Pure-cotton fabric dyeing system saving materials

A dyeing system and pure cotton fabric technology, applied in the field of pure cotton fabric printing and dyeing equipment, can solve the problems of low utilization rate, large amount of dye waste, poor dyeing effect, etc., and achieve the goal of improving utilization rate, saving consumption and improving efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

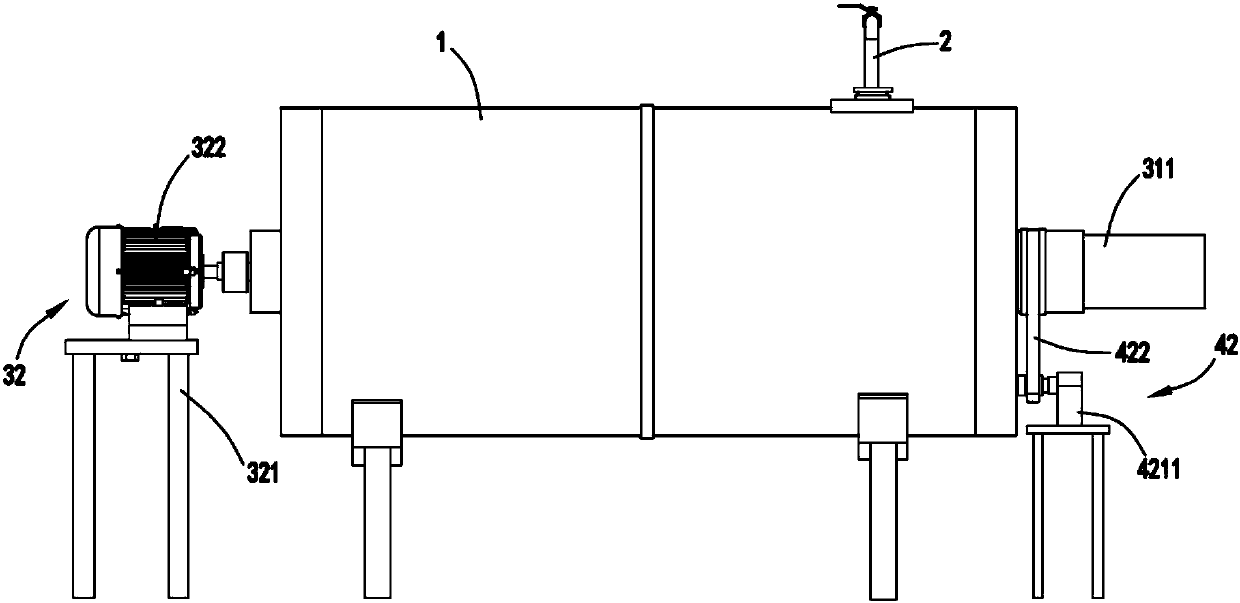

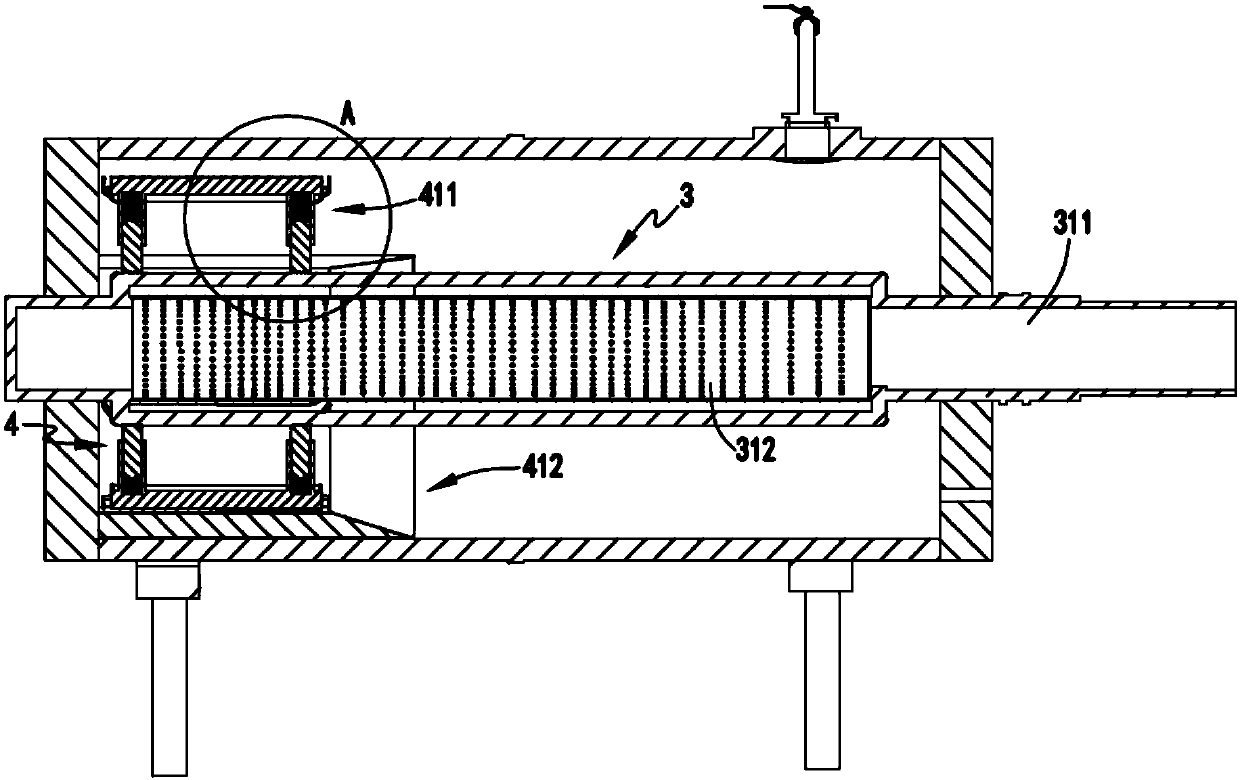

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, a material-saving dyeing system for pure cotton fabrics includes a dye bucket 1, a feeding pipe 2 is arranged above the dye bucket 1, and a

[0039] The screening part 3, the screening part 3 includes a screening mechanism 31 arranged along the length direction of the dye bucket 1 and a power mechanism 32 arranged on one side of the dye bucket 1 for driving the rotation of the screening mechanism 31, said The sieving mechanism 31 is used to sieve the primary dyes in the dye bucket 1 and output the sieved fine dyes to the outside, and leave the sieved coarse particle dyes in the dye bucket 1;

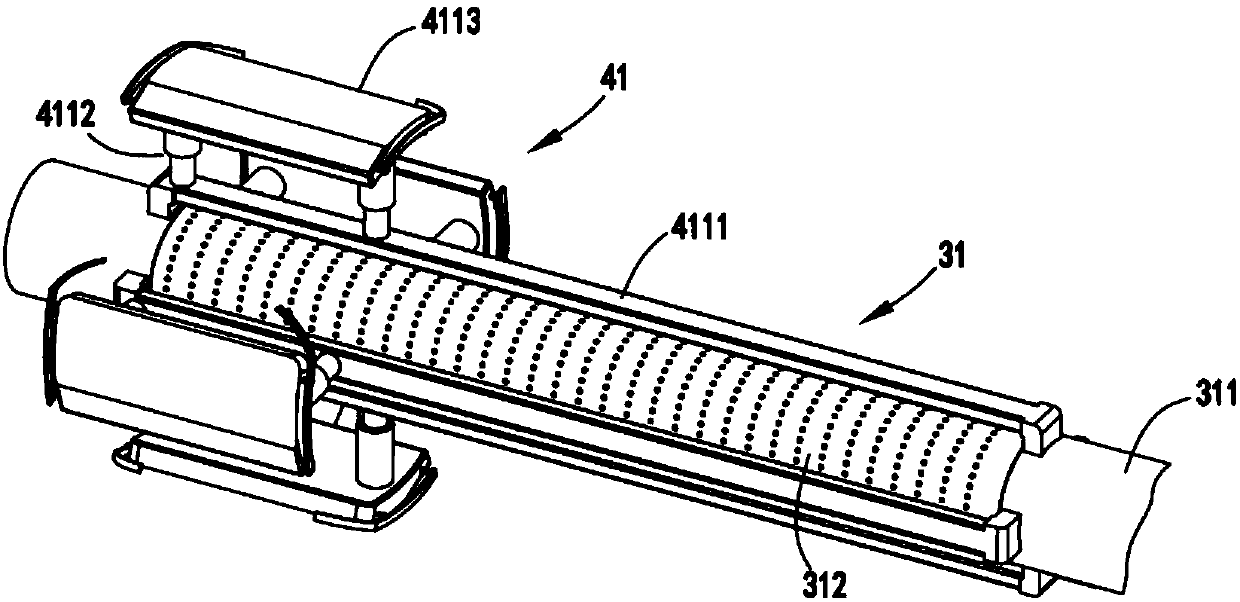

[0040] The grinding part 4, the grinding part 4 includes a grinding mechanism 41 arranged on one side inside the dye barrel 1 and an agitating mechanism 42 arranged on the other side inside the dye barrel 1, the side of the dye barrel 1 close to the grinding mechanis...

Embodiment 2

[0054] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that guides 5 are arranged symmetrically on both sides of the grinding plate 4113, the guides 5 are fixedly connected with the grinding plate 4113, and the grinding plate 4113 rotates until When the pressing surface 40 is placed, its bottom surface is in contact with the pressing surface 40. The guide member 5 includes a first guide section 51 arranged parallel to the side of the grinding plate 4113 and a first guide section 51 whose end is bent to the middle of the arc support member 4121. Two guide segments 52.

[0055] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com