Fluidized-bed reactor and insert for said fluidized-bed reactor

A technology of fluidized bed reactor and fluidized bed gasification, which is applied in the direction of fluidized bed combustion equipment, chemical instruments and methods, fuel burned in a molten state, etc., can solve the problems such as the inability to achieve uniform cooling of inserts, and avoid deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

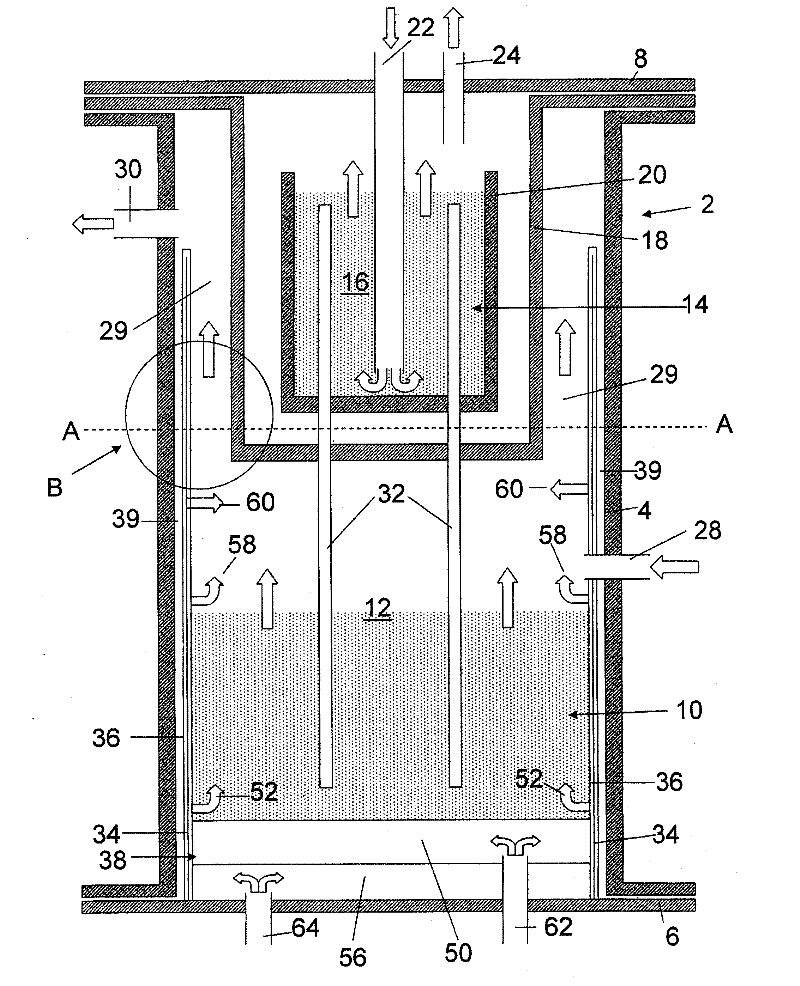

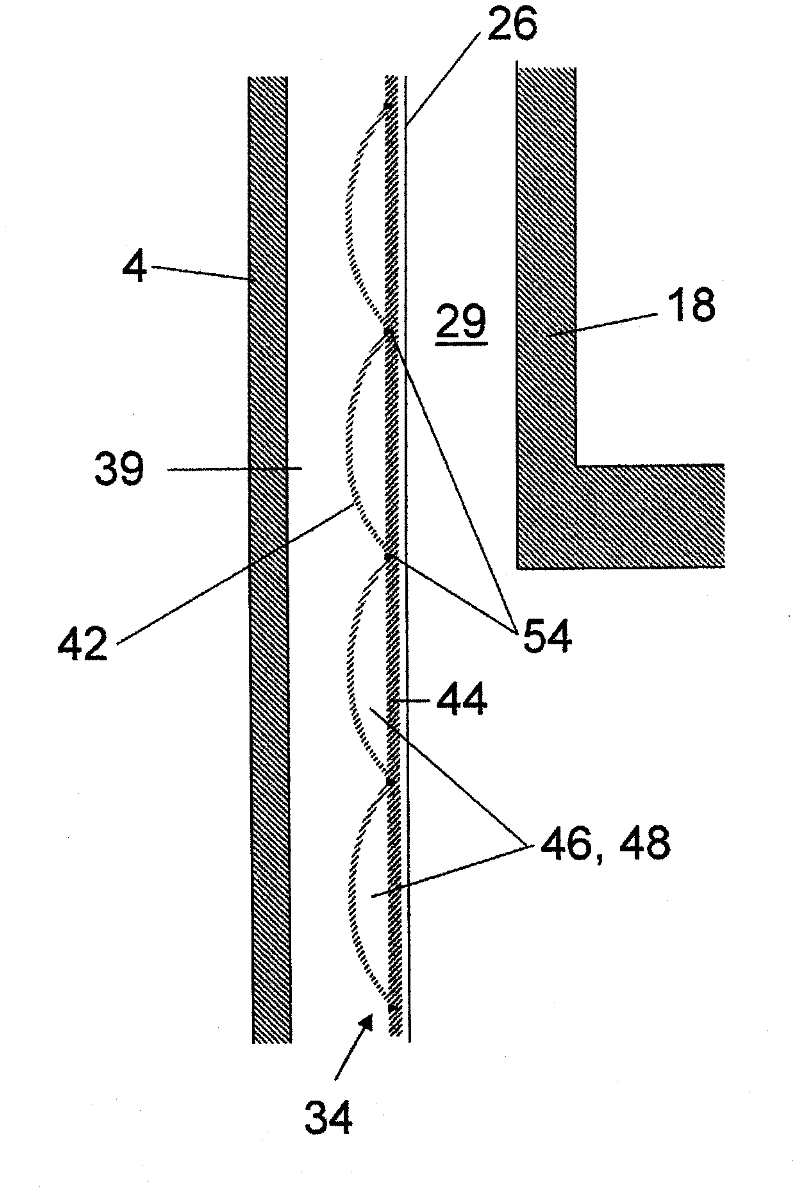

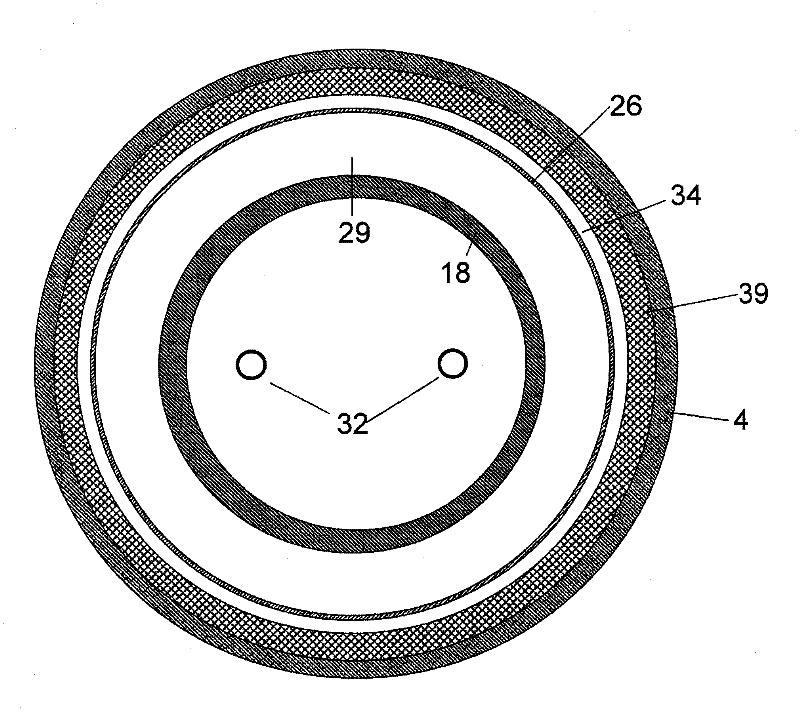

[0034] Figure 1 shows a longitudinal section view of a heat pipe reformer. The device has a cylindrical reactor vessel 2 comprising a reactor jacket 4 , a bottom plate 6 and a cover plate 8 . Figure 3 shows that the reactor vessel 2 is made of steel. In the lower part of the reactor vessel 2, a combustion chamber 10 is arranged, comprising a fluidized bed combustion system 12 therein. In the upper part of the reactor vessel 2, a fluidized bed gasification chamber 14 is arranged, which contains a gasification fluidized bed 16 therein. In the gasification fluidized bed 16, combustion gases are generated by gasification of carbonaceous feedstock at a temperature of about 800° C. by indirectly heating steam.

[0035]The fluidized bed gasification chamber 14 comprises a cylindrical reformer pressure vessel 18 which is closed by the cover plate 8 . A pot-shaped fluidized bed vessel 20 is arranged in the reformer pressure vessel 18 . This fluidized bed container 20 is open above,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com