Aluminum alloy for aircraft wallboard and board preparation method

An aluminum alloy sheet and a technology for aircraft, which are applied in the field of aluminum alloy sheet for aircraft wall panels and its preparation, can solve the problems of difficulty in improving the comprehensive performance of the damage-resistant aluminum alloy sheet, and achieve large-scale industrial production, simple process and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

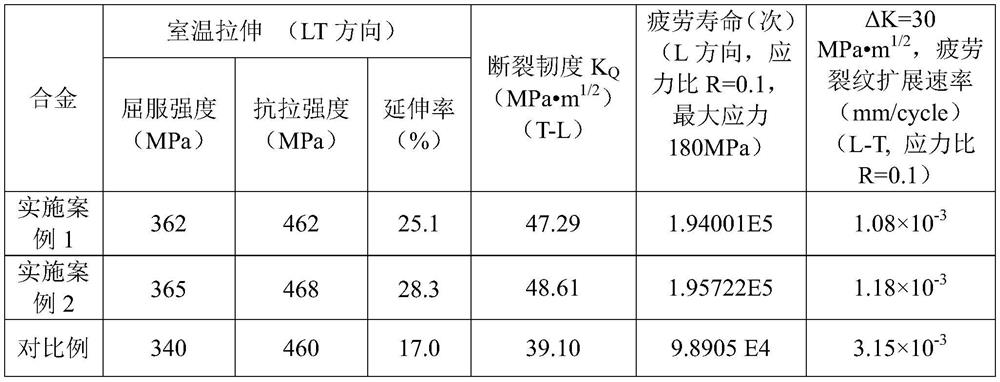

Examples

Embodiment 1

[0026] (1) The alloy composition is: Cu: 4.2%, Mg: 1.5%, Mn: 0.5%, Zr: 0.11%, Sc: 0.15%, the balance is Al and trace impurity elements, and the total content of the impurity elements is less than 0.1% %.

[0027] (2) Carry out alloy smelting according to the designed components to obtain ingots, which are homogenized, milled, and hot-rolled to 40 mm in sequence;

[0028] (2) High temperature heat preservation treatment: put the rolled aluminum alloy plate into a heating furnace for heating, the heating temperature is 480°C, and the heat preservation time is 3h;

[0029] (3) Cooling treatment: take the plate that has been treated with high temperature heat preservation out of the furnace and take air cooling;

[0030] (4) Cryogenic treatment: put the plate after high temperature heat preservation and cooling treatment into an environmental box for cryogenic treatment, the cooling temperature is -90°C, and the holding time is 3h;

[0031] (5) Cold-rolling treatment: Immediatel...

Embodiment 2

[0036] (1) The alloy composition is: Cu: 4.4%, Mg: 1.5%, Mn: 0.5%, Zr: 0.11%, Sc: 0.15%, Ag: 0.2%, the balance is Al and trace impurity elements, the impurity elements The total content is less than 0.1%.

[0037] (2) Carry out alloy smelting according to the designed components to obtain ingots, which are homogenized, milled, and hot-rolled to 35mm in sequence;

[0038] (2) High temperature heat preservation treatment: put the rolled aluminum alloy plate into a heating furnace for heating, the heating temperature is 490°C, and the heat preservation time is 2.5h;

[0039] (3) Cooling treatment: take water mist cooling after the high-temperature insulation-treated plates are taken out of the furnace;

[0040] (4) Cryogenic treatment: put the plate after high temperature heat preservation and cooling treatment into the environmental box for cryogenic treatment, the cooling temperature is -180°C, and the holding time is 3h;

[0041] (5) Cold-rolling treatment: Immediately carry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com