Molding device

A molding device and profile technology, which is applied in the field of molding devices, can solve the problems of hindering the heat conduction of fluid heat to heat exchange coils, reducing the heat exchange of fluid to heat exchange coils, etc., so as to accelerate the heat exchange amount and speed of heat exchange, The effect of sufficient heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

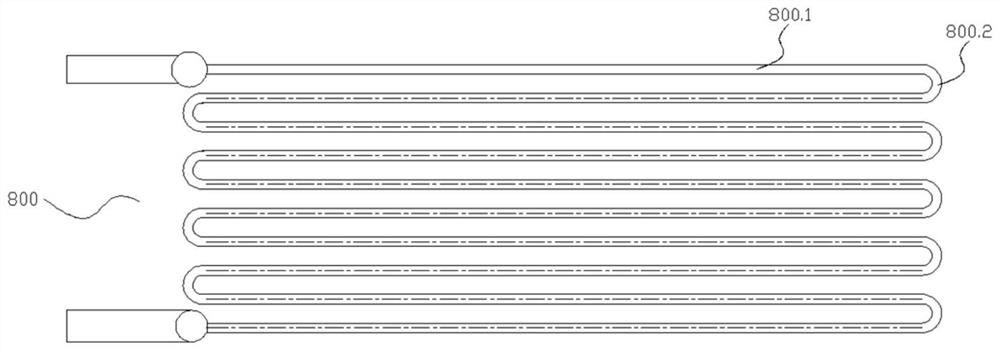

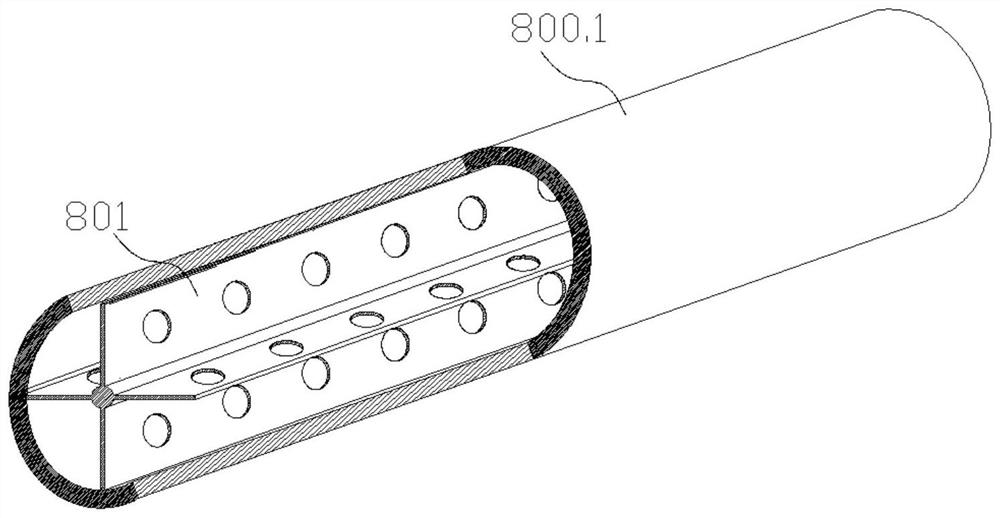

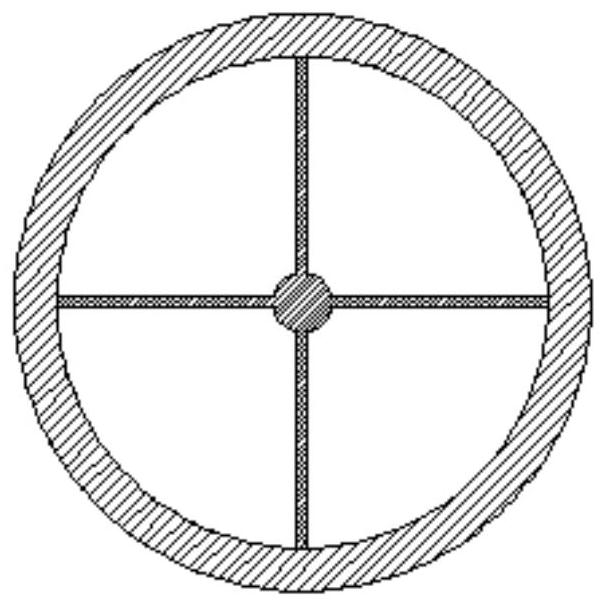

[0049] Embodiment 1, Figure 2-Figure 5 There are four main fins 801.2 of the fin group on the heat-conducting profile 801 of the special-shaped fin, and the main fins 801.2 are set throughout the length of the mandrel 801.1, and there is no dislocation of the first fin group and the second fin group, the special-shaped structure is a hole;

Embodiment 2

[0050] Embodiment 2, Figure 6-Figure 8 There are four main fins 801.2 of the fin group on the heat-conducting profile 801 of the special-shaped fins, and a 45-degree misalignment angle is formed between the first fin group and the second fin group. The special-shaped structure is a hole, and each Three holes are provided on the main fins 801.2 of each fin group.

Embodiment 3

[0051] Embodiment 3, Figure 16 The special-shaped structure on the fin group in the middle is a wave pattern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com