Patents

Literature

37results about How to "Reduce crack growth rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel-base high-temperature alloy with low density and high melting point and preparation process thereof

The invention relates to high-temperature alloy technology, and in particular provides an isometrical cast nickel-base high-temperature alloy with low density, high incipient melting temperature and good casting property and a preparation process thereof, which can be used for floating tile materials of a combustion chamber. The alloy comprises the following compositions by mass percentage: 0.03 to 0.06 percent of C, 5 to 12 percent of Cr, 5.5 to 6.5 percent of Al, 3 to 8 percent of Co, 3 to 7 percent of W, 2 to 4 percent of Mo, 1.6 to 3.2 percent of Nb, 0.01 to 0.03 percent of B, 0.008 to 0.025 percent of Y and the balance of Ni. A vacuum induction furnace is adopted to smelt a master alloy, and a smelting crucible is a CaO crucible or a MgO crucible; and the operation process comprises the following steps: putting alloying elements such as carbon, chromium, cobalt, tungsten, molybdenum and niobium in proportion and a nickel plate into the crucible; melting the alloy when the vacuum degree reaches between 50 and 0.1 Pa; and after completion of the melting, refining for 30 to 300 seconds at a temperature of between 1,550 and 1,600 DEG C, cutting off electricity, forming a film, breaking the film to add Al and Al-Y and Ni-B interalloy for uniform stirring, and casting a master alloy pig at a temperature of between 1,450 and 1,500 DEG C. The invention solves the problems of low incipient melting temperature, poor plasticity and inoxidability and the like of the nickel-base high-temperature alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

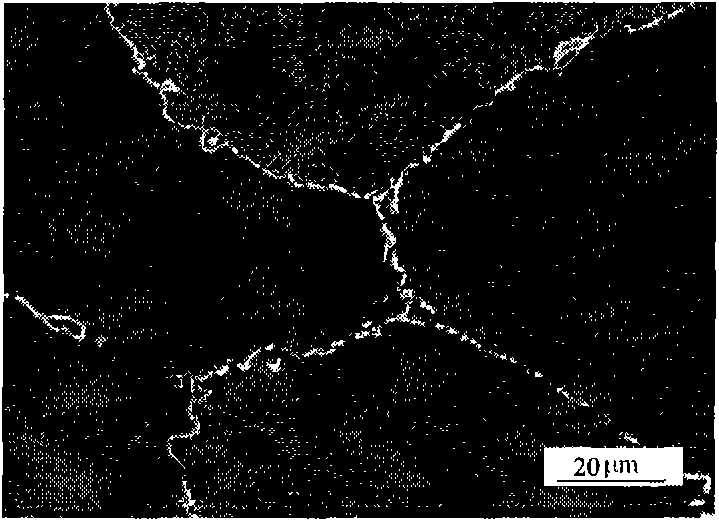

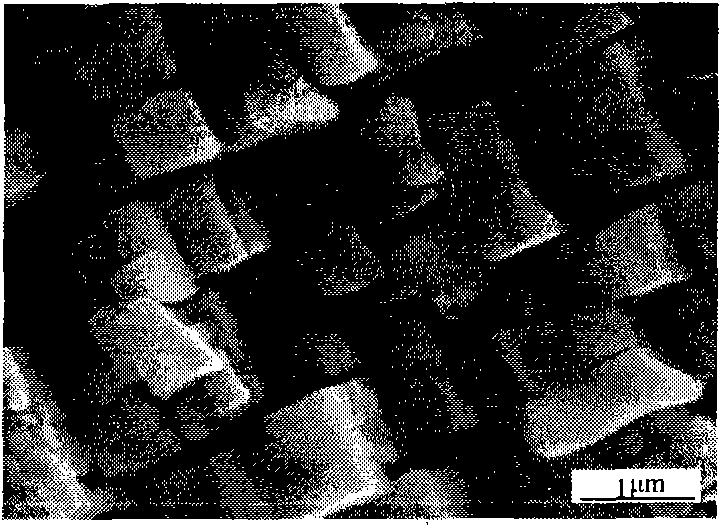

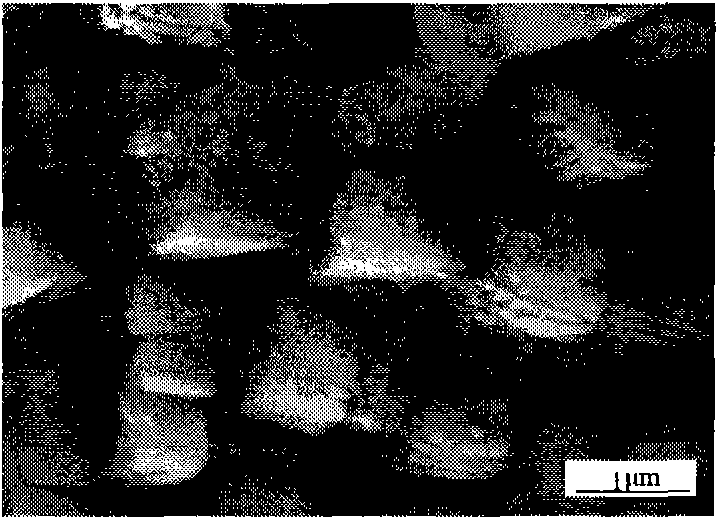

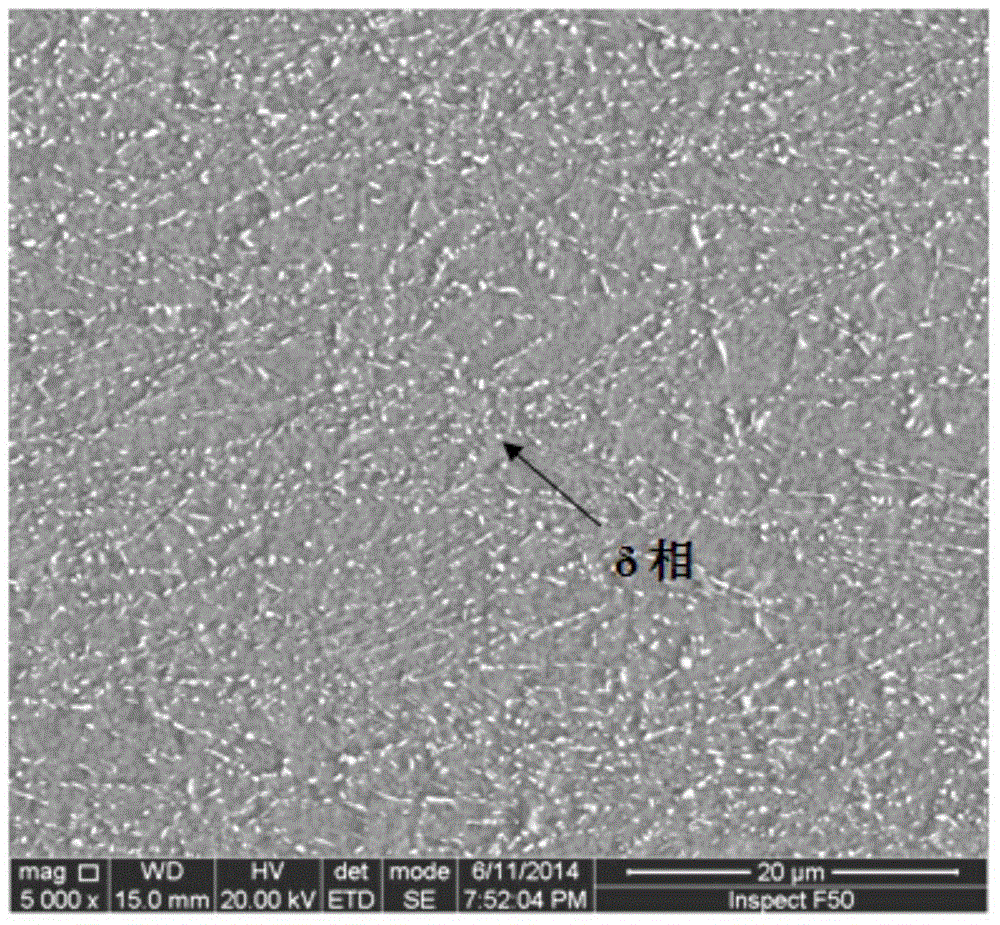

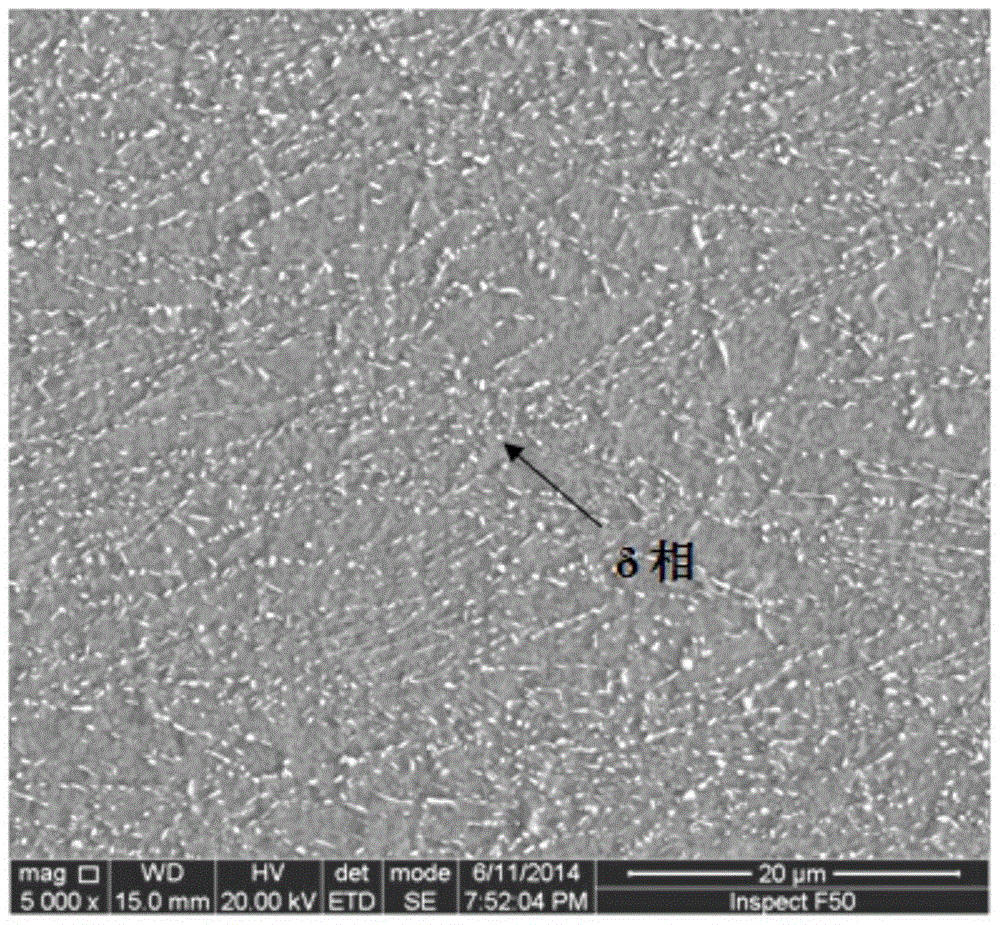

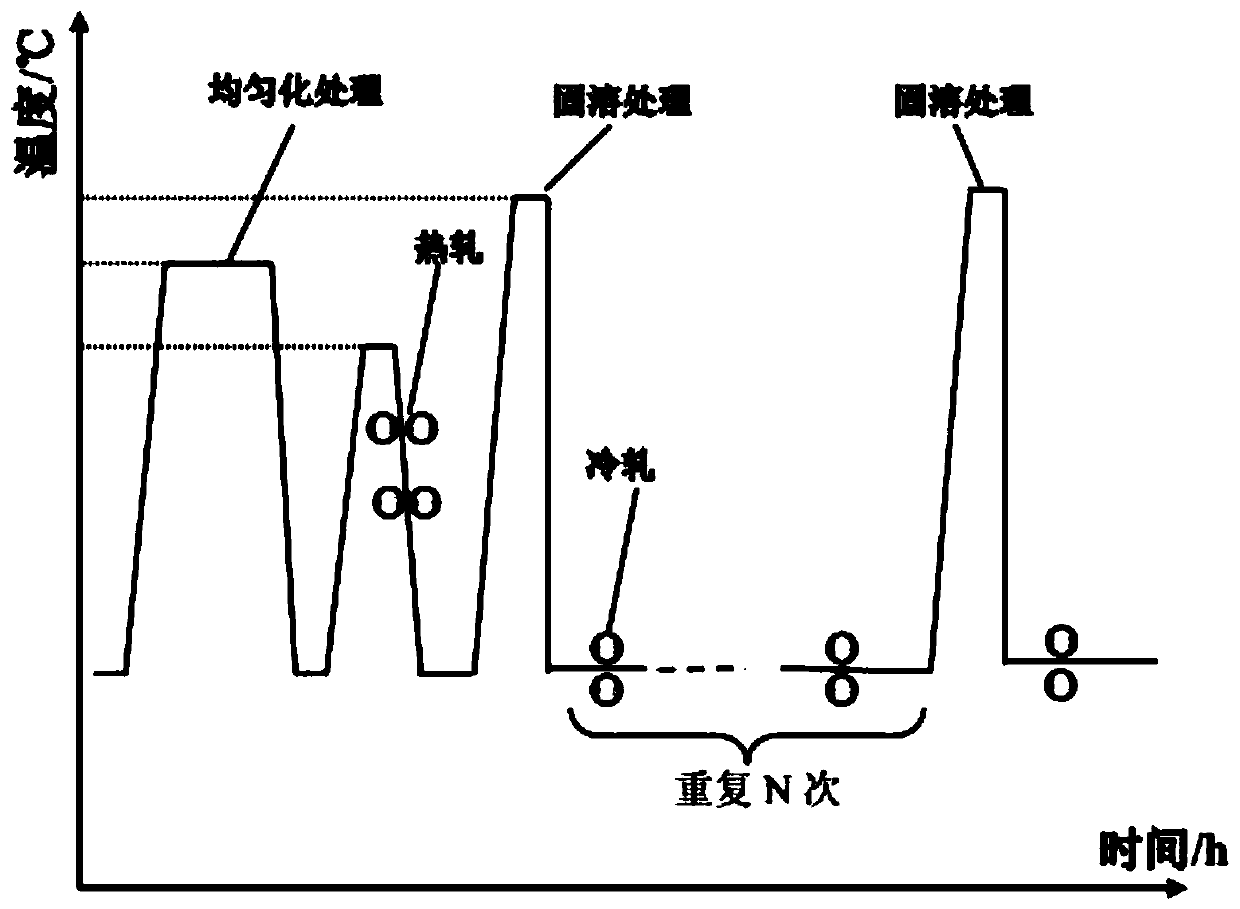

Granular delta-phase uniformly distributed GH4169 alloy preparation method

The invention relates to a granular delta-phase uniformly distributed GH4169 alloy preparation method and belongs to the technical field of preparation of high-temperature alloy materials. On the basis of combination of cold deformation and heat treatment processes, the method includes GH4169 alloy cold deformation and heat treatment. Firstly, plate blanks are subjected to cold rolling deformation more than 30% after solid solution and quickly cooled under vacuum argon shielding after heat preservation at 985+ / 5 DEG C for 1h; secondly, the plate blanks are subjected to standard double aging treatment; finally, granular delta phases uniformly distributed in grains and at grain boundaries of GH4169 alloy are acquired. Therefore, GH4169 alloy strength is improved, and crack growth rate of the GH4169 alloy is decreased to acquire better fatigue performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

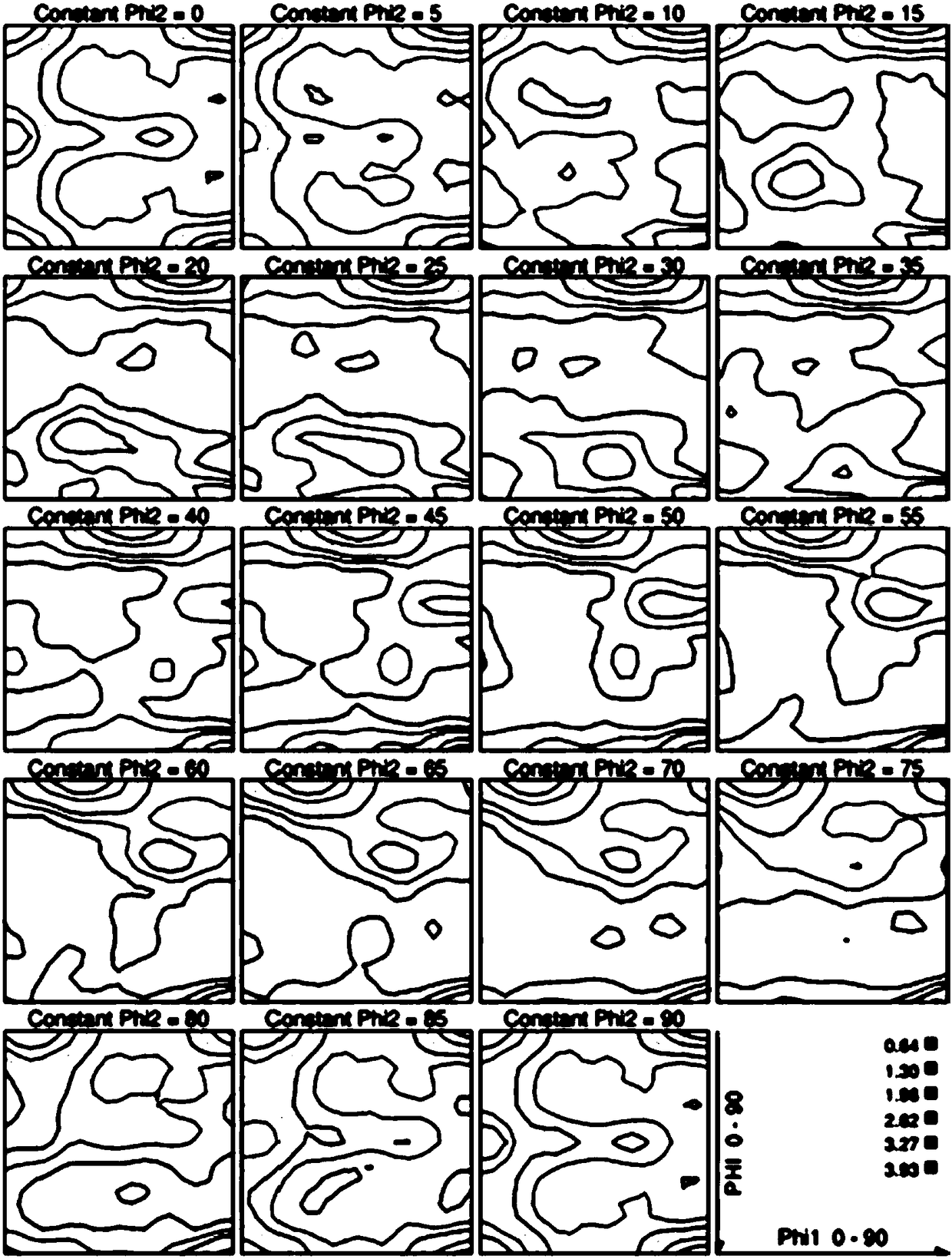

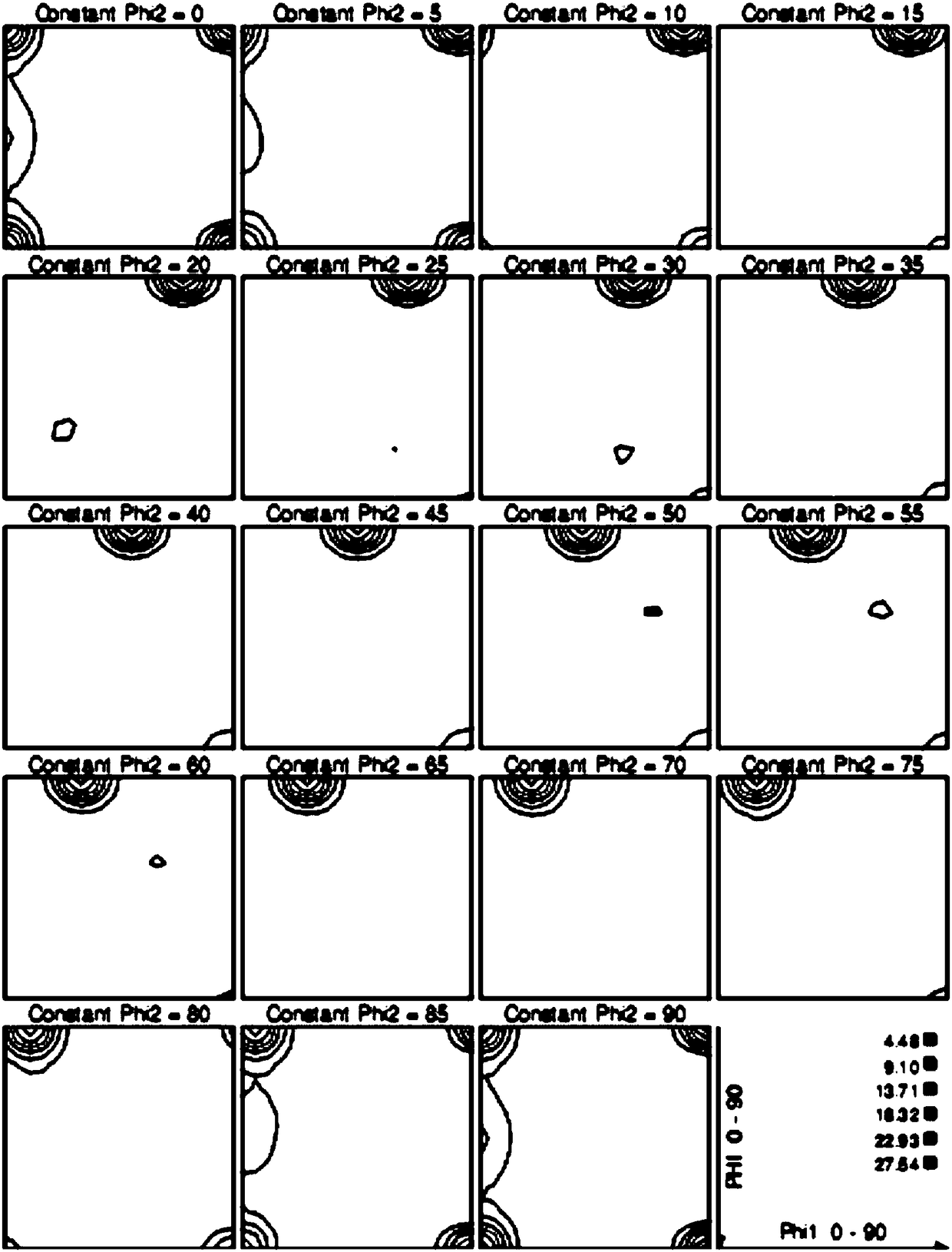

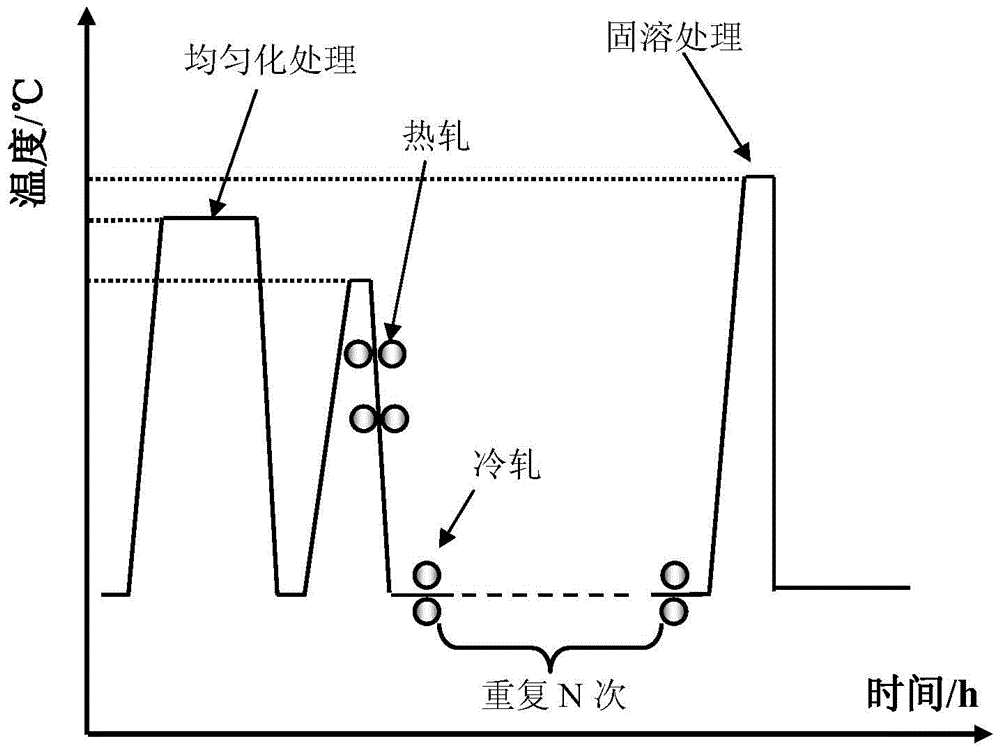

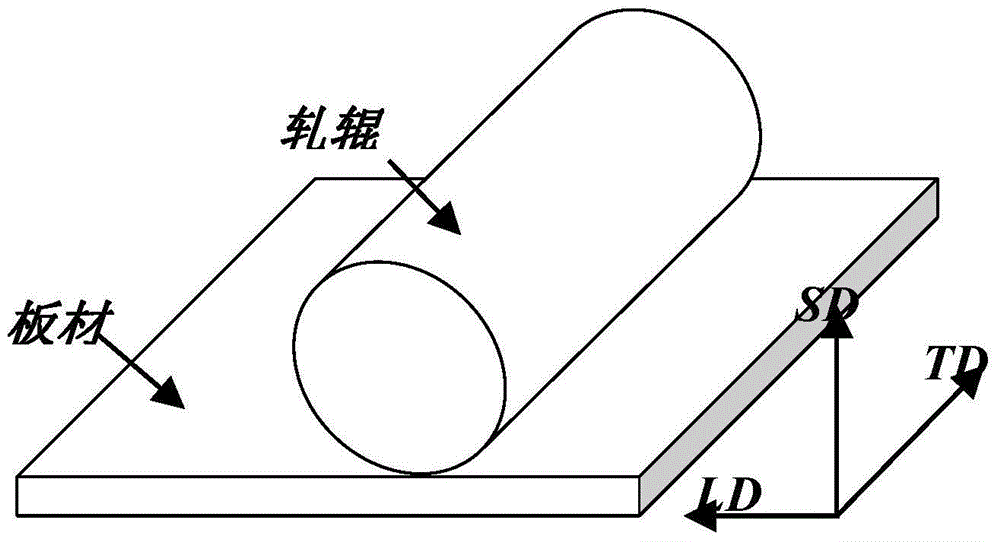

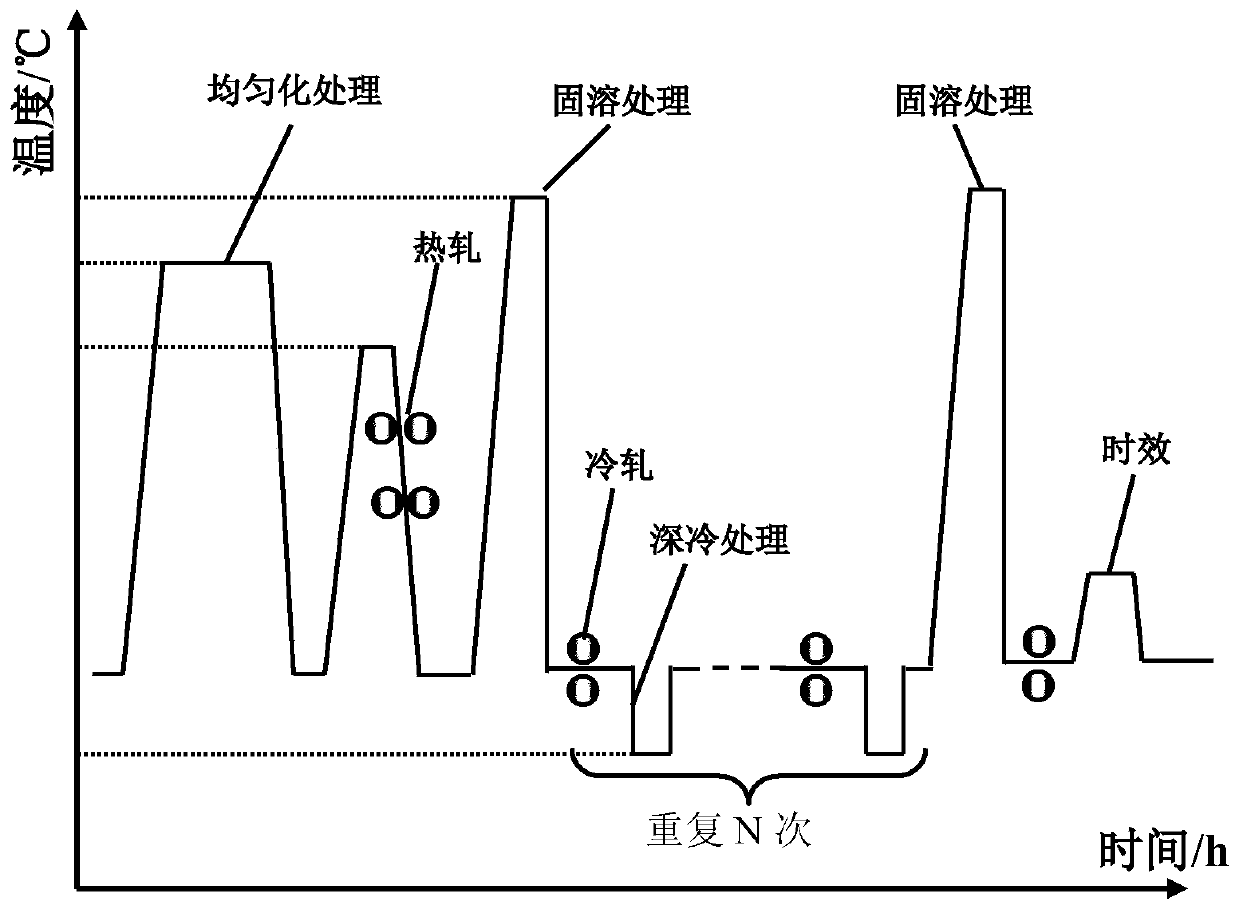

Machining method of fine-grain cubic texture corrosion-fatigue-resistant aluminum alloy plate

The invention relates to a skin material for aviation, in particular to a machining method for preparing corrosion-fatigue-damage-resistant aluminum alloy plates, and belongs to the technical field ofnonferrous metals. The machining method comprises the steps that an aluminum alloy hot rolling material is subjected to solid solution treatment for the first time, then the second time of solid solution treatment is carried out after multi-pass cold rolling with the pass deformation amount being less than or equal to 1.0mm is carried out to achieve the design thickness of the aluminum alloy plate; and in the multi-pass cold rolling process, deep cooling treatment is carried out immediately after each pass of cold rolling, and the temperature of the deep cooling treatment is less than or equal to -100 DEG C. The machining method for preparing the corrosion-fatigue-damage-resistant aluminum alloy plates is reasonable in texture design, the preparation process is simple and controllable, obtained products have good performance, and the machining method for preparing the corrosion-fatigue-damage-resistant aluminum alloy plates is convenient for large-scale industrial application.

Owner:HUNAN UNIV OF SCI & TECH

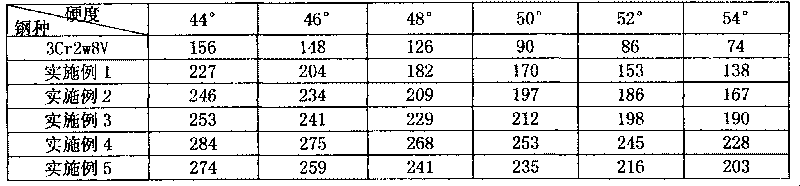

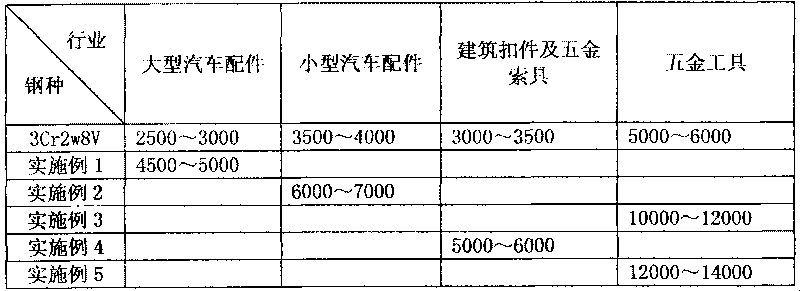

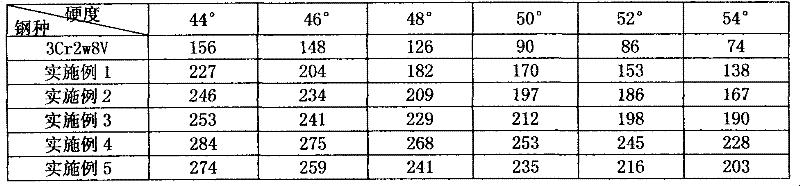

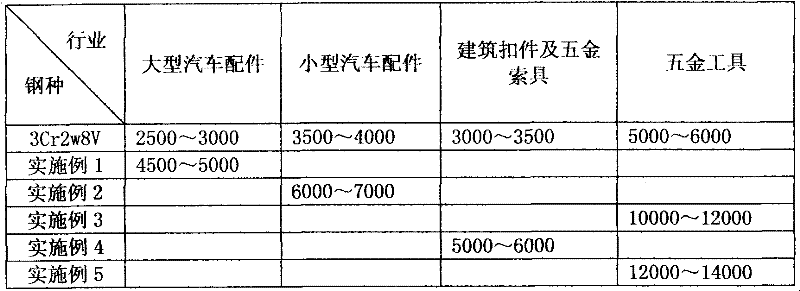

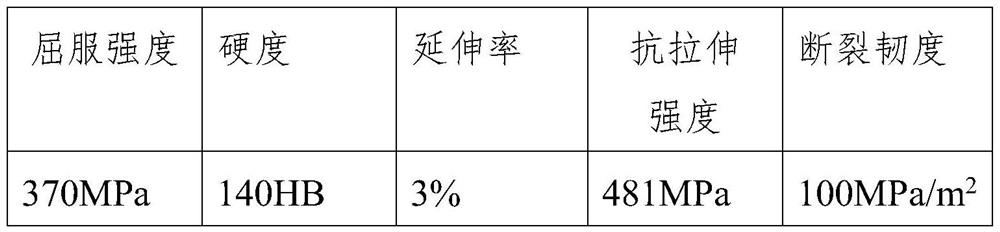

Hot die steel and tempering process thereof

The invention relates to hot die steel which comprises the following components in percentage by weight: 0.32-0.42 percent of carbon, 0.2-0.5 percent of silicon, 0.2-0.5 percent of manganese, 2.2-2.7 percent of chromium, 1.0-3.4 percent of molybdenum, 0.8-2.2 percent of tungsten, 0.4-0.6 percent of vanadium, 0.2-1.5 percent of cobalt and the balance of Fe. A tempering process of the hot die steel comprises the following steps of: firstly, tempering at 440-460 DEG C for 1-2 hours and then cooling to room temperature; then tempering at 520-560 DEG C for 1-2 hours and then cooling to room temperature; and finally, tempering at 520-560 DEG C for 1-2 hours and then cooling to room temperature. The hot die steel has the characteristics of high heat resistance and high toughness. The tempering process greatly reduces the fracture speed of materials and further improves the toughness of die materials.

Owner:ZHEJIANG ZHENGDA MOLD

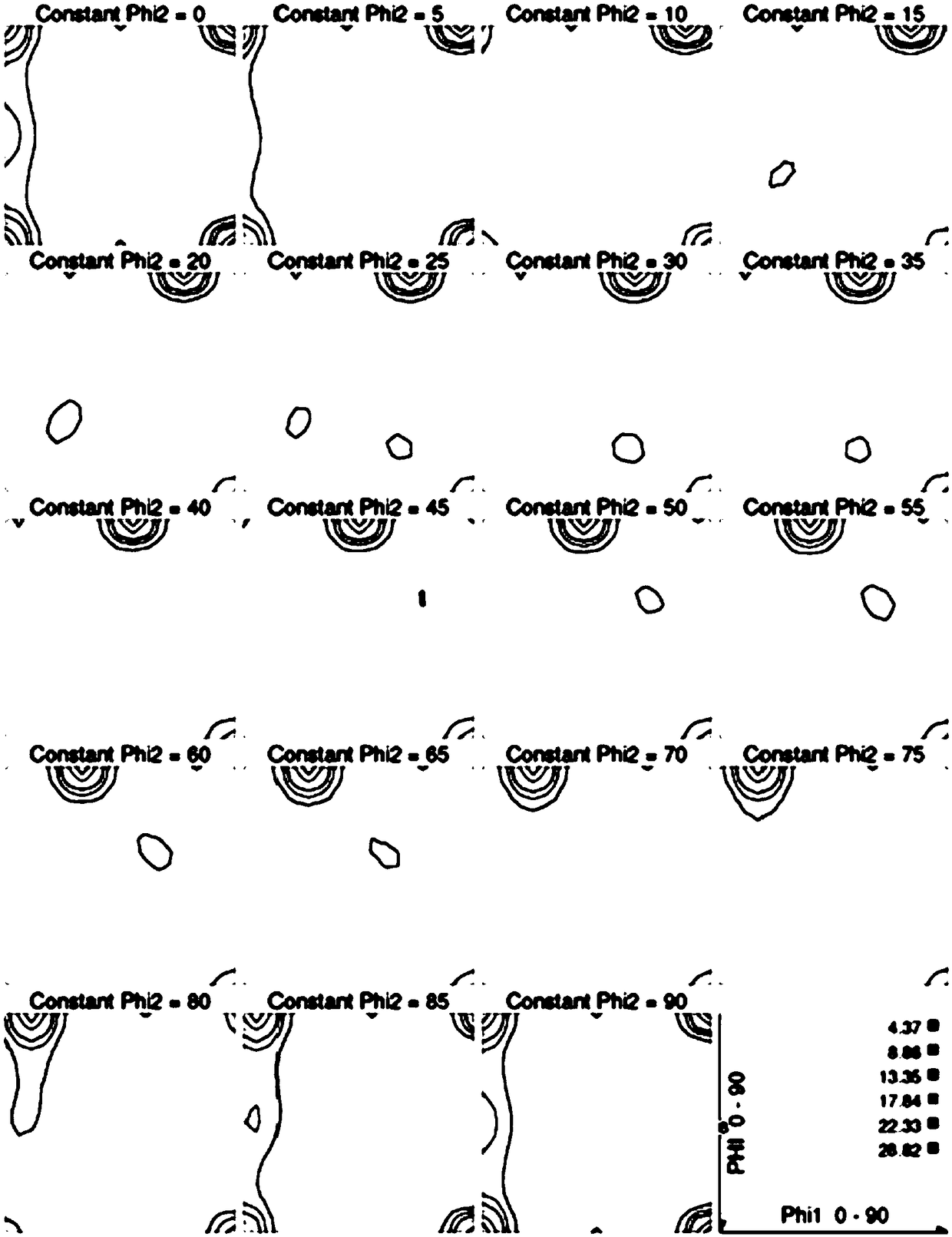

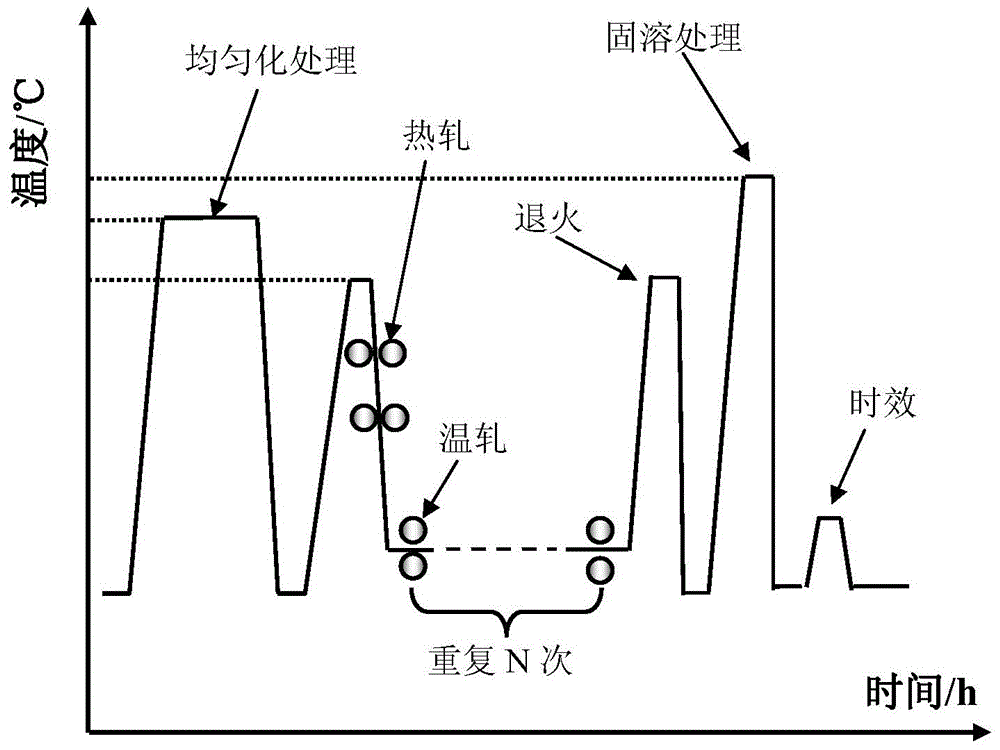

Treatment method for brass texture antifatigue aluminum alloy panel

The invention relates to a treatment method for a brass texture antifatigue aluminum alloy panel, which is characterized in that multiple times of warm rolling is performed on an aluminum alloy hot rolling material until reaching the designed thickness of the aluminum alloy panel, and after annealing treatment and solution treatment, short-term artificial aging is performed. According to the invention, a treatment process of multiple times of warm rolling and annealing is adopted; by virtue of warm rolling, grains of the alloy can be effectively refined, the return process of alloy can be promoted, deformation energy storage can be reduced, and recrystallization can be inhibited; and by virtue of primary annealing treatment, annealing temperature and heat insulation time can be controlled, grains cannot grow up, and a deformation texture can be retained, thus obtaining a relatively strong deformation texture. The treatment method is simple in process method and convenient to operate, can effectively improve the composition and the volume fraction of the texture in an aluminum alloy matrix, can effectively prolong the fatigue life of the aluminum alloy on the premise of ensuring that aluminum alloy strength and ductility meet alloy performance requirements, is suitable for industrial application, and provides a feasible technical solution for preparation of aluminum alloy material for aviation and spaceflight.

Owner:湖南润泰新能源科技有限公司

2-series aluminum alloy

The invention provides 2-series aluminum alloy which consists of 0.06-0.5wt% of Fe, 0.12-0.5wt% of Si, 1.2-1.8wt% of Mg, 3.8-4.9wt% of Cu, 0.3-0.9wt% of Mn and the balance of aluminum. The 2-series aluminum alloy provided by the invention is applicable to the preparation of 2xxx aviation aluminum alloy; and the aluminum alloy provided by the invention is relatively low in crack propagation rate and relatively good in fatigue property and mechanical property.

Owner:SOUTHWEST ALUMINUM GRP

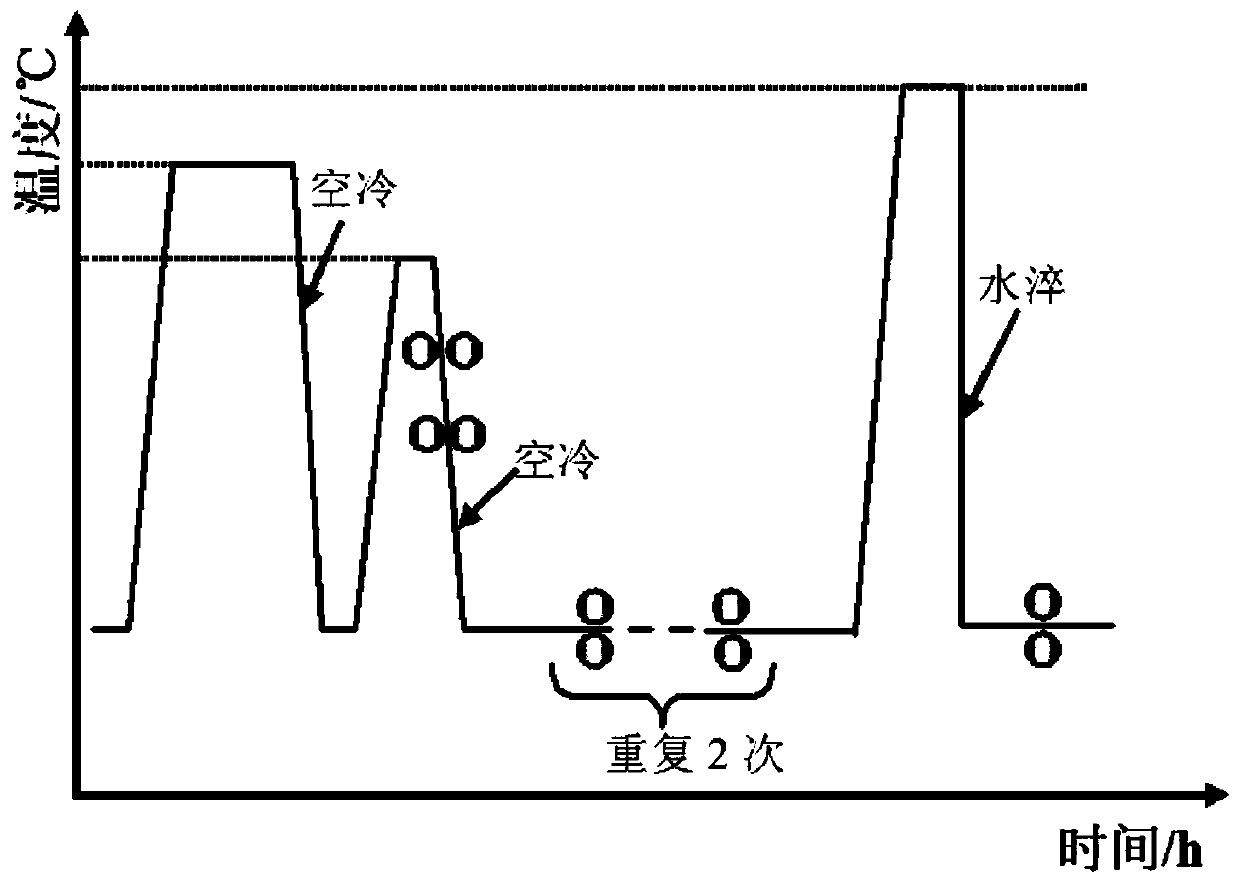

Nickel base alloy composition matching and delta-phase spheroidizing heat treatment process

The invention discloses a nickel base alloy composition matching and delta-phase spheroidizing heat treatment process which comprises the following steps: (1), carrying out solution treatment on nickel base alloy cylindrical forged rods at 1100 DEG C for 1-1.5 h, and water-cooling to room temperature; (2), carrying out heat treatment on the nickel base alloy cylindrical forged rods treated in the step (1), wherein the heat treatment process comprises the steps that keeping heat for 5 h at 885 DEG C, keeping heat for 4.5-5 h at 900 DEG C and rapidly cooling under vacuum argon protection; (3), after the nickel base alloy cylindrical forged rods treated through the step (2) are cooled to room temperature, cutting the nickel base alloy cylindrical forged rods into required shapes. According to the invention, the strength of the nickel base alloy is improved further, the crack propagation rate of the nickel base alloy is reduced and the fatigue life is prolonged.

Owner:SHAOXING UNIVERSITY

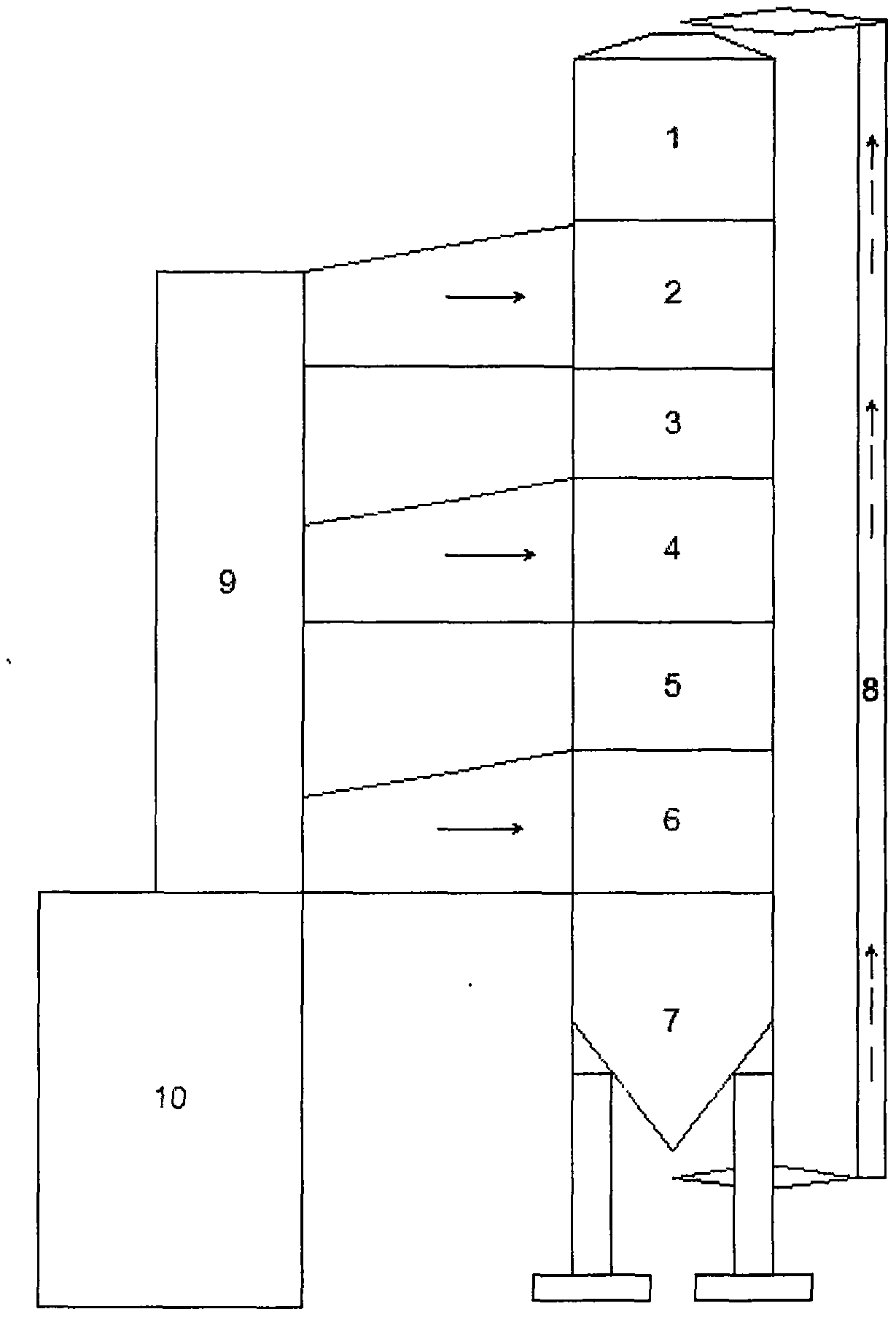

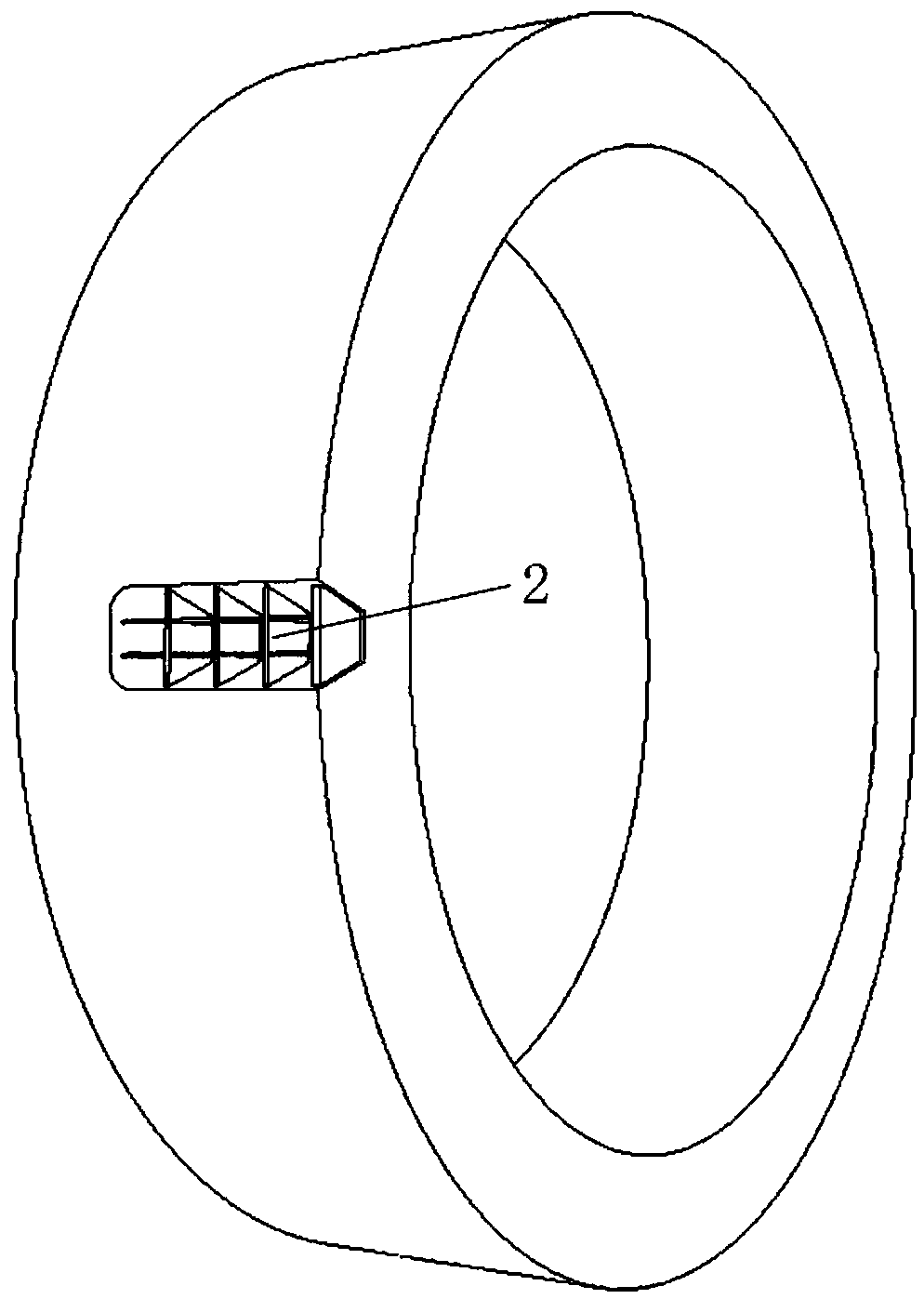

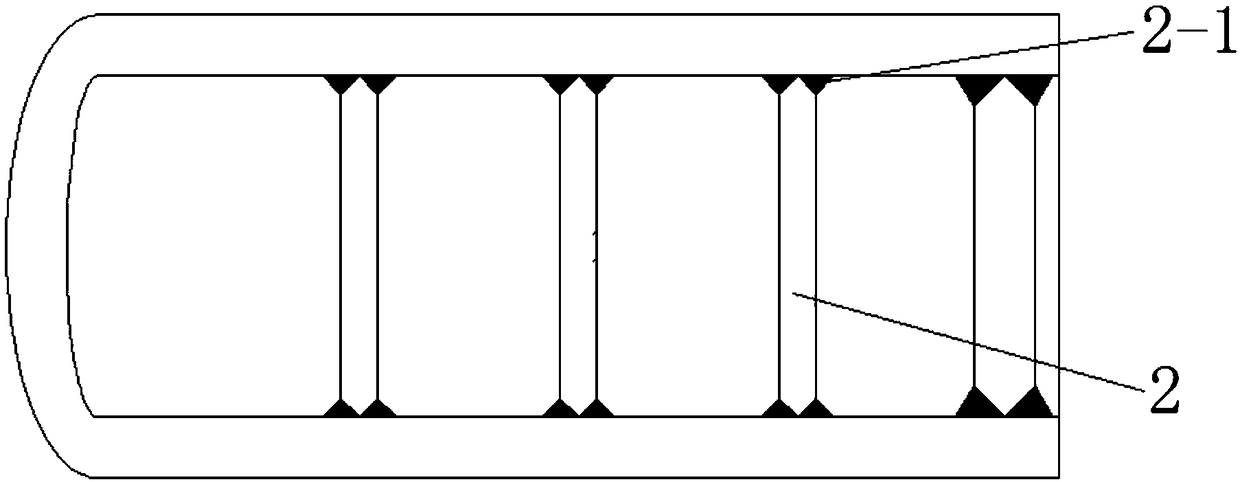

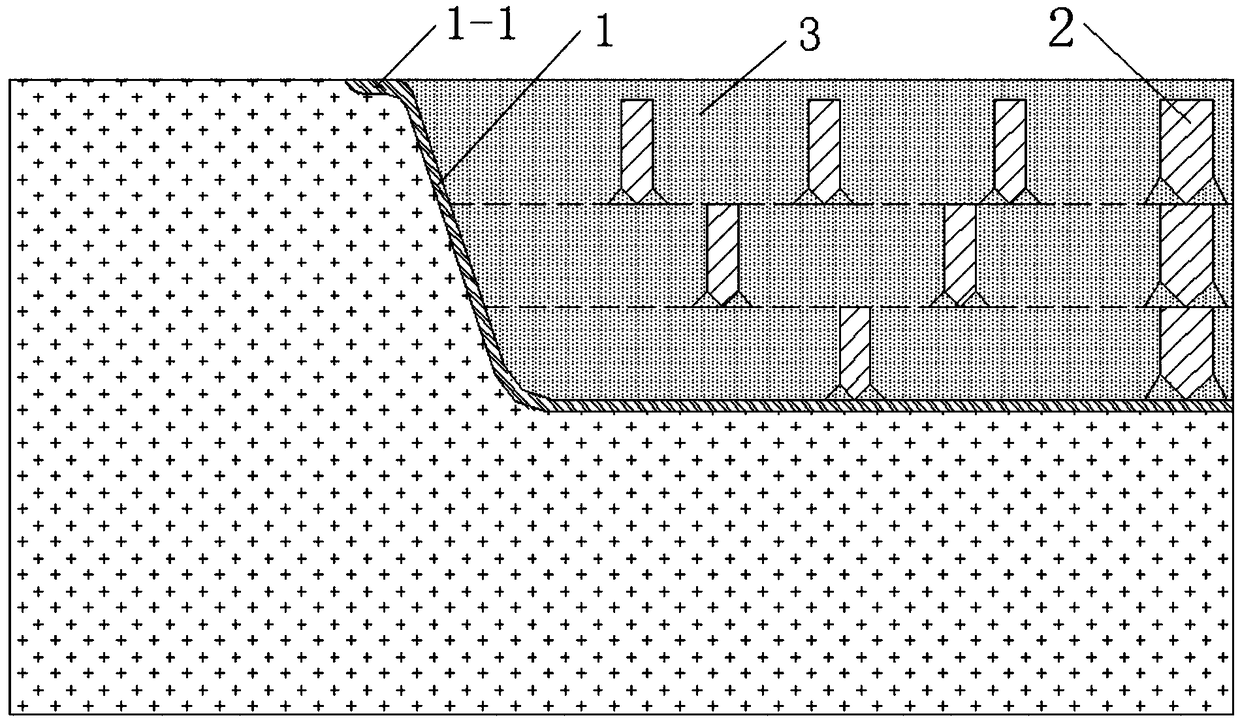

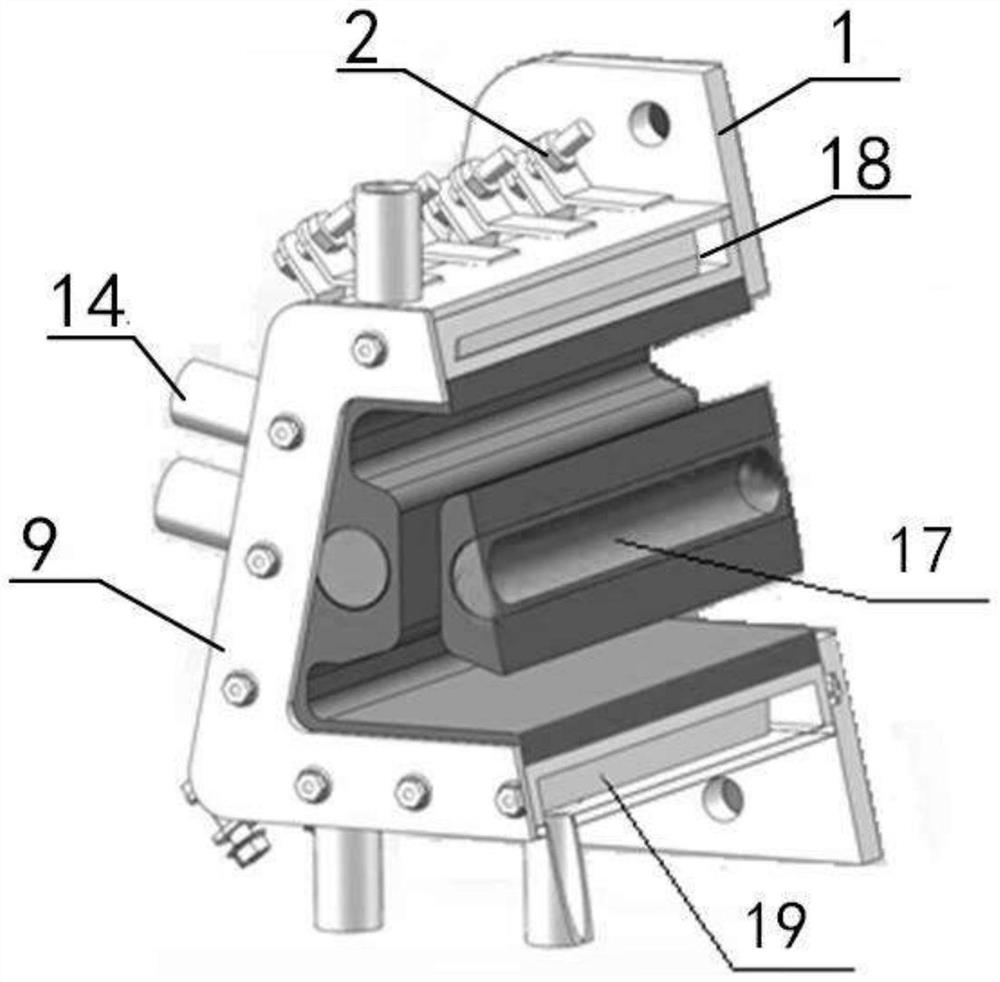

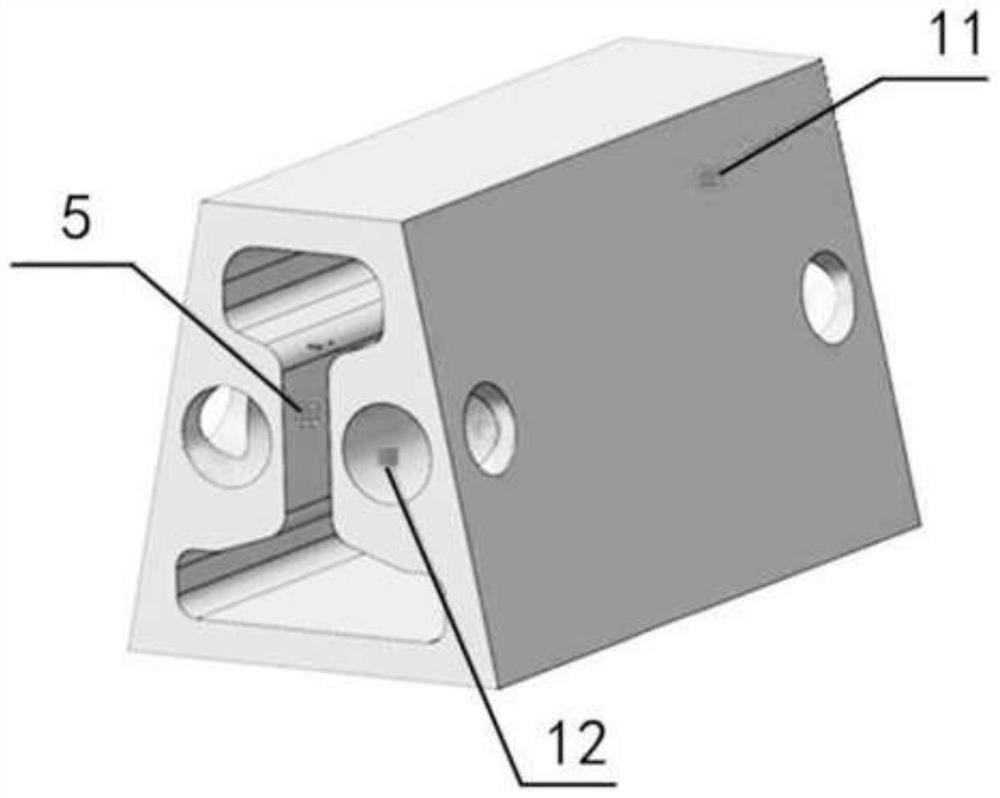

Fair-current and transverse-flow combined grain drying device

InactiveCN108142548AReduce crack growth rateModerate thicknessClimate change adaptationDrying gas arrangementsFuel oilProcess engineering

The present invention discloses a fair-current and transverse-flow combined grain drying device. The grain drying device comprises a dryer and a heat supply system. The dryer mainly comprises a grainstorage section, a first-grade fair-current drying section, a first-grade tempering section, a second-grade fair-current drying section, a second-grade tempering section, a transverse-flow drying section, a grain discharging section, a hoisting machine and a hot air pipeline. A main function of the heat supply system is to provide hot air with high temperature and low humidity, and a fuel oil heatsupply system or a heat pump heat supply system can be equipped according to environmental conditions. The combined drying device has technical advantages of being low in drying energy consumption and adjustable in drying quality. Drying process parameters of drying temperature, drying wind speed and dehydration rate of the drying device can be adjusted.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Production technology of spring steel alloy

ActiveCN105385940APrevent intrusionIncreased amorphous componentCorrosion reactionChemical composition

The invention discloses a production technology of a spring steel alloy. The spring steel alloy is prepared from the following chemical components by weight percent: 0.35-0.5% of C, 1.10-1.70% of Si, 0.10-0.20% of Mn, 0.004% of less of P, 0.005-0.008% of S, 0.18-0.21% of Cu, 0.28-0.41% of Ni, 1.09-1.22% of Cr, 0.04-0.12% of V, 0.4-0.55% of Ti, 0.027% of less of Al and unavoidable impurities. According to the production technology, alloying elements such as Ni, Cr and Cu are added into steel, so that the amorphous components in rust in the corrosion environment are increased, the C1 invasion can be prevented, and the etch pits are prevented from forming and spreading; hydrogen is generated in a placing corrosion reaction, so that the crack propagation rate is effectively decreased, and the corrosion resistance is improved.

Owner:ANHUI CHUJIANG SPECIAL STEEL CO LTD

Alloyed high manganese steel frog and manufacturing process thereof

ActiveCN111411297AImprove toughnessExtended service lifeRail switchesFurnace typesChemical compositionCrazing

The invention discloses an alloyed high manganese steel frog and a manufacturing process thereof. The chemical compositions (wt%) of the alloyed high manganese steel frog are as follows: the C contentis 0.95 to 1.35, the Mn content is 11.0 to 14.0, the Cr content is 0.2 to 1.0, the Mo content is 0. 2 to 1.2, the V content is 0.05 to 0.35, the Si content is 0.3 to 0.8, the Ni content is 0.002 to 1.5, the Re content is 0.001 to 0.05, the Mg content is 0.001 to 0.005, the P content is less than or equal to 0.045, the S content is less than or equal to 0.03, and the balance is Fe. In the alloyedhigh manganese steel frog prepared by the invention, the crystal grain size is 1 to 2 grades finer than that of an ordinary high manganese steel frog, which can improve the toughness of the high manganese steel frog, reduce the crack growth rate and increase the service life.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

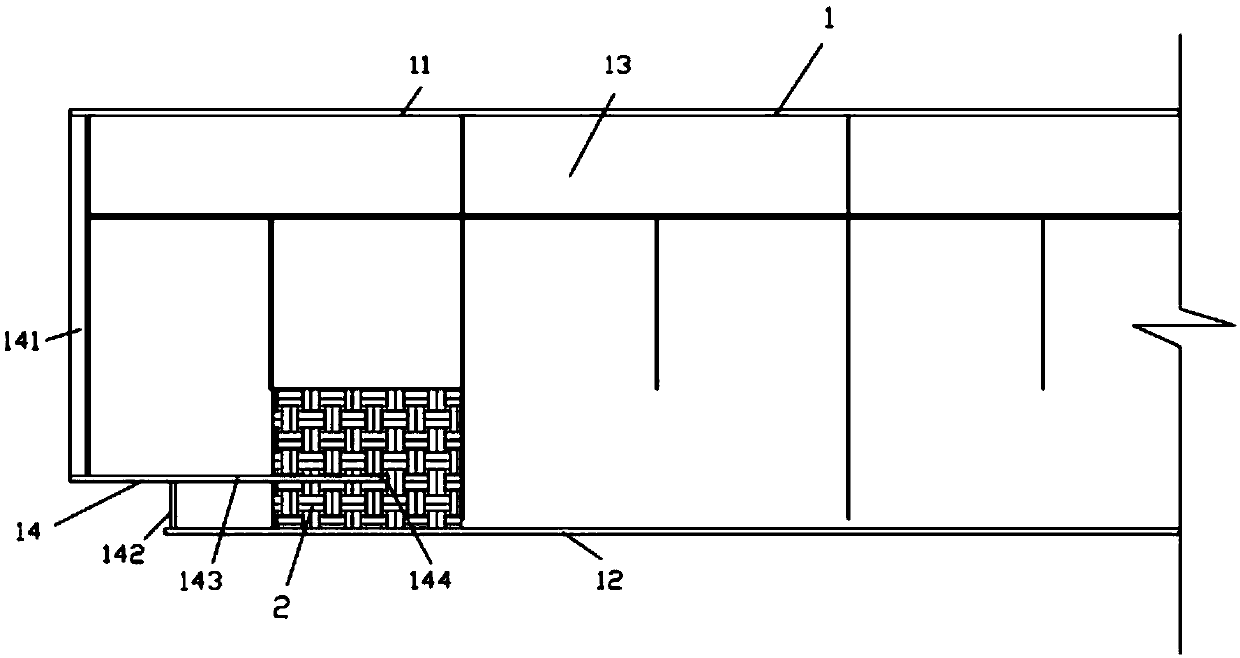

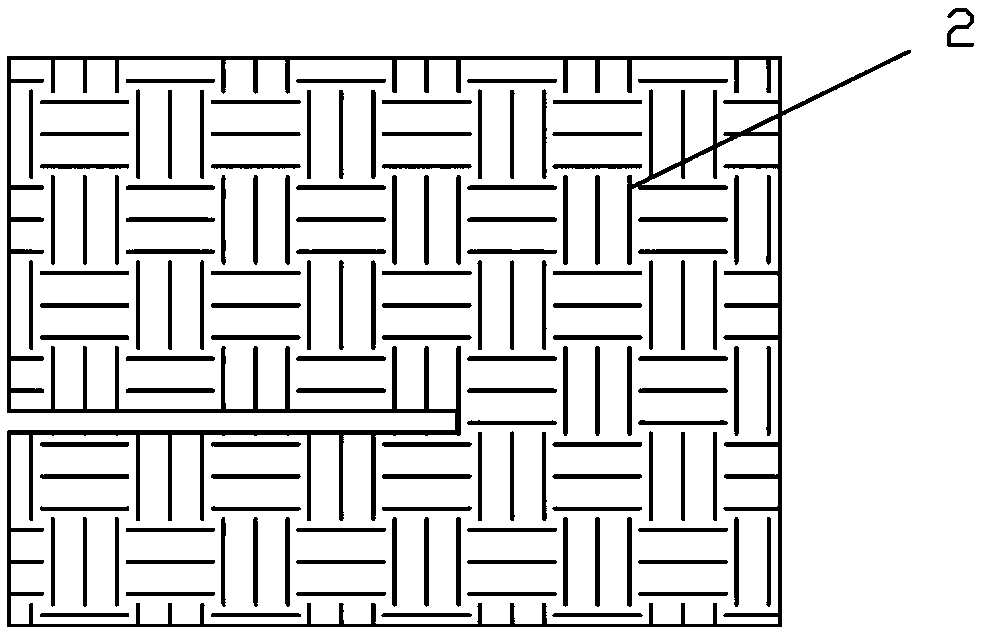

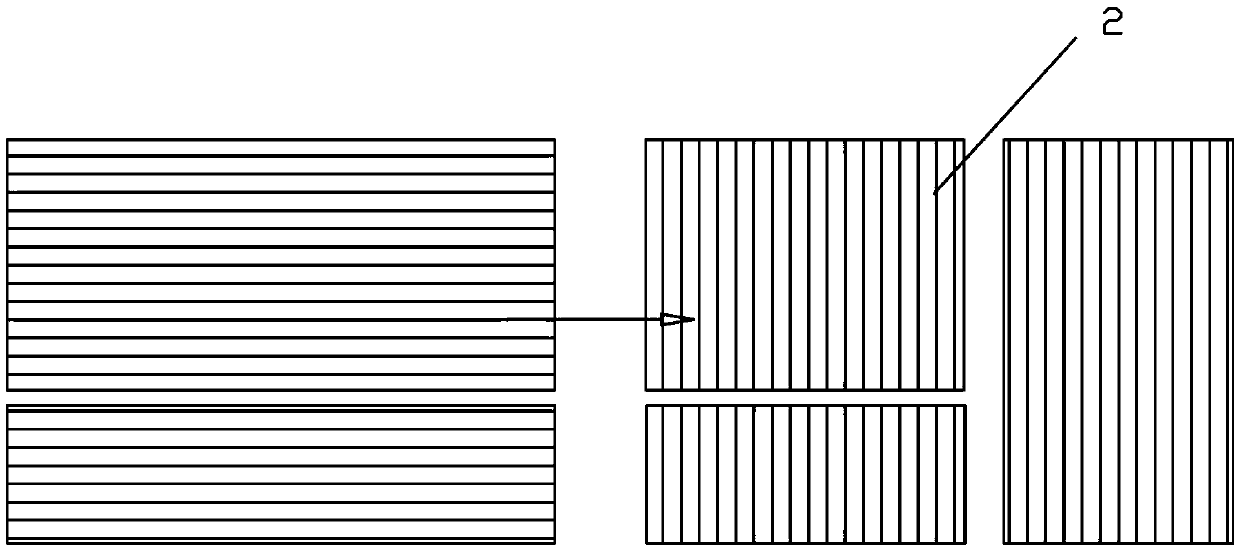

Carbon fiber reinforcing method for variable cross-section crane beam

InactiveCN111379434AReduced Stress Intensity FactorReduce crack growth rateBuilding repairsFiberCarbon fibers

The invention discloses a carbon fiber reinforcing method for a variable cross-section crane beam. The method comprises the following steps that (1) polishing a cracked component to be flat in an areawhere carbon fiber cloth needs to be pasted, and removing floating dust and accumulated dust on the surface; and 2) cutting the carbon fiber cloth according to the size of a reinforcement design, then brushing the carbon fiber cloth soaked with an adhesive, fixing the carbon fiber cloth at a pasting part, and then adopting a roller to roll unidirectionally along a grain direction of the carbon fiber cloth so as to eliminate the internal hollowing. According to the carbon fiber reinforcing method for the variable cross-section crane beam, after the crane beam starts to crack, the crane beam isprolonged by a certain service life by adopting a reinforcing means, and the purpose of short-term or long-term use can be achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

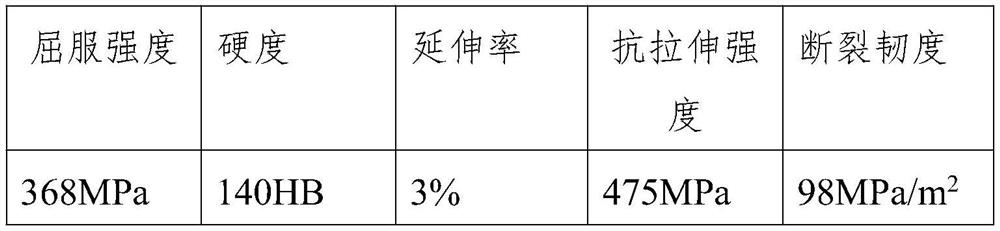

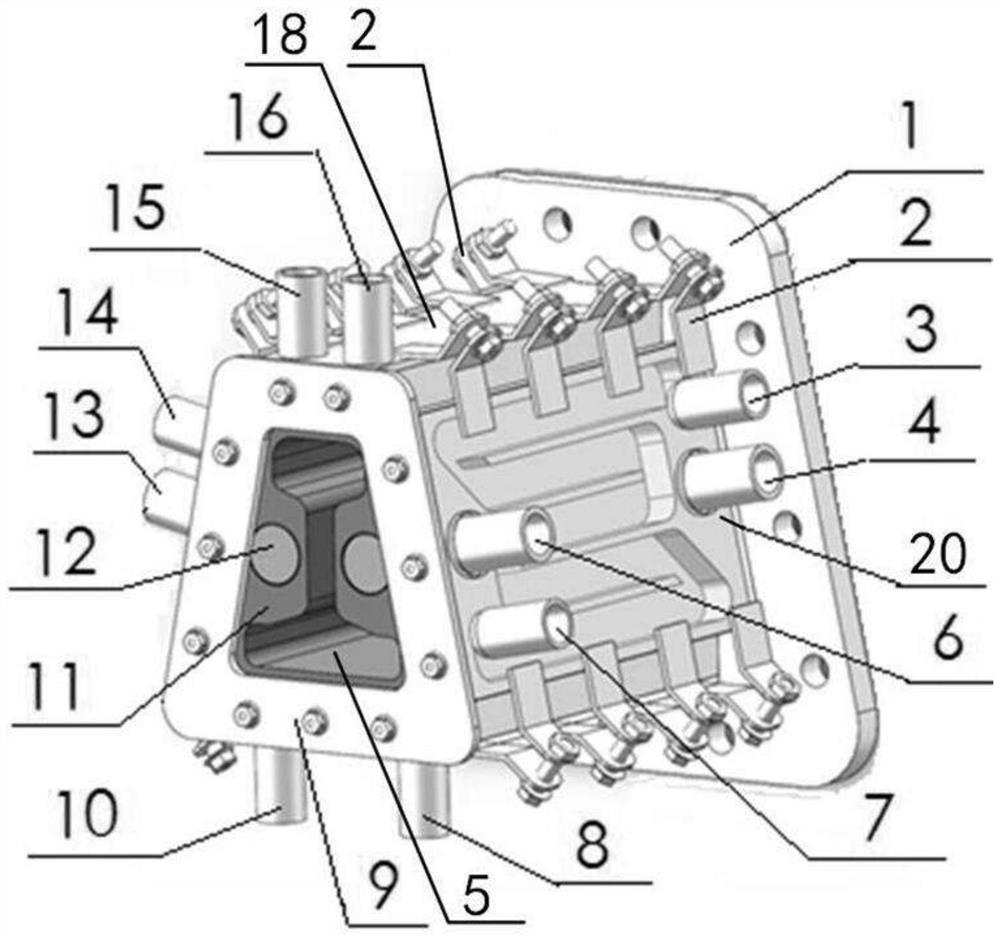

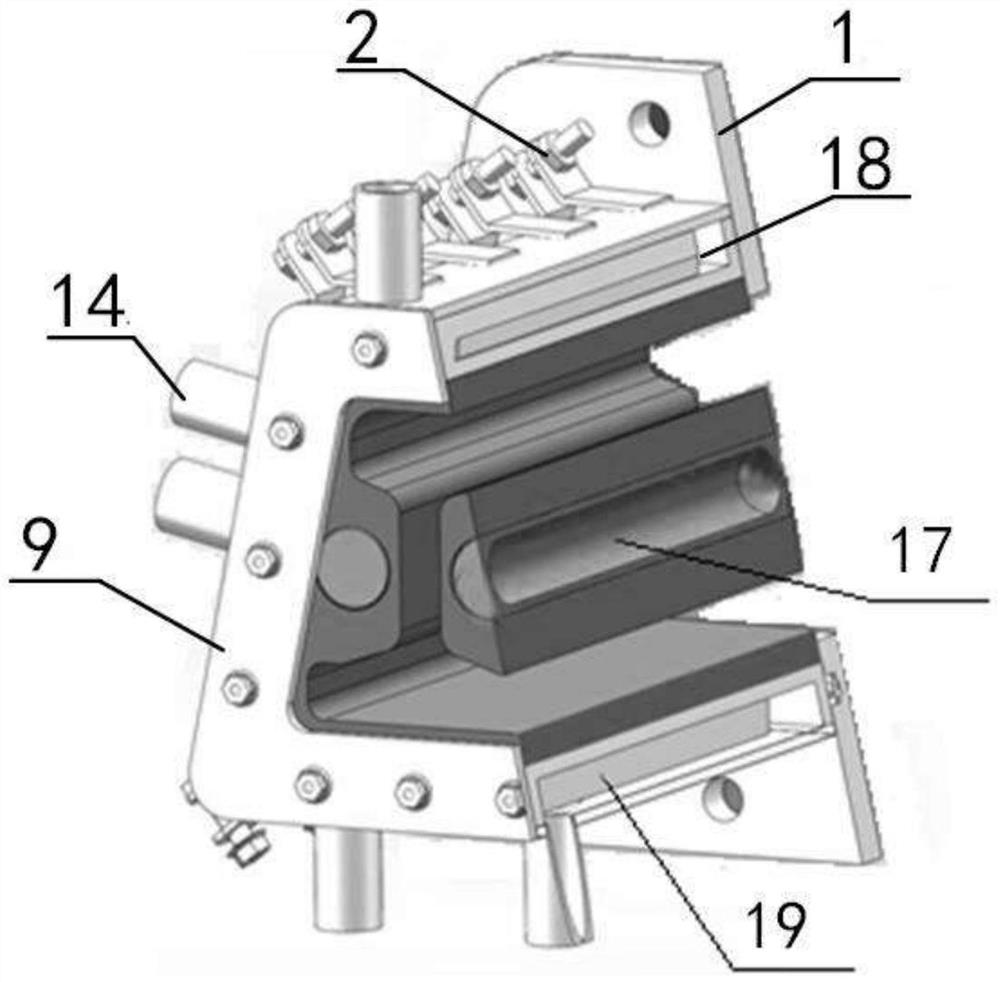

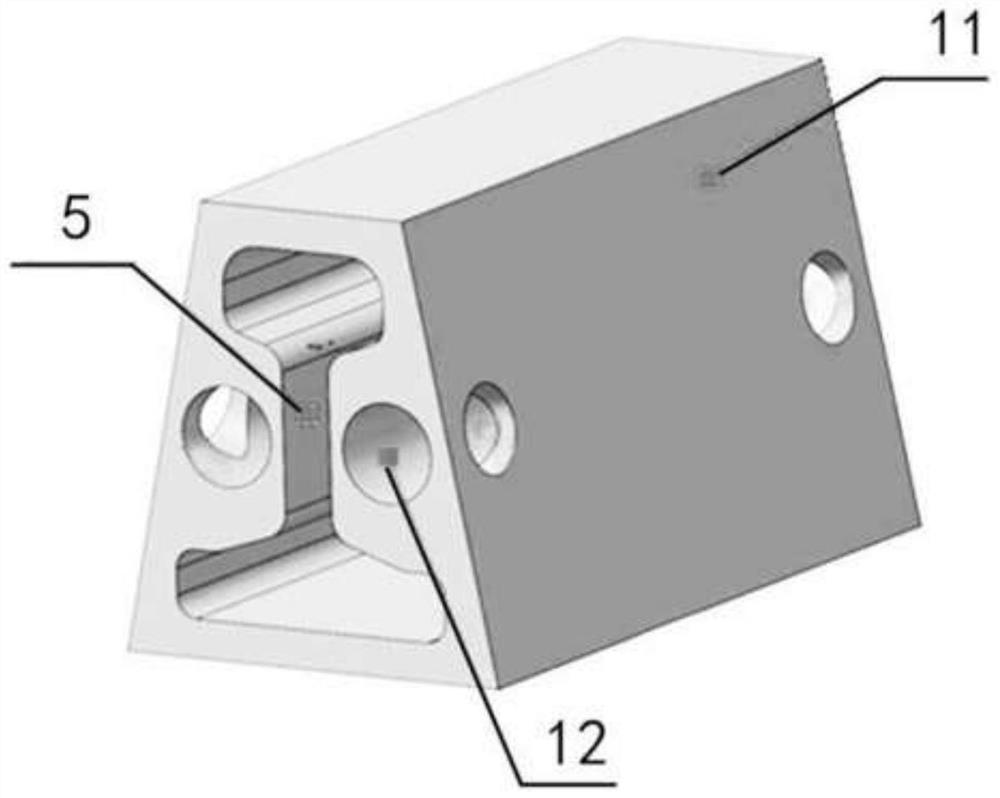

Long-durability die casting machine punch

InactiveCN102218521AImprove thermal fatigue resistanceIncreased fracture toughness valueManganeseDie casting

The invention relates to a long-durability die casting machine punch. The punch comprises the following components in part by weight: 100 parts of copper, 4.0 to 6.0 parts of chromium, 0.1 to 1.5 parts of manganese, 1.0 to 2.5 parts of molybdenum, 0.3 to 0.5 part of carbon, and 0.5 to 2.0 parts of silicon. Compared with the prior art, the long-durability die casting machine punch has the advantages of high wear resistance, long service life and the like.

Owner:SHANGHAI CENSI AUTOMOBILE PARTS

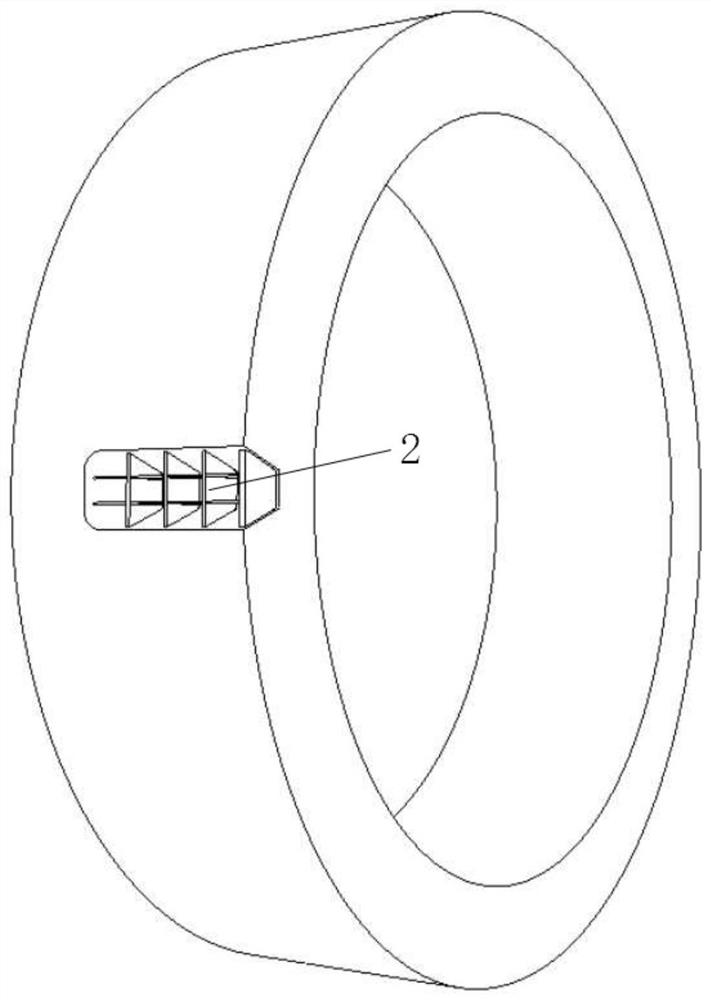

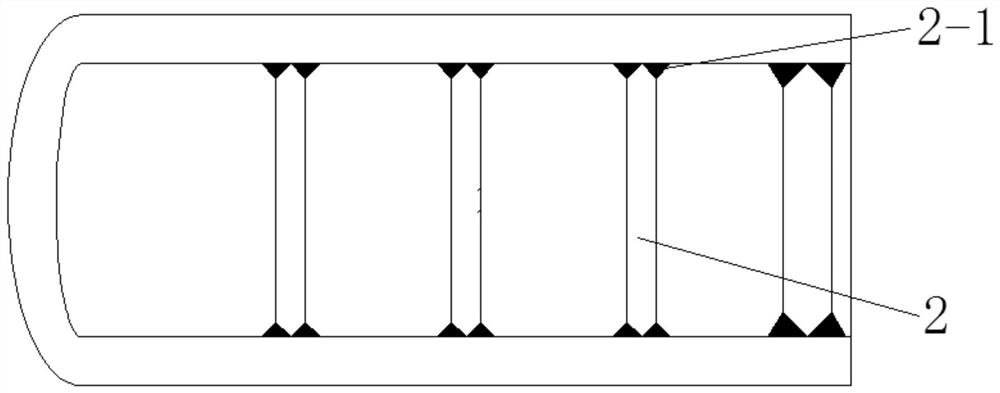

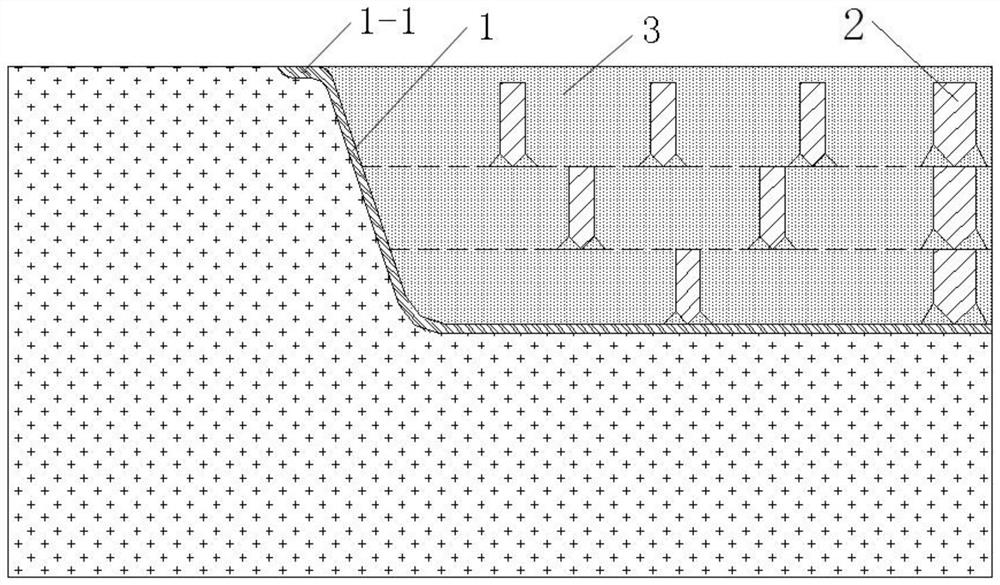

Welding structure of metal defect digging-patching welding groove of steel casting and reinforcing method of welding structure

ActiveCN109014648AImprove thermal field distributionInhibition of harmful effectsWorkpiece edge portionsWelding apparatusStructural stabilityPropagation rate

The invention relates to a welding structure of a metal defect digging-patching welding groove of a steel casting and a reinforcing method of the welding structure. By adoption of the welding structure of the metal defect digging-patching welding groove of the steel casting and the reinforcing method of the welding structure, the technical problems that during digging-patching welding of an existing large cast steel component, deformation of a welding structure is difficult to control, a repair welding area is likely to crack, and the structural stability and fatigue resistance of the weldingstructure cannot be guaranteed easily can be solved. The reinforcing method comprises the steps of first, welding a shell structure; second, arranging a plurality of rows and columns of multi-stage internal steel webs at intervals in the longitudinal and horizontal directions of a weld joint and the depth direction of the groove; third, filling welding deposited metal in a separated space of the welding groove; and fourth, conducting facing welding on the surface of the welding groove. According to the reinforcing method, a shell and rigid framework three-dimensional welding structural systemconstructed through welding can resist and disperse the shrinkage stress of weld joint metal, the welding deformation is effectively controlled, the stability of the welding structure is improved, propagation of fatigue cracks is changed, and accordingly, the propagation rate of the cracks is decreased.

Owner:哈尔滨中正焊接技术开发有限公司 +6

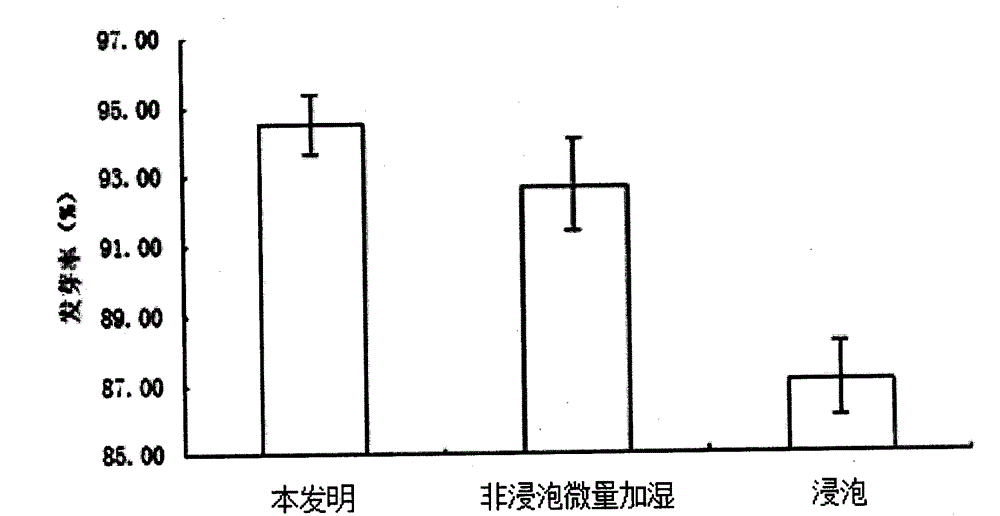

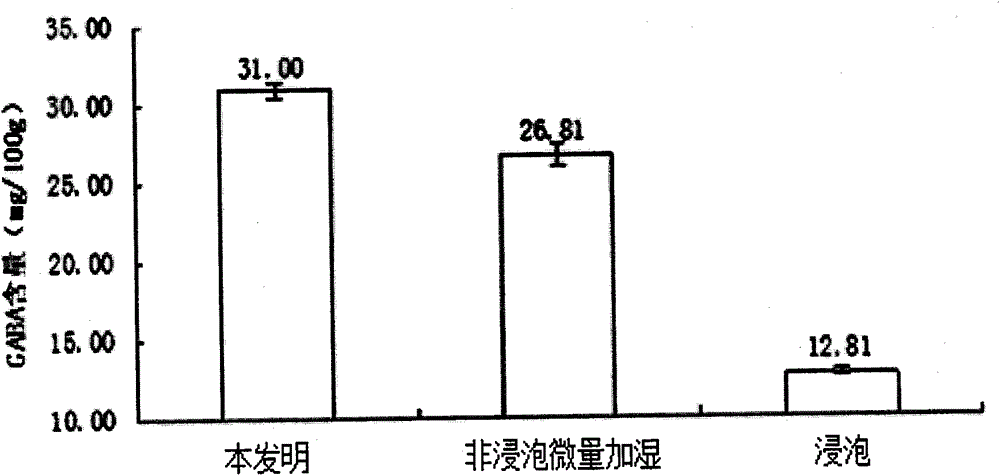

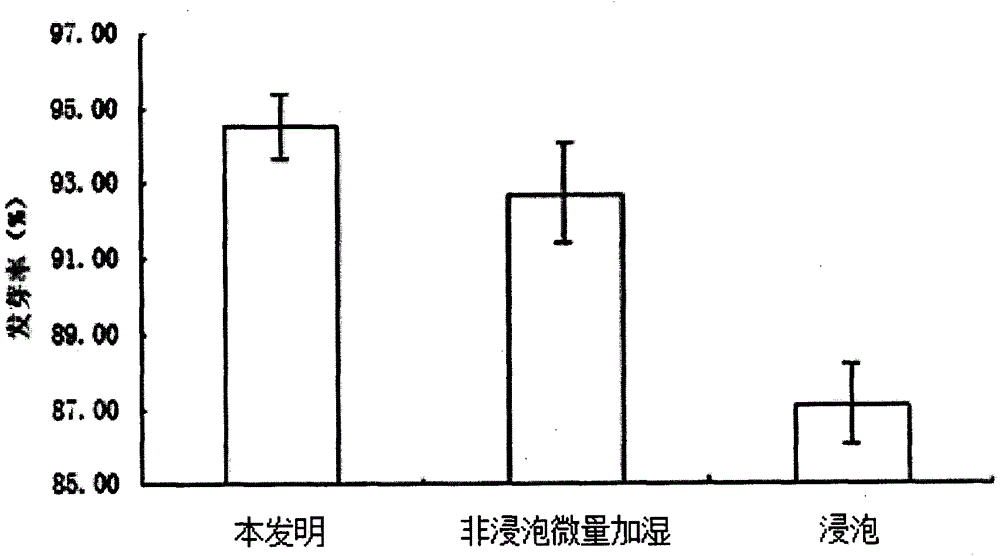

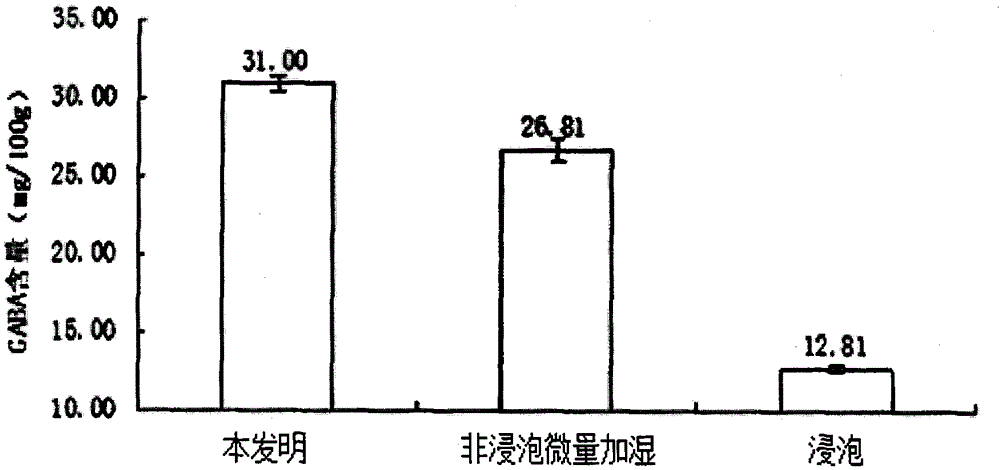

Process for optimizing production of germinated brown rice

InactiveCN103976289AReduce crack growth rateIncrease the content of gamma-aminobutyric acidFood preparationGamma-Aminobutyric acidDissolution

The invention belongs to the technical field of further processing of grain, and in particular relates to a process for optimizing the production of germinated brown rice. The process is characterized in that the engineering method is used to simulate according to the natural germinating process of rice in a soil environment condition, the high germination rate and high gamma-aminobutyric acid content in germinated brown rice are the targets, and on that basis, the optimization process parameter combination meeting the demands on water absorption, temperature, ventilation and other conditions for germination of brown rice are obtained. Compared with the traditional brown rice germination process, the process, provided by the invention, has the advantages that the link of soaking is avoided, so that the natural germination rules of brown rice are met, no sewage is produced, the loss on dissolution of nutritional substances of the brown rice in soaking is avoided, and the energy consumption for drying of the germinated brown rice due to excessive water sucking in the soaking link can also be decreased. With the adoption of the process for optimizing, the germination rate of brown rice can be increased by 5 to 7%, and the gamma-aminobutyric acid content in germinated brown rice can be increased by about 2.4 times.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Forging or rolling process of alloyed high manganese steel frog

The invention provides a forging (or rolling) process of an alloyed high manganese steel frog. The alloyed high manganese steel frog comprises 1.0-1.2 wt% of C, 11.0-14.0 wt% of Mn, 0.1-1.2 wt% of Cr, 0.05-1.2 wt% of Mo, 0.05-0.55 wt% of V, 0.3-0.8 wt% of Si, 0.002-5.0 wt% of Ni, 0.001-0.05 wt% of Re, 0.001-0.01 wt% of Mg, 0.001-0.1 wt% of Zr, less than or equal to 0.035 wt% of P, less than or equal to 0.015 wt% of S and the balance Fe. The process comprises the following steps that a steel billet or a continuous casting billet is subjected to cogging forging or rolling, wherein the steel billet is heated to a temperature 100-150 DEG C below the melting temperature to start forging or rolling, the continuous casting billet can be directly heated to the temperature in a heating furnace without being cooled to the room temperature for cogging rolling, the cogging finish forging or finish rolling temperature is controlled to be 1000 DEG C or above, the cogging forging or rolling ratio is controlled to be 1.2-3.0, and the hammering speed of a hammer head is controlled to be less than 15 m / s during forging; and the billet obtained after cogging forging or rolling is heated to a temperature 100-150 DEG C below the melting temperature and then subjected to forging (or rolling), wherein the finish forging or finish rolling temperature is controlled to be 860 DEG C or above, and the forging or rolling ratio is controlled to be 2.0-15.0.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

A kind of germinated brown rice production optimization process

InactiveCN103976289BReduce crack growth rateIncrease the content of gamma-aminobutyric acidFood scienceGamma-Aminobutyric acidSewage

The invention belongs to the technical field of further processing of grain, and in particular relates to a process for optimizing the production of germinated brown rice. The process is characterized in that the engineering method is used to simulate according to the natural germinating process of rice in a soil environment condition, the high germination rate and high gamma-aminobutyric acid content in germinated brown rice are the targets, and on that basis, the optimization process parameter combination meeting the demands on water absorption, temperature, ventilation and other conditions for germination of brown rice are obtained. Compared with the traditional brown rice germination process, the process, provided by the invention, has the advantages that the link of soaking is avoided, so that the natural germination rules of brown rice are met, no sewage is produced, the loss on dissolution of nutritional substances of the brown rice in soaking is avoided, and the energy consumption for drying of the germinated brown rice due to excessive water sucking in the soaking link can also be decreased. With the adoption of the process for optimizing, the germination rate of brown rice can be increased by 5 to 7%, and the gamma-aminobutyric acid content in germinated brown rice can be increased by about 2.4 times.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Novel non-spangle Mg-In-Ni zinc alloy for zinc and magnesium matrix hot-dip galvanizing

InactiveCN108330324AIncrease coverageHave self-healing abilityHot-dipping/immersion processesZinc alloysMetallurgical industry

The invention discloses the novel non-spangle Mg-In-Ni zinc alloy for zinc and magnesium matrix hot-dip galvanizing and the processing technology thereof. The novel non-spangle Mg-In-Ni zinc alloy comprises the ingredients of, by weight, 5.0% to 8.0% of Mg, 0.2% to 0.3% of Y, 0.4% to 0.6% of In, 1.0% to 1.2% of Ni, 0.3% to 0.5% of Bi, 0.2% to 0.4% of Mo, and the balance zinc. The novel non-spangleMg-In-Ni zinc alloy for zinc and magnesium matrix hot-dip galvanizing can be used for galvanizing on steel plates at the temperature ranging from 320 DEG C to 340 DEG C, and achieves the excellent anti-corrosion capacity. The novel non-spangle Mg-In-Ni zinc alloy for zinc and magnesium matrix hot-dip galvanizing surely has the significance in improving the industrialization process of China and adjusting the structure of the metallurgical industry.

Owner:GUANGZHOU YUZHI TECH CO LTD

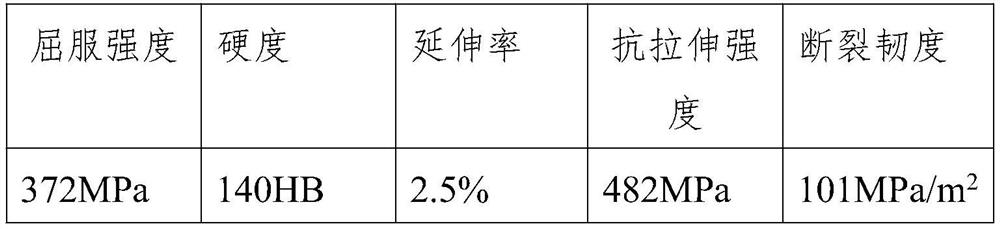

Hot die steel and tempering process thereof

The invention relates to hot die steel which comprises the following components in percentage by weight: 0.32-0.42 percent of carbon, 0.2-0.5 percent of silicon, 0.2-0.5 percent of manganese, 2.2-2.7 percent of chromium, 1.0-3.4 percent of molybdenum, 0.8-2.2 percent of tungsten, 0.4-0.6 percent of vanadium, 0.2-1.5 percent of cobalt and the balance of Fe. A tempering process of the hot die steelcomprises the following steps of: firstly, tempering at 440-460 DEG C for 1-2 hours and then cooling to room temperature; then tempering at 520-560 DEG C for 1-2 hours and then cooling to room temperature; and finally, tempering at 520-560 DEG C for 1-2 hours and then cooling to room temperature. The hot die steel has the characteristics of high heat resistance and high toughness. The tempering process greatly reduces the fracture speed of materials and further improves the toughness of die materials.

Owner:ZHEJIANG ZHENGDA MOLD

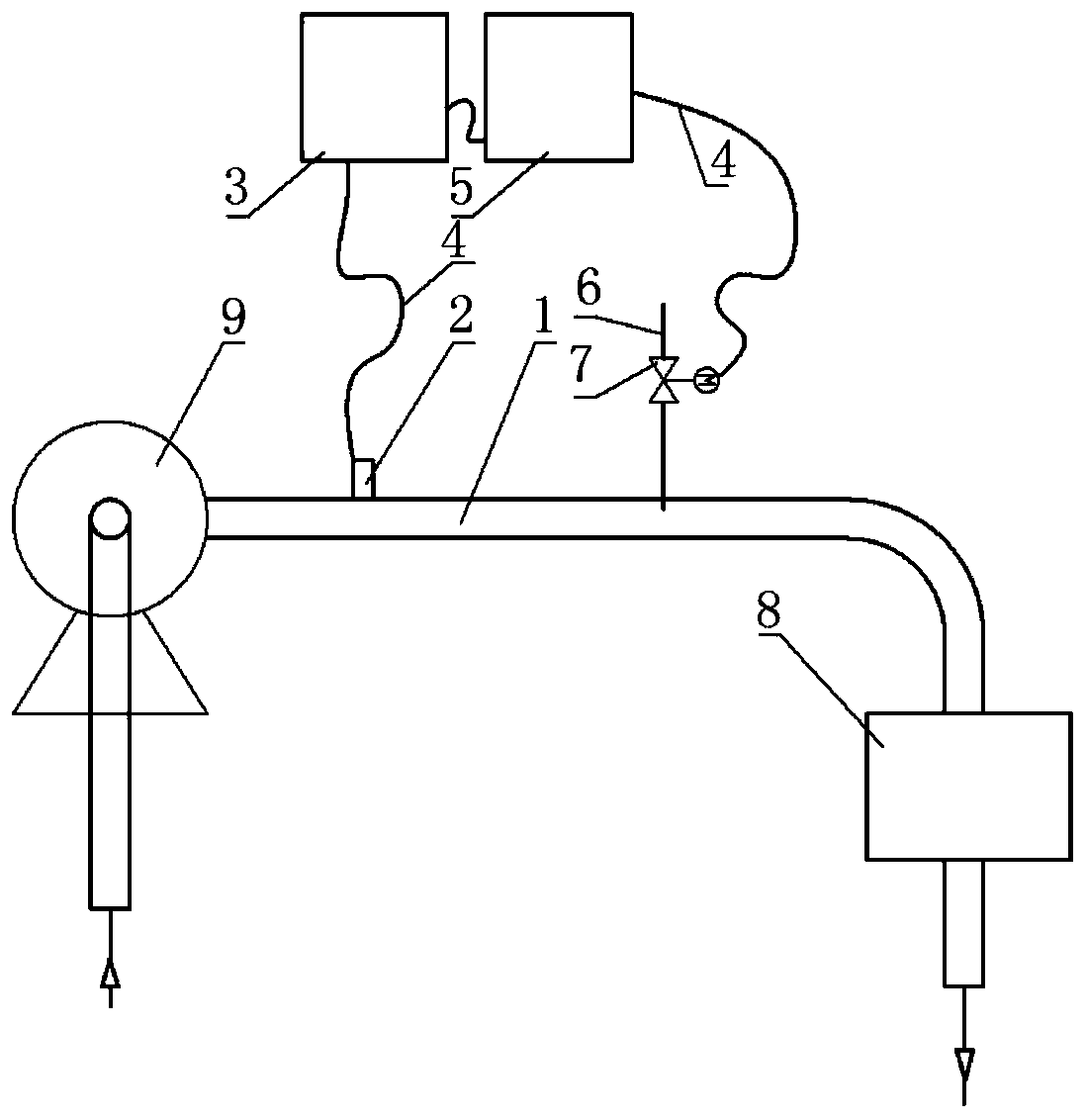

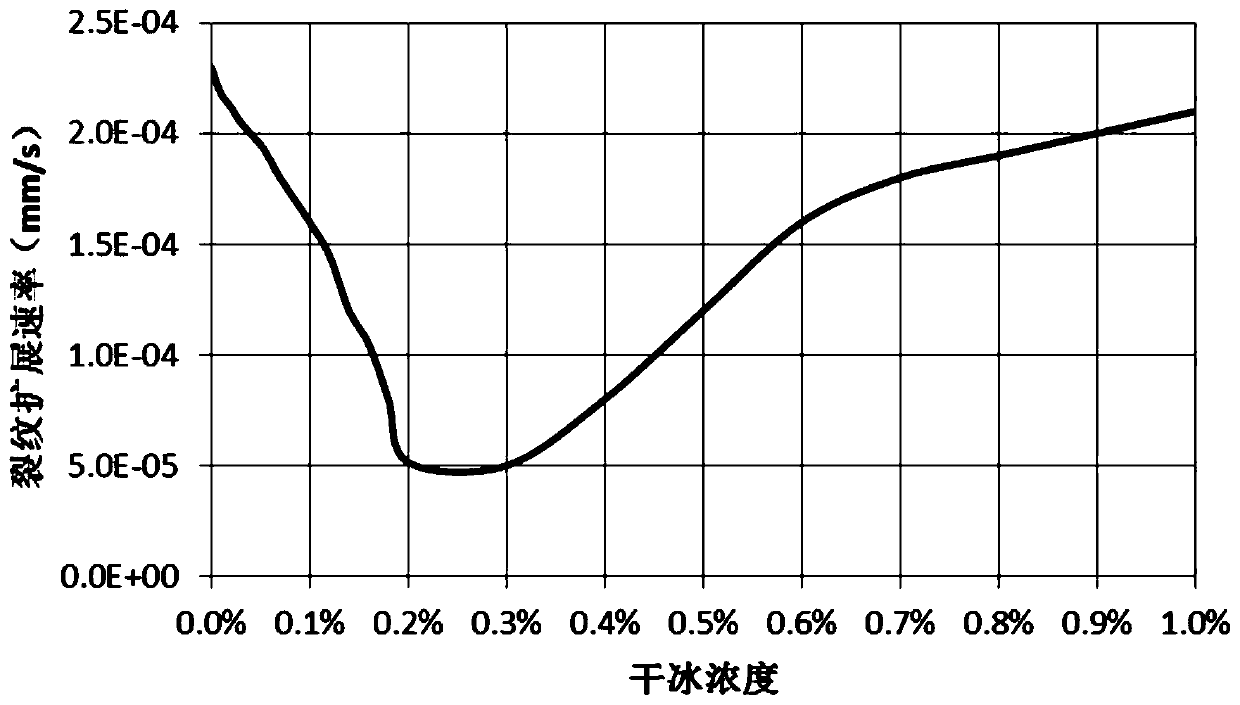

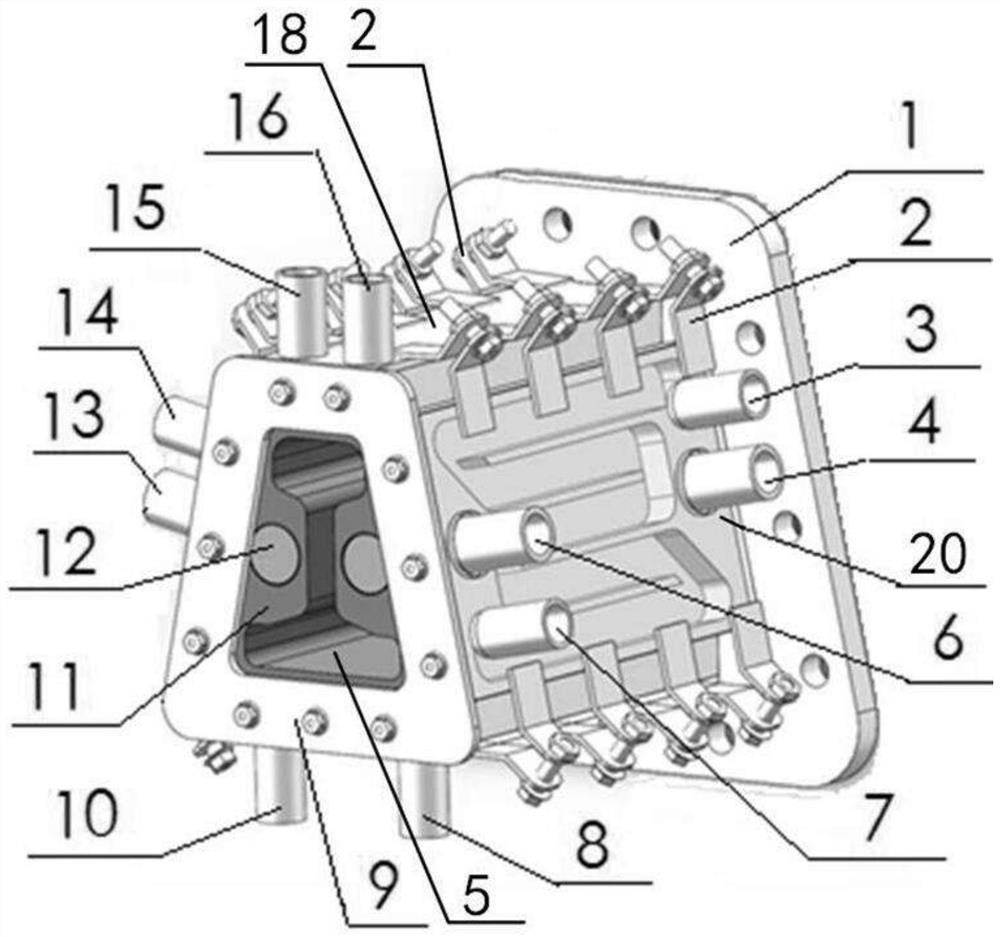

Supercritical carbon dioxide pipeline crack control device and method

PendingCN111579641AControl crack growth developmentImprove safety and reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesOptically investigating flaws/contaminationStructural engineeringProcess engineering

The invention relates to the technical field of supercritical carbon dioxide pipelines. The invention discloses a supercritical carbon dioxide pipeline crack control device and method. The crack control device comprises a crack monitoring mechanism and a dry ice conveying line, the crack monitoring mechanism is used for being connected to the surface of a pipeline and monitoring cracks of the pipeline in real time, and the dry ice conveying line is used for being communicated with the pipeline and injecting dry ice into the pipeline when the crack monitoring mechanism monitors that crack propagation of the pipeline exceeds a preset range. The invention provides a supercritical carbon dioxide pipeline crack control device and method. By arranging the crack monitoring mechanism, the crack propagation condition of the pipeline can be known in real time; when the crack propagation of the dry ice conveying line exceeds an allowable range, the crack propagation rate of the pipeline can be reduced by injecting dry ice into the pipeline, so that the crack propagation development of the supercritical carbon dioxide pipeline can be effectively controlled, the service life of the pipeline isprolonged, and the device and the method have important significance for improving the safety and reliability of the supercritical carbon dioxide pipeline.

Owner:WUHAN SECOND SHIP DESIGN & RES INST

Low-noise steel rail for bridge crane and preparation method thereof

ActiveCN112210710BReduce vibrationSuppress noiseFurnace typesIncreasing energy efficiencyOverhead craneMechanical engineering

The invention discloses a low-noise steel rail for bridge cranes, which consists of the following components according to mass percentage, C: 3.4%-3.6%, Si: 2.4%-2.6%, Mn: 0.3%-0.5%, P: ≤0.02%, S: ≤0.02%, Cr: ≤0.3%, Cu: 0.3%~0.5%, Mg: 0.03~0.045%, the balance is Fe, the sum of the mass percentages of the above components is 100%; The tensile strength is ≥880MPa, the elongation is ≥8%, and the surface hardness of the top surface is ≥55HRC. The invention also discloses a method for preparing a low-noise steel rail for bridge cranes. Suppresses the vibration and noise transmitted by the crane truss.

Owner:JIANGSU HUALONG CAST IRON BAR SECTION CO LTD

Track aluminum profile

ActiveCN114438382AHigh strengthImprove room temperature tensile propertiesExtrusion control devicesSolution treatmentUltimate tensile strength

The invention discloses a rail aluminum profile and a preparation method thereof. The rail aluminum profile comprises the following main components in percentage by mass: 1.35-1.5% of Mg, 0.1-0.2% of Si, 2.0-4.0% of Zn (Zn = 2.7 Mg), 0.09-0.12% of V, 1.0-2.2% of Mn, 3.5-4.5% of Cu, 0.1-1.3% of Cd, 0.1-0.3% of Cr, 0.1% of mischmetal, 0.01-0.05% of Ti and the balance of aluminum and inevitable impurities, the content of Zr accounts for 0.04-0.08%, and the balance is Al. According to the method, raw materials are prepared according to the mass ratio, semi-continuous casting is used, and the extrusion process and the solution treatment process are optimized, so that the strength and the tensile property of the track are greatly improved, the loading capacity of the track is enhanced, meanwhile, the stability of a track sliding groove is improved, and the requirement for the performance of the track in industrial manufacturing is met.

Owner:JIANGYIN MUXIANG ENERGY SAVING DECORATION MATER

Low-noise steel rail used for bridge crane and preparation method of low-noise steel rail

ActiveCN112210710AReduce vibrationSuppress noiseIncreasing energy efficiencyFurnace typesStructural engineeringControl theory

The invention discloses a low-noise steel rail used for a bridge crane. The low-noise steel rail is composed of following components including, by mass, 3.4%-3.6% of C, 2.4%-2.6% of Si, 0.3%-0.5% of Mn, smaller than or equal to 0.02% of P, smaller than or equal to 0.02% of S, smaller than or equal to 0.3% of Cr, 0.3%-0.5% of Cu, 0.03%-0.045% of Mg and the balance Fe, and the sum of the mass percent of the components is 100%. The tensile strength of the steel rail is larger than or equal to 880 MPa, the elongation is larger than or equal to 8%, and the top surface layer hardness is larger thanor equal to 55 HRC. The invention further discloses a preparation method of the low-noise steel rail used for the bridge crane, and the prepared steel rail can have toughness and damping performance at the same time and restrain vibration and noise transmitted by a crane truss.

Owner:江苏华龙精密智造股份有限公司

Butadiene rubber composite material

The invention discloses a butadiene rubber composite material. By filling of carbon black and white carbon black and blending with natural rubber for compounding, crack generation and cracking mechanism of butadiene rubber are explored; and by adding a silane coupling agent (Si69) into the white carbon black filler, interaction between particles and a rubber matrix is enhanced and crack speed of butadiene rubber can be effectively reduced. By adding the silane coupling agent (Si69) into the white carbon black filler for comparative tests, it shows that crack speed of butadiene rubber can be effectively reduced by enhancing the interaction between the particles and the rubber matrix.

Owner:中绿新材料(江苏)有限公司

Automobile heat forming steel non-spangle hot dipping Ca-Hf-Re zinc-aluminum alloy

InactiveCN108441697ASimple processLow costHot-dipping/immersion processesSheet steelEnergy conservation

The invention discloses an automobile heat forming steel non-spangle hot dipping Ca-Hf-Re zinc-aluminum alloy and a preparing technology thereof. The alloy comprises, by weight, 0.3%-0.5% of Ca, 0.1%-0.2% of Na, 0.2%-0.3% of Re, 1.0%-1.5% of Ge, 35.0%-42.0% of Al, 0.2%-0.5% of Hf and the balance zinc. The material can be applied to steel plate hot-dip galvanizing at the temperature ranging from 320 DEG C-340 DEG C; and compared with traditional pure zinc hot dipping, the better decay resistance is achieved. The alloy is of decisive significance in the antiseptic property of heat forming steelfor an automobile, and plays an important role in light weight of the automobile and energy conservation, environment protection and emission reduction.

Owner:GUANGZHOU YUZHI TECH CO LTD

Thermoformed steel anti-corrosion hot-dipped allumen containing Ca-Ta-Sn for automobiles

InactiveCN108342617ASimple processEasy to operateHot-dipping/immersion processesHot-dip galvanizationSteel plates

The invention discloses thermoformed steel anti-corrosion hot-dipped allumen containing Ca-Ta-Sn for automobiles and a processing technique thereof. The allumen is prepared from the following components in percentage by weight: 0.4-0.6wt.% of Ca, 0.2-0.3wt.% of Na, 0.4-0.6wt.% of Y, 2.0-2.5wt.% of Sn, 30.0-40.0 wt.% of Al, 0.6-0.8wt.% of Ta and the balance of Zn. The material can be used for hot-dip galvanizing of steel plates at 320-340 DEG C and has better anti-corrosion properties compared with traditional pure Zn hot dipping. The thermoformed steel anti-corrosion hot-dipped allumen containing Ca-Ta-Sn is of decision significance for improving the anti-corrosion properties of thermoformed steel used for automobiles and is of great significance on light weighting, energy saving, environment protection and emission reduction of the automobiles.

Owner:GUANGZHOU YUZHI TECH CO LTD

A processing method of anti-fatigue aluminum alloy plate with brass texture

The invention relates to a treatment method for a brass texture antifatigue aluminum alloy panel, which is characterized in that multiple times of warm rolling is performed on an aluminum alloy hot rolling material until reaching the designed thickness of the aluminum alloy panel, and after annealing treatment and solution treatment, short-term artificial aging is performed. According to the invention, a treatment process of multiple times of warm rolling and annealing is adopted; by virtue of warm rolling, grains of the alloy can be effectively refined, the return process of alloy can be promoted, deformation energy storage can be reduced, and recrystallization can be inhibited; and by virtue of primary annealing treatment, annealing temperature and heat insulation time can be controlled, grains cannot grow up, and a deformation texture can be retained, thus obtaining a relatively strong deformation texture. The treatment method is simple in process method and convenient to operate, can effectively improve the composition and the volume fraction of the texture in an aluminum alloy matrix, can effectively prolong the fatigue life of the aluminum alloy on the premise of ensuring that aluminum alloy strength and ductility meet alloy performance requirements, is suitable for industrial application, and provides a feasible technical solution for preparation of aluminum alloy material for aviation and spaceflight.

Owner:湖南润泰新能源科技有限公司

Alloyed high manganese steel frog and its manufacturing process

ActiveCN111411297BImprove toughnessExtended service lifeRail switchesFurnace typesChemical compositionCrazing

The invention discloses an alloyed high manganese steel frog and its manufacturing process. The chemical composition (wt%) of the frog is: C: 0.95-1.35, Mn: 11.0-14.0, Cr: 0.2-1.0, Mo: 0.2~1.2, V: 0.05~0.35, Si: 0.3~0.8, Ni: 0.002~1.5, Re: 0.001~0.05, Mg: 0.001~0.005, P:≦0.045, S:≦0.03, and the rest is Fe. The alloyed high manganese steel frog prepared by the invention has a grain size 1-2 grades smaller than that of common high manganese steel frogs, which can improve the toughness of the high manganese steel frogs, reduce the crack growth rate and increase the service life.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

A preparation method of gh4169 alloy with uniform distribution of granular delta phase

The invention relates to a granular delta-phase uniformly distributed GH4169 alloy preparation method and belongs to the technical field of preparation of high-temperature alloy materials. On the basis of combination of cold deformation and heat treatment processes, the method includes GH4169 alloy cold deformation and heat treatment. Firstly, plate blanks are subjected to cold rolling deformation more than 30% after solid solution and quickly cooled under vacuum argon shielding after heat preservation at 985+ / 5 DEG C for 1h; secondly, the plate blanks are subjected to standard double aging treatment; finally, granular delta phases uniformly distributed in grains and at grain boundaries of GH4169 alloy are acquired. Therefore, GH4169 alloy strength is improved, and crack growth rate of the GH4169 alloy is decreased to acquire better fatigue performance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Welding Structure and Reinforcing Method of Metal Defect Digging and Repairing Welding Groove of Steel Castings

ActiveCN109014648BImprove thermal field distributionChange stress conditionsWorkpiece edge portionsWelding apparatusWeld seamDeformation control

The invention relates to a welding structure of a metal defect digging-patching welding groove of a steel casting and a reinforcing method of the welding structure. By adoption of the welding structure of the metal defect digging-patching welding groove of the steel casting and the reinforcing method of the welding structure, the technical problems that during digging-patching welding of an existing large cast steel component, deformation of a welding structure is difficult to control, a repair welding area is likely to crack, and the structural stability and fatigue resistance of the weldingstructure cannot be guaranteed easily can be solved. The reinforcing method comprises the steps of first, welding a shell structure; second, arranging a plurality of rows and columns of multi-stage internal steel webs at intervals in the longitudinal and horizontal directions of a weld joint and the depth direction of the groove; third, filling welding deposited metal in a separated space of the welding groove; and fourth, conducting facing welding on the surface of the welding groove. According to the reinforcing method, a shell and rigid framework three-dimensional welding structural systemconstructed through welding can resist and disperse the shrinkage stress of weld joint metal, the welding deformation is effectively controlled, the stability of the welding structure is improved, propagation of fatigue cracks is changed, and accordingly, the propagation rate of the cracks is decreased.

Owner:哈尔滨中正焊接技术开发有限公司 +6

A processing method of fine-grained cubic texture anti-corrosion fatigue aluminum alloy plate

The invention relates to a skin material for aviation, in particular to a machining method for preparing corrosion-fatigue-damage-resistant aluminum alloy plates, and belongs to the technical field ofnonferrous metals. The machining method comprises the steps that an aluminum alloy hot rolling material is subjected to solid solution treatment for the first time, then the second time of solid solution treatment is carried out after multi-pass cold rolling with the pass deformation amount being less than or equal to 1.0mm is carried out to achieve the design thickness of the aluminum alloy plate; and in the multi-pass cold rolling process, deep cooling treatment is carried out immediately after each pass of cold rolling, and the temperature of the deep cooling treatment is less than or equal to -100 DEG C. The machining method for preparing the corrosion-fatigue-damage-resistant aluminum alloy plates is reasonable in texture design, the preparation process is simple and controllable, obtained products have good performance, and the machining method for preparing the corrosion-fatigue-damage-resistant aluminum alloy plates is convenient for large-scale industrial application.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com