Machining method of fine-grain cubic texture corrosion-fatigue-resistant aluminum alloy plate

An aluminum alloy sheet and cubic texture technology, which is applied in the field of skin materials and the preparation of corrosion-resistant fatigue-resistant aluminum alloy sheets, can solve problems such as the inability to meet aircraft service performance requirements, and achieve excellent corrosion-fatigue resistance and grain size. The effect of refining and suppressing the recovery phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0119] 1. Homogenize the 40mm aluminum alloy ingot at 495°C for 18 hours, then air cool;

[0120] 2. Keep the cast ingot at a temperature of 450°C for 1 hour, then perform hot rolling deformation to 6.0mm, and air-cool;

[0121] 3. The hot-rolled sheet is subjected to solution treatment at 500°C for 0.5h, and then water quenched;

[0122] 4. Cold rolling the plate at room temperature, the deformation of each pass is 0.8mm, after each pass of deformation, put the plate into liquid nitrogen for 10min cryogenic treatment, until the final thickness is 2.0mm;

[0123] 5. The plate is subjected to solid solution treatment at 500°C for 0.5h, and then water quenched;

[0124] 6. Carry out 0.2mm cold rolling deformation treatment;

[0125] 7. Short-term artificial aging of the plate at 195°C for 15 minutes, and then air-cooled to room temperature.

[0126] Its performance test values are shown in Tables 1 and 2.

[0127] The reason for the reduction of the corrosion fatigue crack...

Embodiment 2

[0130] The specific implementation steps are:

[0131] 1. Homogenize the 40mm aluminum alloy ingot at 490°C for 24 hours, then air cool;

[0132] 2. Heat the ingot at 420°C for 1 hour, then hot-roll and deform it to 8mm, and air-cool;

[0133] 3. The hot-rolled plate is subjected to solution treatment at 505°C for 15 minutes, and then water quenched;

[0134] 4. Cold rolling the plate at room temperature, the deformation of each pass is 1.0mm, after each pass of deformation, put the plate into liquid nitrogen for 15min cryogenic treatment, until the final thickness is 2.0mm;

[0135] 5. The plate is subjected to solid solution treatment at 505°C for 40 minutes, and then water quenched;

[0136] 6. Carry out 0.2mm cold rolling deformation treatment;

[0137] 7. Short-term artificial aging of the plate at 190°C for 0.5h, and then air-cooled to room temperature.

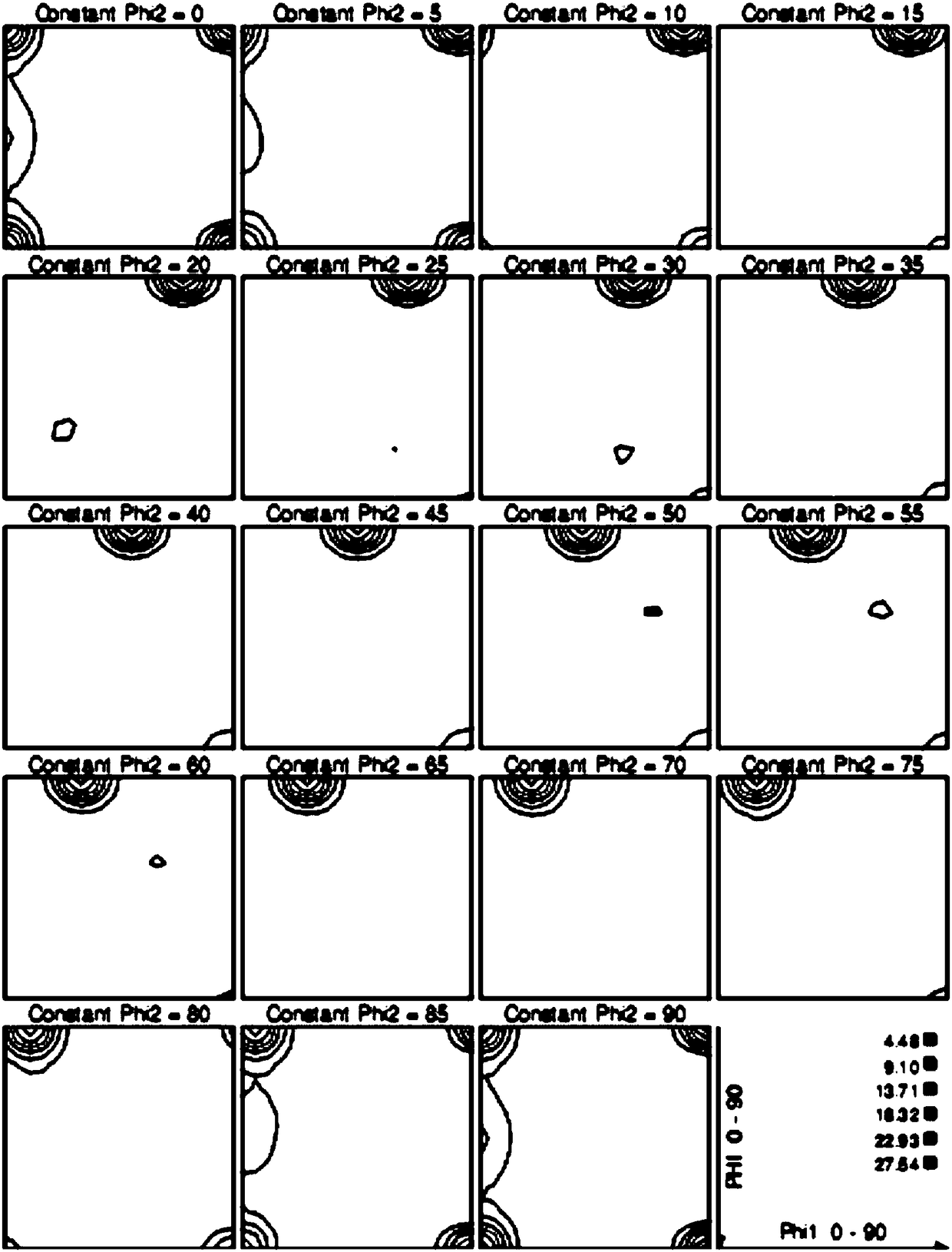

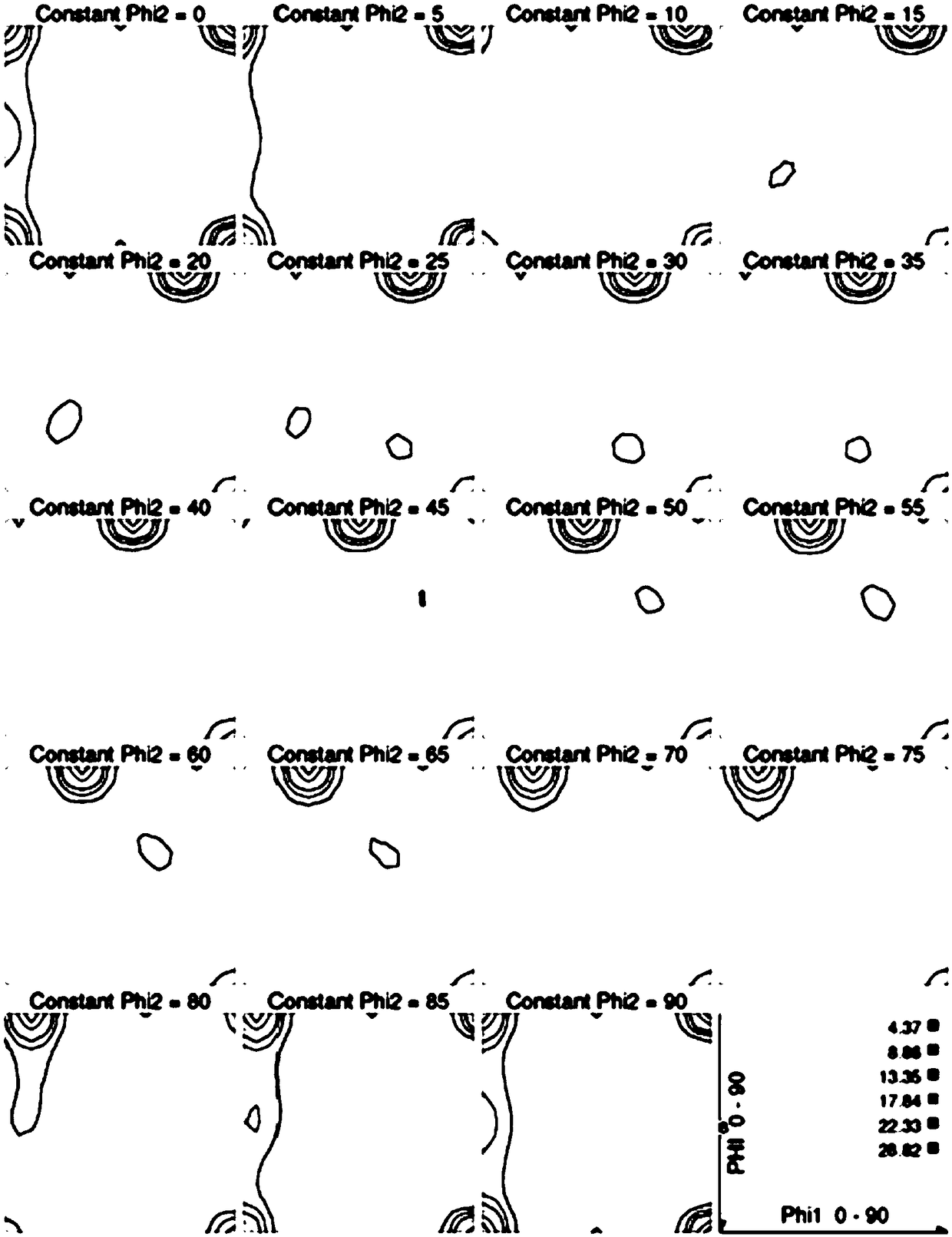

[0138] The grains of the alloy in Example 2 of the present invention are equiaxed, and the grain size is very sma...

Embodiment 3

[0150] The specific implementation steps are:

[0151] 1. Homogenize the 40mm aluminum alloy ingot at 485°C for 48h, then air cool;

[0152] 2. Heat the ingot at 450°C for 1 hour, then hot-roll and deform it to 6mm, and air-cool;

[0153] 3. The hot-rolled plate is subjected to solution treatment at 495°C for 40 minutes, and then water quenched;

[0154] 4. Cold rolling the plate at room temperature, the deformation of each pass is 0.9mm, after each pass of deformation, put the plate into liquid nitrogen for 15min cryogenic treatment, until the final thickness is 1.5mm;

[0155] 5. The plate is subjected to solution treatment at a temperature of 505°C for 15 minutes, and then water quenched;

[0156] 6. Carry out 0.2mm cold rolling deformation treatment;

[0157] 7. Short-term artificial aging of the plate at 195°C for 15 minutes, and then air-cooled to room temperature.

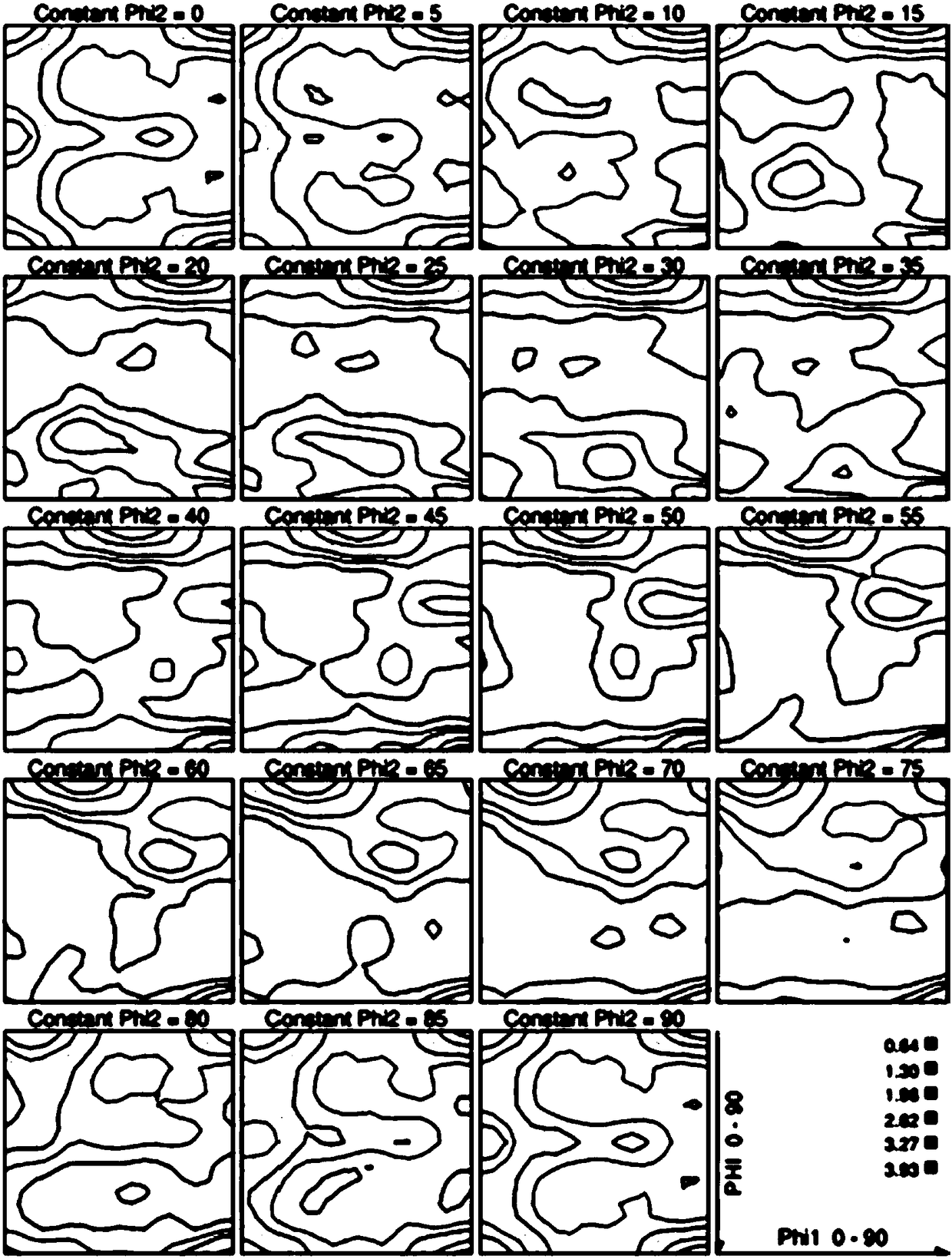

[0158] The texture volume fraction of the alloy prepared by the method of embodiment 3

[0159]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com