Liquid cooling arrangement for electric

A fluid cooling and machine technology, applied in the direction of cooling/ventilation devices, electromechanical devices, electric components, etc., can solve the problems of setting holes for air passage, impossibility of electric machines, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

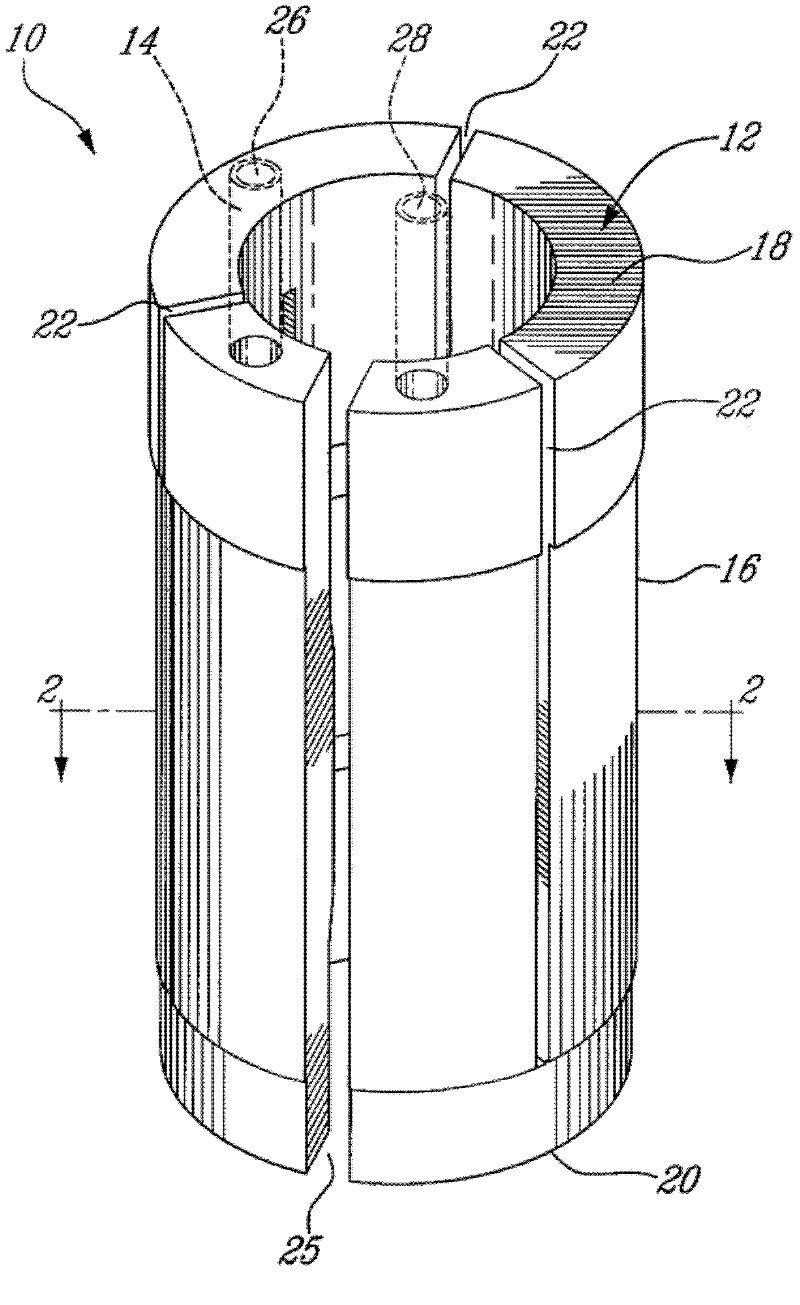

[0034] now turn Figure 1-Figure 6 , the fluid cooling device 10 according to the first exemplary embodiment will be described.

[0035] The fluid cooling device 10 comprises a thermal storage element in the form of a tubular body 12 and a cooling path in the form of a continuous serpentine cooling tube 14 embedded in the tubular body 12 .

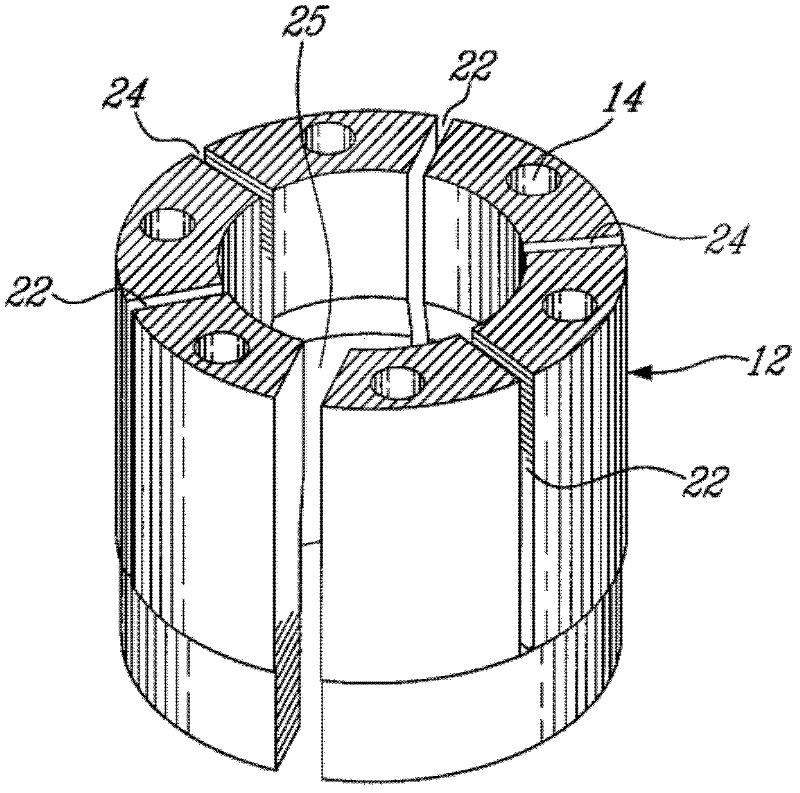

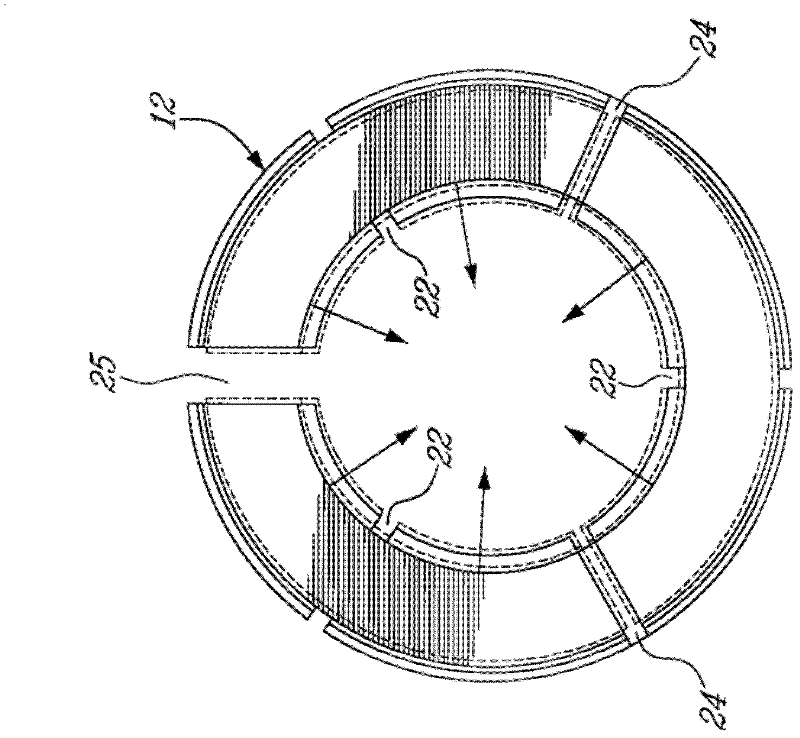

[0036] Tubular body 12 is generally C-shaped and includes an outer surface 16 and first and second longitudinal ends 18 and 20 . Three expansion slots 22 are provided from the first longitudinal end 18 and two expansion slots 24 are provided from the second longitudinal end 20 (see figure 2 ). The expansion slot 22 opens towards the first longitudinal end 18 but does not reach the second longitudinal end 20 . On the contrary, if the image 3 As better seen in the bottom plan view of , the expansion slot 24 opens towards the second longitudinal end 20 but does not reach the first longitudinal end 18 .

[0037] The C-shape of the tubul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com