Production equipment and method for rapid-hardening and non-shrinkage concrete

A technology for production equipment and concrete, which is applied to fast-hardening non-shrinking concrete production equipment and its production field, and can solve the problems of inability to automatically identify crushed stones with a diameter of 5-10 mm, low-quality fast-hardening non-shrinking concrete products, and wrong configuration components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment proposes a kind of fast hardening non-shrinkage concrete, and the fast hardening non-shrinkage concrete of preparation per cubic meter volume comprises the following components:

[0037]240kg of ordinary Portland cement, 60kg of sulphoaluminate cement, 30kg of expansion agent, 40kg of fly ash, 40kg of slag powder, 280kg of river sand, 420kg of machine-made sand, 450kg of crushed stone with a diameter of 5-10mm, and crushed stone with a diameter of 12-20mm Stone 680kg, polycarboxylate high-performance superplasticizer 5.6kg and water 165kg.

[0038] Do the test in the following table, in which, ultra-fine sand is gravel with a diameter of 5-10mm; machine-made sand is gravel with a diameter of 12-20mm; 25% ultra-fine sand means that the mass ratio of each mixing is 25%.

[0039]

[0040]

[0041] The mixture of 5-10mm crushed stones and 12mm-20mm crushed stones is mixed sand. In order to avoid excessive shrinkage ratio after solidification cau...

Embodiment 2

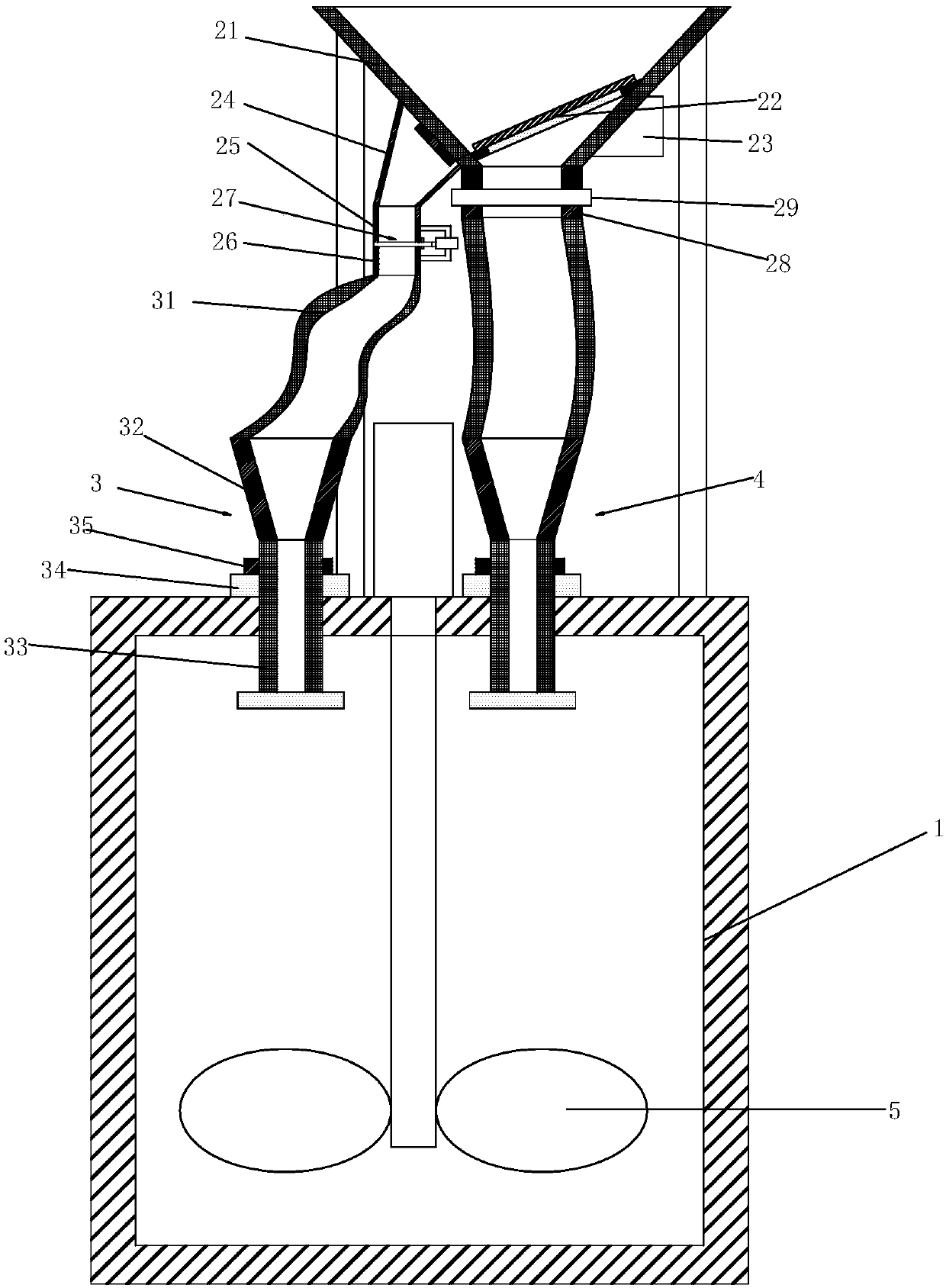

[0043] This embodiment proposes a rapid-hardening non-shrinkage concrete production equipment, including: a mixing device for mixing the components of the rapid-hardening non-shrinkage concrete in Example 1.

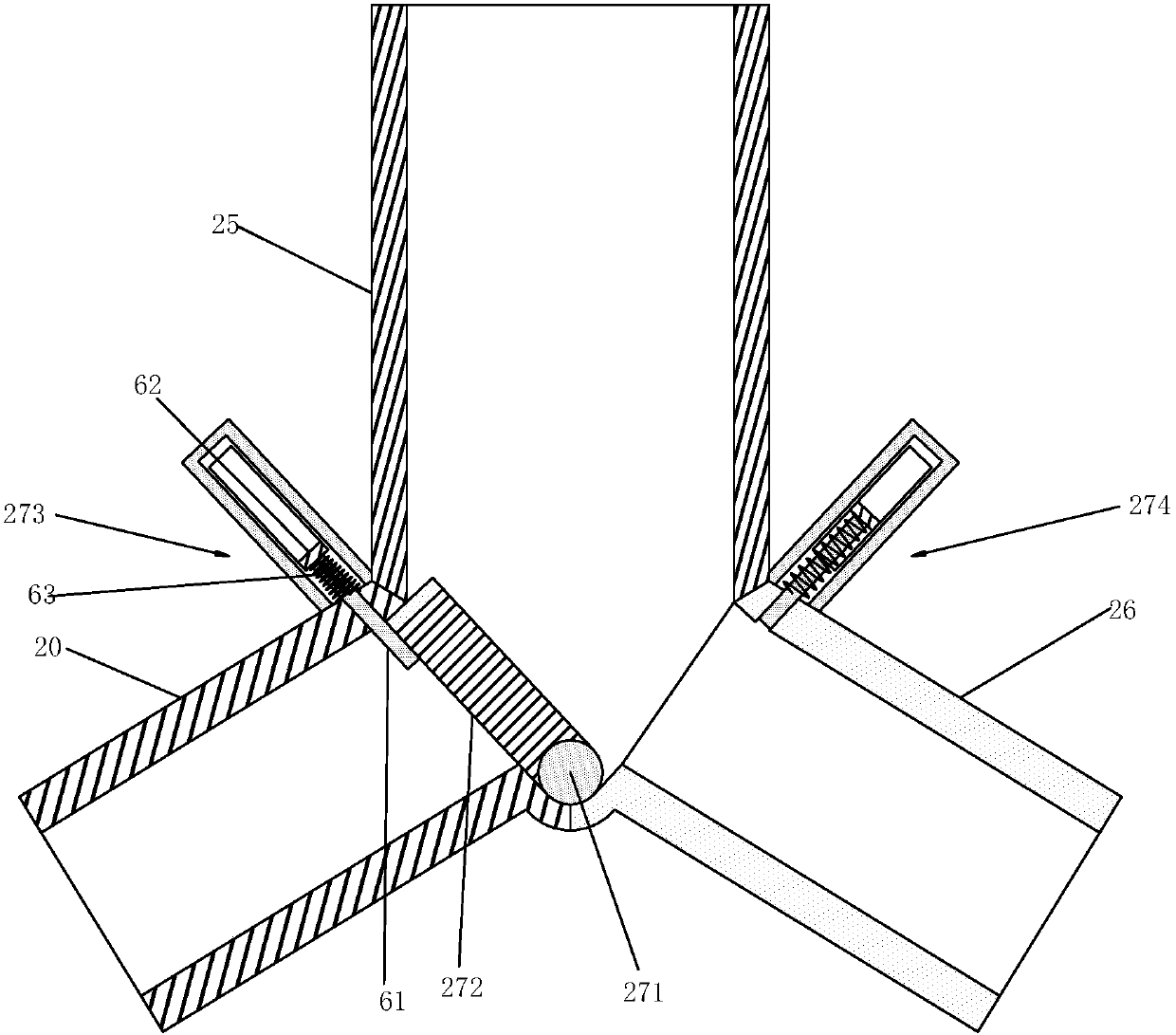

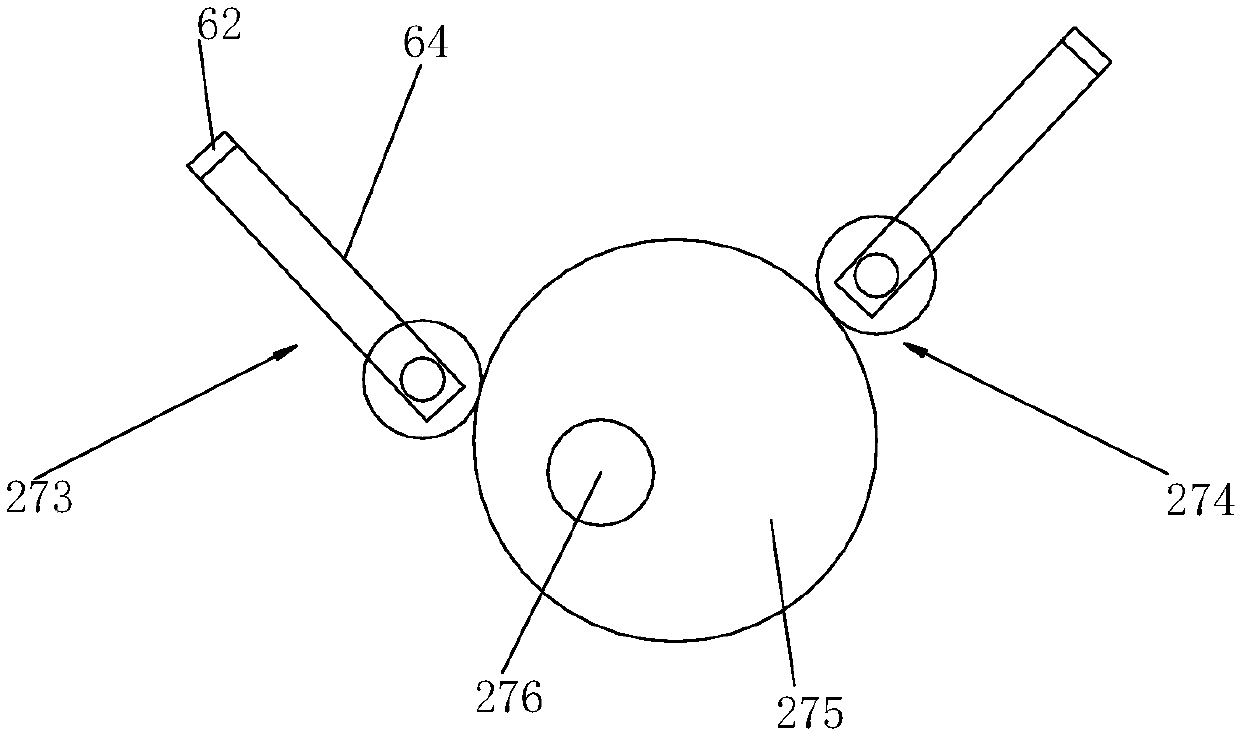

[0044] Such as figure 1 As shown, in order to design a mixing device with a simple structure and realize automatic identification of crushed stones with a diameter of 5-10mm and crushed stones with a diameter of 12-20mm, the mixing device includes:

[0045] mixing box 1;

[0046] The feeding assembly includes a material receiving funnel 21, the material receiving funnel 21 stands on the top of the mixing box 1 through a mounting frame, a filter screen 22 is installed in the material receiving funnel 21, the filter screen 22 includes a mounting frame, and the mounting frame is installed on the material receiving On the funnel 21 inner walls, the installation frame is closed by a mesh body, and the mesh body can pass through crushed stones with a diameter of 5-10mm. The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Fineness modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com