Area grain combine harvester

A combine harvester and grain technology, applied to harvesters, agricultural machinery and implements, threshing equipment, etc., can solve the problems of low grain breakage rate and loss rate, mixed species, high work efficiency, etc., and achieve grain breakage rate and loss rate Low cost, high work efficiency, and the effect of reducing the loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

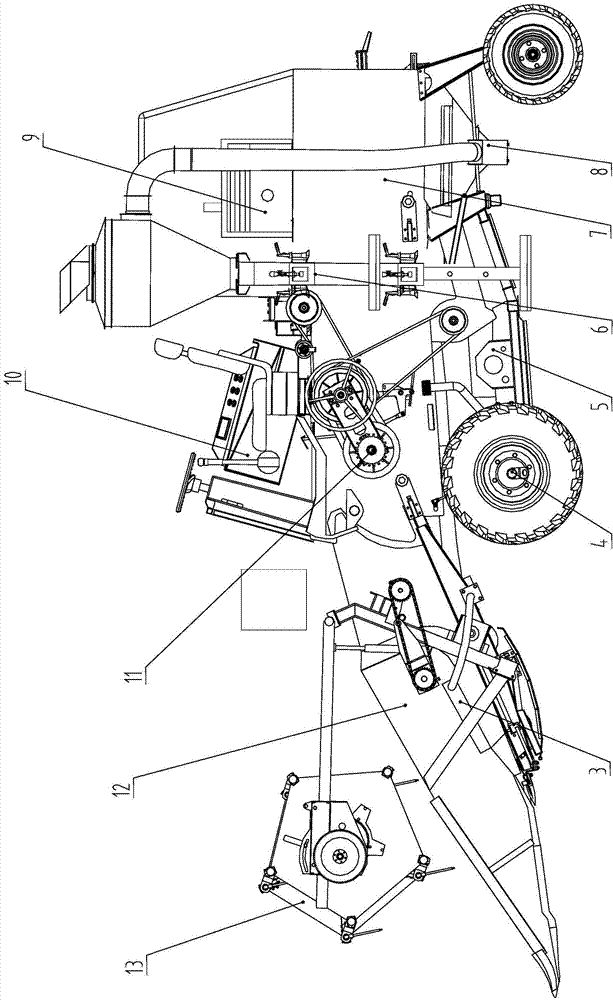

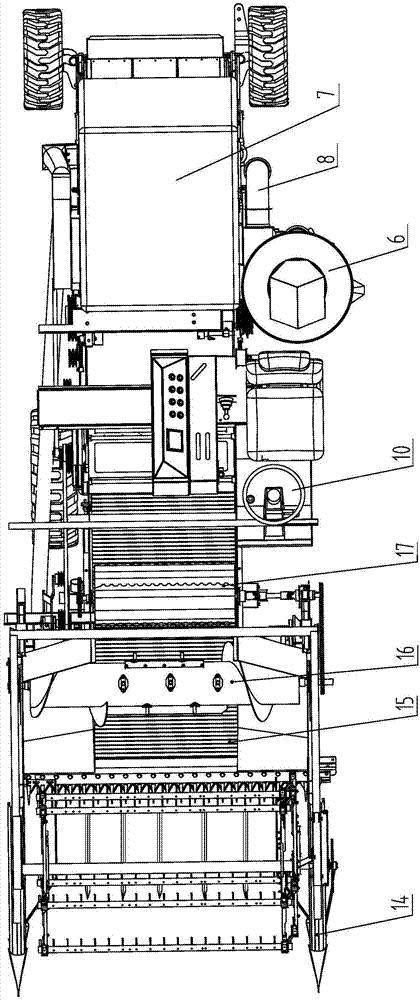

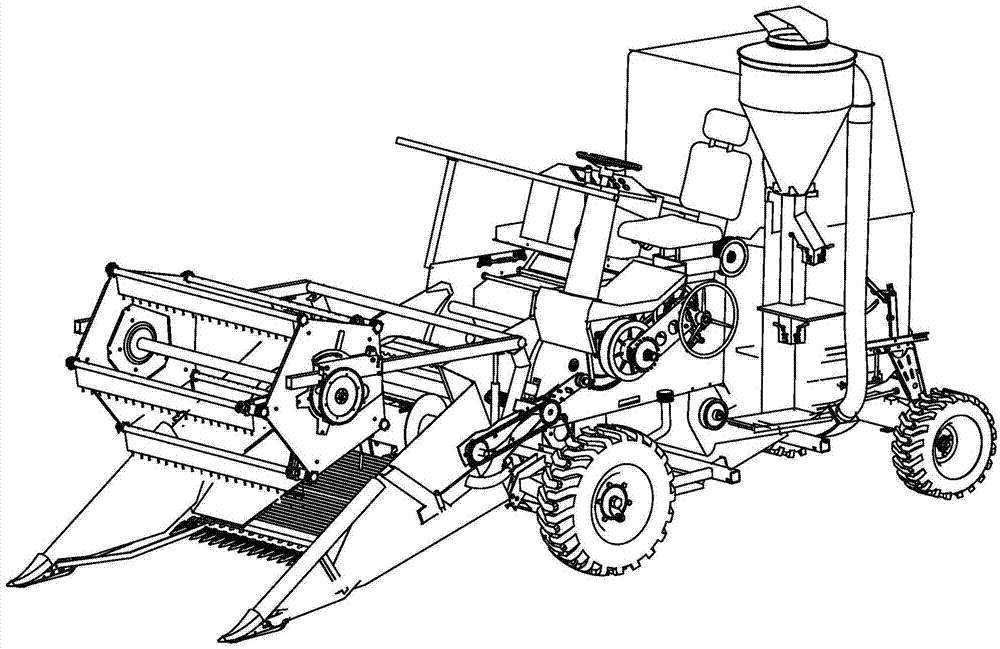

[0036] A small area grain combine harvester, including a frame and a walking device 4 arranged on the frame, a pneumatically assisted header device 12, a threshing device 11, a cleaning device 7, a pneumatic conveying device 8, a bagging device 6, a hydraulic integrated Device 5, steering control device 10 and engine device 9. The walking device 4 is located at the bottom of the whole machine, and the hydraulic system drives the four wheels to rotate and walk, so as to realize the advance and retreat of the harvester. The pneumatic assisted header device 12 is located at the front end of the complete machine, and the threshing device 11 and the cleaning device 7 are sequentially arranged behind the pneumatic assisted header device 12 . The pneumatically assisted harvesting unit 12 supports and cuts the grains and feeds them together with the stalks and ears to the threshing device 11, and the cleaning device 7 cleans the threshed mixture to separate grain and grass. The pneum...

Embodiment 2

[0046] Different from Embodiment 1, the pneumatic assisted header device 12 also includes a lateral airflow chamber 3, which is connected to the header fan 25 through an airflow hose 124; the side baffle includes a front side Plate 18 and rear side plate 23, the bottom side of described rear side plate 23 is provided with transverse airflow hole 22, and described transverse airflow hole 22 is connected with transverse airflow chamber 3; The falling seed grains are blown to the conveying device I 15 in the middle section.

Embodiment 3

[0048] Different from Embodiment 2, the connecting device of the described connection frame and the elastic cover 43 of the manuscript includes an adjustment bolt 46, a spring I 45 and a stop 44, and the adjustment bolt 46 and the stop 44 are fixed on the frame; The adjusting bolt 46 is connected with the upper end of the elastic cover 43 by the spring I 45, and realizes the adjustment of the tension force between the spring I 45 and the elastic cover 43 by the adjusting bolt 46; Contact, to limit the position of the elastic cover 43 of the draft. By arranging the draft elastic cover 43, the drafts on the draft device 42 are evenly distributed by elastic resistance, which is beneficial to the sufficient separation of residual grains.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com