Aerated concrete waste comprehensive utilization method and system

A technology for aerated concrete and concrete is applied in the field of comprehensive utilization method and system of aerated concrete waste, which can solve the problems of product quality impact and high processing cost, and achieve the effects of avoiding product quality decline, low energy consumption and reducing dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

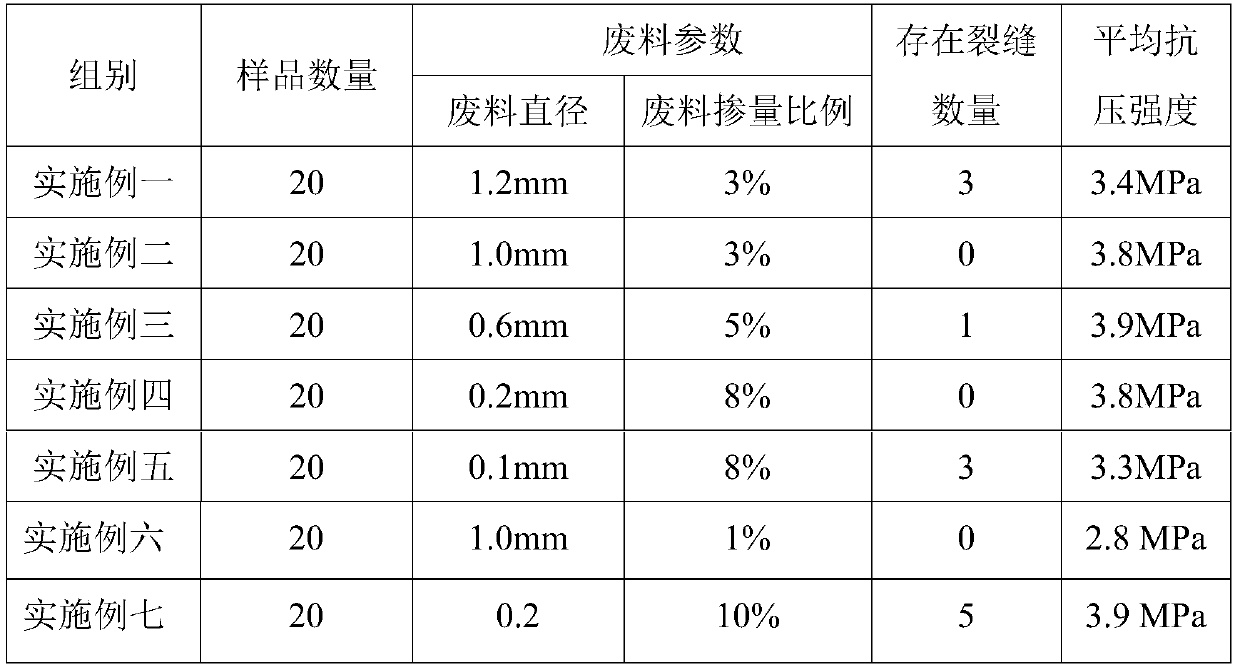

Embodiment 1

[0031] The purpose of the present invention is to process aerated concrete waste such as scraps removed in the cutting process in the aerated concrete slab and block production line, and waste generated by truncating unrepairable aerated concrete slabs and blocks. Reduce pollution and land occupation caused by waste aerated concrete.

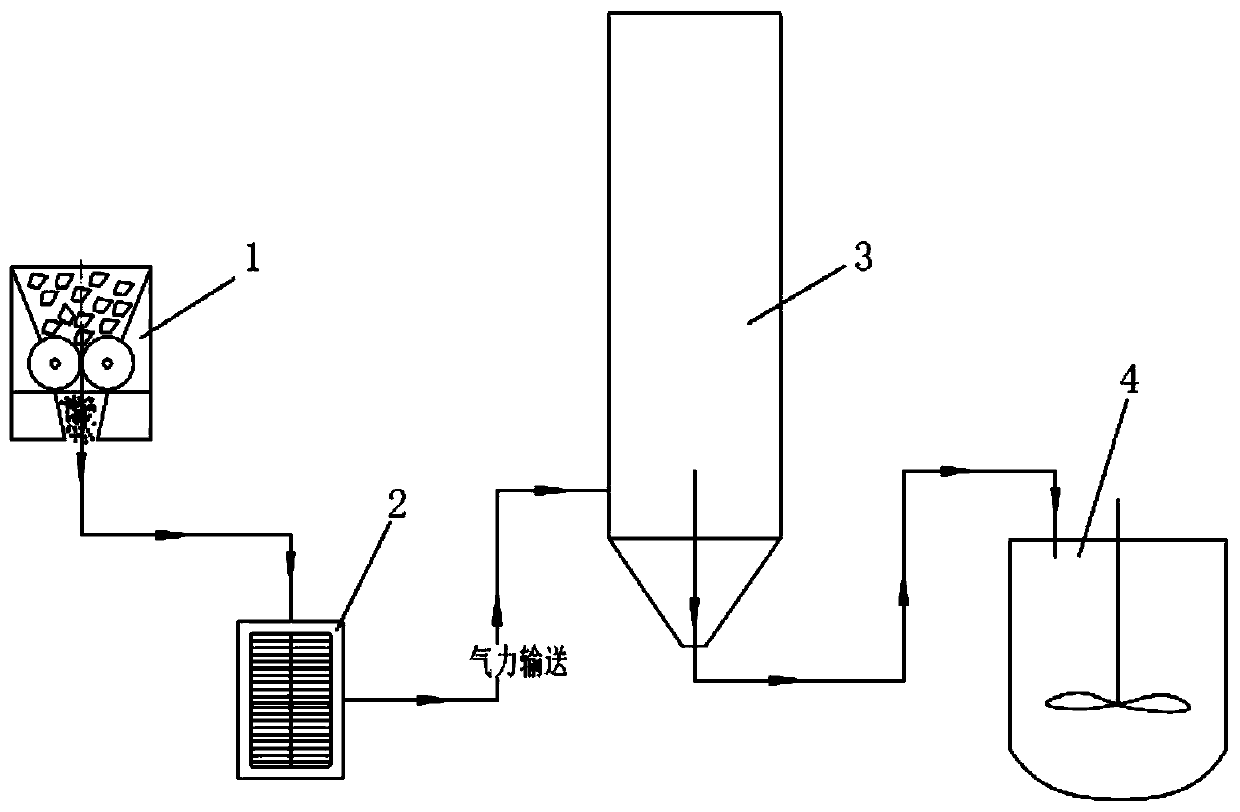

[0032] combined with figure 1 As shown, the processing method uses the comprehensive utilization system of aerated concrete waste, including a double-shaft metal crusher 1, a ring hammer European-style crusher 2, a transition bin 3 and a pouring mixer 4.

[0033] The discharge port of the double-shaft metal crusher 1 is connected to the feed port of the European version of the ring hammer crusher 2, and a filter screen (not shown in the figure) is arranged inside the ring hammer crusher 2, and the mesh diameter of the filter screen is 1.2mm, so as to control the diameter of the waste after crushing; the discharge port of the ring hammer Europea...

Embodiment 2

[0040] The purpose of the present invention is to process aerated concrete waste such as scraps removed in the cutting process in the aerated concrete slab and block production line, and waste generated by truncating unrepairable aerated concrete slabs and blocks. Reduce pollution and land occupation caused by waste aerated concrete.

[0041] combined with figure 1 As shown, the processing method uses the comprehensive utilization system of aerated concrete waste, including a double-shaft metal crusher 1, a ring hammer European-style crusher 2, a transition bin 3 and a pouring mixer 4.

[0042] The discharge port of the double-shaft metal crusher 1 is connected to the feed port of the European version of the ring hammer crusher 2, and a filter screen (not shown in the figure) is arranged inside the ring hammer crusher 2, and the mesh diameter of the filter screen is 1.0mm, so as to control the diameter of the waste after crushing; the discharge port of the ring hammer Europea...

Embodiment 3

[0049] The purpose of the present invention is to process aerated concrete waste such as scraps removed in the cutting process in the aerated concrete slab and block production line, and waste generated by truncating unrepairable aerated concrete slabs and blocks. Reduce pollution and land occupation caused by waste aerated concrete.

[0050] combined with figure 1 As shown, the processing method uses the comprehensive utilization system of aerated concrete waste, including a double-shaft metal crusher 1, a ring hammer European-style crusher 2, a transition bin 3 and a pouring mixer 4.

[0051] The discharge port of the double-shaft metal crusher 1 is connected to the feed port of the European version of the ring hammer crusher 2, and a filter screen (not shown in the figure) is arranged inside the ring hammer crusher 2, and the mesh diameter of the filter screen is 0.6mm, so as to control the diameter of the waste after crushing; the discharge port of the ring hammer Europea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com