Energy-saving waste liquid heat exchange treatment device

A heat treatment device and waste liquid technology, which is applied in the field of printing and dyeing machinery, can solve the problems of slow heat exchange, easy scaling, and high price, and achieve the effects of fast heat exchange, avoiding scaling, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

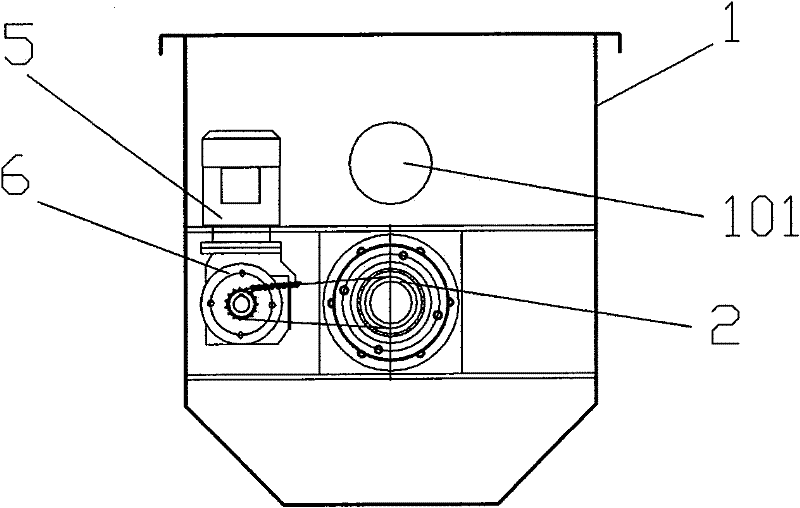

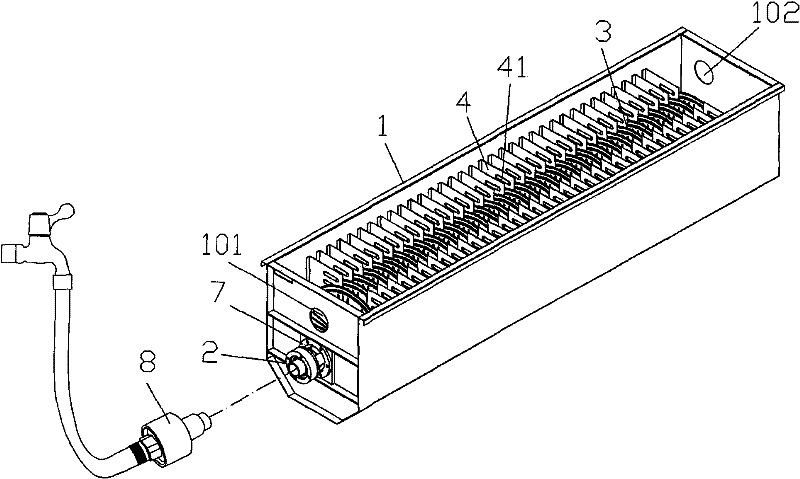

[0016] Example: see Figure 1~4 , a waste liquid energy-saving heat exchange treatment device, a waste liquid inlet 101 and a waste liquid outlet 102 are respectively opened on the two end side plates of the heat exchange box 1, a rotating shaft 2 is arranged in the heat exchange box 1, and a number of shafts are fixed on the rotating shaft 2 Each blade 3, the baffle plate 4 is fixed on the side plates on the two sides of the heat exchange box 1, each blade 3 is placed in the middle of the two baffle plates 4, and several blades 3 are arranged on the rotating shaft 2 in a spiral ascending shape , the motor 5 drives the reducer 6 to rotate, the reducer 6 drives the rotating shaft 2 to rotate, the two end side plates of the heat exchange box 1 are fixed with a bearing seat 7, and the rotating shaft 2 is installed on the bearing seat 7;

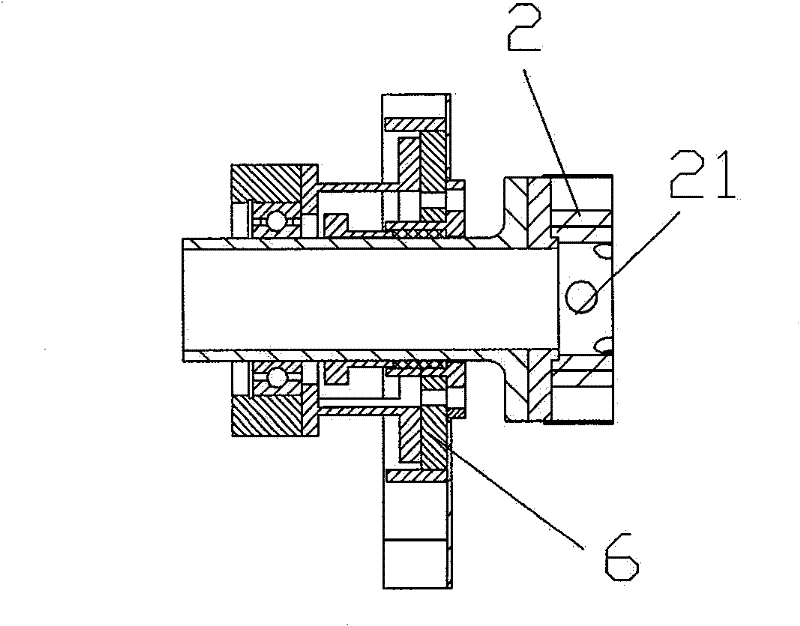

[0017] The rotary joint 8 is connected to the end of the rotating shaft 2, and the rotating shaft 2 is formed with a water outlet hole 21 commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com