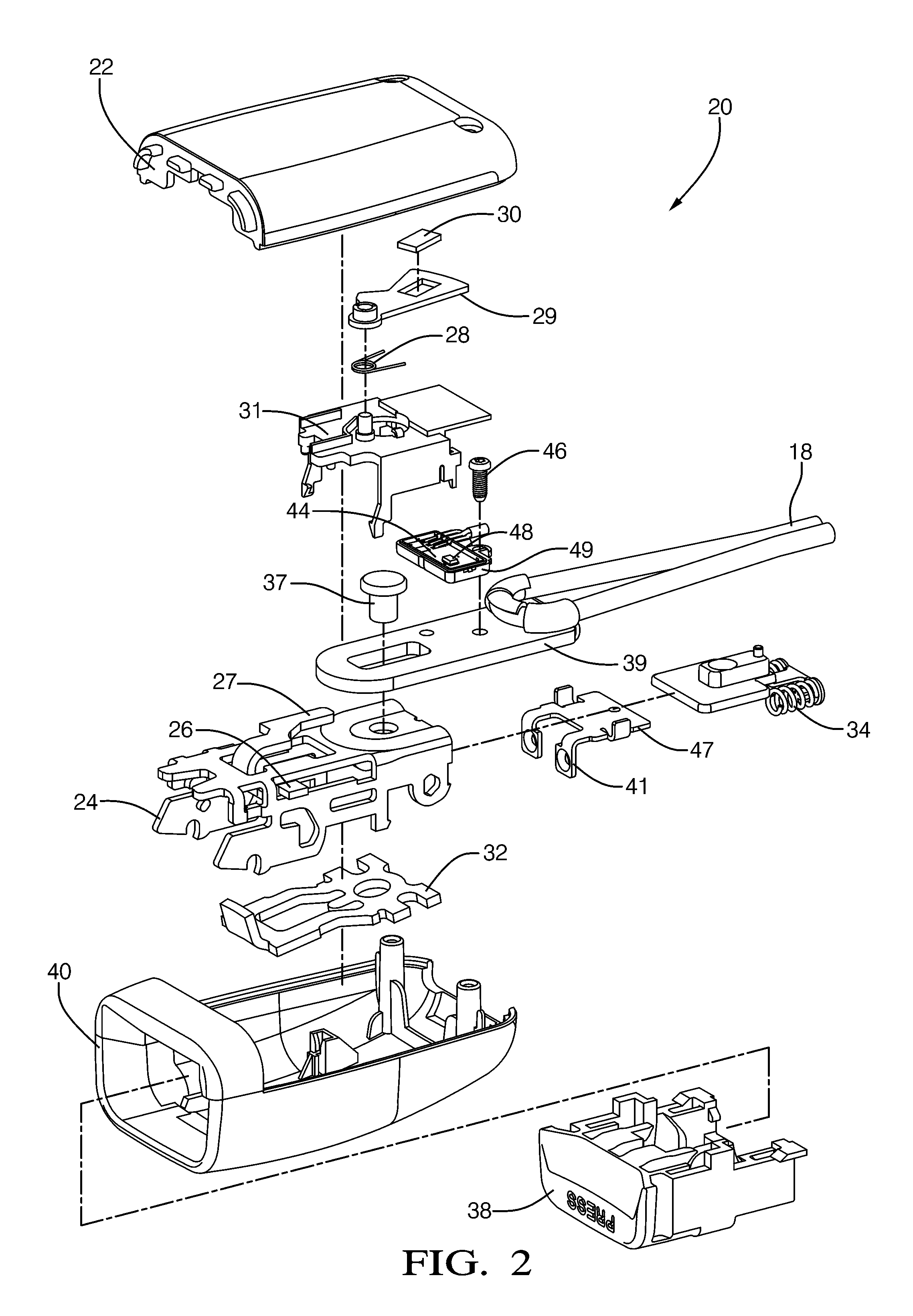

Seat belt system with buckle latch and tension sensor

ActiveUS20130207442A1Good output signalEnsure sufficient separationMagnetic measurementsSlide fastenersRelative displacementMagnet

A seat belt system configured for use in a vehicle includes a seat belt buckle assembly that is configured to determine the both the latch condition of the seat belt buckle assembly with the seat belt tongue, and the tension applied to the seat belt webbing in a seat belt system. The seat belt buckle assembly includes a latch configured to receive and engage the seat belt tongue, a magnet, and a magnetic sensor configured to determine relative displacement of the magnet. The seat belt buckle assembly is configured to cause a first displacement between the magnet and the magnetic sensor in response to engagement of the seat belt tongue with the latch and cause a second displacement between the magnet and the magnetic sensor in response to tension on the seat belt webbing via the seat belt tongue. The first displacement is distinct from the second displacement.

Owner:APTIV TECH LTD

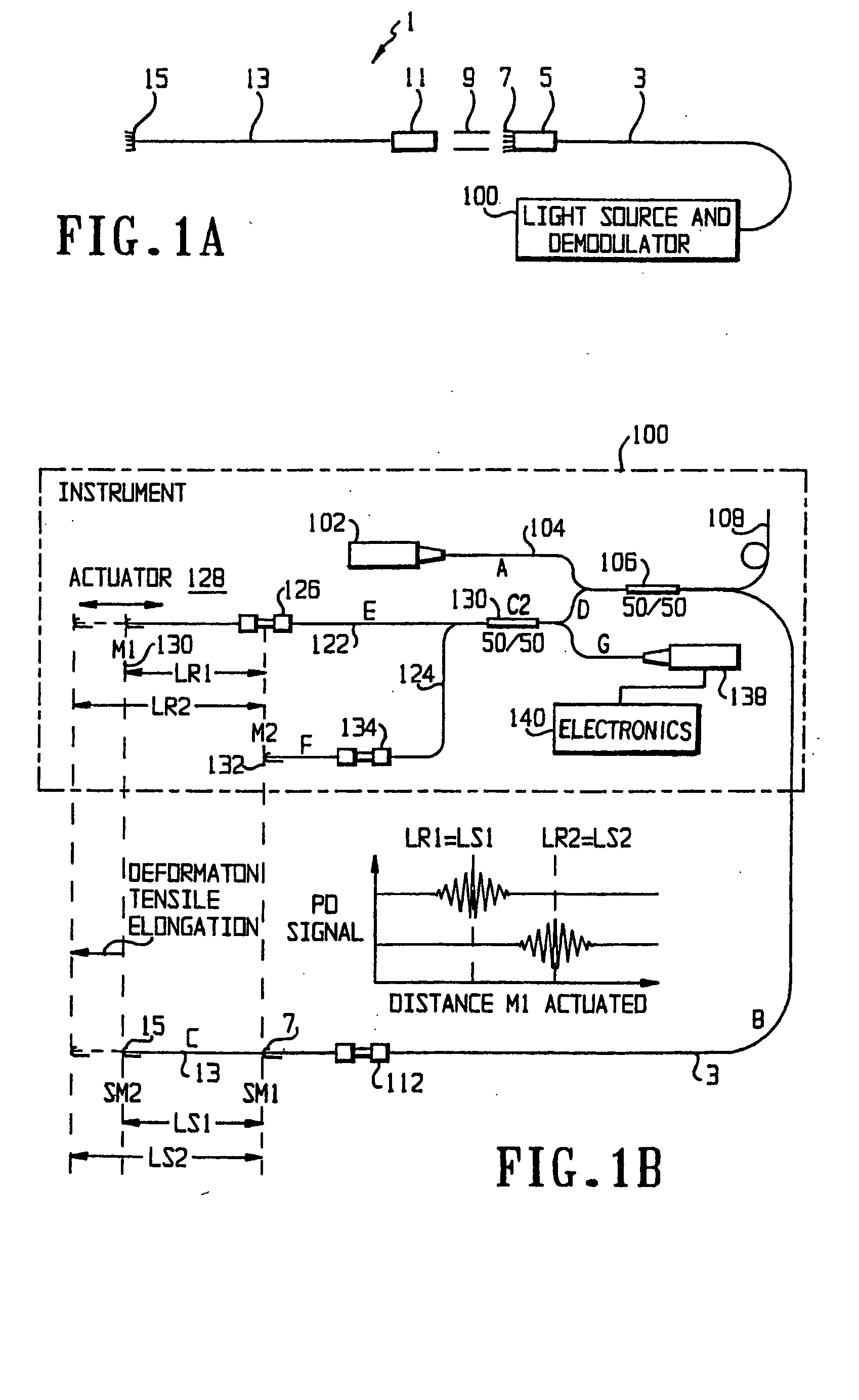

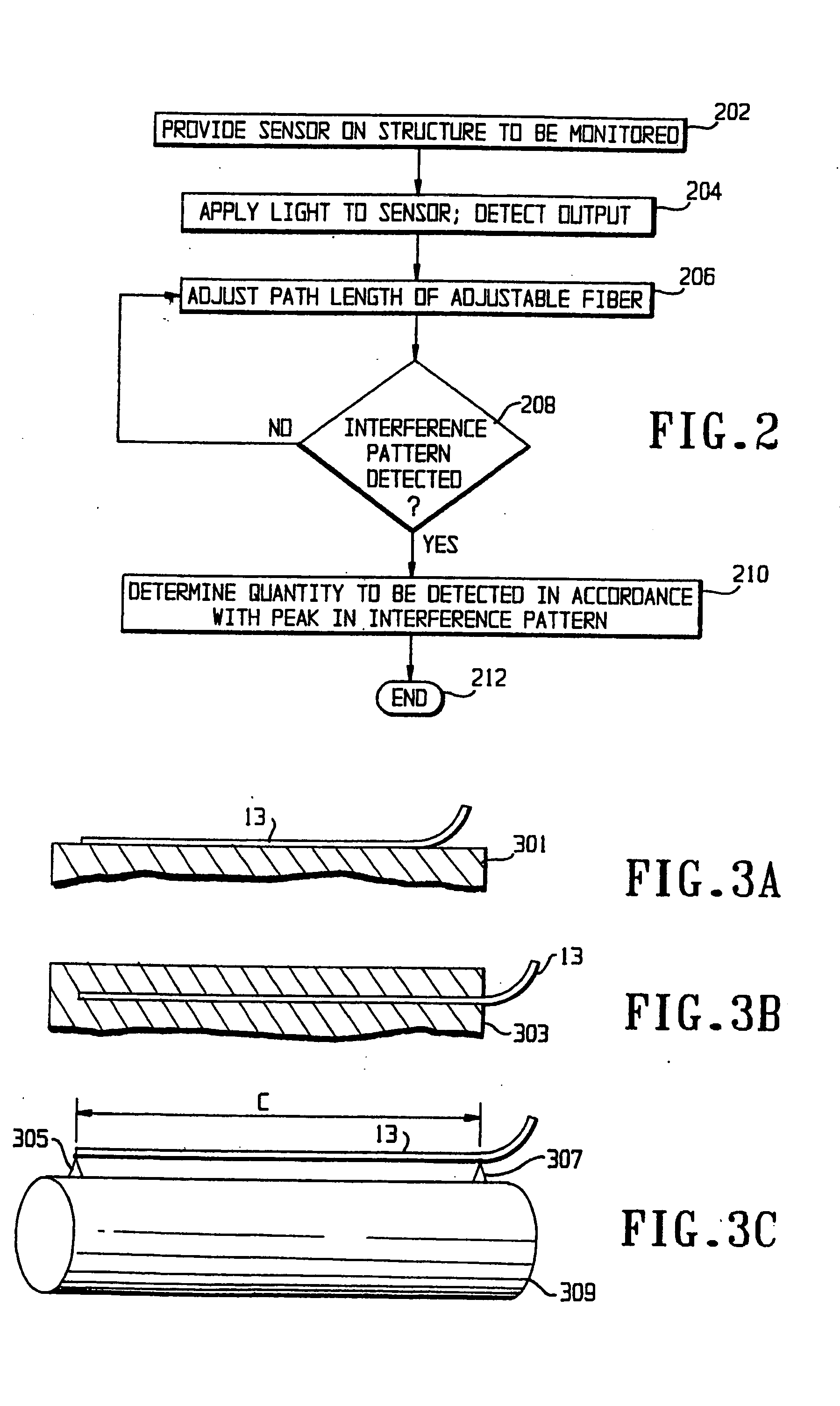

Fiber optic sensing instrument and system with fiber of adjustable optical path length and method of using it

InactiveUS20050046861A1Ensure sufficient separationEasy to separateUsing optical meansConverting sensor output opticallyFiberOptical pathlength

An interoferometric fiber optic sensing system uses three optical fibers. A sensing optical fiber is applied to a structure to be monitored to detect displacement or the like by changing its optical path length. A reference optical fiber has a fixed optical path length. An adjustable length optical fiber is controllably adjusted in its optical path length. The three optical fibers form optical paths whose light outputs are caused to interfere. The adjustable length optical fiber is adjusted until an interference fringe appears. The quantity to be detected is derived from the maximum of the interference fringe. Several sensing optical fibers can be multiplexed; by staggering their optical path lengths, their interference fringes can be separated sufficiently to resolve them.

Owner:MORISON W DON +4

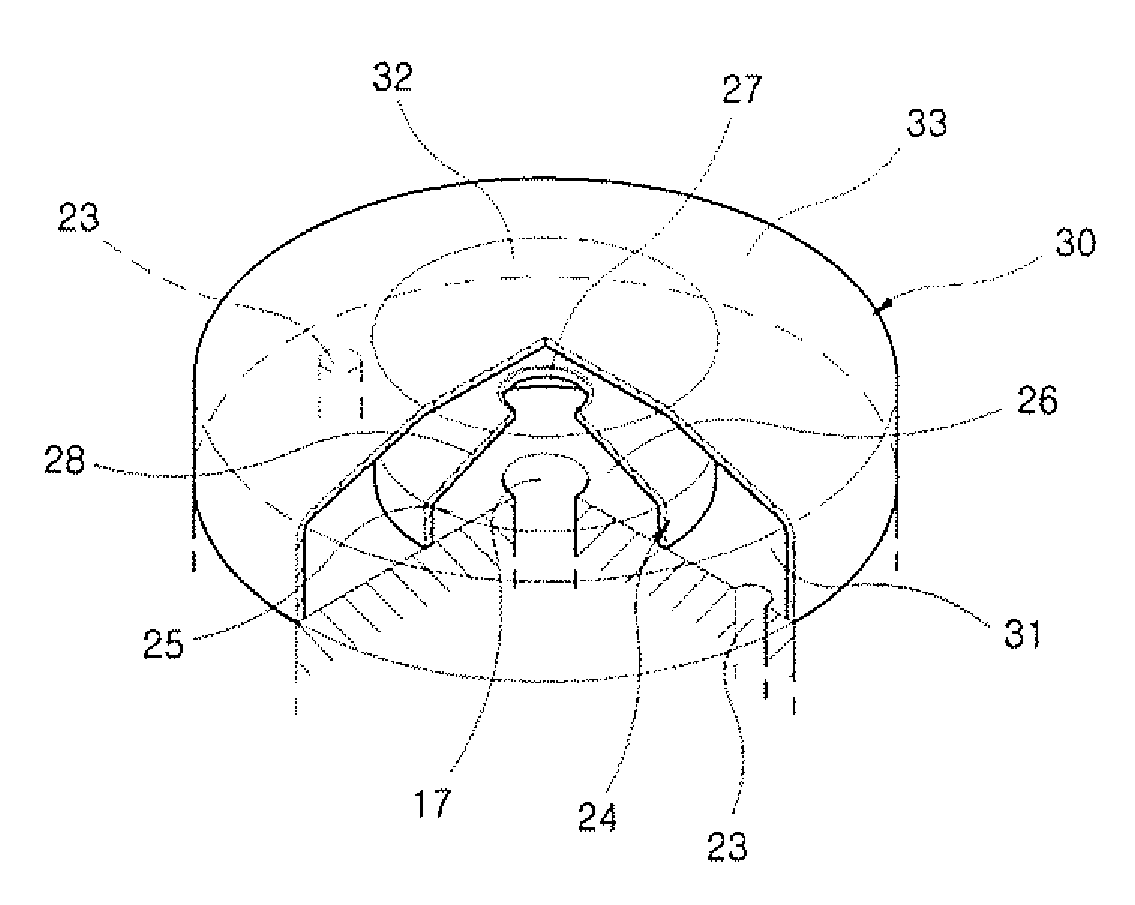

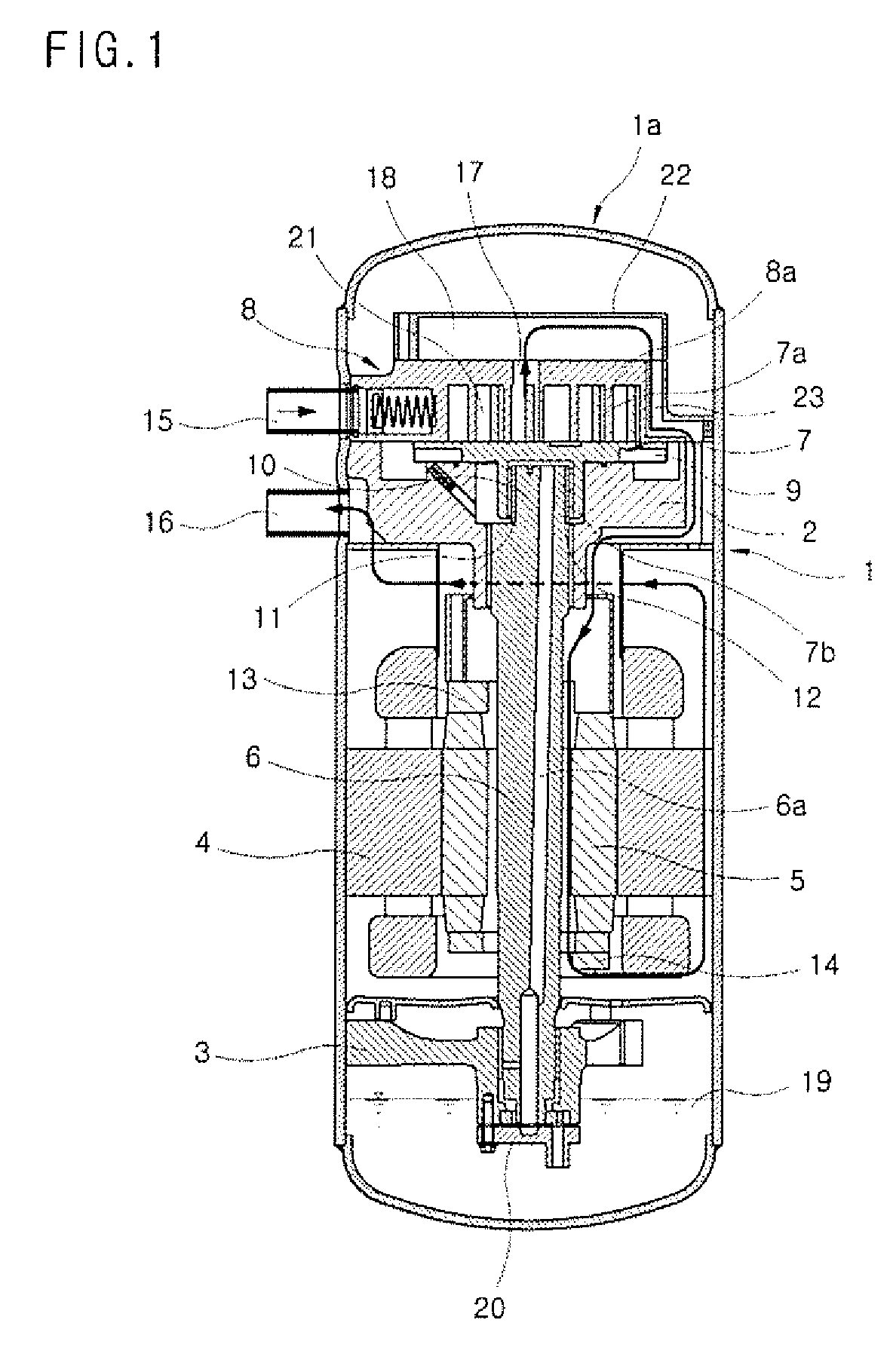

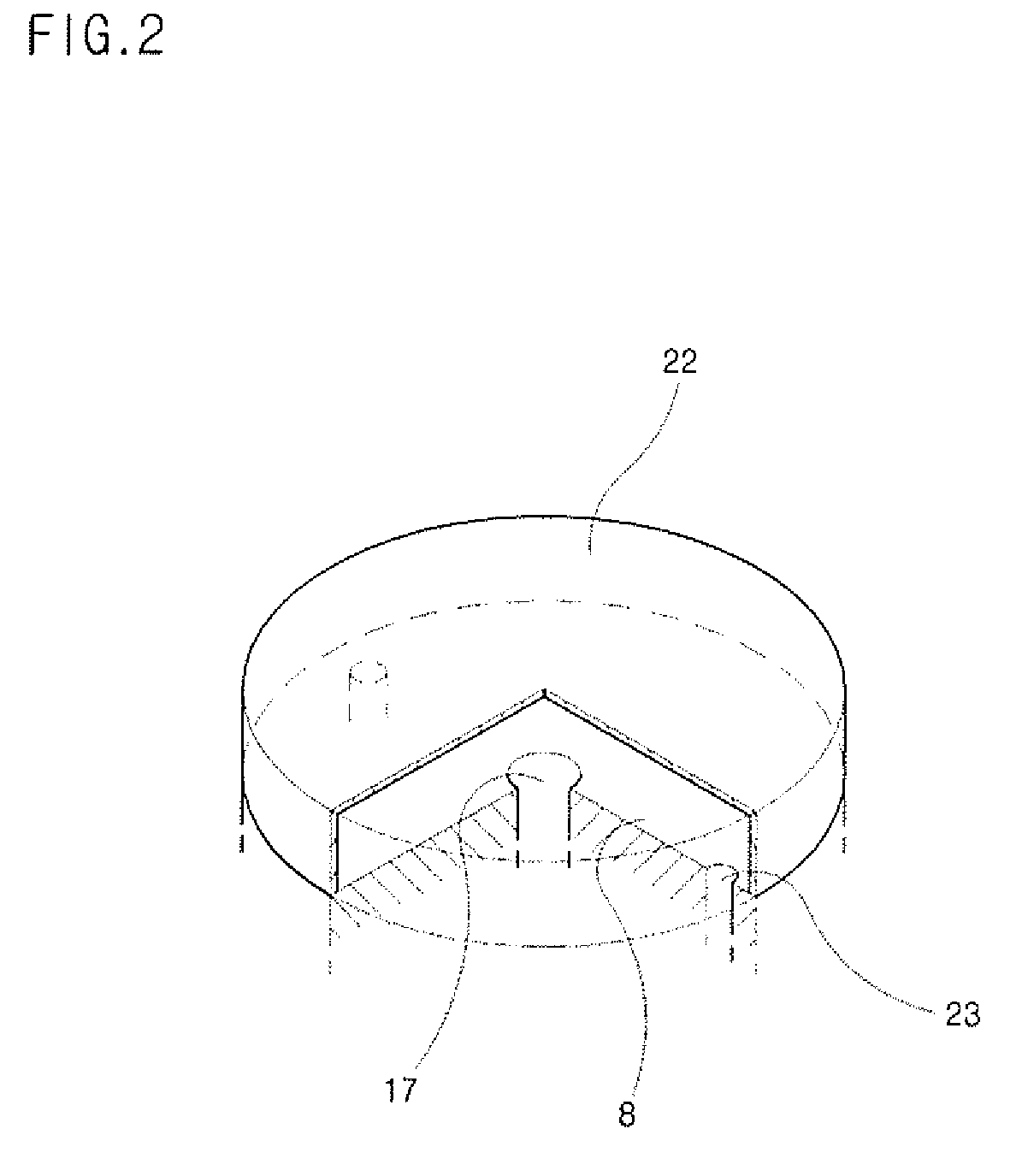

Muffler of scroll compressor

ActiveUS20080008612A1Sufficient noise transmission lossEnsure sufficient separationRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeEngineeringDischarge pressure

Disclosed herein is a muffler of a scroll compressor. The muffler includes a first muffler having a pair of chambers defined above an outlet of a fixed scroll to communicate with the outlet and a gas passage hole formed at the center of an upper end thereof, and a second muffler located around the first muffler to be spaced apart from the gas passage hole of the first muffler and having a chamber including one or more guidance paths of the fixed scroll. The muffler can achieve reduction of operational noise, sufficient separation of oil contained in discharge gas, and efficient isolation between a discharge pressure inside the muffler and outside suction pressure.

Owner:LG ELECTRONICS INC

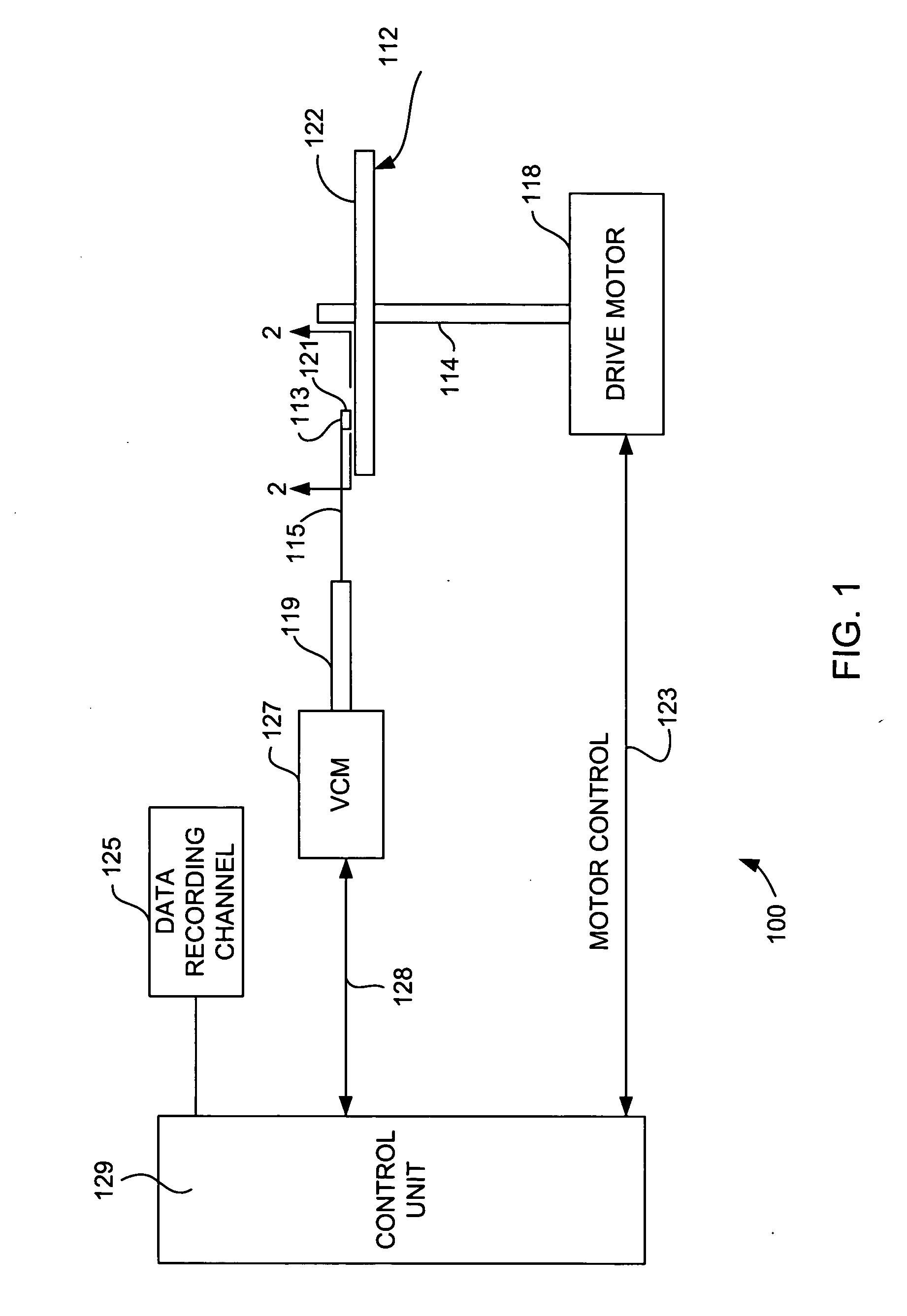

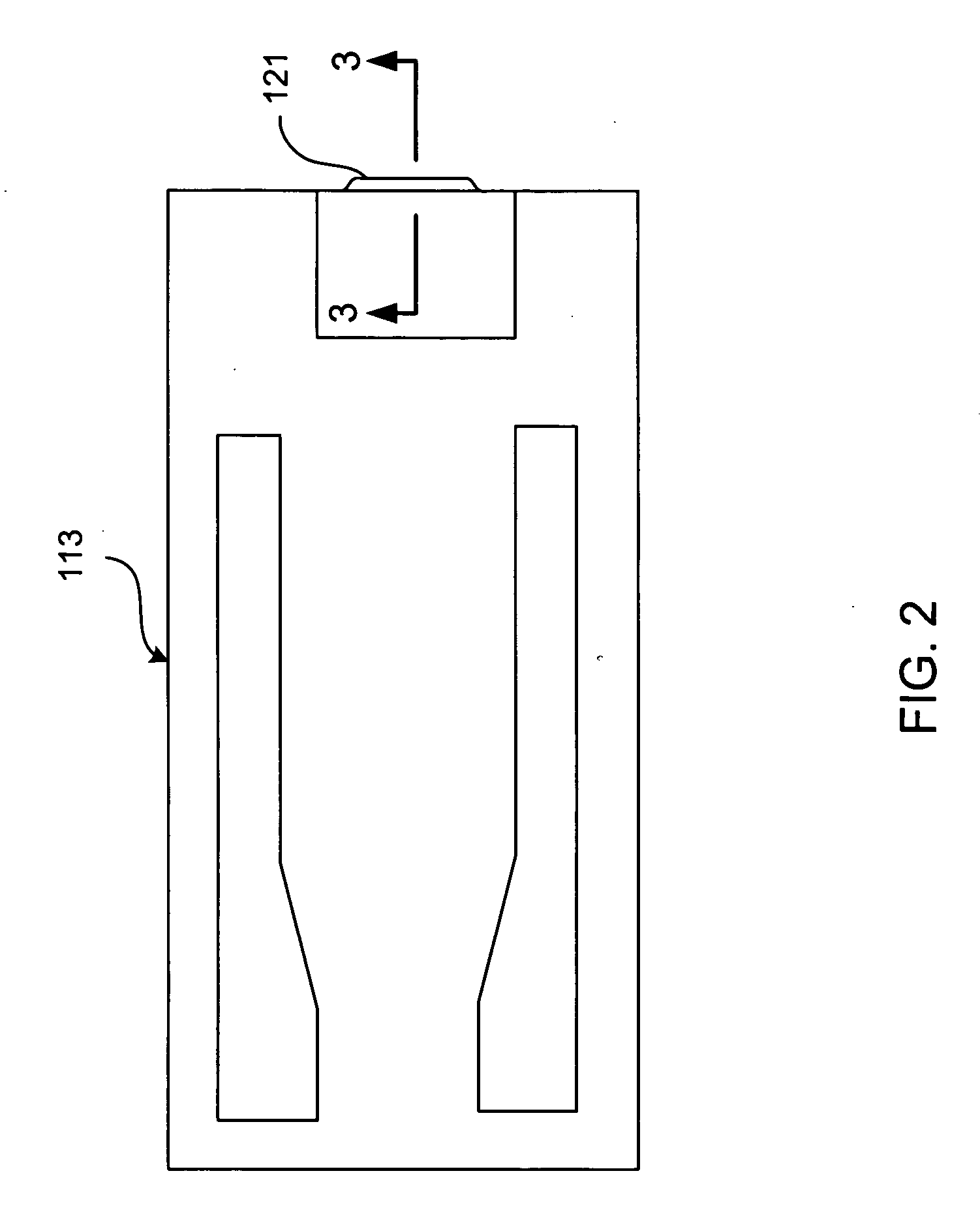

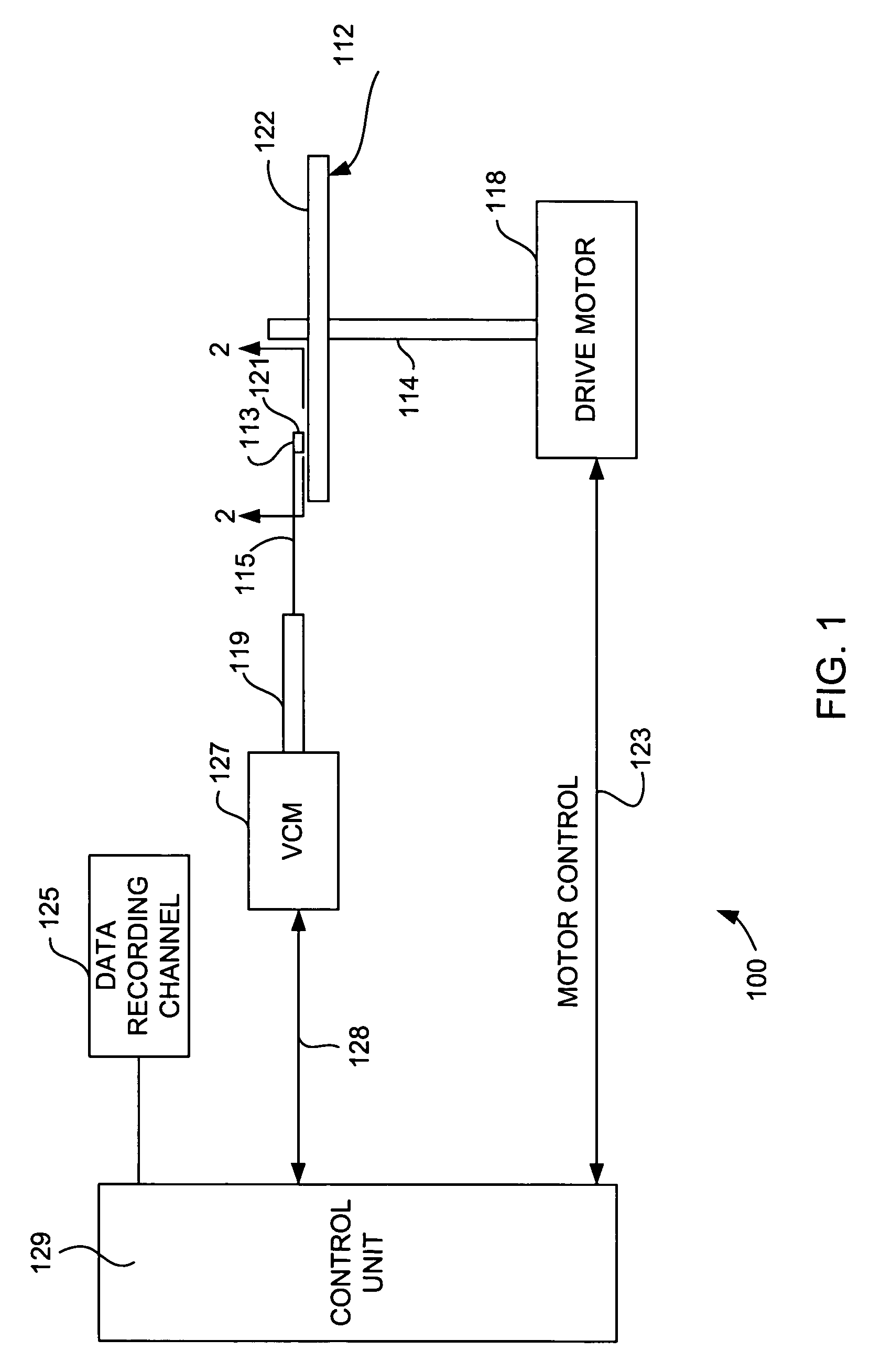

Write head design with improved bump to control write saturation

InactiveUS7110217B2Less topographyPole process robustConstruction of head windingsFluid-dynamic spacing of headsEngineeringMechanical engineering

A magnetic head having an air bearing surface (ABS) and a first pole tip. A second pole tip is spaced apart from and facing the upper end of the first pole tip across a write gap. A bump extends into a portion of the upper end of the first pole tip and a portion of the bottom end of the second pole tip, the bump being positioned away from the ABS. The bump defines a throat height of the first and second pole tips.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

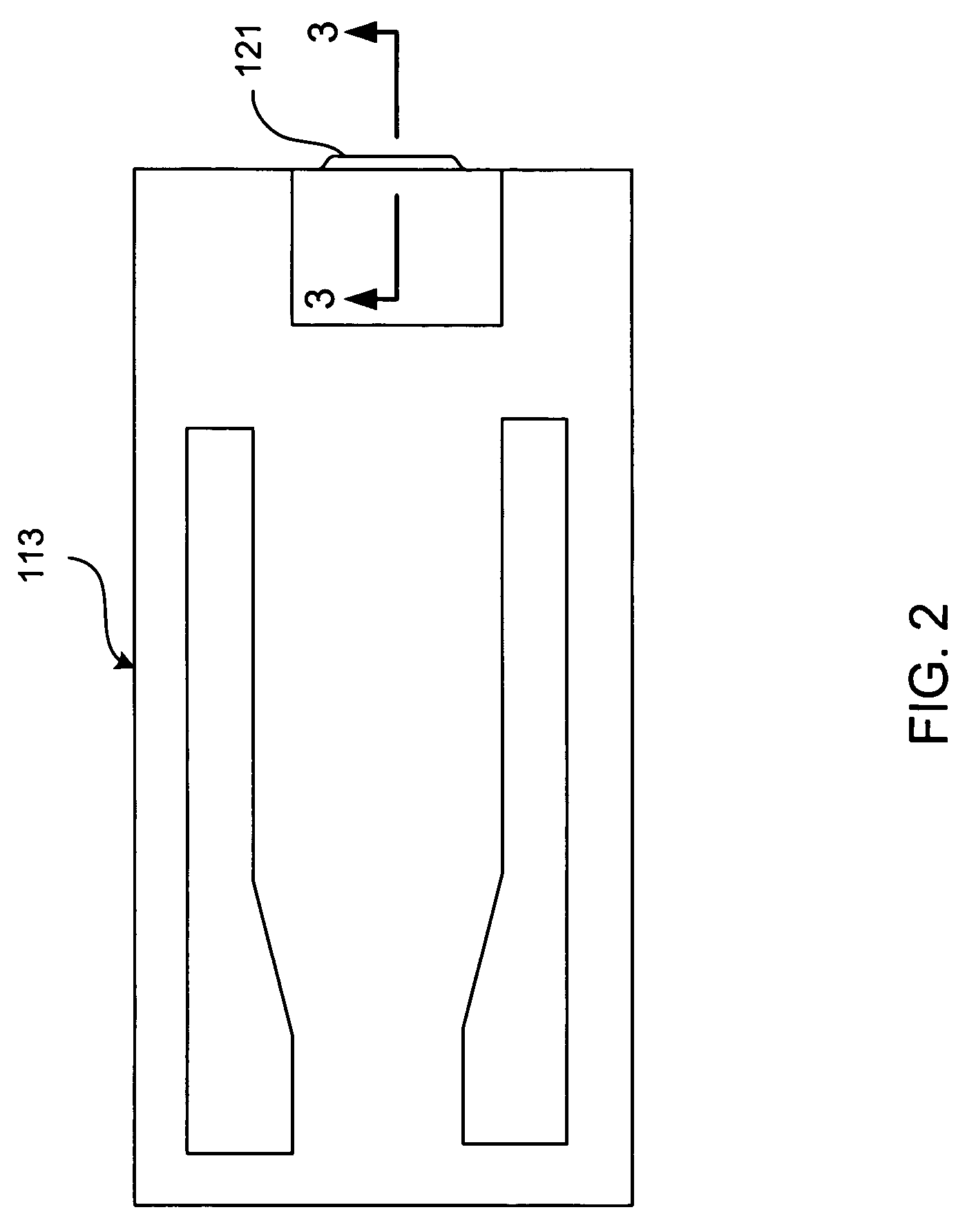

Method of purging trapped gas from a system fluid contained in an actuation valve

ActiveUS7169616B2Ensure sufficient separationMinimize dispersion and dilutionWithdrawing sample devicesSteam trapsInspired gasVALVE PORT

An apparatus and method for delivering repetitive, precision, low volume liquid dispensing from a dispensing orifice of a non-contact liquid dispensing apparatus. An elongated communication passageway of the dispensing apparatus is defined by interior walls having one end in fluid communication with a system fluid reservoir and an opposite end terminating at the dispensing orifice. A system fluid is placed in the communication passageway extending substantially continuously from the system fluid reservoir to the dispensing orifice. A relatively small volume of gaseous fluid is aspirated through the dispensing orifice, and into the communication passageway in a manner such that the gaseous fluid extends substantially continuously across the transverse cross-sectional dimension of the communication passageway. Subsequently, a dispensing liquid is aspirated through the dispensing orifice and into the communication passageway in a manner such that the relatively small volume of aspirated gaseous fluid forms a minute, unitary air gap fully enclosed between the interior walls of the communication passageway and a liquid interface between the system fluid and the dispensing liquid contained in the communication passageway. This minute air gap substantially prevents dispersion and dilution therebetween at the liquid interface. To effect dispensing, a rapid pressure pulse with a predetermined pulse width is applied to the system fluid upstream from the minute air gap, causing the pressure pulse to traverse the minute air gap to the dispensing liquid without substantial fluid compression of the minute air gap. This enables substantially accurate, relatively small volume, non-contact liquid dispensing of the dispensing liquid from the dispensing orifice.

Owner:BIONEX SOLUTIONS

Color light receiving device and image pickup device

InactiveUS7579665B2Ensure sufficient separationTelevision system detailsTelevision system scanning detailsPhotoelectric conversionLength wave

A light receiving device and an image pickup device in which a plurality of light receiving devices are arranged are provided. The light receiving device comprises a single semiconductor substrate and a light receiving device that has a first photoelectric conversion part and a second photoelectric conversion part. The single semiconductor substrate comprises regions of a first conductivity type and regions of a second conductivity type in an alternately multiply stacked manner. Depths of each of the junction surfaces between the regions of first conductivity type and second conductivity type are formed at depths such that light mainly in the blue or red wavelength regions can be photo-electrically converted. The respective detected wavelengths of the first photoelectric conversion part and second photoelectric conversion part are longer than the central wavelength of the blue wavelength region, and shorter than the central wavelength of the red wavelength region.

Owner:FUJIFILM HLDG CORP +1

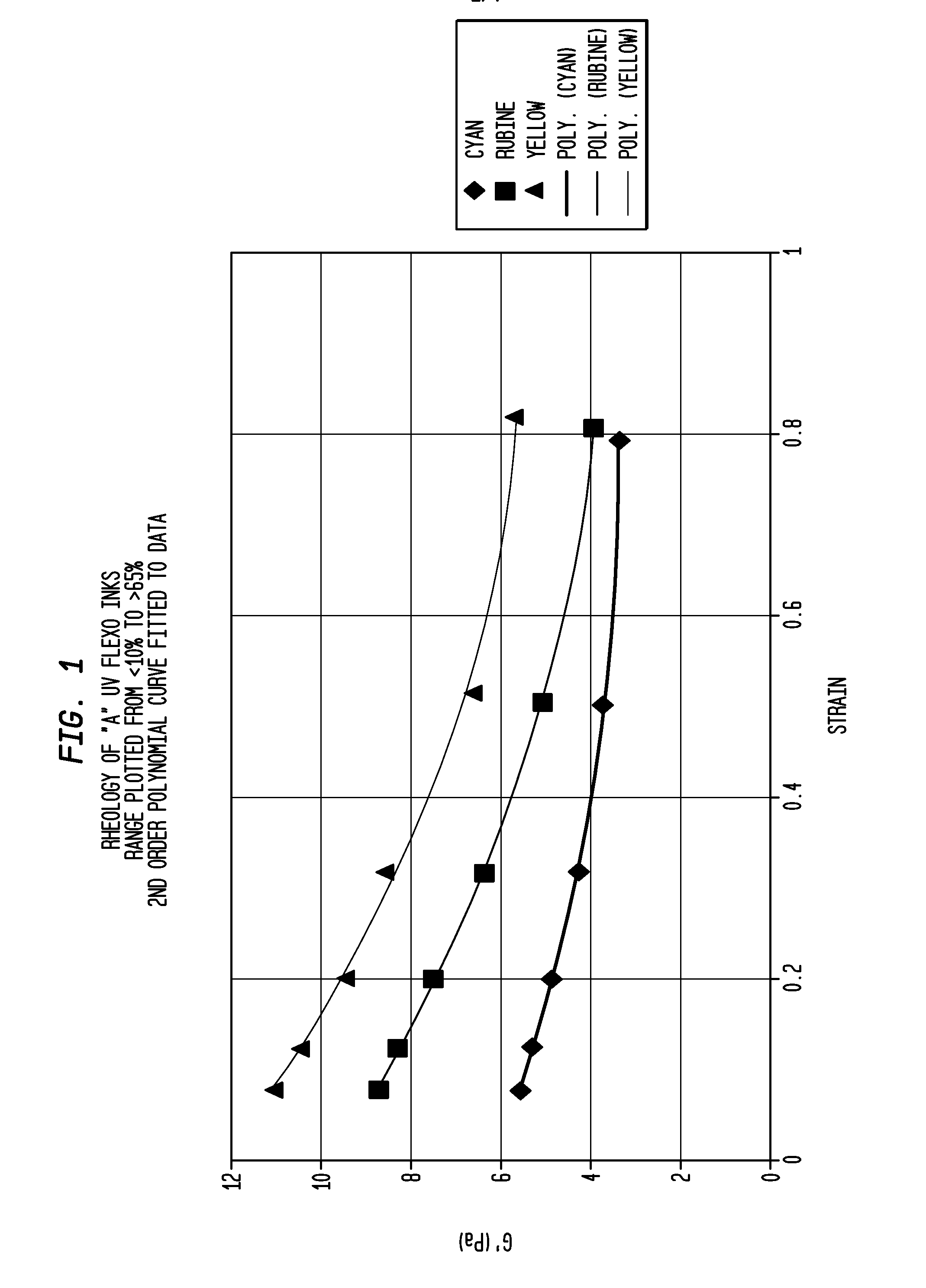

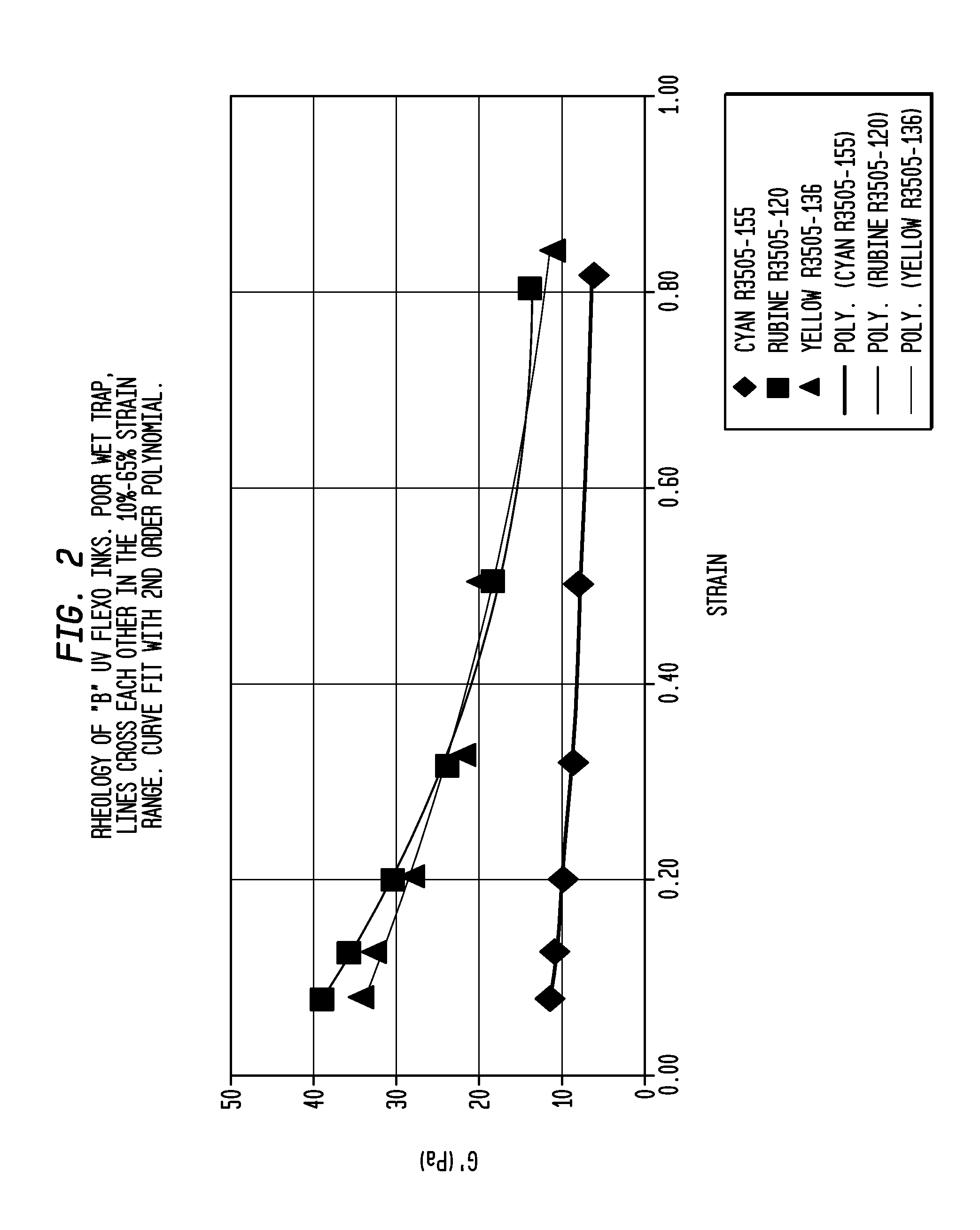

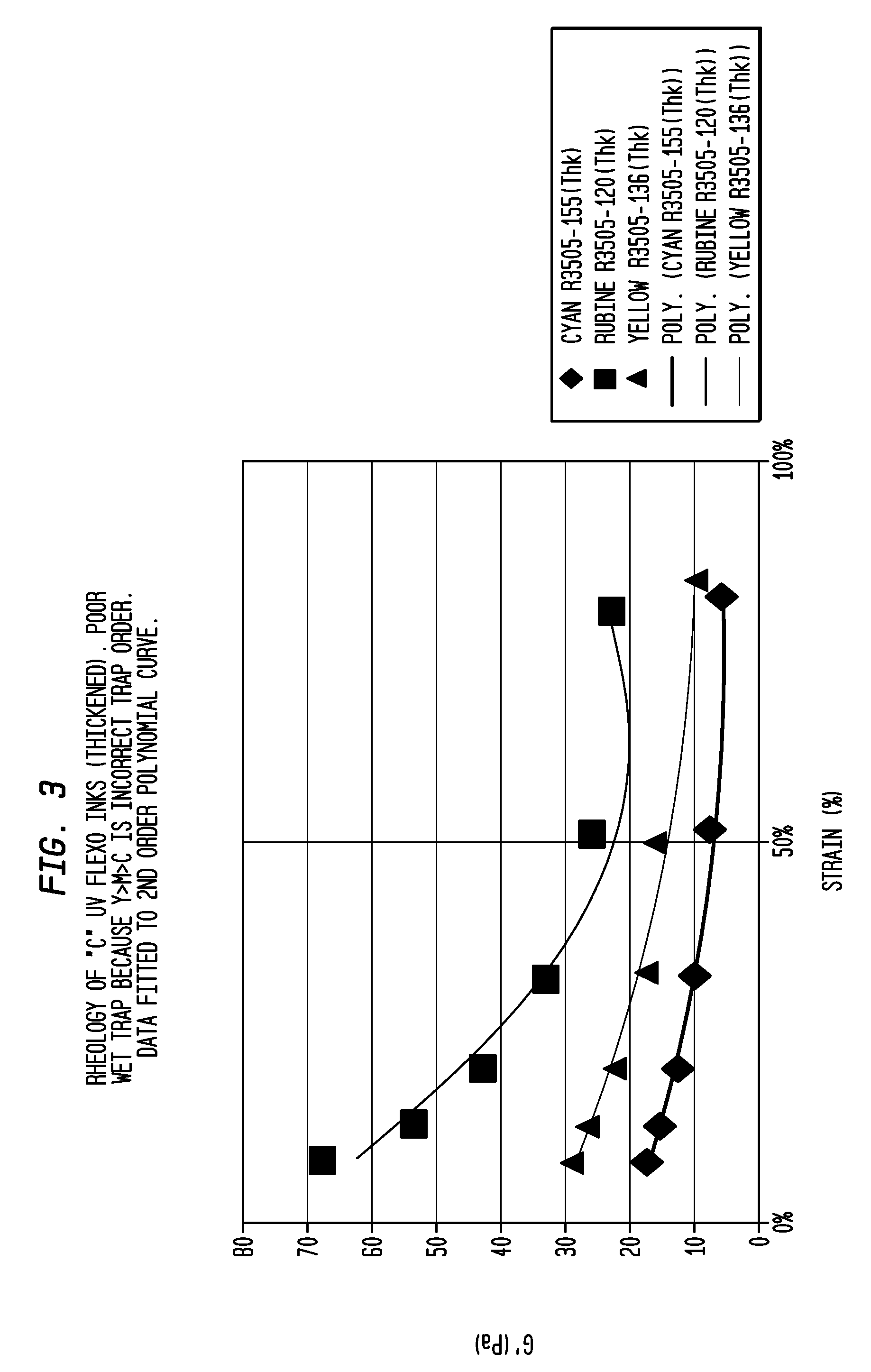

Wet-trapping of energy curable flexographic inks and coatings

ActiveUS20120304879A1Good trappingEnsure sufficient separationInksOther printing apparatusColor printingTrapping

Methods and apparatus for flexographic color printing, and more particularly for implementing “wet trapping” in flexographic printing using energy curable flexographic liquid inks are presented. Radiation curable inks can be formulated that wet trap over each other without back-trapping onto the plates and anilox units of down-line printing units by controlling the storage modulus of the inklcoating. The storage modulus G′ in the inks can be controlled to ensure that the highest G′ ink is printed ISt down with successive colors being trapped in the order of their (declining) G′ values. An image in wet ink can thus be trapped over a different image in wet ink of a different color without picking the ISt ink back up and redepositing it onto the subsequent plates and rollers in the printing press (back-trapping).

Owner:SUN CHEM CORP

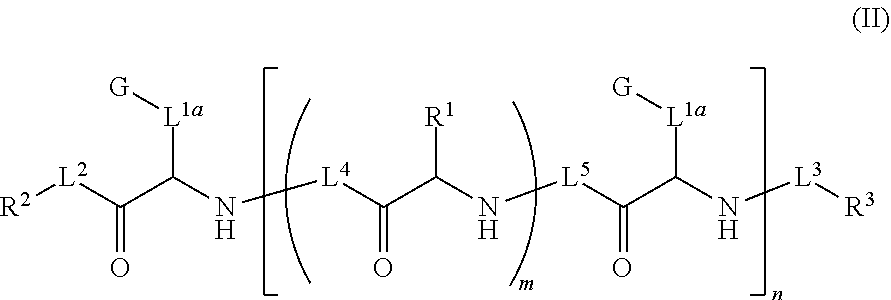

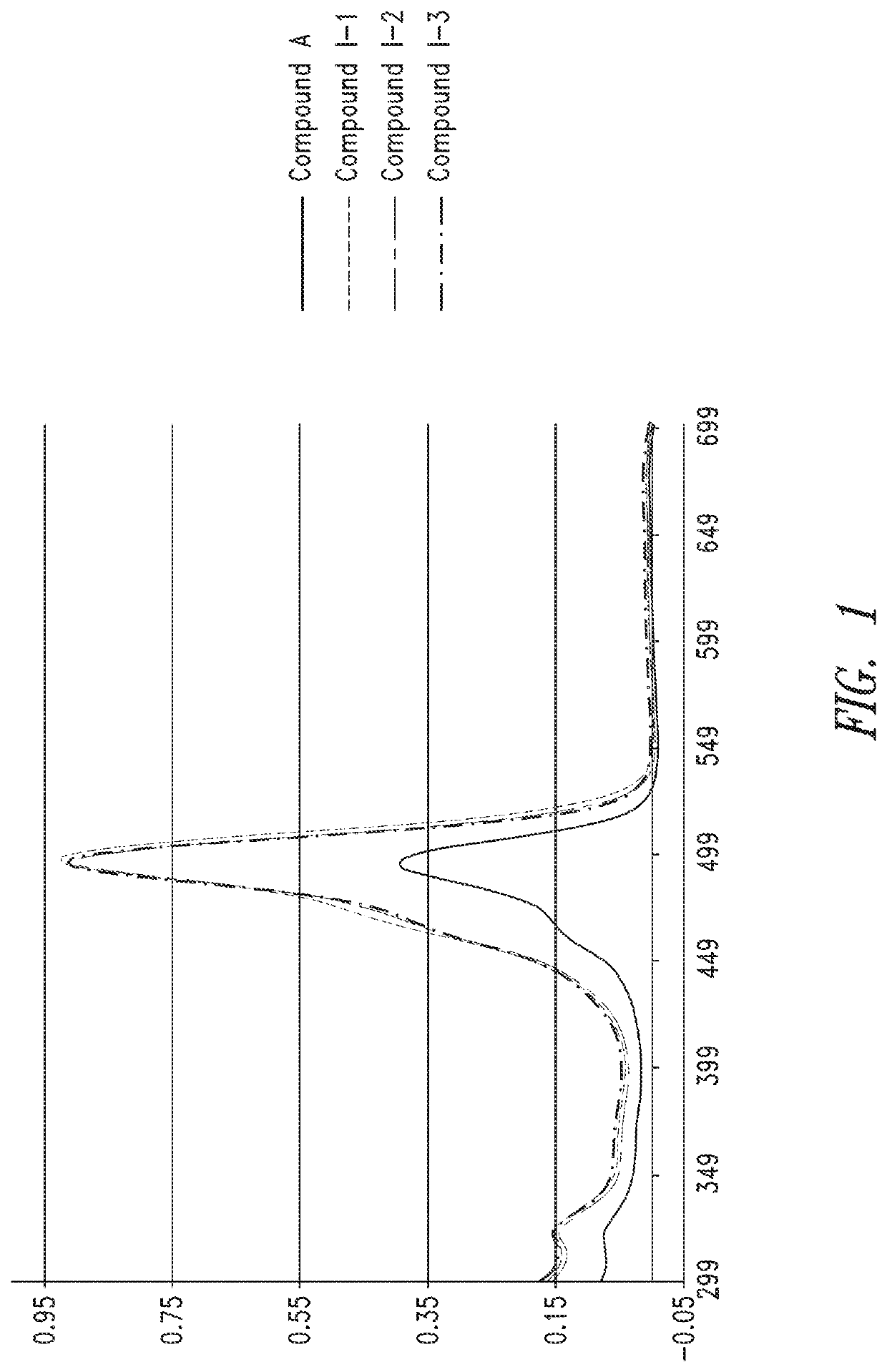

Ultra bright dimeric or polymeric dyes with rigid spacing groups

ActiveUS20200392345A1Ensure sufficient separationFluorescence quenching is reduced and/or eliminatedGroup 5/15 element organic compoundsPreparing sample for investigationStereoisomerismPhotochemistry

Compounds useful as fluorescent or colored dyes are disclosed. The compounds have the following structure (I) or a stereoisomer, tautomer or salt thereof, wherein R1, R2, R3, R4, R5, L1, L2, L3, L4, L5, A, M, m and n are as defined herein. Methods associated with preparation and use of such compounds are also provided.

Owner:SONY CORP

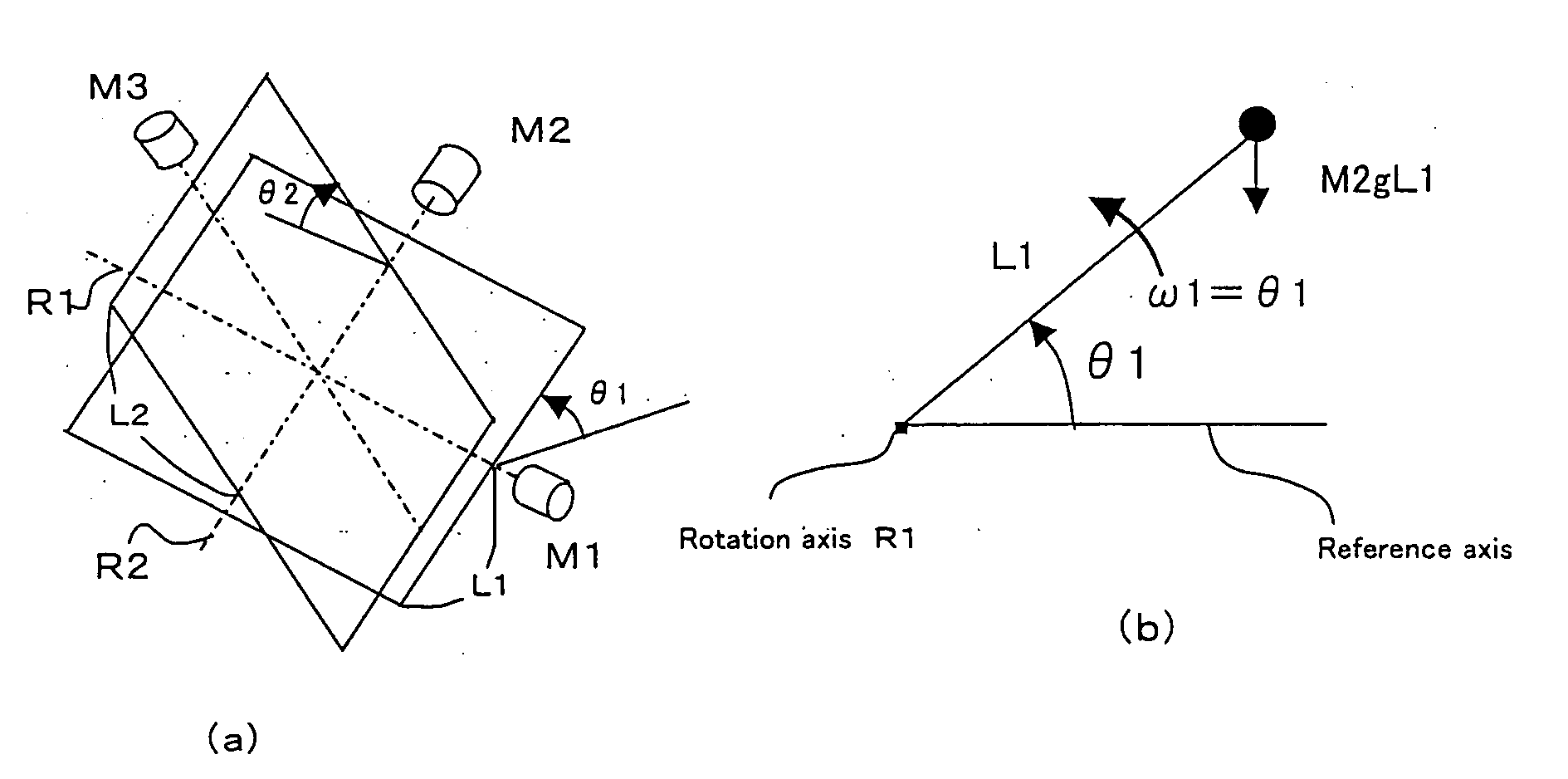

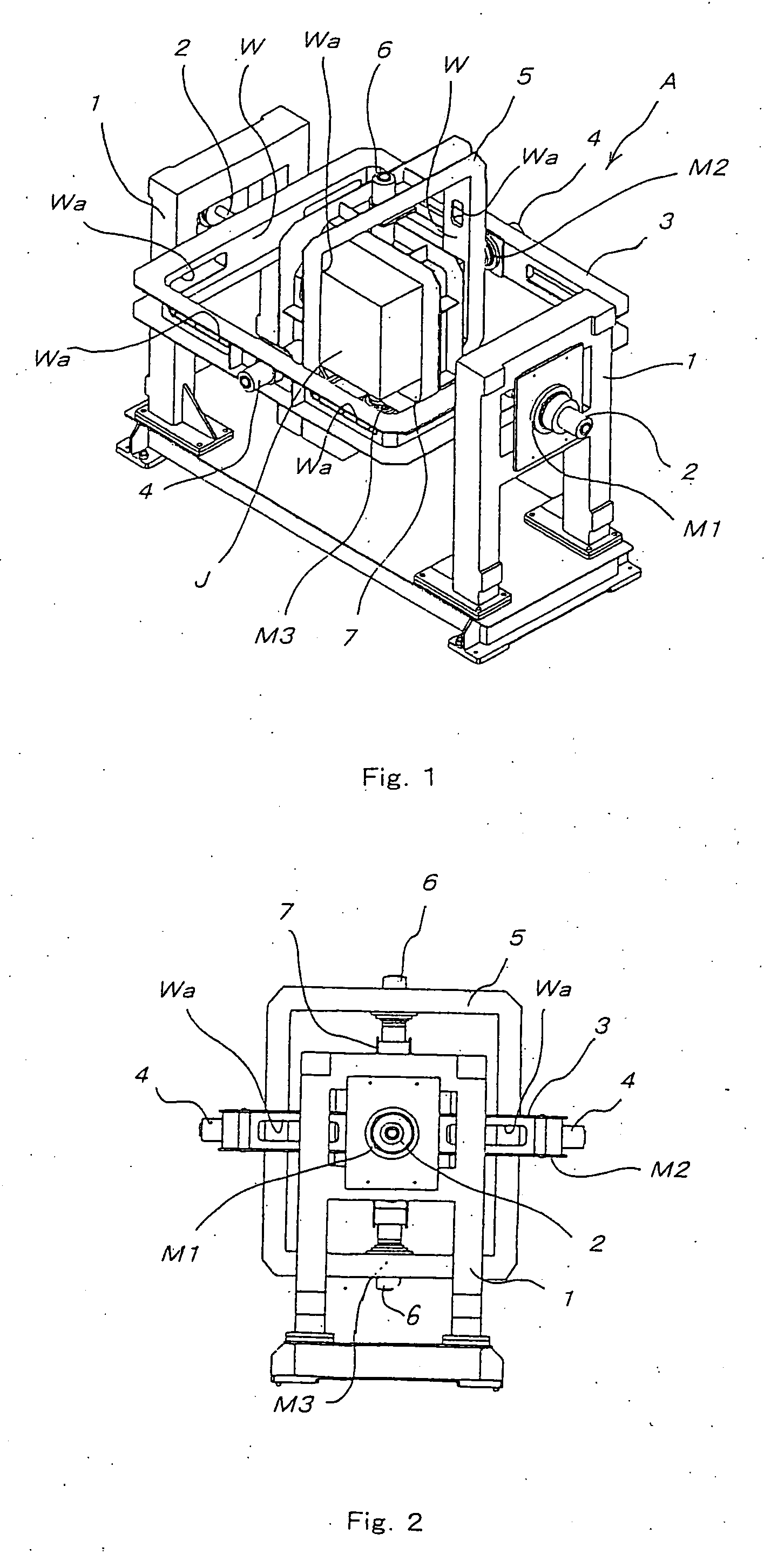

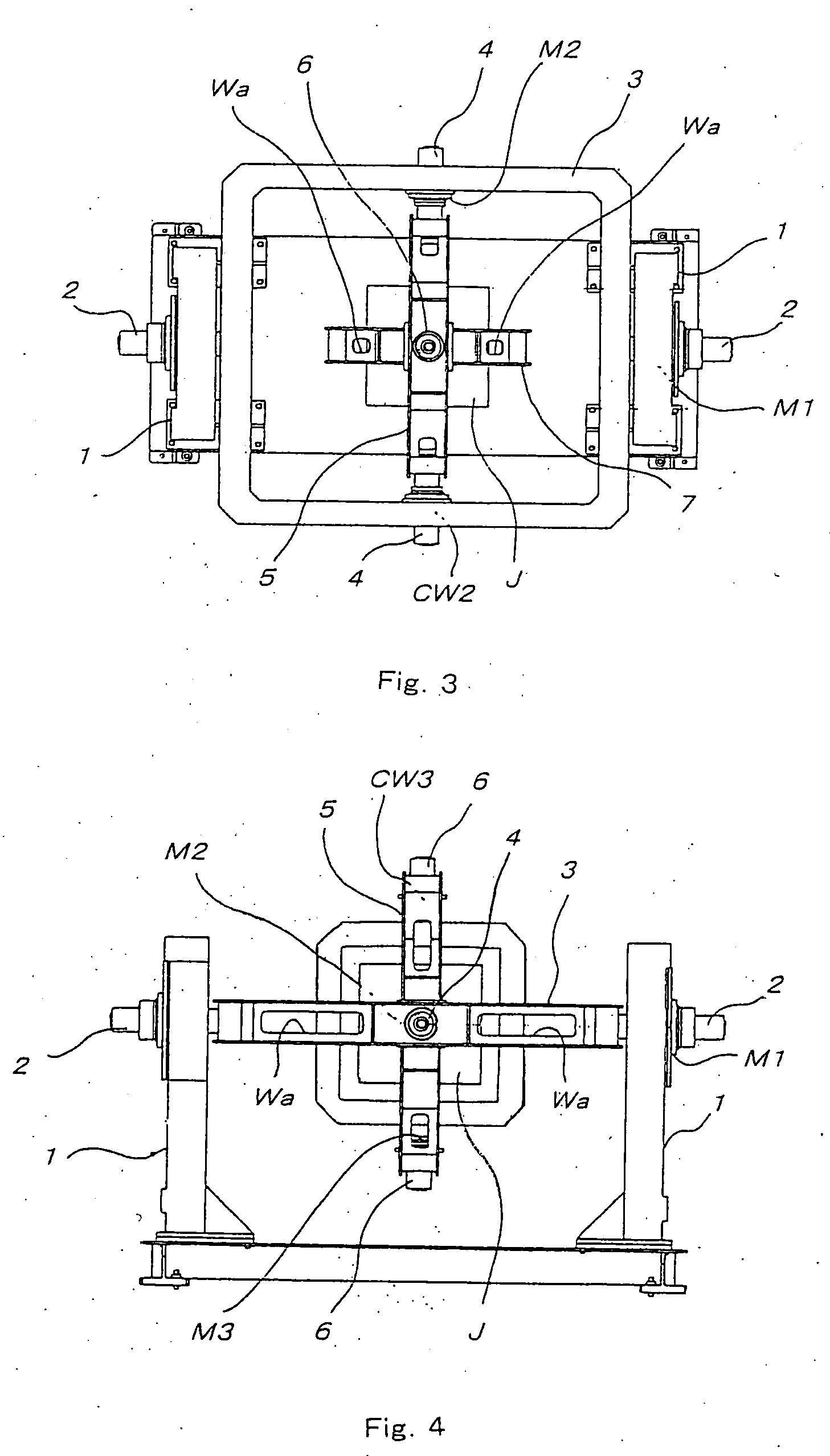

Three-axis motion table

InactiveUS20060293795A1Reduce weightStay rigidComputer controlSimulator controlRotational axisMiniaturization

The present invention aims at providing a three-axis motion table capable of ensuring smooth rotations around three rotation axes orthogonal to each other and decreasing an overall weight. The three-axis motion table according to the present invention has an outside frame (3), an (e.g., approximately square) intermediate frame (5), and an (e.g., approximately square) inside frame (7). The outside frame (3) is rotatably mounted around a first rotation axis (2) by means of a pair of both-end supporting legs (1, 1). The intermediate frame (5) is rotatably mounted around a second rotation axis (4) by means of the outside frame (3). The inside frame (7) is rotatably mounted around a third rotation axis (6) by means of the intermediate frame (5). The inside frame (7) has a holding mechanism for a tested model (J). One of the both-end supporting legs (1, 1) is provided with a first motor (M1) to rotate the outside frame (3). The outside frame (3) is provided with a second motor (M2) to rotate the intermediate frame (5). The intermediate frame (5) is provided with a third motor (M3) to rotate the inside frame (7). According to the above-mentioned configuration, the first through third motors (M1 through M3) rotate. The inside frame (7) holding the tested model (J) rotates in the space inside the intermediate frame (5). The intermediate frame (5) rotates in the space inside the outside frame (3). In this manner, rotations are provided around the three rotation axes (2, 4, 6) orthogonal to each other. The pair of both-end supporting legs (1, 1) works as a base for supporting the entire three-axis motion table (A). The pair of both-end supporting legs (1, 1) is more stable than a base (B in FIG. 10) according to the conventional technology using only one vertical rotation axis for supporting one end. The pair of both-end supporting legs (1, 1) is capable of miniaturization and weight saving.

Owner:NIHON UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com