Multipoint floating locking device for printed circuit board

A printed circuit board and locking device technology, applied to the circuit layout, fixing device, elastic/clamping device and other directions on the support structure, can solve the problems of inconvenient disassembly and assembly of the printed circuit board, and achieve the improvement of heat conduction efficiency and structural design. Simple, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

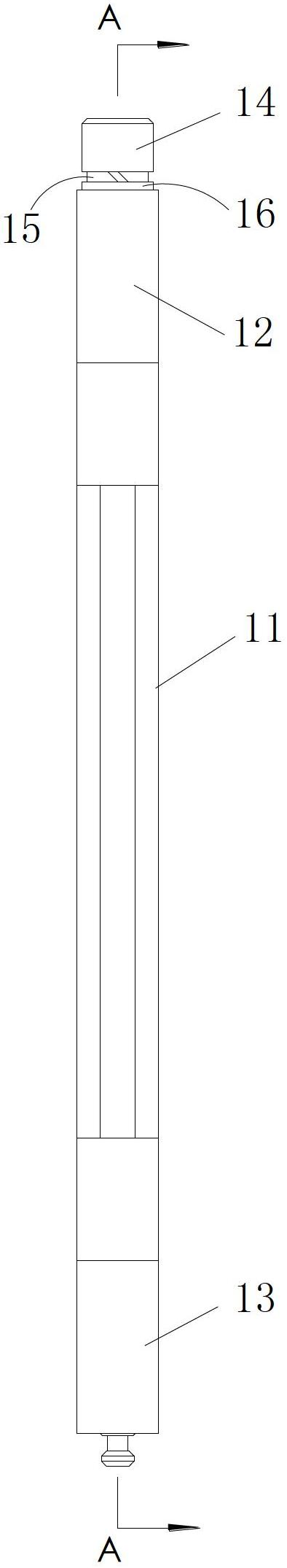

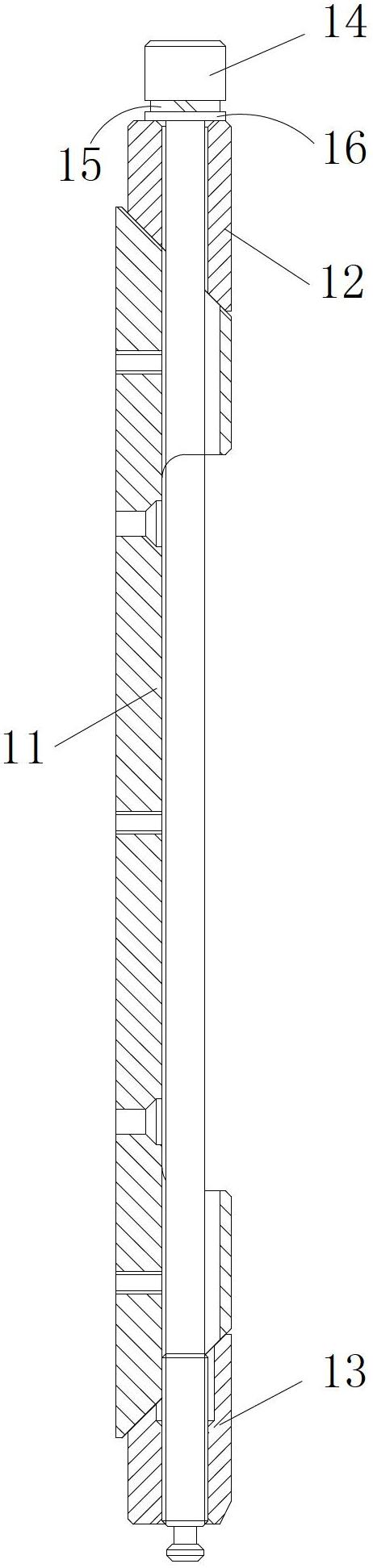

[0029] see figure 1 , figure 2 , image 3 The shown multi-point floating locking device for printed circuit boards includes a base 11, an outer locking slider 12, an inner locking slider 13 and bolts 14, and the longitudinal section of the base 11 is an isosceles trapezoid , the outer locking slider 12 is arranged in front of the base 11, the inner locking slider 13 is arranged at the rear of the base 11, the inner end of the outer locking slider 12 and the inner end of the inner locking slider 13 respectively adopt The slope structure, the slope angles of the slopes at the inner end of the outer locking slider 12 and the slopes at the inner end of the inner locking slider 13 correspond to the slope angles at both ends of the base 11 . The outer locking slider 12, the base 11 and the inner locking slider 13 are connected to form a cuboid, the outer locking slider 12, the base 11 and the inner locking slider 13 respectively offer through holes along the axis of the cuboid, a...

Embodiment 2

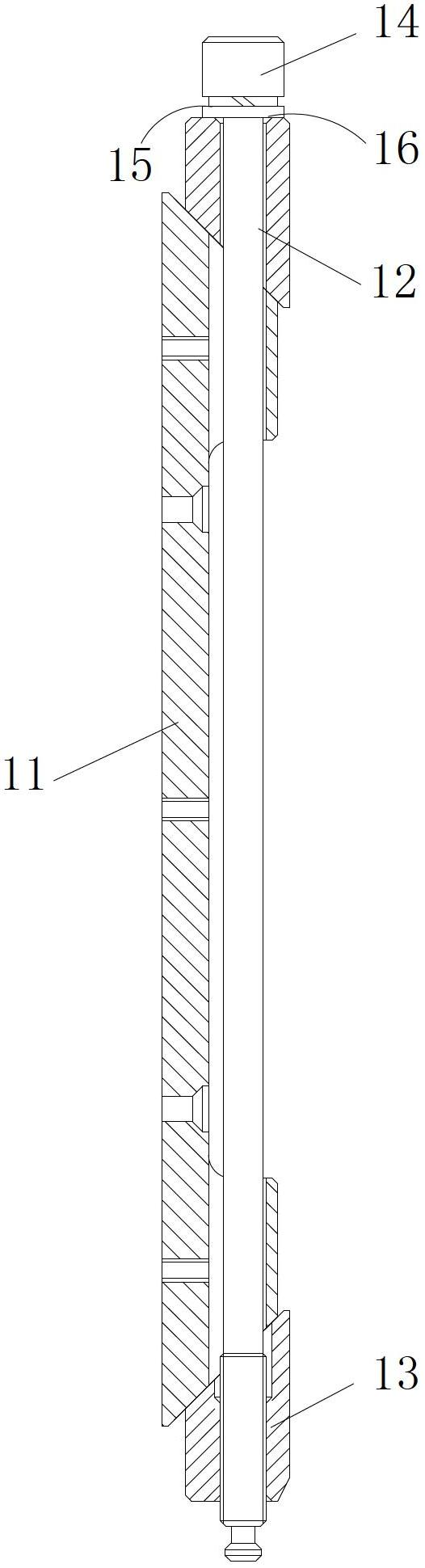

[0032] see again Figure 4 , Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that two bases are arranged in sequence along the longitudinal direction of the printed circuit board, and the two bases are connected in series through the middle locking slider 17, and the middle locking The two ends of the tight slider 17 respectively adopt inclined-plane structures, and the inclined angles of the inclined surfaces at both ends of the middle locking slider 17 correspond to the inclined angles of the front and rear base 11 two ends respectively. The longitudinal section of the middle locking slider 17 can be an isosceles triangle or an isosceles trapezoid. When the bolt moves radially along the through hole of the base, it will drive the outer locking slider, the inner locking slider and the middle locking slider to move outward synchronously and be tightly connected with the printed circuit board isolation block, so that the printed circuit board Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com