Permanently-magnetic synchronous heat-stretching roller motor

A technology of permanent magnet synchronization and hot drawing, applied in synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of reduced cooling effect, short axial dimension, shortened service life, etc., and achieve low insulation aging and heat insulation The effect of extending the distance and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] see Figure 3 ~ Figure 5 Shown is a preferred embodiment of the present invention.

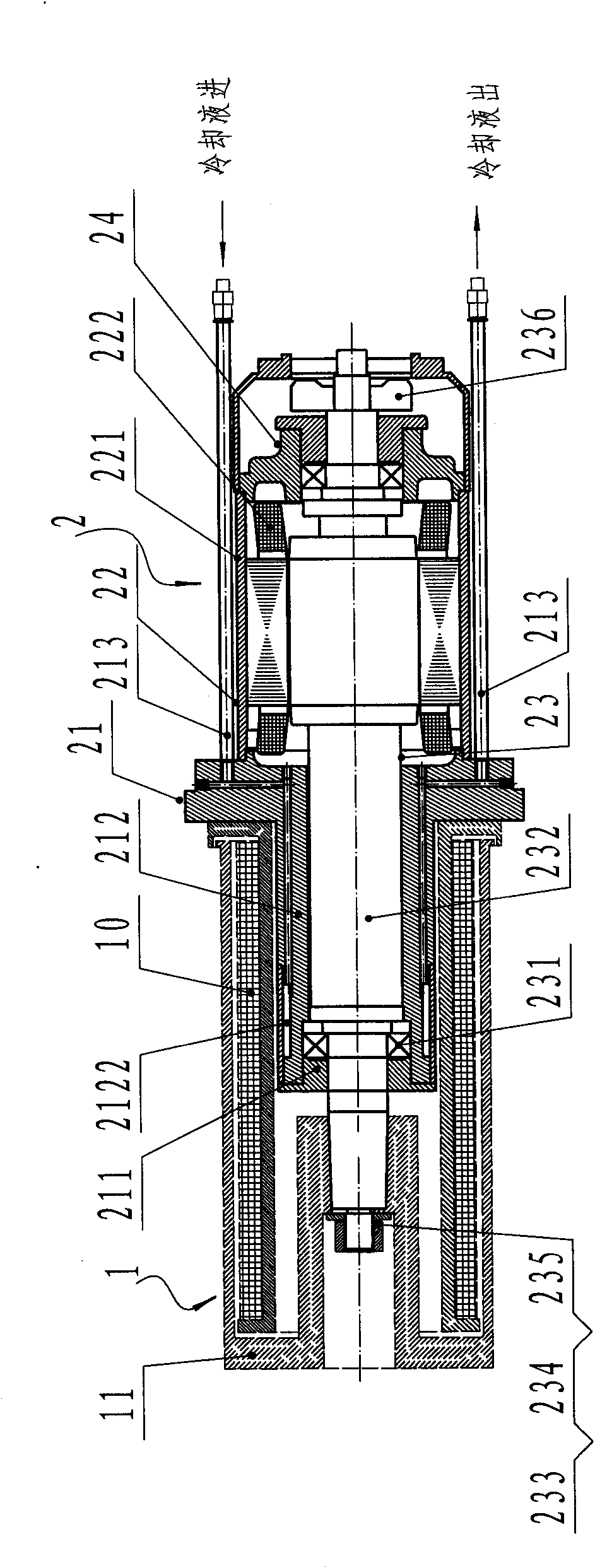

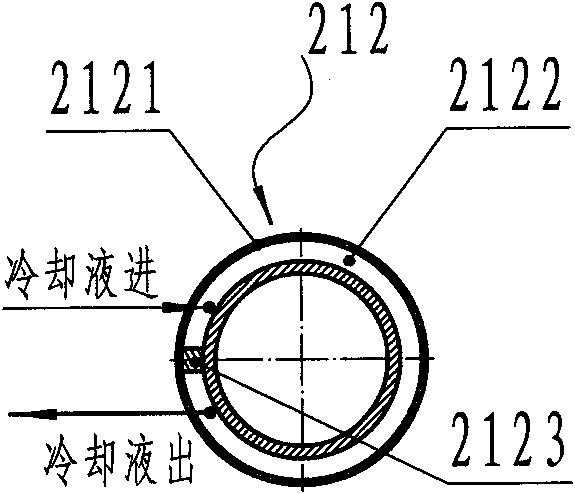

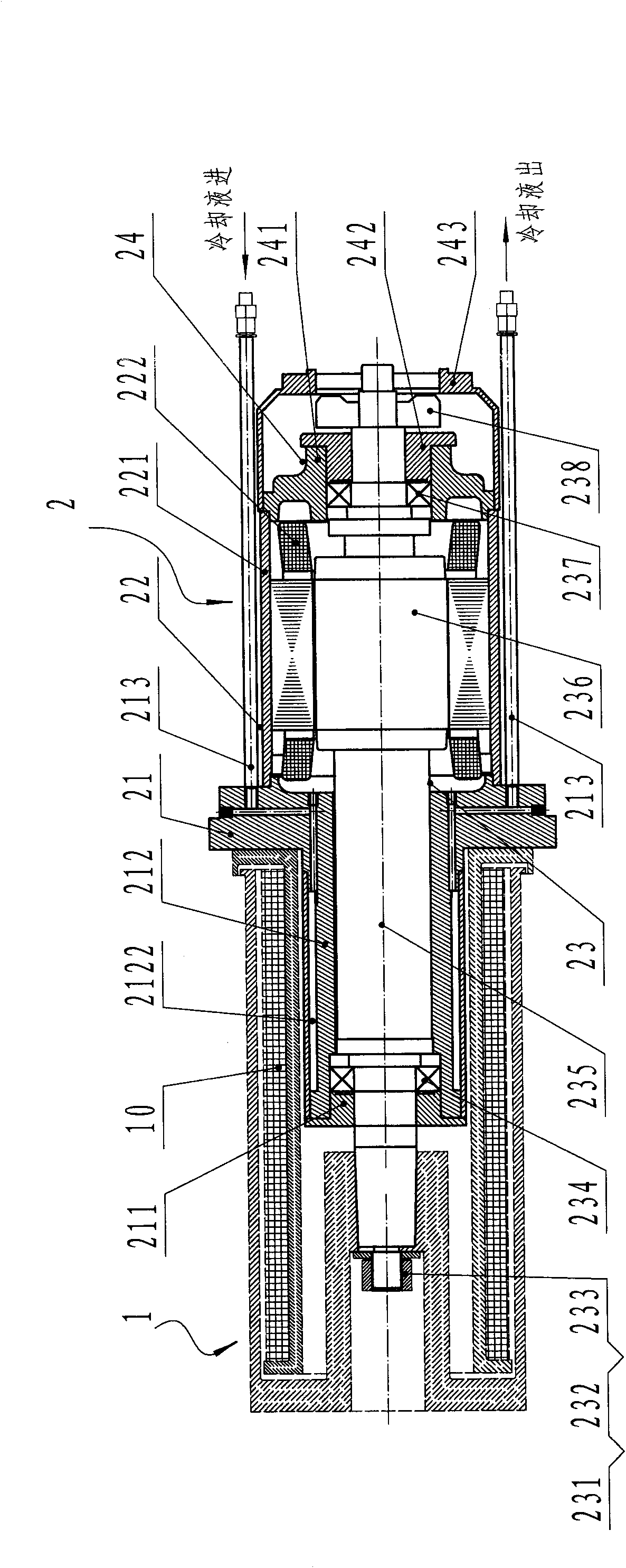

[0024] A permanent magnet synchronous thermal drafting roller motor is composed of a hollow roller body 1 and a motor assembly 2. The motor assembly 2 is composed of a rear end cover 24, a stator assembly 22, a rotor assembly 23 and a front end cover 21. The rear end cover 24 is composed of a rear end cover 241, a rear gland 242 and a windshield 243. The stator assembly 22 is press-fitted together by a machine base 221 and a winding core 222. The rear end cover 241 is fixedly connected to the machine base 221. The front end cover The part 21 is composed of a front gland 211, a front end cover 212 and an inlet and outlet coolant pipe 213 located on the machine base 221. The front end cover 212 is a cylindrical structure extending in the roller body part 1, and its bottom end surface is fixedly connected with the machine base 221. And its far-end surface is fixedly connected with the fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com