A kind of low-cost high-strength toughness deformable magnesium alloy capable of high-speed extrusion and its preparation method

A wrought magnesium alloy, low-cost technology, applied in the field of metal materials and its processing, can solve the problems of low extrusion speed and mechanical properties, achieve the effects of good comprehensive mechanical properties, improve production efficiency, and inhibit the growth of grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

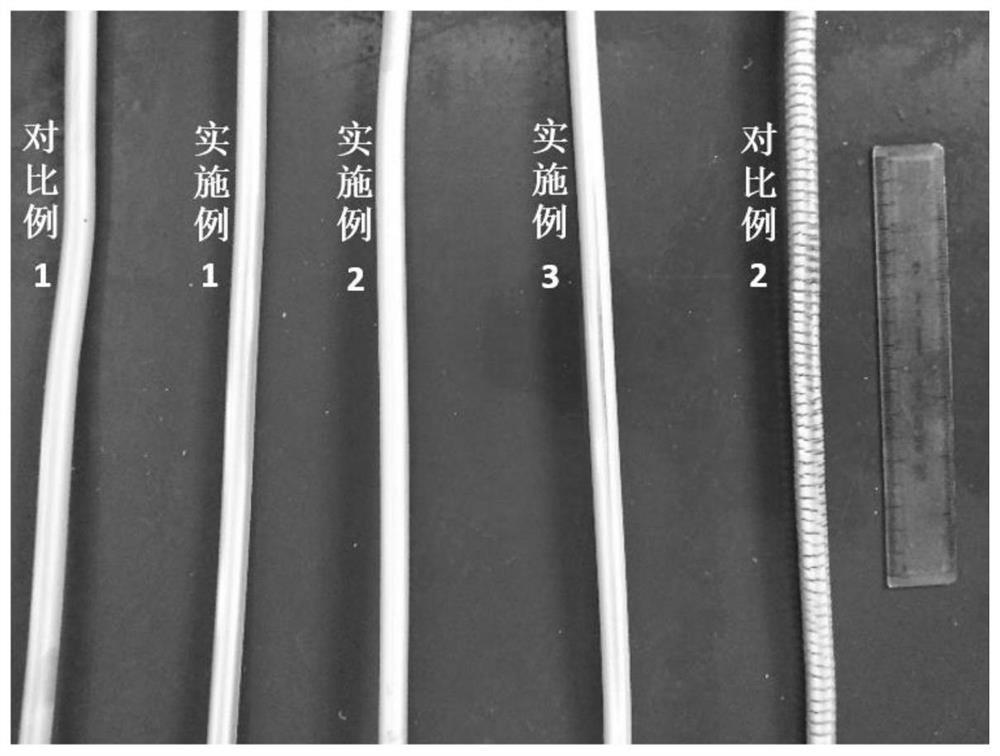

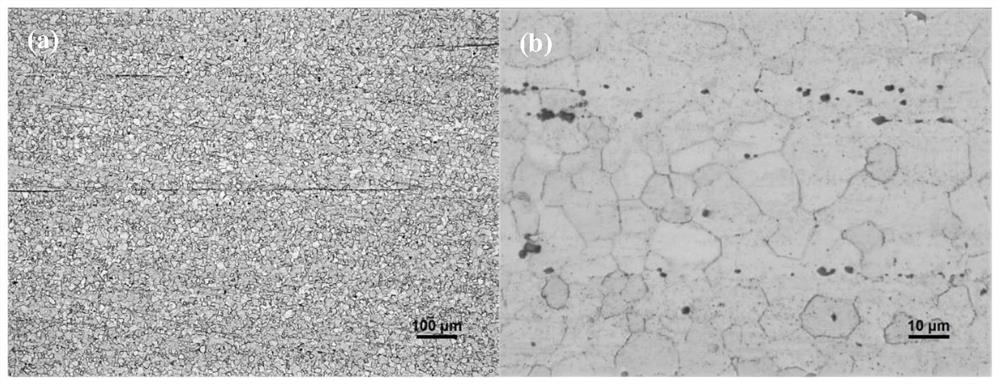

Embodiment 1

[0041] The design selects Mg-2.5Bi-2.5Sn-2Al-0.2Ca (wt%), and forms a magnesium alloy according to the composition ratio. The preparation method includes the following steps:

[0042] ① First clean the melting furnace and heat it up to 450°C, put the magnesium ingot preheated to 200°C into the crucible of the melting furnace and heat it, so that the furnace temperature rises to 720°C at a heating rate of 20°C / min.

[0043] ② After the pure magnesium ingot is completely melted, add pure bismuth and pure Sn preheated to about 50°C, pure aluminum and Mg-20Ca intermediate alloy preheated to about 200°C, and raise the furnace temperature to 750°C and keep it warm to The alloy melts.

[0044] ③ After all the raw materials in step 2) are melted, mechanically stir for 5 minutes, adjust the furnace temperature to 740° C., keep the temperature for 8 minutes, so that all alloying elements are evenly distributed in the magnesium alloy melt.

[0045] ④ Skim off the scum on the surface of ...

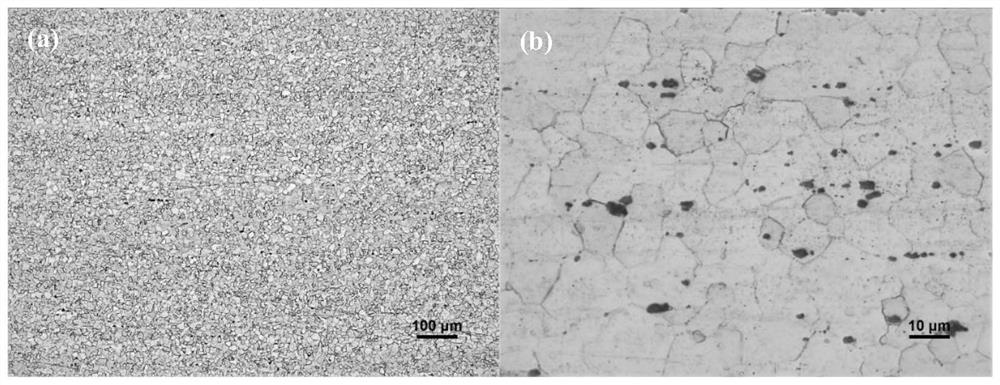

Embodiment 2

[0052] The design selects Mg-2.5Bi-2.5Sn-2Al-0.15Ca (wt%), and forms a magnesium alloy according to the composition ratio. The preparation and processing method includes the following steps:

[0053] ① First clean the melting furnace and heat it to 450°C, put the magnesium ingot preheated to 200°C into the crucible of the melting furnace, and heat it so that the furnace temperature rises to 720°C at a heating rate of 20°C / min.

[0054] ② After the pure magnesium ingot is completely melted, add pure bismuth and pure Sn preheated to about 50°C, pure aluminum and Mg-20Ca intermediate alloy preheated to about 200°C, and raise the furnace temperature to 750°C and keep it warm to The alloy melts.

[0055] ③ After all the raw materials in step 2) are melted, mechanically stir for 5 minutes, adjust the furnace temperature to 740° C., keep the temperature for 8 minutes, so that all alloying elements are evenly distributed in the magnesium alloy melt.

[0056] ④ Skim off the scum on th...

Embodiment 3

[0062] The design selects Mg-4Bi-4Sn-1Al-0.3Ca, and forms a magnesium alloy according to the composition ratio. The preparation and processing method includes the following steps:

[0063] ① First clean the melting furnace and heat it to 450°C, put the magnesium ingot preheated to 200°C into the crucible of the melting furnace, and heat it so that the furnace temperature rises to 720°C at a heating rate of 20°C / min.

[0064] ② After the pure magnesium ingot is completely melted, add pure bismuth and pure Sn preheated to about 50°C, pure aluminum and Mg-20Ca intermediate alloy preheated to about 200°C, and raise the furnace temperature to 750°C and keep it warm to The alloy melts.

[0065] ③After all the raw materials in step 2) are melted, mechanically stir for 5 minutes, adjust the temperature of the furnace to 740° C., keep the temperature for 9 minutes, so that all alloy elements are evenly distributed in the magnesium alloy melt.

[0066] ④ Skim off the scum on the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com