Patents

Literature

31results about How to "Raise the initial melting temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel-base high-temperature alloy with low density and high melting point and preparation process thereof

The invention relates to high-temperature alloy technology, and in particular provides an isometrical cast nickel-base high-temperature alloy with low density, high incipient melting temperature and good casting property and a preparation process thereof, which can be used for floating tile materials of a combustion chamber. The alloy comprises the following compositions by mass percentage: 0.03 to 0.06 percent of C, 5 to 12 percent of Cr, 5.5 to 6.5 percent of Al, 3 to 8 percent of Co, 3 to 7 percent of W, 2 to 4 percent of Mo, 1.6 to 3.2 percent of Nb, 0.01 to 0.03 percent of B, 0.008 to 0.025 percent of Y and the balance of Ni. A vacuum induction furnace is adopted to smelt a master alloy, and a smelting crucible is a CaO crucible or a MgO crucible; and the operation process comprises the following steps: putting alloying elements such as carbon, chromium, cobalt, tungsten, molybdenum and niobium in proportion and a nickel plate into the crucible; melting the alloy when the vacuum degree reaches between 50 and 0.1 Pa; and after completion of the melting, refining for 30 to 300 seconds at a temperature of between 1,550 and 1,600 DEG C, cutting off electricity, forming a film, breaking the film to add Al and Al-Y and Ni-B interalloy for uniform stirring, and casting a master alloy pig at a temperature of between 1,450 and 1,500 DEG C. The invention solves the problems of low incipient melting temperature, poor plasticity and inoxidability and the like of the nickel-base high-temperature alloy.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

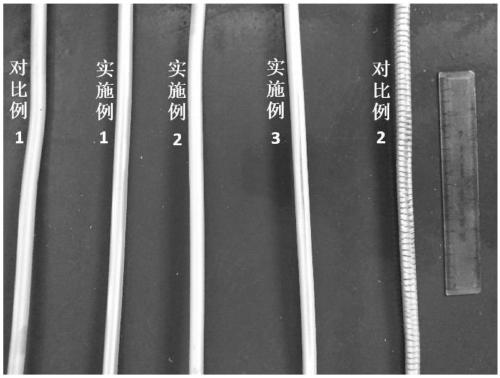

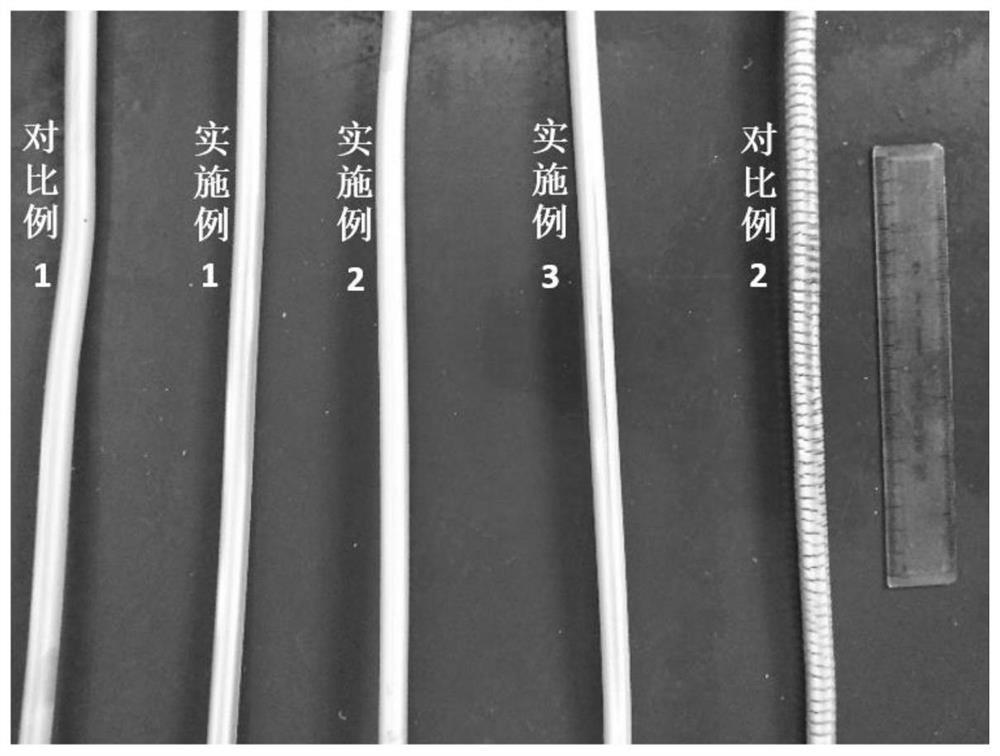

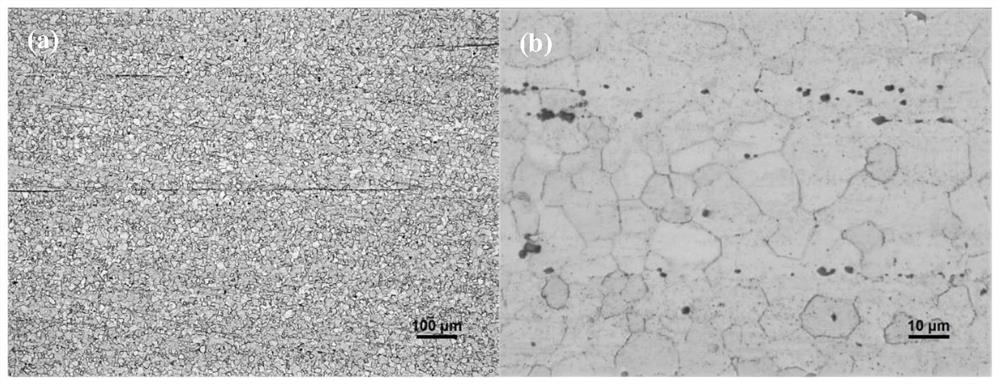

Preparation method of abrasion-proof and corrosion-resistant nickel-based alloy wire

The invention discloses an abrasion-proof and corrosion-resistant nickel-based alloy wire and a preparation method thereof. The alloy wire comprises the following components: 17-21% of C, 20-25% of Co, 1.8-2.2% of W, 6.4-9.5% of Mo, 1.4-1.8% of Al, 3.2-4.5% of Ti, 0.1-0.5% of Nb, 0.1-0.5% of Hf, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr, 0.005-0.008% of Mg, and the balance Ni. The preparation technology of the alloy comprises the steps of vacuum smelting, remelting, forging, hot rolling, drawing, solid solution treatment and aging treatment, namely, raw materials are prepared and smelted based on mass percent and then smelted; the smelted materials are forged and rolled into obtain alloyed wire rods; the alloyed wire rods are drawn at a plurality of times to obtain phi 0.05-0.4mm alloy wires; finally the alloy wires are subjected to solid solution treatment and aging treatment. The abrasion-proof and corrosion-resistant nickel-based alloy wire can be used as a brush wire material for brush sealing of an aircraft engine, a gas turbine, etc., thus the brush sealing effect can be effectively improved, and the service life can be prolonged.

Owner:江苏鑫信润科技股份有限公司

Method for melting nickel-base high-temperature return material K441alloy

InactiveCN101717865AMeet production requirementsRaise the initial melting temperatureInduction furnaceChromium

The invention relates to a method for melting nickel-base high-temperature return material K441 alloy, comprising the following steps: refining the return material and / or waste cast pieces in a vacuum induction furnace, decreasing the temperature of molten alloy and casting the molten alloy into a primary material ingot, analyzing the chemical components of the primary material ingot and adjusting the components of the molten alloy by adopting the nickel, aluminum, tungsten, chromium, molybdenum, zirconium, chromium boron master alloy and / or the carbon as the adjusting element component material; refining the primary material ingot and the nickel, the tungsten, the chromium and / or the molybdenum in the adjusting element component material for the second time and heating to cast the molten alloy after a film forming on the molten alloy or adding the carbon, aluminum, chromium boron master alloy and / or the zirconium to the molten alloy to alloy and heating to cast the molten alloy into an alloy ingot after a film forming on the molten alloy. The qualification rate of the return material K441 alloy produced with the method is equal to the qualification rate of the cast piece produced from the new material, and the initial melting temperature of the return material K441 alloy is higher than the initial melting temperature of the alloy produced from the new material with the original production technology.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

High-temperature oxidation resistant wearproof Co-based alloy wire and preparation method thereof

ActiveCN106756257AGood high temperature and wear resistanceHigh temperature and wear resistanceWire rodOxidation resistant

The invention discloses a high-temperature oxidation resistant wearproof Co-based alloy wire and a preparation method thereof. The high-temperature oxidation resistant wearproof Co-based alloy wire comprises the following ingredients: 13-17% of Cr, 11-15% of Ni, 10-14% of W, 2.4-4.3% of Mo, 1.2-1.6% of Al, 2.8-3.6% of Ti, 0.1-0.5% of Nb, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr and the balance of Co. The alloy preparation process route is vacuum melting-remelting-forging-hot rolling-drawing-solid solution treatment-aging treatment. Raw materials are compounded according to percentage by mass and then melted and re-melted; after that, forging and rolling are performed to obtain an alloy wire rod; multi-drawing is conducted to prepare an alloy wire of phi 0.06-0.4 mm; and finally, solid solution treatment and aging treatment are performed. Through reasonable ingredient control and adding of alloy elements, the alloy wire has high yield and excellent high-temperature wear resistance, high-temperature corrosion resistance, oxidation resistance and high strength. As a sealing brush wire material, the high-temperature oxidation resistant wearproof Co-based alloy wire has the advantages that the sealing effect can be effectively improved, and the service life is prolonged.

Owner:SOUTHEAST UNIV

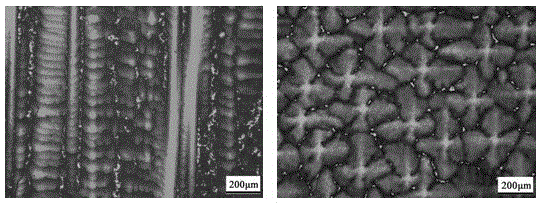

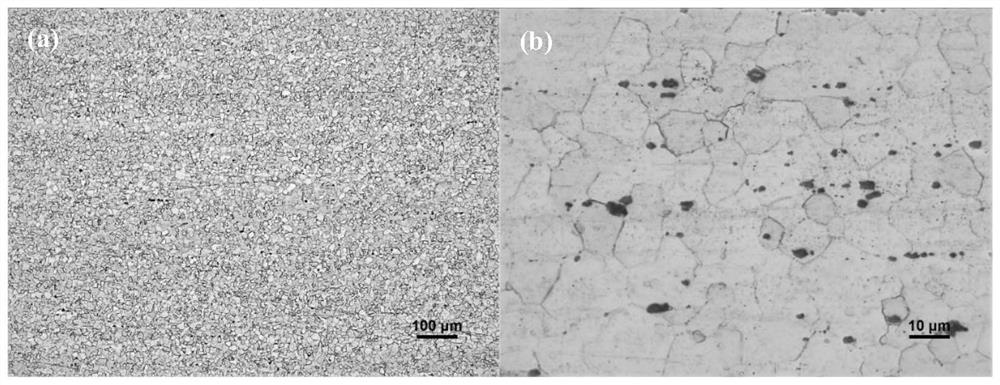

Heat treatment process of nickel base single crystal superalloy

InactiveCN104746145AImprove durabilityRaise the initial melting temperaturePolycrystalline material growthAfter-treatment detailsSingle crystal superalloySingle crystal

The invention discloses a heat treatment process of nickel base single crystal superalloy. A differential thermal analysis method and metallographic test method are used to determine the incipient melting temperature of the alloy at 1280 DEG C; and an optical metalloscope is used for observation of the microstructure of alloy after different solid solution treatments, and the stress rupture properties of the alloy are tested. The results show that optimum heat treatment process of the alloy is as below: 1245 DEG C / 2h, AC+1275 DEG C / 4h, AC+1100 DEG C / 2h, AC+850 DEG C / 24h, AC. The single crystal superalloy treated by the process has excellent durability, and creep rupture life reaching 159.35h under 980 DEG C and 235MPa.

Owner:QINGDAO YUGUANG PRECISION CASTING FACTORY

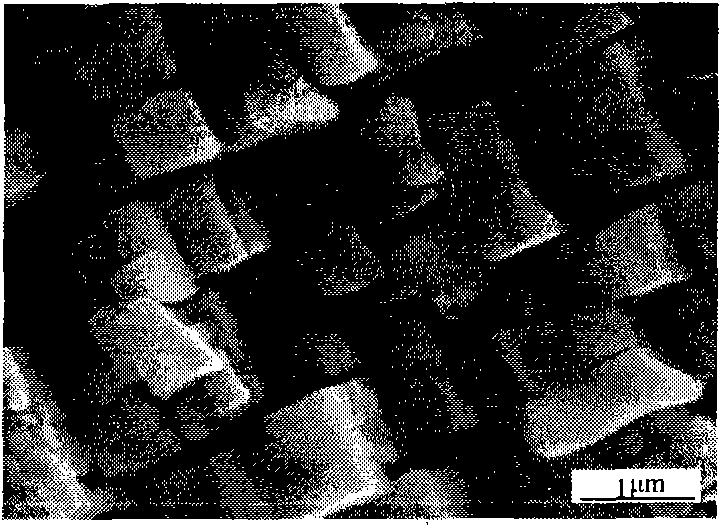

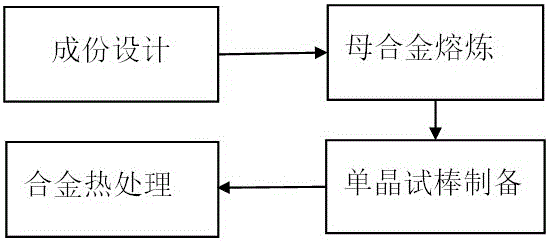

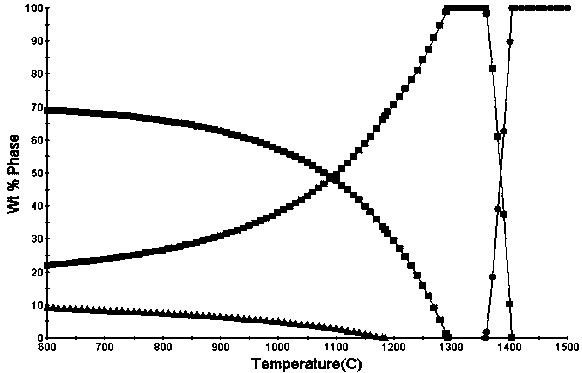

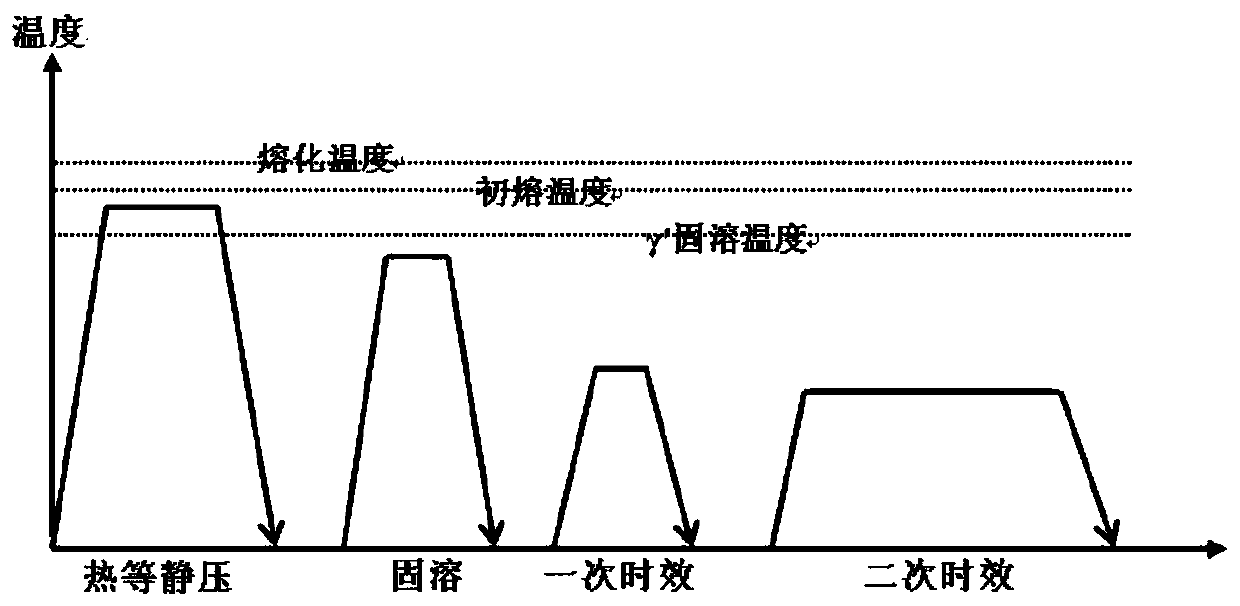

Low-rhenium third-generation nickel-based single crystal alloy and preparation method thereof

ActiveCN106011540ARaise the initial melting temperatureWide melting rangePolycrystalline material growthFrom frozen solutionsDirectional solidificationCorrosion

The invention belongs to the field of nickel-based superalloys, in particular to a low-rhenium third-generation nickel-based single crystal alloy and a preparation method thereof. Its composition includes Cr, Co, W, Mo, Re, Ta, Al, Hf and Ni, among which Re: 3.0‑4.5%, and it is characterized in that the value of Ta / (W+Mo) is controlled between 1:1‑2 . The main steps of the invention are to use a vacuum consumable furnace to prepare the raw material into a consumable electrode, and to prepare a master alloy through multiple tests; then use the spiral crystal selection method to prepare a single crystal test rod through a directional solidification furnace, and finally test the single crystal at high temperature Alloy test bars were heat treated. The alloy of the present invention mainly improves the durable strength and hot corrosion resistance of the alloy by adjusting the ratio of Ta / (W+Mo), so that the alloy meets the performance of the third-generation nickel-based single crystal superalloy, and contains less Re, and can be used at 900 ° C There is no TCP phase precipitation during long-term aging, and the stability is good.

Owner:JIANGSU UNIV

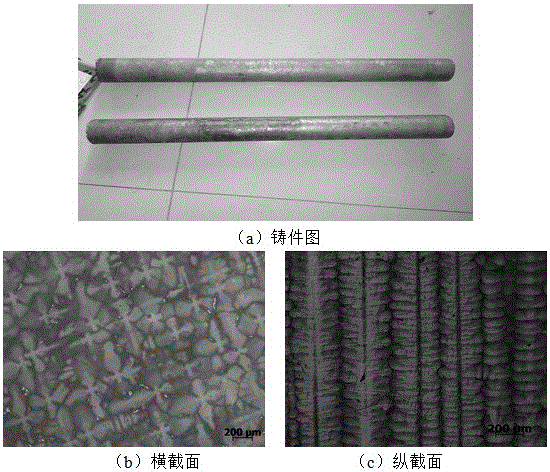

Directional solidification nickel-base high-temperature alloy and heat treatment process thereof

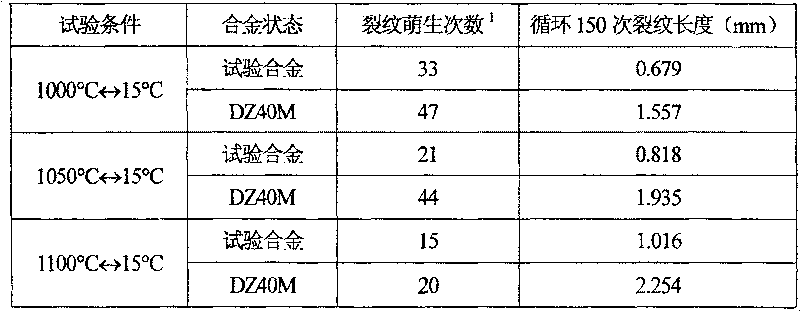

The invention relates to a directionally solidified nickel-based superalloy and a heat treatment process thereof. In particular, it provides a guide vane material with low density, low cost, high initial melting temperature, good oxidation corrosion resistance and thermal fatigue performance. And a heat treatment process to improve the alloy's tensile properties, durability and thermal fatigue properties. Alloy composition (percentage by weight) of the present invention: B 0.003~0.03, C 0.02~0.2, Cr 8.0~10.0, Al 4.5~6.5, Co 4.0~12.0, Nb 1.8~2.5, W 2.5~4.5, Mo 2.5~4.5, Y 0.005~0.05, more than Ni. The heat treatment process of the present invention: (1) at a temperature of 1210°C to 1240°C, heat preservation for 3h to 5h, and air-cool to room temperature; (2) at a temperature of 1040°C to 1080°C, heat preservation for 3h to 5h, and air cooling to room temperature; ( 3) At a temperature of 850°C to 900°C, keep warm for 16h to 32h, and air cool to room temperature. The alloy of the invention has the characteristics of low density, low cost, high initial melting temperature, good oxidation corrosion resistance and thermal fatigue performance, and is suitable for directional nickel-based guide vane materials.

Owner:辽宁红银金属有限公司

Preparation method for magnesium alloy profile material for automobile oil tank

InactiveCN106591658AReduce heat sensitivityImprove solderabilityUnderstructuresFuel supplyRare-earth elementFuel tank

The invention discloses a magnesium alloy profile material for an automobile oil tank. The magnesium alloy profile material comprises the following components of, by mass, 8%-15% of Al, 2%-4% of Mn, 10%-13% of Zn, 1%-3% of Ni, 7%-9% of Ca, 1%-3% of Cu, 1%-3% of Sc, 0.2%-0.3% of P, 1%-3% of Zr, 2%-4% of B, 0.1%-0.4% of V, 0.002%-0.004% of Nb, 2%-5% of So, 0.01%-0.03% of C, 2%-4% of Co, 0.2%-0.5% of Fe, 0.5%-0.8% of rare earth elements, and the balance Mg. The invention further relates to a preparation method for the magnesium alloy profile material for the automobile oil tank. The preparation method is simple and easy to operate, the prepared oil tank has good corrosion resistance, the service life is long, and the cost is low.

Owner:SUZHOU NIUDONG PRECISION MFG TECH CO LTD

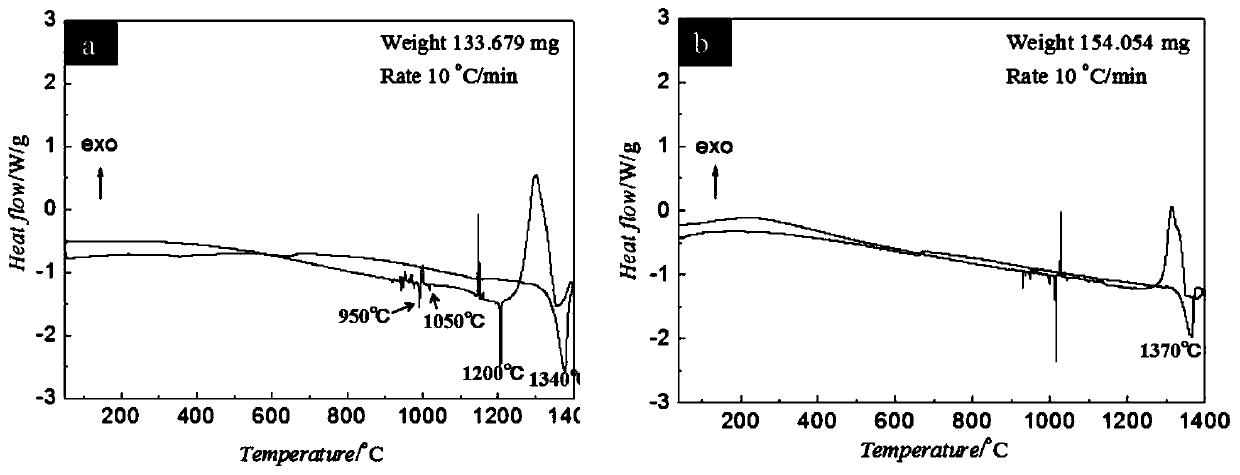

Heat treatment process of nickel-based single crystal superalloy

InactiveCN105755544AImprove durabilityRaise the initial melting temperaturePolycrystalline material growthAfter-treatment detailsSolution treatmentSingle crystal superalloy

The invention discloses a heat treatment process of a nickel-based single crystal superalloy. A differential thermal analysis method and a metallographic test method are adopted for determining an incipient melting temperature of the alloy to be about 1280 DEG C; an optical metalloscope is used for observation of a microstructure of an alloy after different solid solution treatments, and the endurance properties of the alloy are tested. Results show that an optimum heat treatment process of the alloy comprises 1245 DEG C / 2h, AC+1275 DEG C / 4h, AC+1100 DEG C / 2h, AC+850 DEG C / 24h, and AC. The single crystal superalloy treated by the process has excellent endurance properties, and the endurance life reaches 159.35 h under the conditions of the temperature of 980 DEG C and the pressure of 235 MPa.

Owner:QINGDAO NPA IND

Low-cost high-toughness wrought magnesium alloy capable of being extruded at high speed and preparation method thereof

The invention relates to low-cost high-toughness wrought magnesium alloy capable of being extruded at high speed and a preparation method thereof. The alloy is Mg-Bi-Sn-Al-Ca magnesium alloy and comprises, by mass, 2-45 of Bi, 2-4% of Sn, 1-3% of Al, 0.05-0.5% of Ca and the balance magnesium, wherein the mass ratio of Bi to Sn in the alloy is (0.8-1.2):1. The alloy can be used for high-speed extrusion production at the extrusion speed up to 25 m / min, the production efficiency is improved, and meanwhile, the production cost is reduced. Crystalline grains of a finally extruded product are uniform and fine, a large number of second phases are dispersed in a matrix, the comprehensive mechanical property is good, and the alloy is relatively good in flame retardancy.

Owner:HEBEI UNIV OF TECH

Material for magnesium alloy doors and windows and production method of material

The invention discloses a material for magnesium alloy doors and windows. The material for the magnesium alloy doors and windows is composed of Mg, Al, Mn, Zn, Cu, Ni, Sc, P, Zr, Y, Ca, Sr, B, Co and a rare earth element, wherein the rare earth element is composed of Ce, Nd, Gd, Pr, Dy, Yb, La and Sm; the invention further discloses a production method of the material for the magnesium alloy doors and windows, and the method comprises the following steps: smelting, heat treatment, forging, quenching and tempering heat treatment, cooling, checking and storing, the production method is simple and easy, the manufacturing cost is low, and the produced material for the magnesium alloy doors and windows is excellent in corrosion resistance, can resist high temperature, is solderable, and has a prolonged service life.

Owner:SUZHOU CITY WUZHONG DISTRICT XUKOU FENGSHOU MACHINERY PARTS FACTORY

High-performance cobalt-based high-temperature alloy brush wire material

The invention discloses a high-performance cobalt-based high-temperature alloy brush wire material. The high-performance cobalt-based high-temperature alloy brush wire material is characterized in that the brush wire material comprises, by mass percent, 0.02%-0.1% of C, 1%-1.5% of Al, 0.5%-2% of Ti, 0.003%-0.01% of B, 10%-14% of W, 9%-11% of Cr, 17%-25% of Ni and the balance Co and inevitable impurities. The material has high-temperature-resistance wear resistance, high-temperature-resistance corrosion resistance and oxidization resistance, in addition, high strength is achieved, in other words, a proper alloy component ratio, a corresponding processing and preparing technology and a corresponding heat treatment technology are selected, and due to the fact that alloy strengthening elements are properly added and the processing and preparing technology is improved, the alloy performance is greatly strengthened, the tissue evenness is improved, grains are refined, defects are lowered, impurities are reduced, and the yield of alloys is increased. Meanwhile, the comprehensive performance of the alloys should be improved as much as possible on the premise that plasticity of the alloys is not changed.

Owner:江苏鑫信润科技股份有限公司

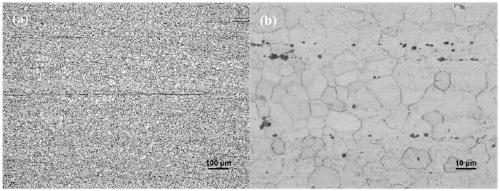

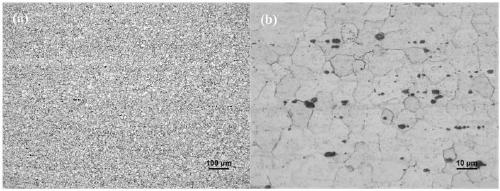

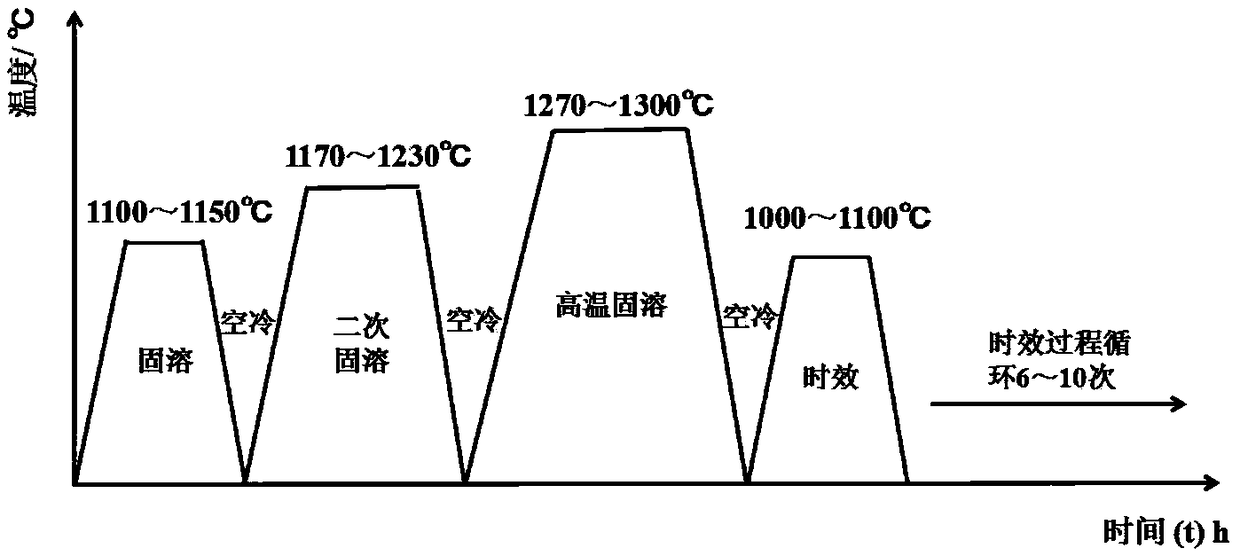

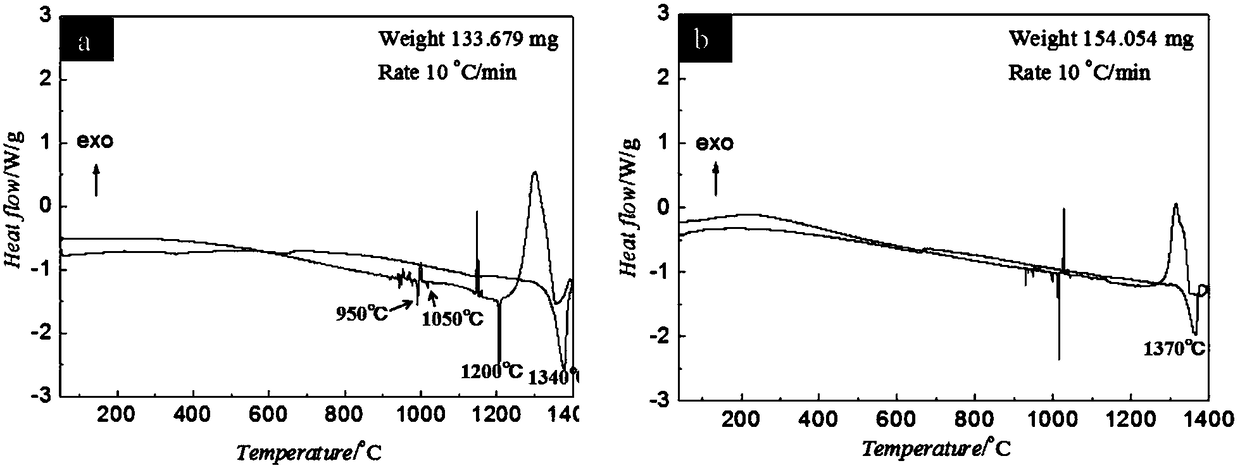

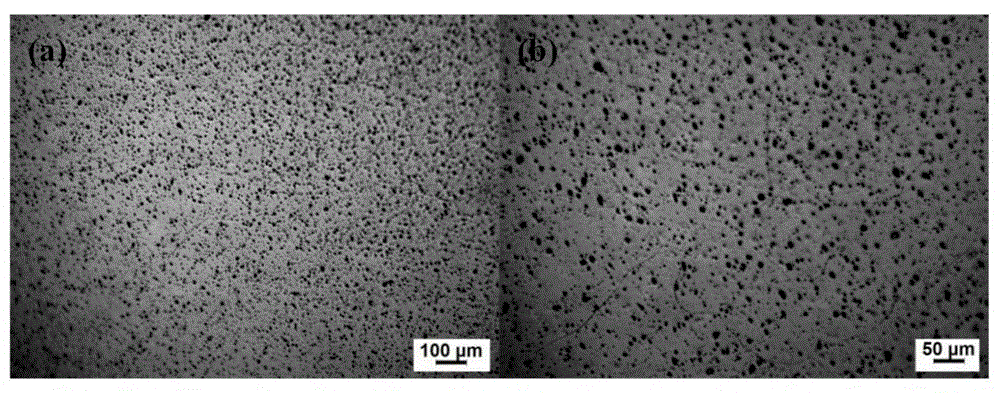

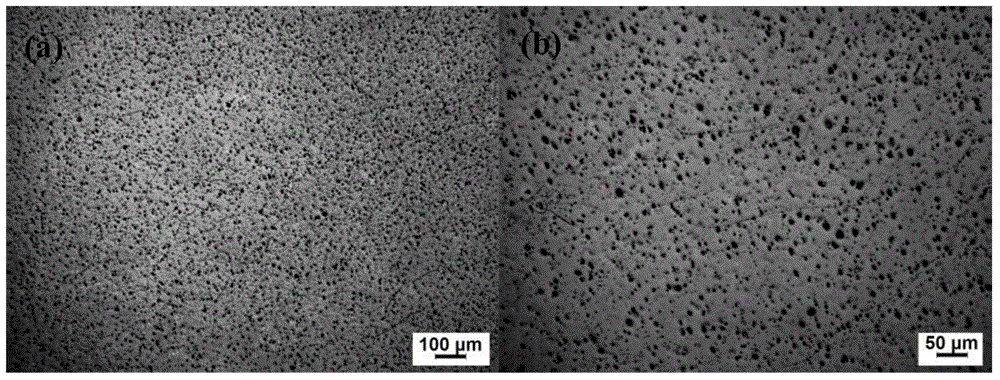

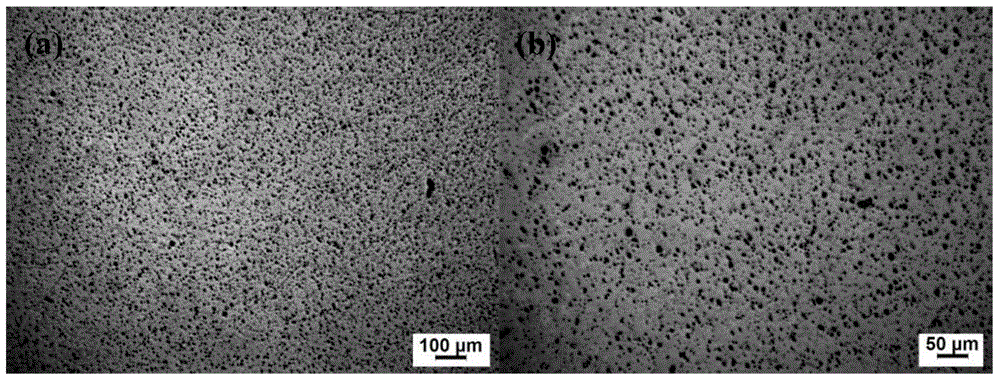

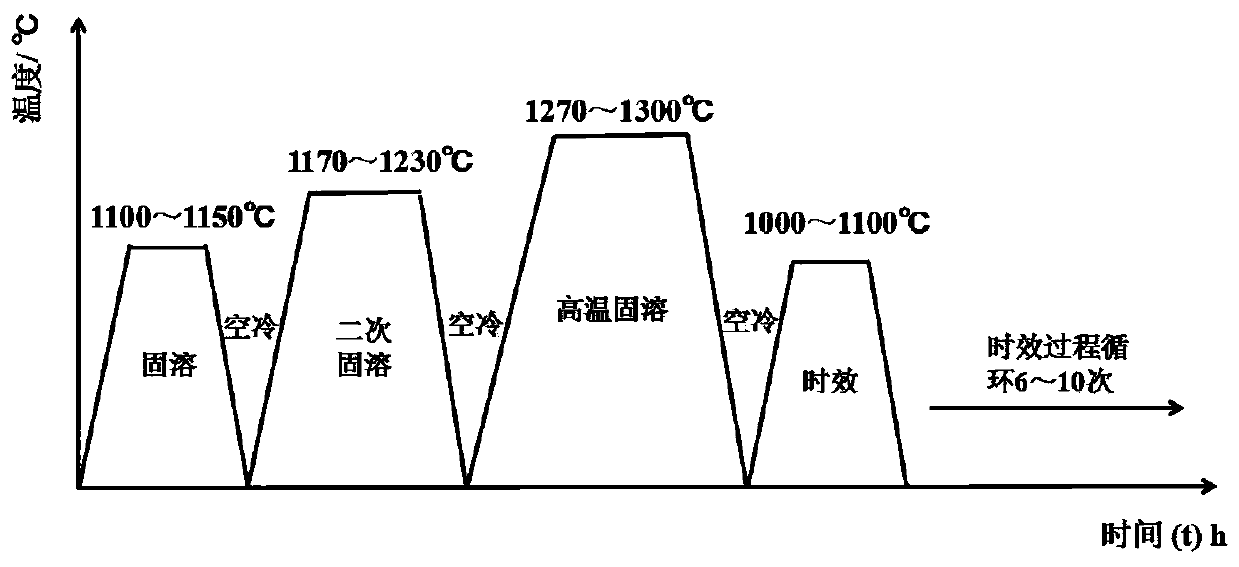

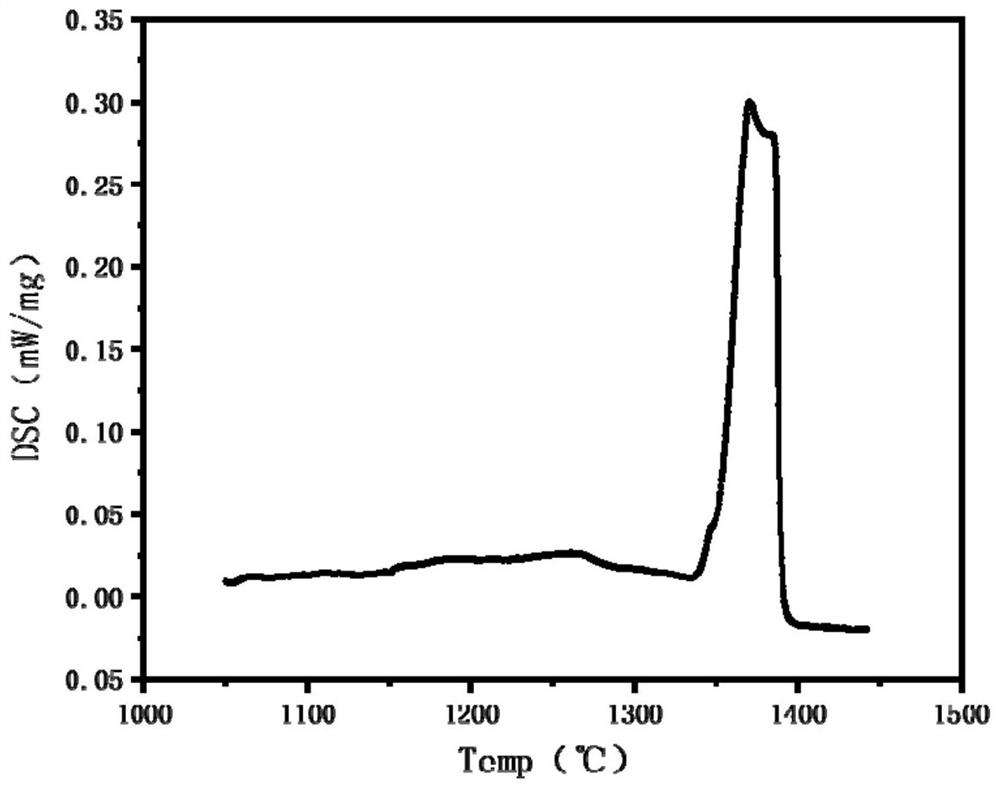

Heat treatment method for enhancing deforming stability of polycrystal Ni3Al based high temperature alloy

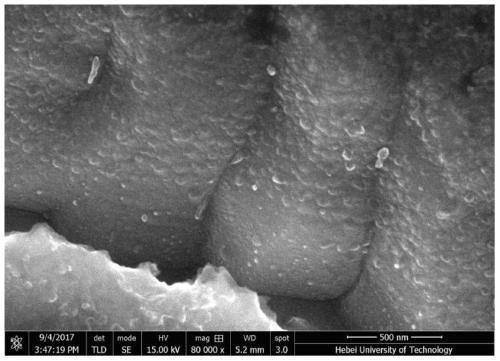

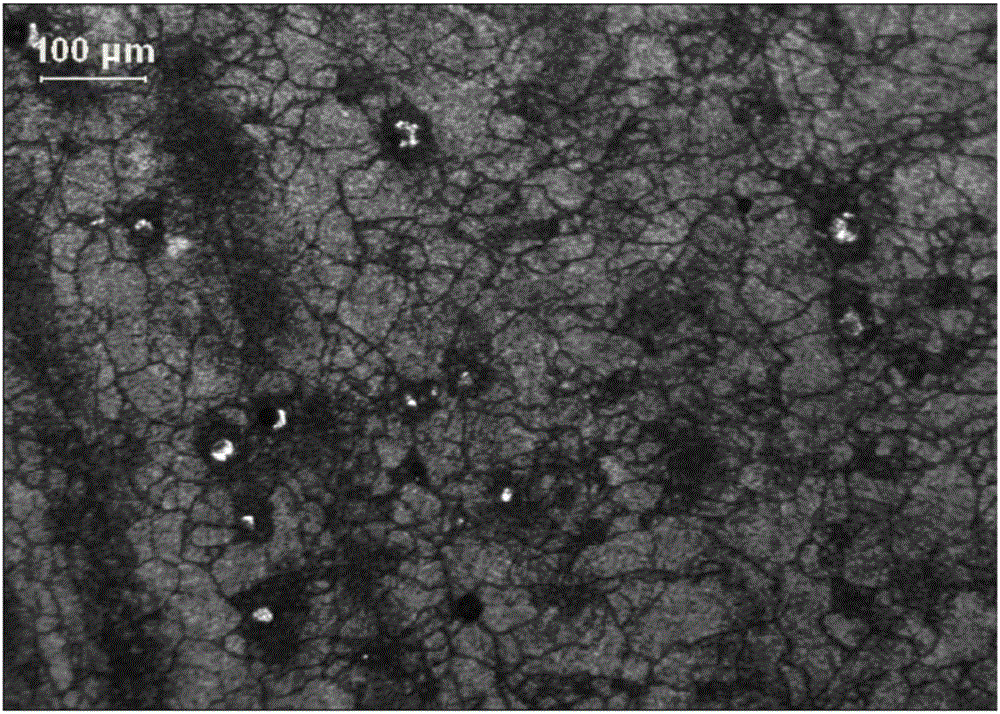

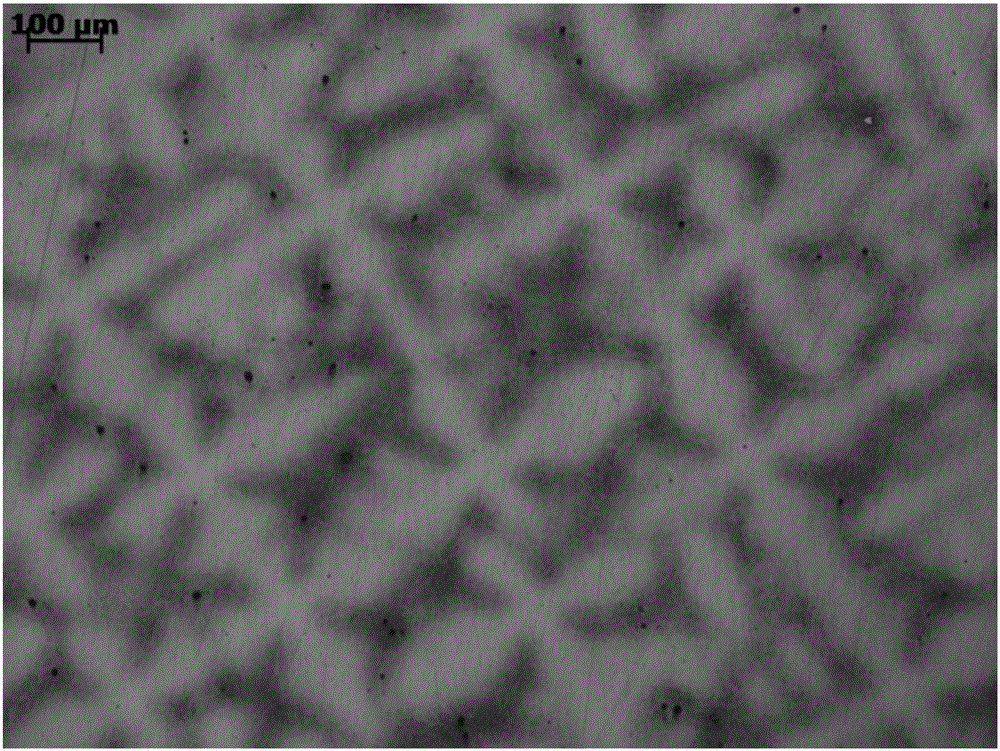

ActiveCN108396269ARaise the initial melting temperatureImproved deformation stabilityAlloySolid solution

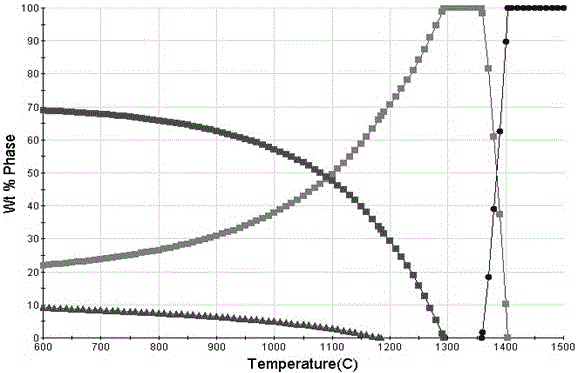

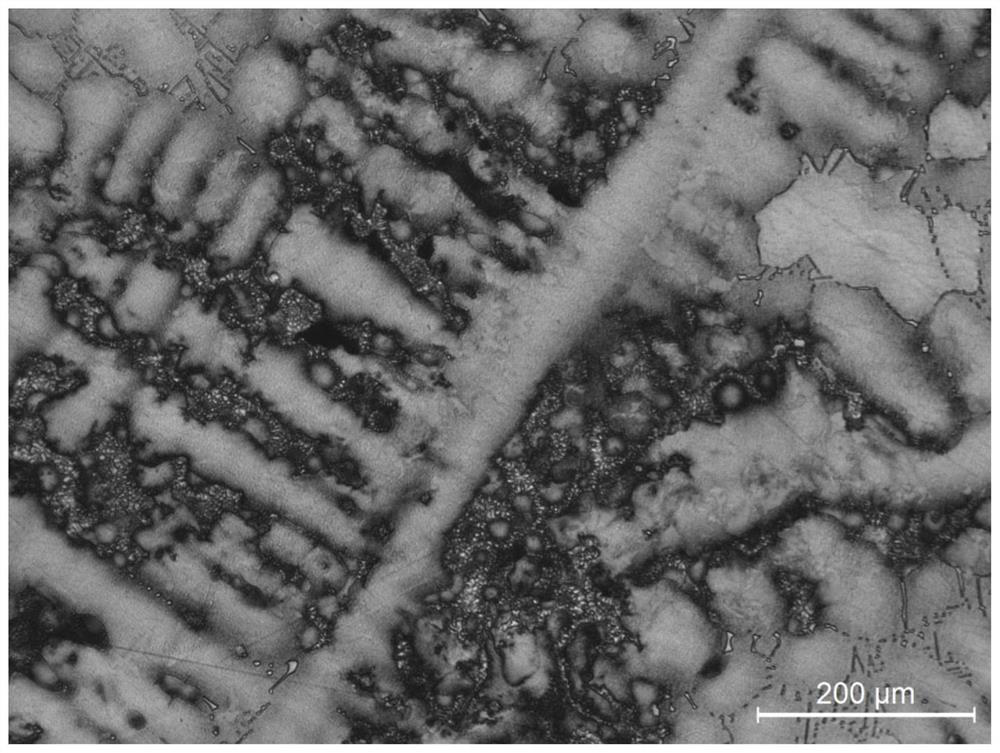

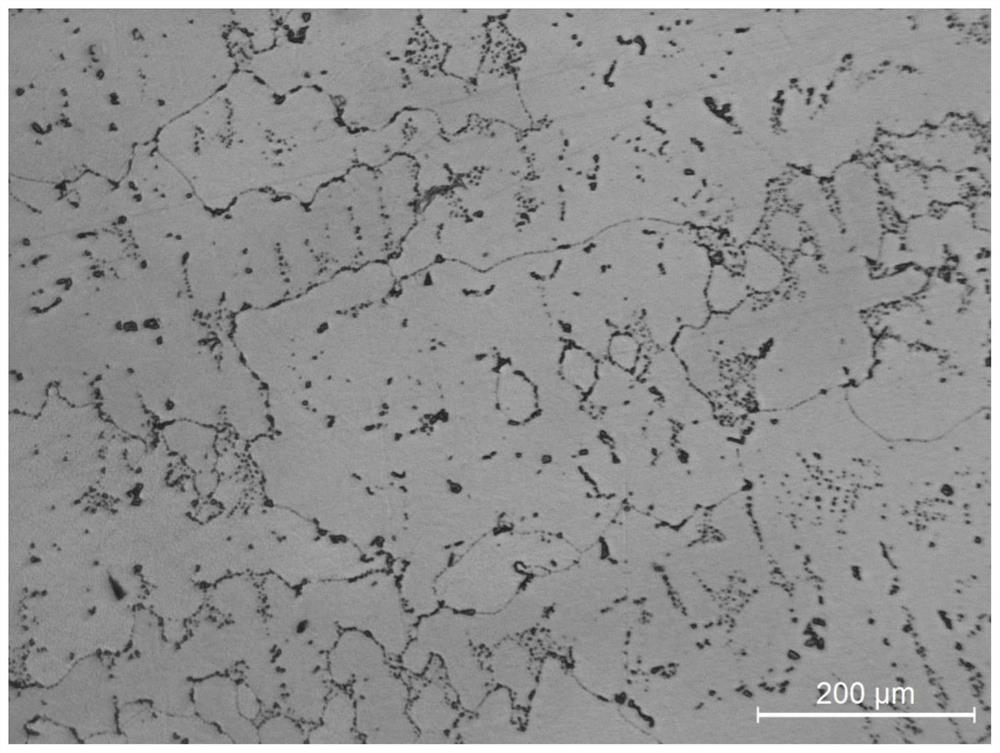

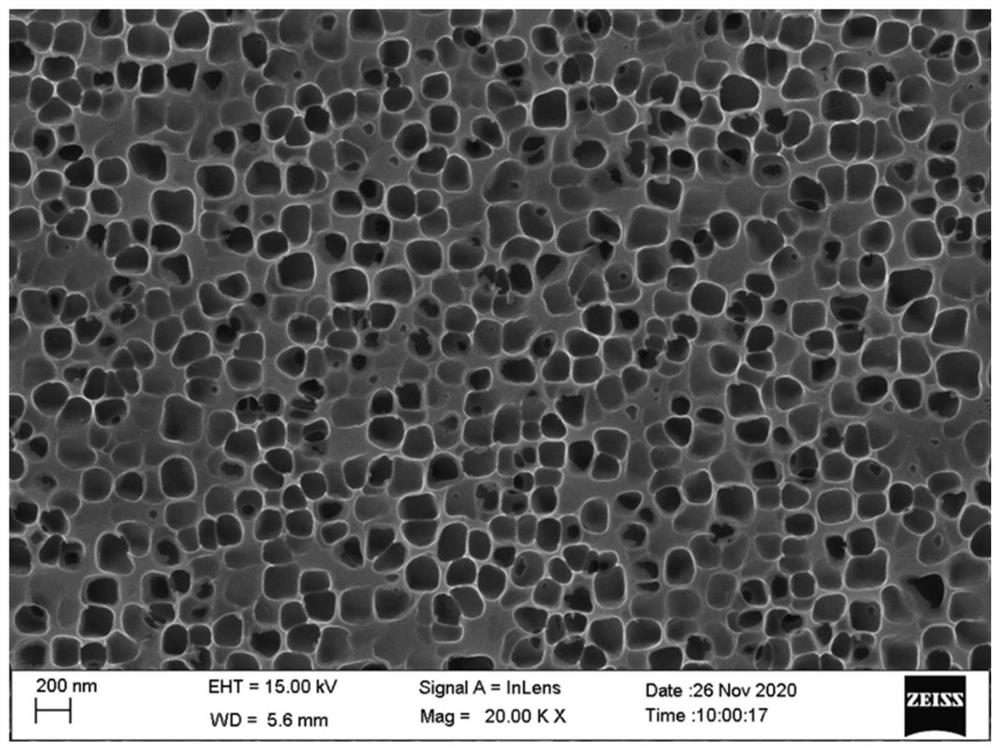

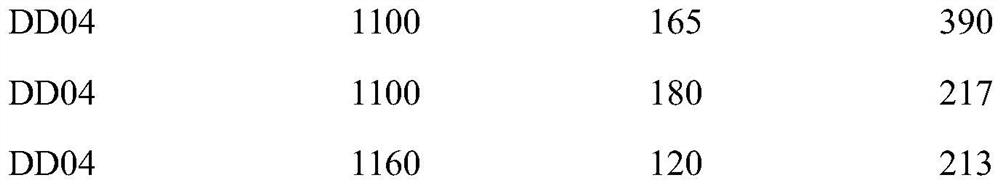

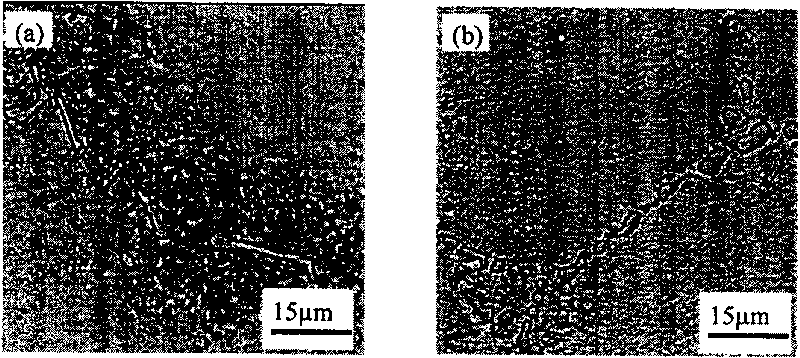

The invention discloses a heat treatment method for enhancing deforming stability of a polycrystal Ni3Al based high temperature alloy. The method comprises following steps that the alloy is subject tosolid melt treatment at the temperatures of 1100 to 1150 DEG C, 1170 to 1230 DEG C and 1270 to 1300 DEG C, intermediate temperature aging treatment is carried out at the temperature of 1000 DEG C to1100 DEG C, the step is repeated for six to ten times, and finally, the Ni3Al based high temperature alloy with deformation stability enhanced is obtained. After three-segment solid solution treatmentand a series of steps of medium temperature circular aging, the incipient melting temperature of the obtained alloy is improved to about 1370 DEG C from the 1345 DEG C under the as-cast condition, anenhanced type gamma' phase with the small size and the round shape can be evenly separated out from the eutectic area and coexistence region interfaces, and deforming stability of the Ni3Al based alloy under the high temperature condition can be improved.

Owner:HEBEI UNIV OF TECH

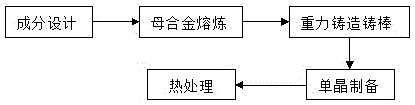

Heat treatment process for casting precipitation strengthened nickel-based superalloy

A treatment process for casting precipitation strengthened nickel-based superalloy comprises the following steps that firstly, mother alloy of the casting precipitation strengthened nickel-based superalloy is put into a vacuum induction furnace to be smelted and then drawn into an alloy bar; secondly, the temperature of the alloy bar in the first step is increased to 1205-1215 DEG C from the room temperature, heat preservation is conducted for 6-8 h, then the temperature is increased to 1220-1230 DEG C, heat preservation is conducted for 10-20 h, and then the alloy bar is cooled to the room temperature through air; thirdly, the alloy bar subjected to solid solution heat treatment in the second step is subjected to stabilizing heat treatment; and fourthly, the alloy bar subjected to heat treatment in the third step is subjected to aging heat treatment. After the alloy is treated by the process, dendritic segregation and eutectic structures are eliminated, the microstructure uniformity is remarkably improved, and the mechanical property of the alloy is greatly improved.

Owner:CHINA HUANENG GRP CO LTD +1

High-strength cast magnesium alloy and preparation method thereof

ActiveCN105112751AGood aging precipitation strengthening effectImprove mechanical propertiesUltimate tensile strengthAluminium element

The invention relates to a high-strength cast magnesium alloy. The high-strength cast magnesium alloy is an Mg-Bi-Al-Zn-Sr alloy and comprises components in percentage by weight as follows: 3wt%-8.0wt% of Bi, 0.5wt%-4.0wt% of Al, 0.1wt%-1.0wt% of Zn, 0.05wt%-0.15wt% of Sr and the balance of Mg. The Bi element is used as a main alloy element, a large quantity of Mg3Bi2 phases are formed through simple alloying means, a small quantity of aluminum and zinc elements are used for improving the strength of the alloy, so that the high-strength cast magnesium alloy is developed from the alloy series, and the alloy has the tensile strength of 276-296 MPa, the yield strength of 155-170 MPa and the elongation of 5.3%-7.3% and has mechanical properties comparable with those of rear earth magnesium alloys.

Owner:HEBEI UNIV OF TECH

An enhanced polycrystalline Ni 3 Heat Treatment Methods for Deformation Stability of Al-Based Superalloys

ActiveCN108396269BRaise the initial melting temperatureImproved deformation stabilitySolid solutionSuperalloy

The invention discloses a heat treatment method for enhancing deforming stability of a polycrystal Ni3Al based high temperature alloy. The method comprises following steps that the alloy is subject tosolid melt treatment at the temperatures of 1100 to 1150 DEG C, 1170 to 1230 DEG C and 1270 to 1300 DEG C, intermediate temperature aging treatment is carried out at the temperature of 1000 DEG C to1100 DEG C, the step is repeated for six to ten times, and finally, the Ni3Al based high temperature alloy with deformation stability enhanced is obtained. After three-segment solid solution treatmentand a series of steps of medium temperature circular aging, the incipient melting temperature of the obtained alloy is improved to about 1370 DEG C from the 1345 DEG C under the as-cast condition, anenhanced type gamma' phase with the small size and the round shape can be evenly separated out from the eutectic area and coexistence region interfaces, and deforming stability of the Ni3Al based alloy under the high temperature condition can be improved.

Owner:HEBEI UNIV OF TECH

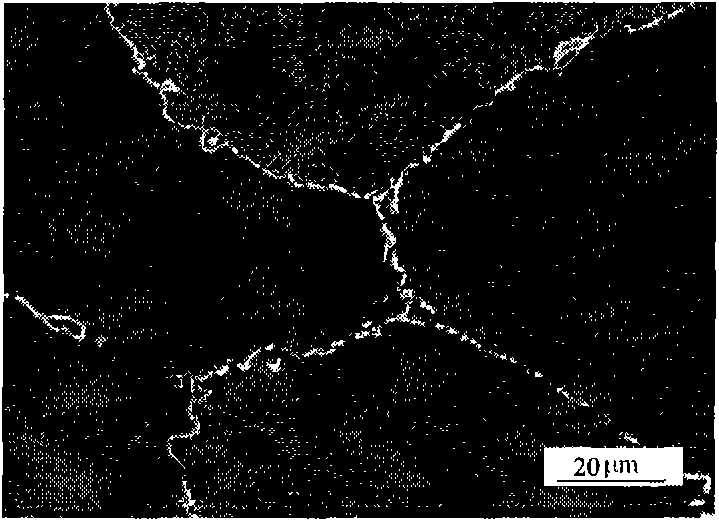

Method for preventing DD99 alloy single crystal blade from generating initial melting defect

ActiveCN106119748ARaise the initial melting temperatureAvoid incipient defectsThermal insulationAlloy

The invention provides a method for preventing a DD99 alloy single crystal blade from generating an initial melting defect. The method comprises the steps that in a high-temperature heat treatment technology of the DD99 alloy single crystal blade, a pre-treatment technology is added, a temperature is taken between 10 DEG C and 25 DEG C below the treatment temperature during pre-treatment for thermal insulation, and therefore a low-melting-point eutectic phase inside an alloy is removed in advance. When blade high-temperature heat treatment is carried out after pre-treatment, due to the fact that the content of eutectic crystals inside the alloy is small, the initial melting temperature of the alloy is improved, and generation of the initial melting defect of the single crystal blade is avoided.

Owner:AECC AVIATION POWER CO LTD

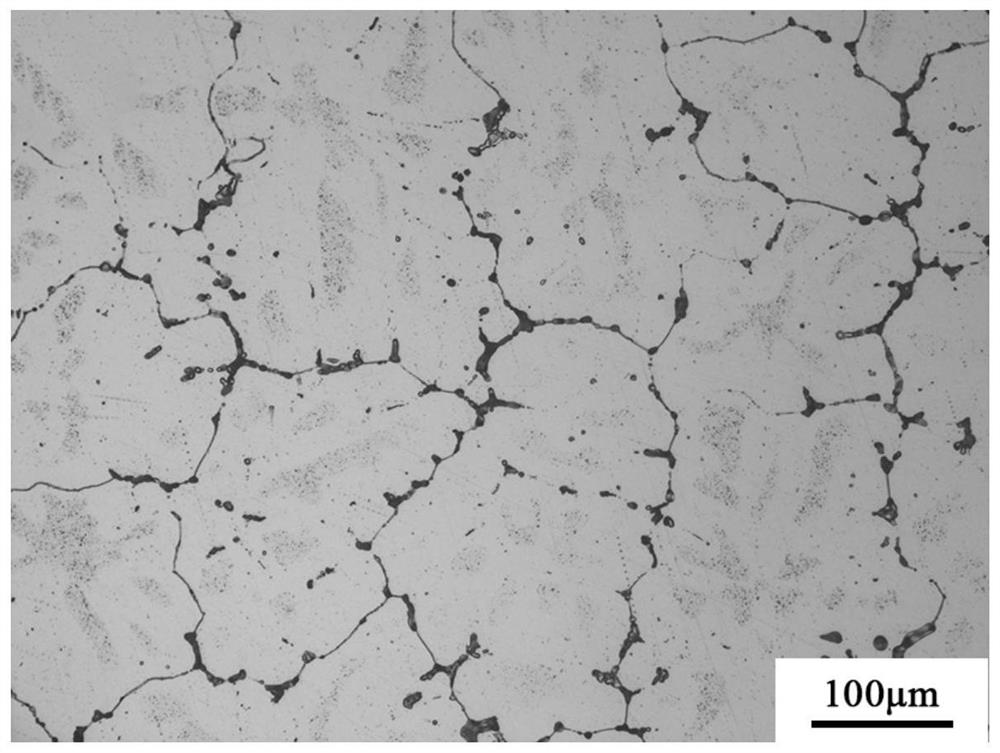

Solid solution heat treatment method for reducing solid solution hole content of high-rhenium nickel-based single crystal superalloy

ActiveCN114250519AReduce solid solution void contentImprove densification performancePolycrystalline material growthAfter-treatment detailsRheniumSolution treatment

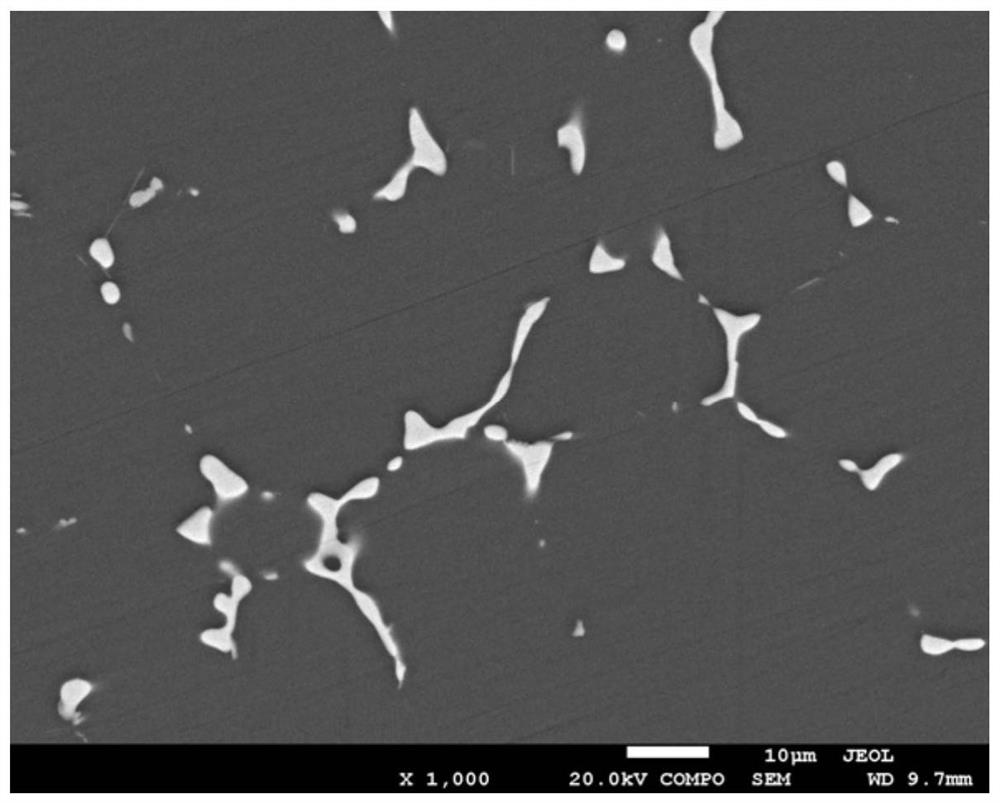

The invention provides a solid solution heat treatment method for reducing the content of solid solution holes in a high-rhenium nickel-based single crystal superalloy, and belongs to the field of heat treatment technology.The method comprises the steps that alloy raw materials are subjected to vacuum melting, a master alloy ingot is obtained and put into a vacuum induction melting furnace to be remelted; casting by adopting a rapid cooling method and a spiral crystal selection method to prepare a single crystal alloy test bar; cutting the cast high-rhenium nickel-based single-crystal high-temperature alloy test bar casting to obtain a high-rhenium nickel-based single-crystal high-temperature alloy test bar; cutting a small test block from the middle section of the high-rhenium nickel-based single-crystal high-temperature alloy test bar, and carrying out a differential thermal analysis experiment; carrying out homogenization treatment on the high-rhenium nickel-based single-crystal high-temperature alloy test bar; and carrying out high-temperature solution treatment on the homogenized high-rhenium nickel-based single-crystal high-temperature alloy test bar. The heat treatment process is easy to operate and high in feasibility, the content of solid solution holes in the high-rhenium nickel-based single-crystal high-temperature alloy can be greatly reduced, and the structure compactness of the alloy is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

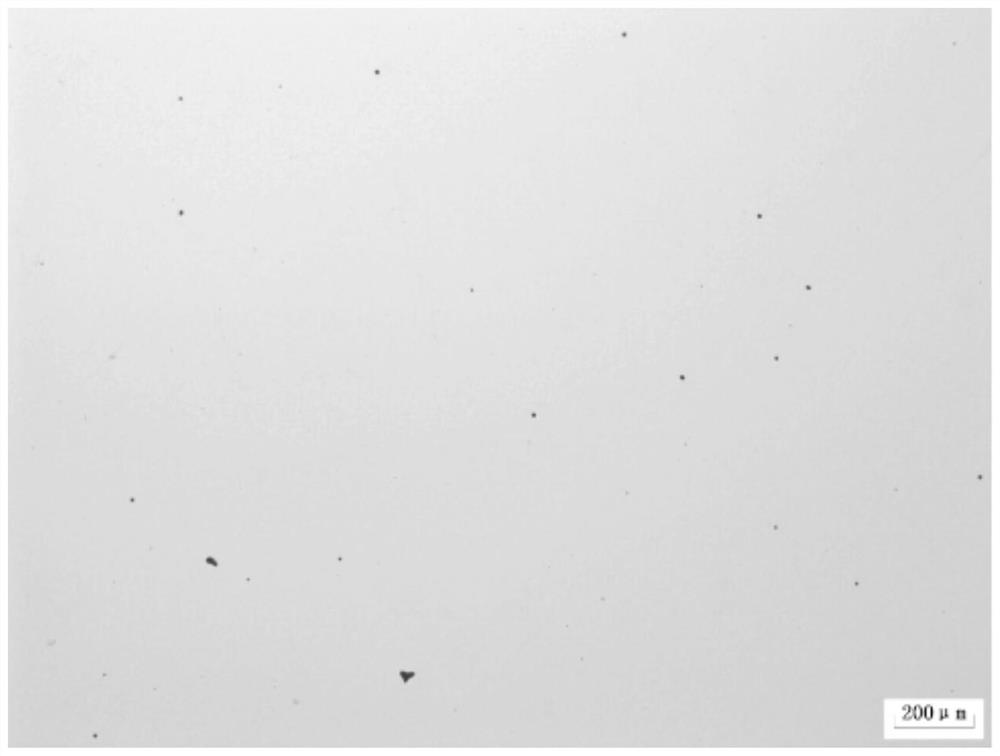

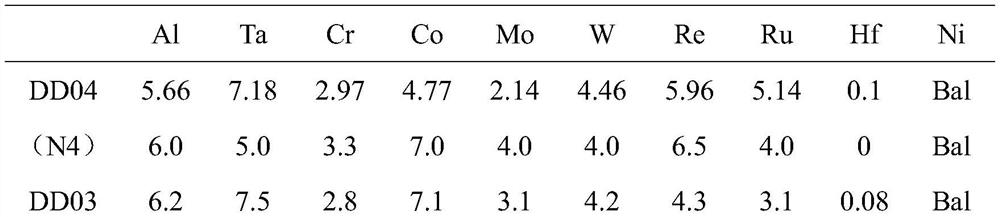

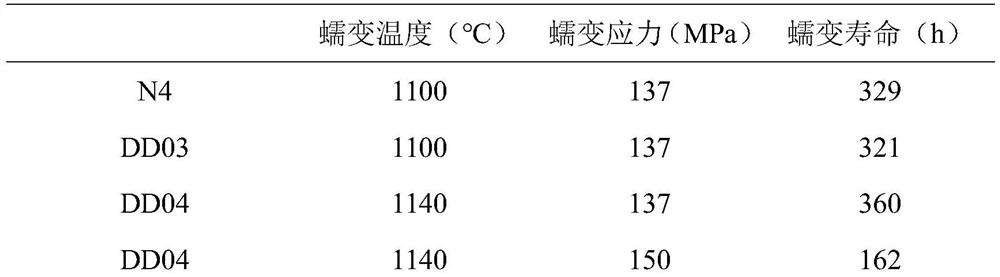

High-concentration Re/Ru nickel-based single crystal superalloy with high temperature bearing capacity and high creep resistance

InactiveCN112522543ADistribution ratio is goodImprove thermal stabilityPolycrystalline material growthAfter-treatment detailsRheniumHigh concentration

The invention relates to a high-concentration Re / Ru nickel-based single crystal superalloy with high temperature bearing capacity and high creep resistance, and belongs to a new material for special purposes. The nickel-based superalloy comprises the following components of, in percentage by mass, 5.4-6.2% of aluminum, 7.2-7.8% of tantalum, 2.6-3.5% of chromium, 1.7-2.5% of molybdenum, 4.2-4.8% ofcobalt, 4.2-5.0% of tungsten, 5.8-6.4% of rhenium, 4.7-5.4% ruthenium, 0.07-0.12% of hafnium and the balance nickel. The preparation method of the nickel-based superalloy comprises a heat treatment process. The single-crystal nickel-based alloy has high temperature bearing capacity, good high-temperature mechanical property and creep property, good creep strength and long service life under the ultrahigh-temperature condition, and is a nickel-based single-crystal superalloy suitable for producing blades of hot end parts of high-thrust-ratio aero-engines and gas turbines.

Owner:GUIZHOU UNIV OF ENG SCI

Directional solidification nickel-base high-temperature alloy and heat treatment process thereof

ActiveCN101121977BLow densityRaise the initial melting temperatureThermal fatigueDirectional solidification

The invention relates to a directionally solidified Ni-based high temperature alloy and a heat treatment technology of the alloy, in particular to a guide wheel blade material with low density, low cost, high incipient melting temperature, oxidation and corrosion resistance and good heat fatigue performance, and a heat treatment technology of enhancing the tensile performance, duration, heat and cold fatigue of the alloy. The alloy components (in weight percent) are as follows: B 0.003 to 0.03, C 0.02 to 0.2. Cr8.0to 10.0, A 14.5 to 6.5, Co 4.0 to 12.0, Nb 1.8 to 2.5, W2.5 to 4.5, Mo 2.5 to 4.5, Y 0.005 to 0.05, and the rest is Ni. The heat treatment technology of the invention is as follows :(1) the temperature of the material is preserved for 3 to 5 hours at the temperature of 1210 to 1240DEG C, and the material is air cooled to room temperature; (2) the temperature of the material is preserved for 3 to 5 hours at the temperature of 1040 to 1080DEG C, and the material is air cooled to room temperature; and (3) the temperature of the material is preserved for 16 to 32 hours at the temperature of 850 to 900DEG C, and the material is air cooled to room temperature. The alloy of theinvention is characterized by low density, low cost, high incipient melting temperature, oxidation and corrosion resistance, good heat fatigue performance, etc., and is applicable to the directional nickel-based guide wheel blade material.

Owner:辽宁红银金属有限公司

A kind of rhenium-free nickel-based single crystal superalloy and preparation method thereof

ActiveCN103436740BImprove antioxidant capacityAccelerated corrosionPolycrystalline material growthFrom frozen solutionsRheniumSolution treatment

Owner:NANJING UNIV OF SCI & TECH

High-performance cobalt-based superalloy brush wire material

The invention discloses a high-performance cobalt-based high-temperature alloy brush wire material. The high-performance cobalt-based high-temperature alloy brush wire material is characterized in that the brush wire material comprises, by mass percent, 0.02%-0.1% of C, 1%-1.5% of Al, 0.5%-2% of Ti, 0.003%-0.01% of B, 10%-14% of W, 9%-11% of Cr, 17%-25% of Ni and the balance Co and inevitable impurities. The material has high-temperature-resistance wear resistance, high-temperature-resistance corrosion resistance and oxidization resistance, in addition, high strength is achieved, in other words, a proper alloy component ratio, a corresponding processing and preparing technology and a corresponding heat treatment technology are selected, and due to the fact that alloy strengthening elements are properly added and the processing and preparing technology is improved, the alloy performance is greatly strengthened, the tissue evenness is improved, grains are refined, defects are lowered, impurities are reduced, and the yield of alloys is increased. Meanwhile, the comprehensive performance of the alloys should be improved as much as possible on the premise that plasticity of the alloys is not changed.

Owner:江苏鑫信润科技股份有限公司

A kind of preparation method of wear-resistant and anti-corrosion nickel base alloy wire

Owner:江苏鑫信润科技股份有限公司

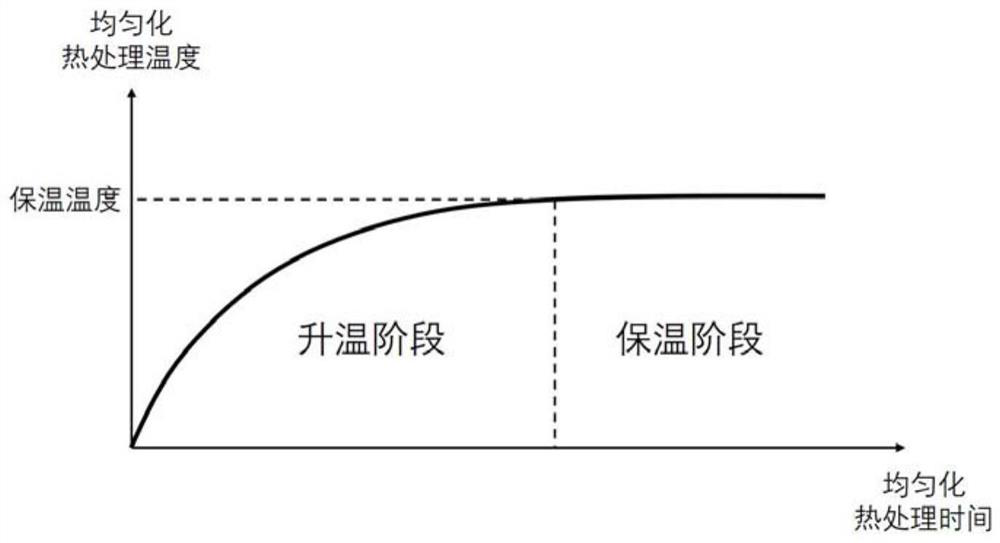

Homogenizing heat treatment method for 7xxx series aluminum alloy with low Cu content

ActiveCN114717495AUniform precipitationRaise the initial melting temperatureIncreasing energy efficiencyIngotHeat treated

The invention relates to a homogenization heat treatment method for a low-Cu-content 7xxx series aluminum alloy, and belongs to the technical field of metal heat treatment. The method comprises the following steps: (1) a temperature rising stage: the alloy is subjected to a temperature rising process with a gradually reduced temperature rising rate, so that a dispersed phase is uniformly separated out, and the initial melting temperature of an AlZnMgCu phase is increased; and (2) a heat preservation stage: the alloy is subjected to a homogenization heat preservation process, so that the AlZnMgCu phase is redissolved. According to the homogenizing heat treatment method, the initial melting temperature of the quaternary phase can be effectively increased, rapid redissolution of the quaternary phase is achieved, the heat treatment time is saved, and meanwhile it can be ensured that the size and number density of the precipitated dispersed phase meet the requirements. More importantly, the method is simple in process control, strong in operability and high in heat treatment efficiency, can achieve the effect of conventional two-stage homogenization treatment, and is particularly suitable for homogenization treatment of industrial large-specification cast ingots.

Owner:GRIMAT ENG INST CO LTD

A kind of anti-high temperature oxidation and wear-resistant cobalt-based alloy wire and its preparation method

ActiveCN106756257BGood high temperature and wear resistanceHigh temperature and wear resistanceWire rodWear resistant

The invention discloses a high-temperature oxidation resistant wearproof Co-based alloy wire and a preparation method thereof. The high-temperature oxidation resistant wearproof Co-based alloy wire comprises the following ingredients: 13-17% of Cr, 11-15% of Ni, 10-14% of W, 2.4-4.3% of Mo, 1.2-1.6% of Al, 2.8-3.6% of Ti, 0.1-0.5% of Nb, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr and the balance of Co. The alloy preparation process route is vacuum melting-remelting-forging-hot rolling-drawing-solid solution treatment-aging treatment. Raw materials are compounded according to percentage by mass and then melted and re-melted; after that, forging and rolling are performed to obtain an alloy wire rod; multi-drawing is conducted to prepare an alloy wire of phi 0.06-0.4 mm; and finally, solid solution treatment and aging treatment are performed. Through reasonable ingredient control and adding of alloy elements, the alloy wire has high yield and excellent high-temperature wear resistance, high-temperature corrosion resistance, oxidation resistance and high strength. As a sealing brush wire material, the high-temperature oxidation resistant wearproof Co-based alloy wire has the advantages that the sealing effect can be effectively improved, and the service life is prolonged.

Owner:SOUTHEAST UNIV

A kind of high-strength casting magnesium alloy and preparation method thereof

ActiveCN105112751BGood aging precipitation strengthening effectImprove mechanical propertiesRare earthBi element

The invention is a high-strength casting magnesium alloy, which is a Mg-Bi-Al-Zn-Sr alloy, and the weight percentages of its components are: Bi3-8.0wt%; Al 0.5-4.0wt%; Zn 0.1-1.0wt%; Sr 0.05-0.15wt%, the rest is Mg. In the present invention, Bi element is used as the main alloy element, and a large amount of Mg3Bi2 phase is formed through a simple alloying method, supplemented by a small amount of aluminum element and zinc element to improve the strength of the alloy, thereby developing a high-strength cast magnesium alloy in this alloy series , the tensile strength of the alloy is 276-296MPa, the yield strength is 155-170MPa, and the elongation is 5.3-7.3%, achieving mechanical properties comparable to those of rare earth magnesium alloys.

Owner:HEBEI UNIV OF TECH

A low-rhenium third-generation nickel-based single crystal alloy and its preparation method

ActiveCN106011540BRaise the initial melting temperatureWide melting rangePolycrystalline material growthFrom frozen solutionsRheniumSingle crystal superalloy

The invention belongs to the field of nickel-based high-temperature alloy, and particularly relates to low-rhenium third-generation nickel-based single crystal alloy and a preparation method thereof. The alloy is composed of Cr, Co, W, Mo, Re, Ta, Al, Hf and Ni, wherein the content of Re is 3.0%-4.5%, and the alloy is characterized in that the value of Ta / (W+Mo) is controlled to be between 1 to (1-2). The main steps are that a vacuum self-consuming furnace is adopted, and raw materials are prepared into consumable electrodes which are prepared into mother alloy through multiple tests; and then a directional solidification furnace is adopted for preparing single crystal testing bars through a spiral crystal selection method, and finally the single crystal high-temperature alloy testing bars are subjected to heat treatment. The way of adjusting the value of Ta / (W+Mo) is mainly adopted for improving the persistent strength and hot corrosion resistance of the alloy, the alloy is made to meet the requirement for the third-generation nickel-based single crystal high-temperature alloy, the Re content is low, and no TCP phases are precipitated during long-term ageing at 900 DEG C, so that the stability is good.

Owner:JIANGSU UNIV

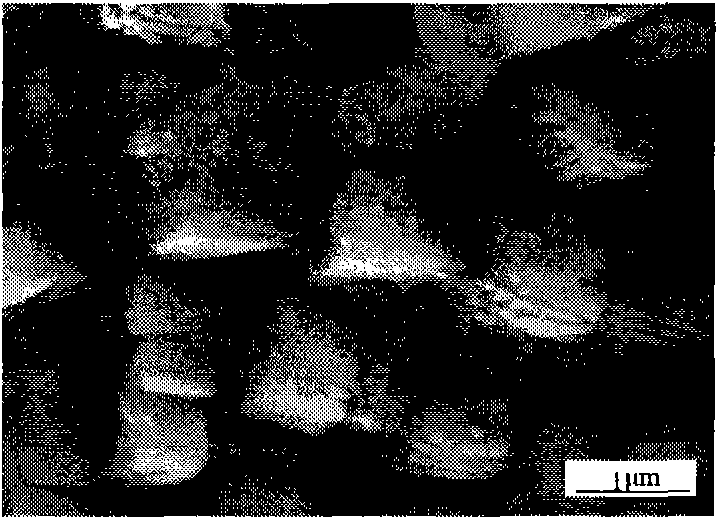

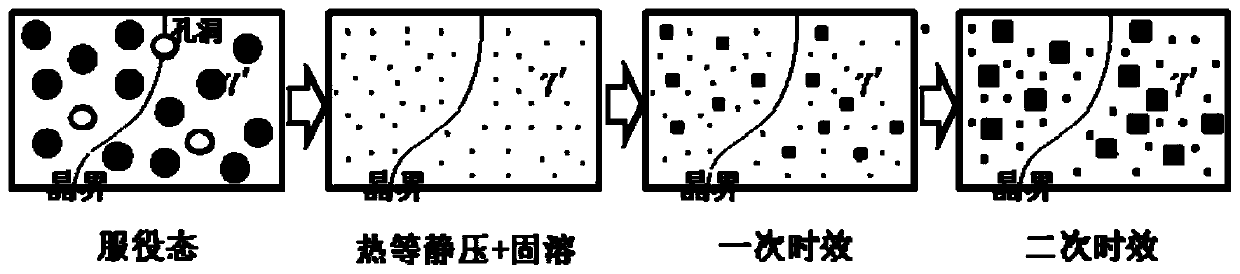

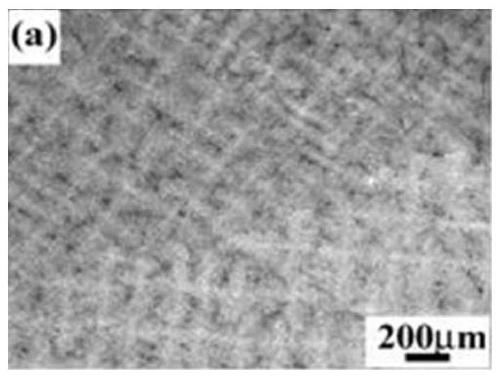

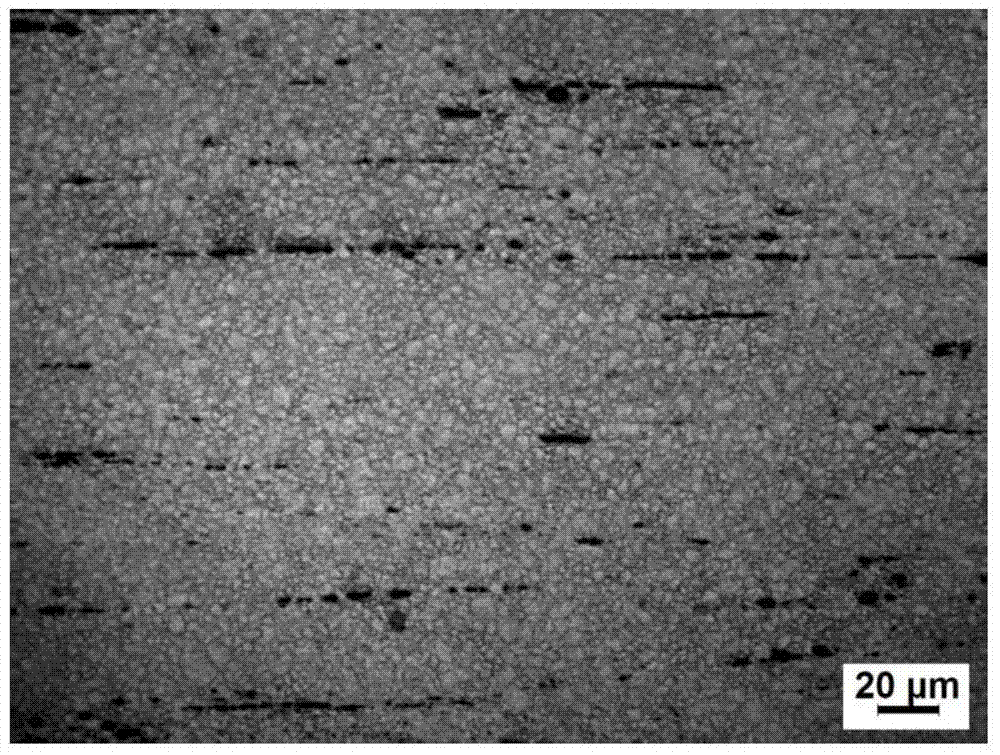

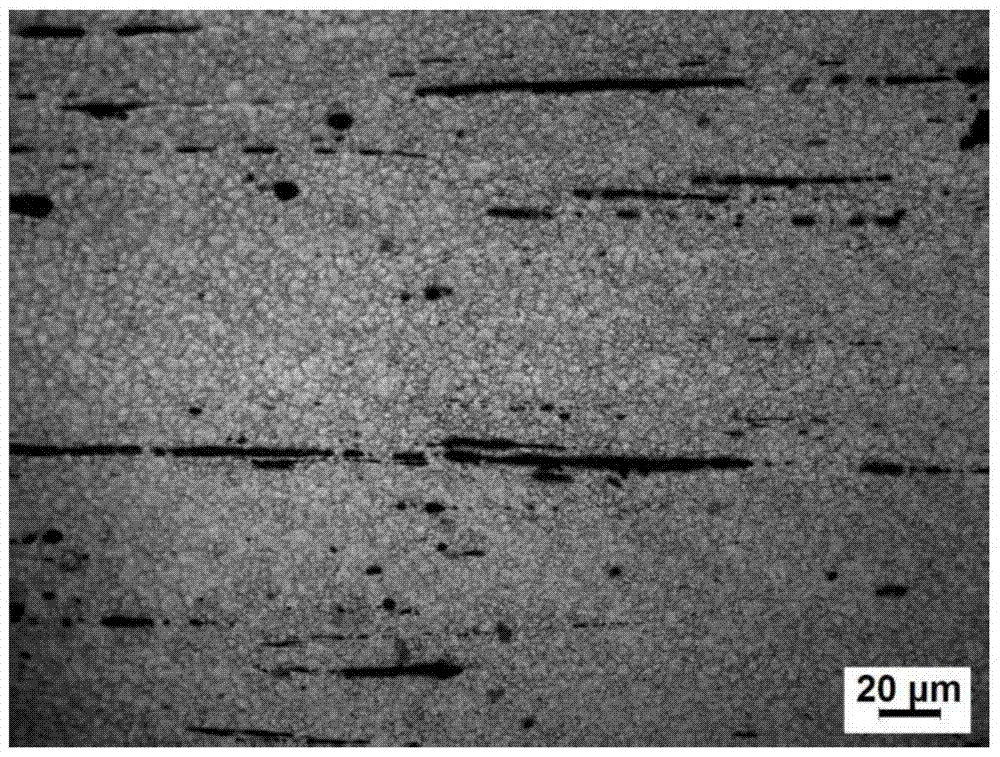

A service damage recovery method for precipitation-strengthened polycrystalline cast nickel-based alloys

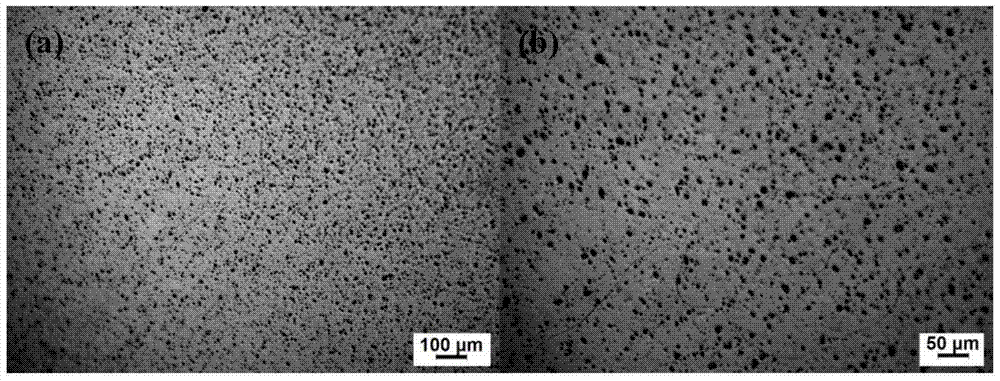

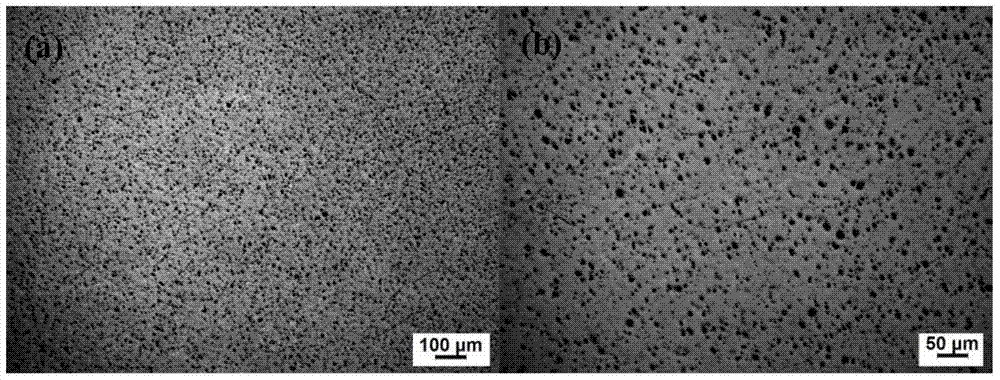

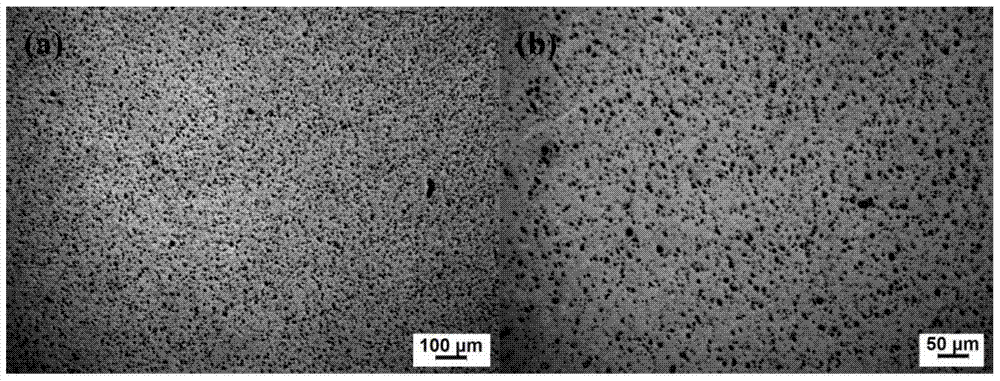

ActiveCN107488825BService life extensionImprove high temperature performanceRecovery methodRestoration method

The invention belongs to the technical field of metallurgy, and provides a service damage recovery method of a precipitation strengthening type polycrystal cast nickel-based alloy. The method mainly comprises the processes of hot isostatic pressing, solid solution and aging. Hot isostatic pressing is used for overcoming hole and loose defects in an alloy material, meanwhile dissolving part of coarsened or nodulized gamma' and ensuring that incipient melting does not happen to the alloy material. Solid solution testament is used for dissolving residual coarsened or nodulized gamma' phases formed in the service process of the alloy material. Aging treatment is used for adjusting the form and size of gamma' so as to obtain optimal matching of strength and plasticity, and finally the nickel-based alloy material without hole defects and with large-size square gamma' and small-size point-like gamma' coexisting is obtained. After recovery treatment, the high-temperature endurance performance of the alloy material can be close to the level before service. According to the service damage recovery method, operation is simple, the production efficiency is high, the economic benefits are high, and universality, generality and adaptability are high; and the requirements for repair and life prolonging of gas turbine high-temperature components can be met.

Owner:XIAN THERMAL POWER RES INST CO LTD

A kind of low-cost high-strength toughness deformable magnesium alloy capable of high-speed extrusion and its preparation method

The invention relates to low-cost high-toughness wrought magnesium alloy capable of being extruded at high speed and a preparation method thereof. The alloy is Mg-Bi-Sn-Al-Ca magnesium alloy and comprises, by mass, 2-45 of Bi, 2-4% of Sn, 1-3% of Al, 0.05-0.5% of Ca and the balance magnesium, wherein the mass ratio of Bi to Sn in the alloy is (0.8-1.2):1. The alloy can be used for high-speed extrusion production at the extrusion speed up to 25 m / min, the production efficiency is improved, and meanwhile, the production cost is reduced. Crystalline grains of a finally extruded product are uniform and fine, a large number of second phases are dispersed in a matrix, the comprehensive mechanical property is good, and the alloy is relatively good in flame retardancy.

Owner:天津河北工业大学资产经营有限责任公司

A high-speed extrudable deformed magnesium alloy and its preparation method

ActiveCN105154734BImprove mechanical propertiesImprove plastic processing performanceManganeseZinc alloys

The invention relates to a high-speed extrudable deformed magnesium alloy and a preparation method thereof. The mass percentages of the alloy components are: 2-10wt% Bi, 0.5-5wt% Al, 0.1-2wt% Zn, 0.1-1.0wt% %Mn, the rest is magnesium. The magnesium alloy of the present invention uses Bi element as the main alloy element, forms a large amount of Mg3Bi2 phase through simple alloying means, supplements a small amount of aluminum element and zinc element to improve the plasticity of the alloy, and cooperates with manganese element to improve the corrosion resistance. , so that a high-strength magnesium alloy that can be extruded at a high speed has been developed in this alloy series, which can be used for high-speed extrusion with an extrusion speed of not less than 20m / min.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com