A processing method of anti-fatigue aluminum alloy plate with brass texture

A technology of aluminum alloy sheet and brass texture, which is applied in the field of processing and skin materials for the preparation of fatigue-resistant aluminum alloy sheet, can solve problems such as not meeting the performance requirements of aircraft service, achieve excellent fatigue resistance, and promote the recovery process , Reduce the effect of deformation energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

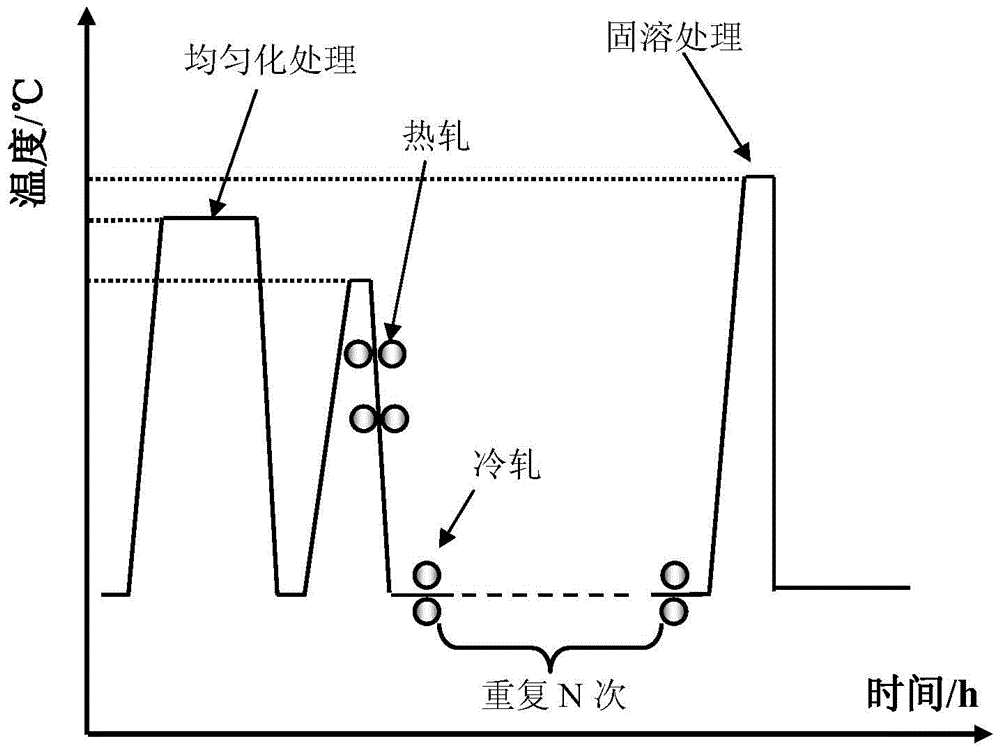

[0077] 1. Homogenize the 40mm aluminum alloy ingot at 493°C for 24 hours, then air cool;

[0078] 2. Keep the cast ingot at a temperature of 440°C for 1 hour, then perform hot rolling deformation to 8.0mm, and air-cool;

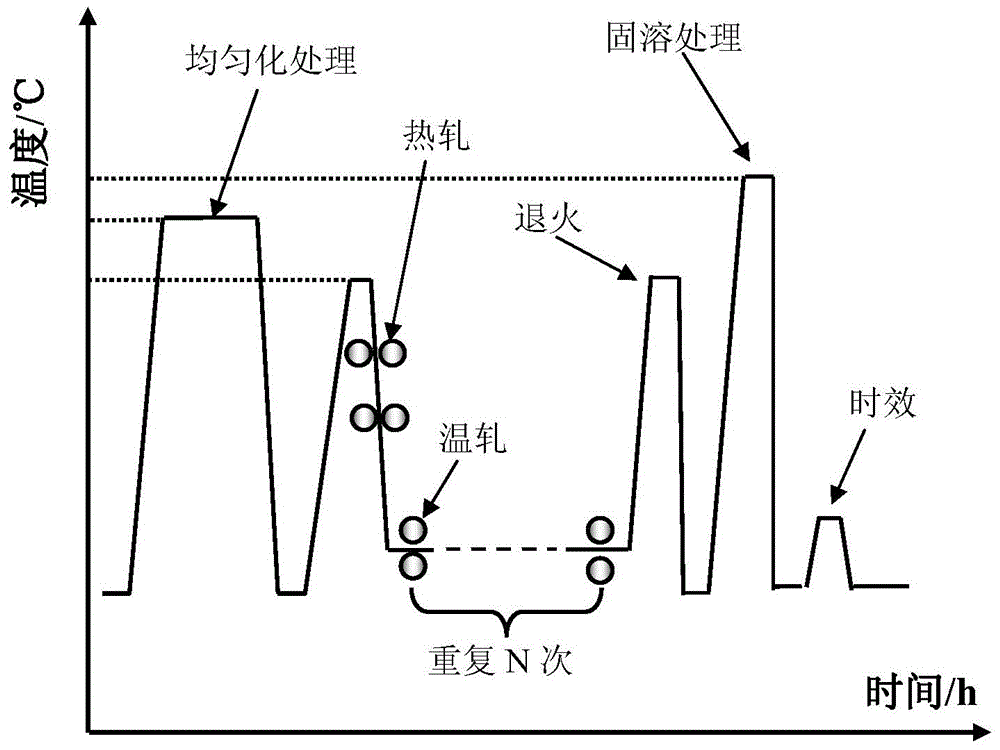

[0079] 3. Warm rolling at 160°C, with a deformation of 1.0mm in each pass, until the final thickness is 2.0mm;

[0080] 4. Anneal the plate at 380°C for 1 hour, then air cool;

[0081] 5. The plate is subjected to solid solution treatment at a temperature of 500°C for 1 hour, and then water quenched;

[0082] 6. Carry out 0.2mm cold rolling deformation treatment;

[0083] 7. Short-term artificial aging of the plate at 190°C for 0.5h, and then air-cooled to room temperature.

[0084] Table 1 has shown alloy of the present invention, existing industry 2E12-T3 alloy and the mechanical property that previous method obtains alloy; As can be seen from Table 1:

[0085] Table 1

[0086]

[0087] In the alloy prepared in Example 1, the volume fractions of cub...

Embodiment 2

[0094] 1. Homogenize the 40mm aluminum alloy ingot at 495°C for 18 hours, then air cool;

[0095] 2. Heat the ingot at 420°C for 1 hour, then hot-roll and deform it to 7mm, and air-cool;

[0096] 3. Warm rolling is carried out at 180°C, the deformation amount of each pass is 1.4mm, until the final thickness is 2.0mm;

[0097] 4. Anneal the plate at 400°C for 0.5h, then air cool;

[0098] 5. The plate is subjected to solid solution treatment at 505°C for 0.5h, and then water quenched;

[0099] 6. Carry out 0.1mm cold rolling deformation treatment;

[0100] 7. Short-term artificial aging of the plate at 175°C for 2.0h, and then air-cooled to room temperature.

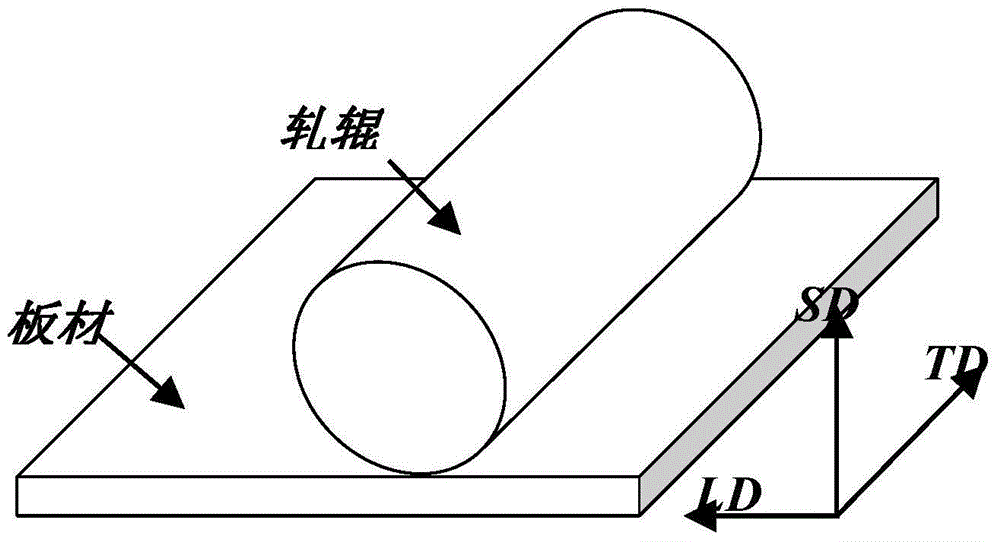

[0101] The grain length-diameter ratio of the alloy prepared in Example 2 is relatively large, and some grains are obviously fibrous. The average grain sizes of the three directions of LD, TD and SD are 254 μm, 93 μm and 27 μm, respectively.

[0102] In the 2E12-T3 alloy prepared in Example 2, the volume fractions of...

Embodiment 3

[0111] 1. Homogenize the 20mm aluminum alloy ingot at 485°C for 48h, then air cool;

[0112] 2. Keep the cast ingot at a temperature of 460°C for 1 hour, then perform hot rolling deformation to 8mm, and air-cool;

[0113] 3. Warm rolling at 180°C, with a deformation of 0.8mm in each pass, until the final thickness is 1.6mm;

[0114] 4. Anneal the plate at 360°C for 1.5h, then air cool;

[0115] 5. The plate is subjected to solid solution treatment at 498°C for 1.0h, and then water quenched;

[0116] 6. Carry out 0.2mm cold rolling deformation treatment;

[0117] 7. Short-term artificial aging of the plate at 180°C for 1.0h, and then air-cooled to room temperature.

[0118] The grain length-diameter ratio of the alloy prepared in Example 3 is relatively large, and some grains are obviously fibrous. Its average grain size in LD, TD and SD directions is 193 μm, 72 μm and 16 μm, respectively.

[0119] In the 2E12-T3 alloy prepared in Example 3, the volume fractions of cubic t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| fatigue limit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com