Heat treatment method for obtaining titanium alloy with high damage tolerance

A heat treatment method and damage tolerance technology, applied in the field of titanium alloys, can solve problems such as difficulty in meeting high damage tolerance, and achieve the effects of high temperature creep performance, large specific surface area, and high resistance to fatigue crack growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

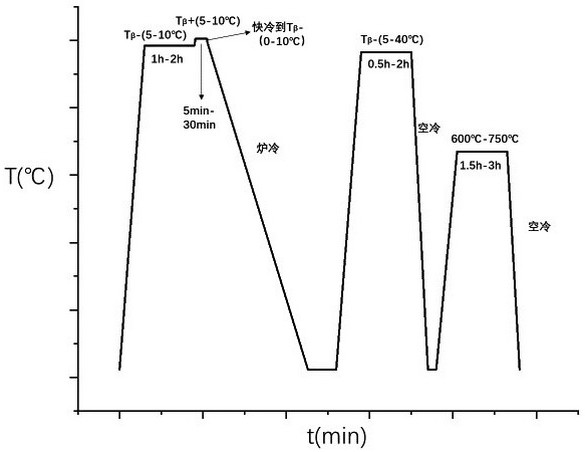

Method used

Image

Examples

Embodiment 1

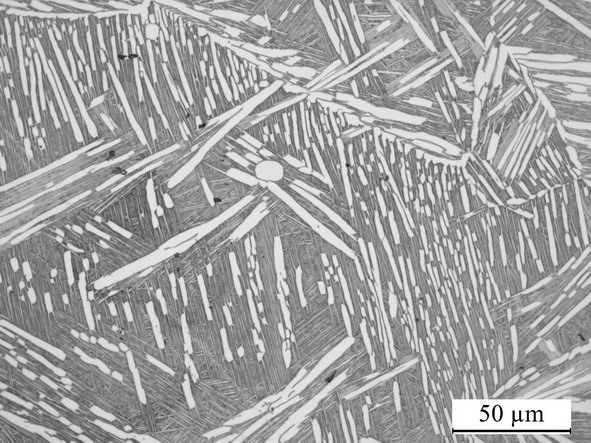

[0028] For the TA15 titanium alloy with two-state structure after α + β forging, the phase change point is obtained after the phase change point test by the metallographic method is 995 °C, and then the same heat treatment furnace is applied, heated to 990 °C for 1 hour, then heated to 1005 °C for 20 minutes, the specimen is removed from the heat treatment furnace for 10 seconds, cooled to 985 °C, the heat treatment furnace temperature is set to 985 °C, the specimen is put back into the heat treatment furnace, and the furnace is closed and cooled to room temperature. After the two-stage annealing heat treatment, heated to 960 °C for 1 hour after air cooling to room temperature, and then reheated to 670 °C for 2 hours after air cooling to room temperature to obtain a bimorphic tissue containing tentacle-like primary α phase and β transformation tissue, wherein the tentacle-like primary α phase volume fraction of 32-37%, its tissue morphology is as follows Figure 2 as shown. The resul...

Embodiment 2

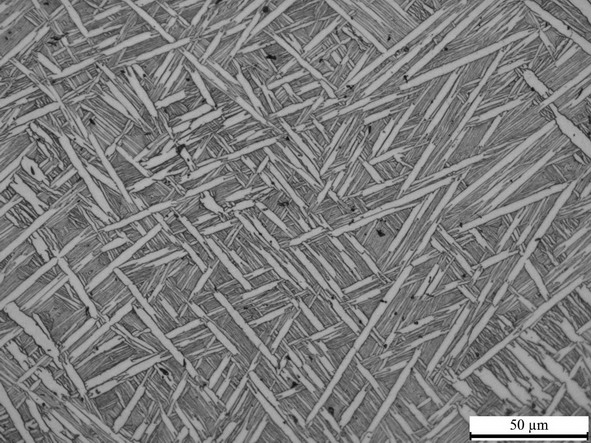

[0030] For the TC4 titanium alloy with mesh basket organization after laser additive manufacturing, the phase change point is obtained after the phase change point test by metallographic method is 1005 °C, and the α phase width is 2 μm, the same heat treatment furnace is applied, heated to 1000 °C for 1 hour, and then the furnace is closed and cooled to room temperature. After the two-stage annealing heat treatment, heated to 985 °C for 1 hour after air cooling to room temperature, and then reheated to 680 °C after 1.5 hours of air cooling to room temperature to obtain a bimorphic tissue containing tentacle-like primary α phase and β transformation tissue, wherein the volume fraction of the tentacle-like primary α phase is 30-33%, and its tissue morphology is as follows Figure 3 as shown. The resulting specimen is tested for its plane fracture toughness, K IC Reach 124MPa*m 1 / 2 , impact toughness a KU Reached 42-46J / cm 2 。 Damage tolerance is good.

Embodiment 3

[0032]For the forged TC4DT with coarse deformation Wei's structure, the α phase width is 7 μm, and the phase change point is obtained by the metallographic method of the phase change point test is 1000 °C, the same heat treatment furnace is applied, heated to 980 °C, and after 1 hour of heat preservation, air cooled to room temperature. It is then reheated to 650 °C, kept warm for two hours and then cooled to room temperature. Bimorphic tissues with tentacle-like α phases and β transformational tissues were obtained, and the volume fraction of the tentacle-like α phase reached 38-40%. Test on its plane fracture toughness, K IC Reached 130MPa*m 1 / 2 The impact toughness reached 48J / cm 2 。 Excellent damage performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition point | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Phase transition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com