Technology for manufacturing mold core by using steel molding sand

A molding sand and sand core technology, which is applied in the technical field of manufacturing cores by using steel molding sand, can solve the problems of low thermal conductivity of cores, achieve high thermal conductivity, uniform cooling speed, and improve the quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

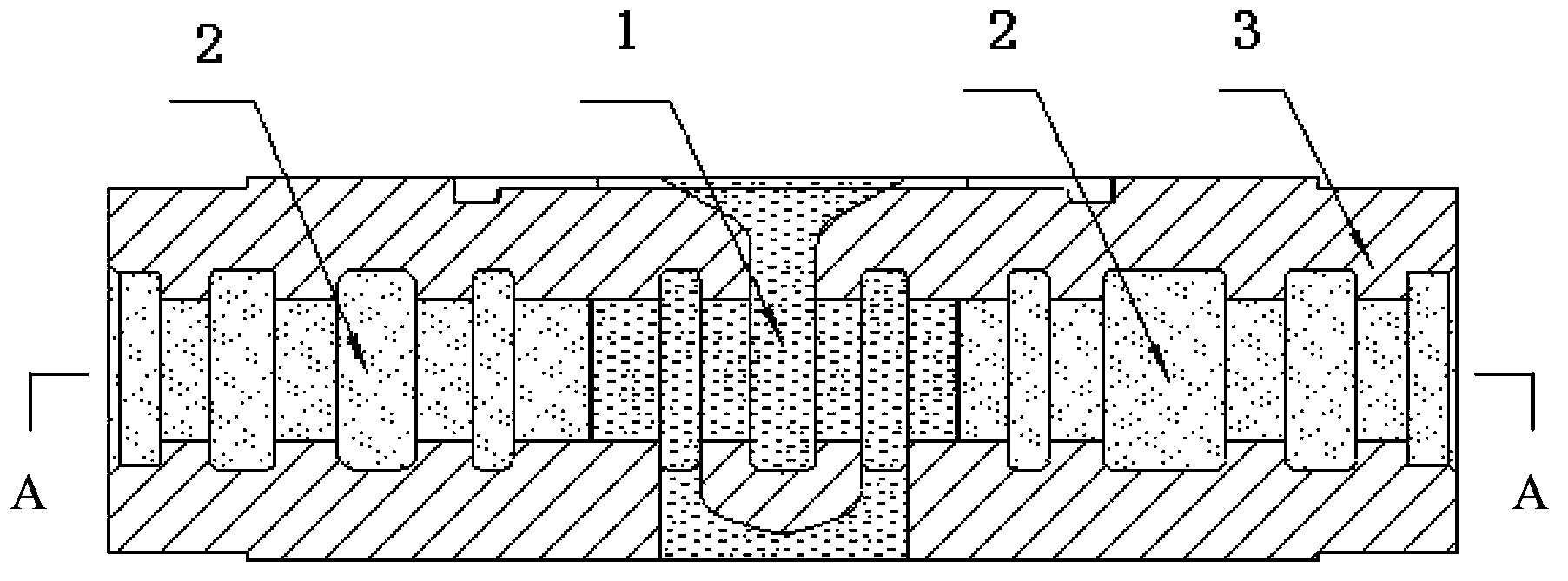

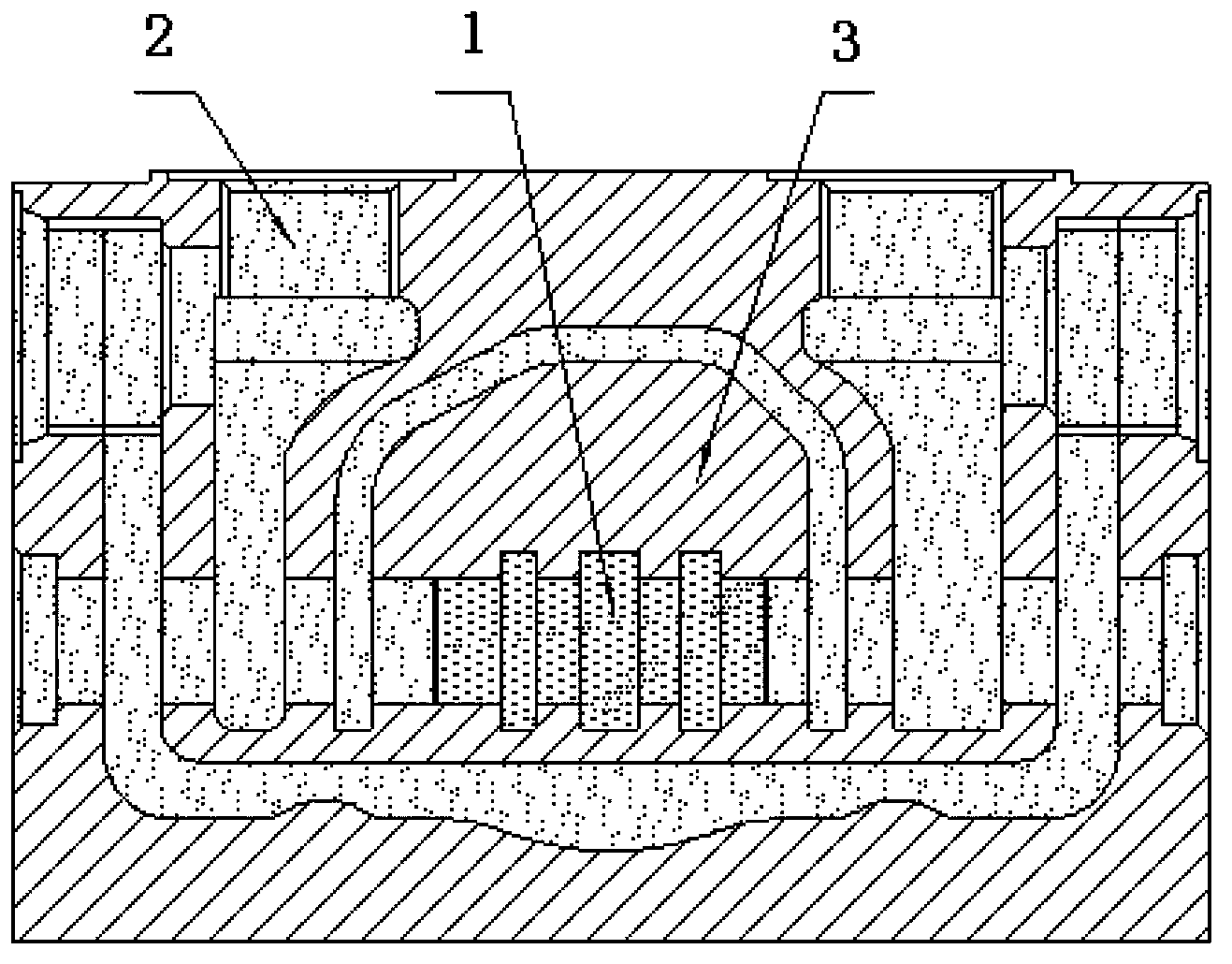

[0014] The embodiments of the present invention will be further described below in conjunction with the drawings.

[0015] Such as figure 1 As shown, a process for manufacturing a core using steel molding sand, the operation steps are as follows:

[0016] ①Use steel balls as raw sand to coat phenolic resin, curing agent and lubricant by thermal coating to make steel molding sand;

[0017] ②According to the method of core shooting, the steel sand core is made of steel moulding sand;

[0018] ③Place the steel sand core on the pre-processed position of the integral mold, and shoot the coated sand core, so that the steel sand core and the coated sand core are combined to form an integral sand core.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com