Cooling device and method for hot assembly equipment

A cooling device and equipment technology, applied in lighting and heating equipment, household refrigeration equipment, metal processing equipment, etc., can solve the problems of microstructure change, slow metal cooling speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

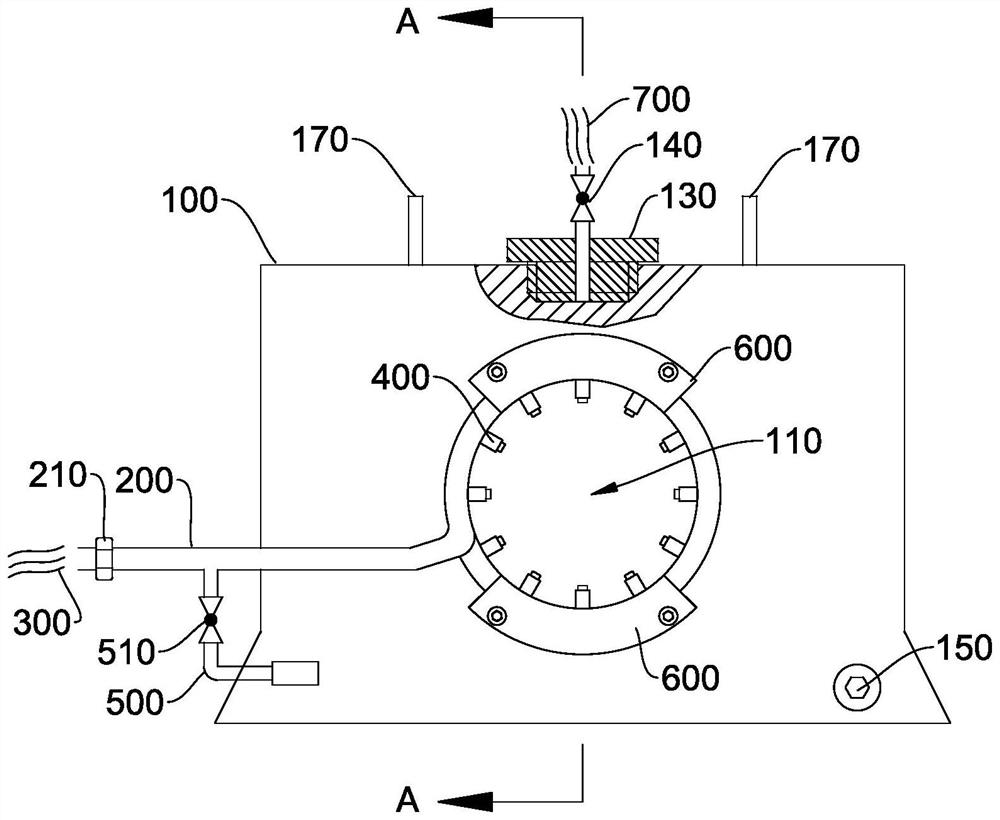

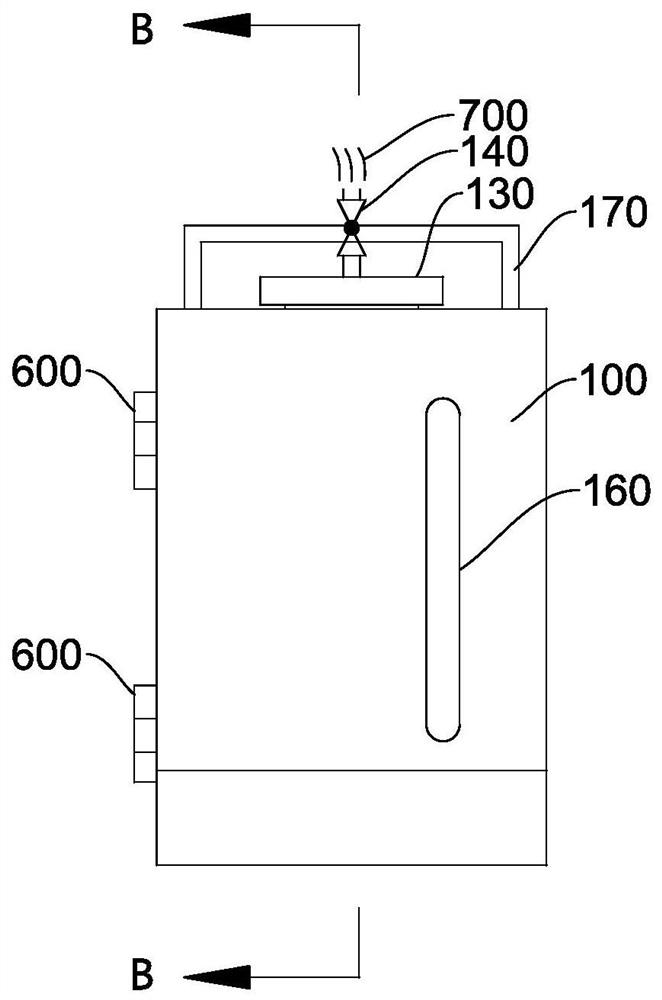

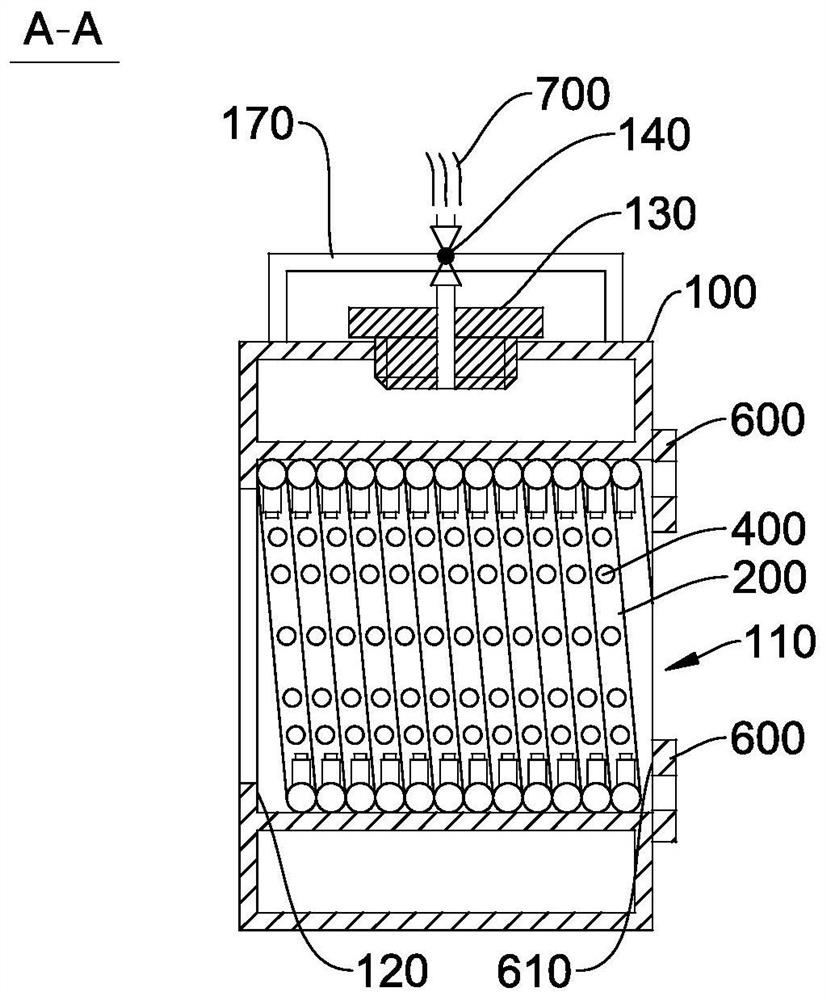

Image

Examples

Embodiment

[0041] In the field of metallurgical industry, the traditional method of cooling hot-loading equipment includes using fans, normal temperature water, etc. to cool the heated equipment.

[0042] Fan cooling is to blow the hot-loaded equipment by the fan, and the airflow takes away the heat to make the equipment reach normal temperature. The disadvantage of this cooling method is that the wind cannot be concentrated on the hot-loading equipment that needs to be cooled, and the air volume cannot be blown in a concentrated manner. One operation process cannot be carried out, which affects the efficiency of thermal assembly.

[0043] The normal temperature water cooling method is that the operator holds a water pipe or uses a container to pour water directly on the heated equipment, and the water takes away the heat, so that the heated equipment can quickly return to normal temperature. The disadvantage of this cooling method is that when the metal equipment is rapidly cooled by n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com